-

Tweeting from the Pi

09/06/2014 at 23:10 • 0 commentsGot a new Raspberry Pi up and running, installed Twython for sending twitter feeds, and run the first test.

Awesome! It worked.

So, now I'll be looking at connecting the Raspberry Pi to the load cell test circuit. The test circuit is currently with Arduino Uno, and at this point it is about getting the concept working, and then finalize the controller hardware later.

-

We've got sensor readings, Skipper

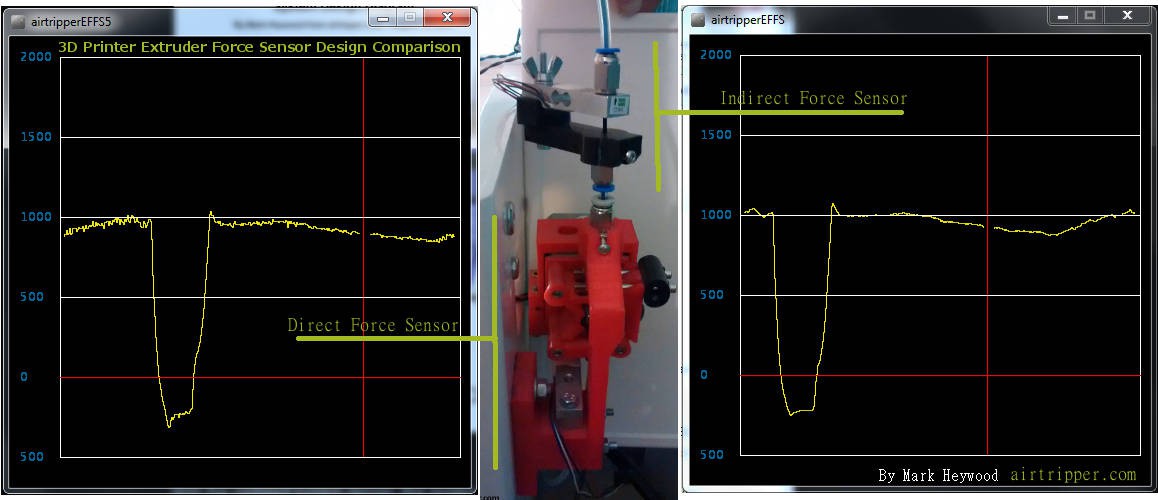

08/25/2014 at 20:27 • 0 comments3D Printer Extruder Filament Force Sensor Design Comparison

![]()

First test shows sensor readings that are surprisingly similar from both sensor designs. Both Processing graphs were running side by side while printing an airtripper extruder part. More testing will be done later, however, current test results provide enough confidence to continue with the light weight indirect force sensor design set-up.

The reduced noise in the indirect force sensor graph is due to the light weight design of the load cell bracket.

The load cell calibration process used is covered in this guide, however, I used a revised circuit for lower voltage in this test. I'll publish the revised circuit used for this test later.

-

Looking Good

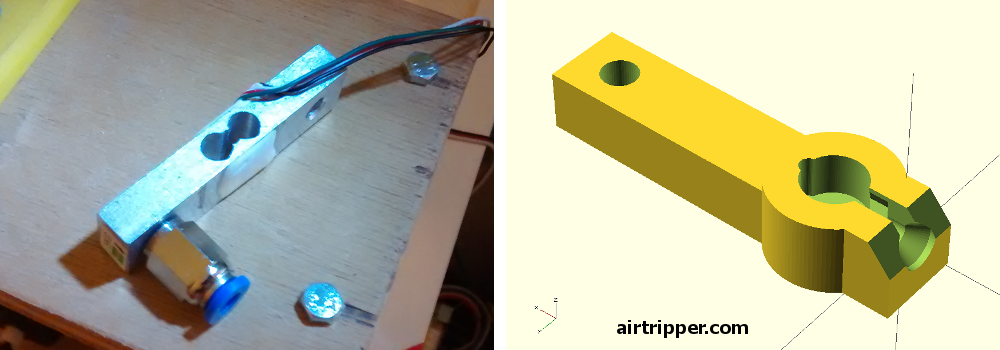

08/24/2014 at 22:37 • 0 commentsIndirect Force Sensor Test Set-Up

![]()

So, the new indirect filament force sensor now piggybacks on the direct filament force sensor. The new sensor turned out to be light enough to be supported entirely by the PTFE bowden tube, so no extra bracket needed. The sensor will move as the Y axis moves but this should not effect the force readings too much.

The next step is to calibrate a new circuit, and then the readings can be taken to compare the two different load cell set-ups. Once I get some readings, I'll be first checking if the indirect force sensor is providing linear readings as with the direct force sensor or kitchen scales.

You can see with the design of load cell that it should fit many extruder designs that use similar tube fittings like in the above picture.

-

Step 1, and so it begins.

08/23/2014 at 22:16 • 0 commentsIndirect Sensor Load Cell Bracket

![]()

Got delivery of two more scales today which have this load cell installed, probably the smallest 5 kg load cell you can get hold of for less than 5 GBP. I did an Electronic Kitchen Scales Teardown Versus Load Cells article which includes the scale that contains the load cell above, it is the WH-B05 scale, these are very popular on Ebay, best to search 5kg scale and then match the casing style in the listings to be sure to get all the sellers selling these.

If you are using the straight push fit tube fitting with M6 screw thread, you can make use of one of the 5mm fixing holes in the load cell by tapping an M6 thread, the other hole then can be used to attach the 3d printed bracket which holds another push fit fitting.

I'm hoping to complete the sensor bracket tomorrow if time permits. I'll attach the completed load cell bracket above the existing filament force sensor bracket, and then I can begin comparing indirect force sensing to direct force sensing.

-

What Title Change?

08/20/2014 at 22:09 • 0 commentsWell , today I got the concept video done and uploaded, also the system design diagram for indirect force sensing is now up in the details.

I've also changed the project title to reflect the goal of this project, and updated other text to better reflect what this project is about. The project detail section needs a bit of work but should start taking shape as I get the resources together.

I now know which libraries I'm using on the Raspberry Pi for Twitter and Xively:

https://github.com/ryanmcgrath/twython

https://github.com/xively/xively-python

I'll perhaps log high resolution data, taken from the force sensor, on the Raspberry Pi , and then compile the data I need from the log to transmit to Twitter and xively.

And I've been for eye test today and now have to wear glasses so I can see what I'm doing close up. Soldering and breadboarding should be a lot easier now.

-

Direct Force Sensing

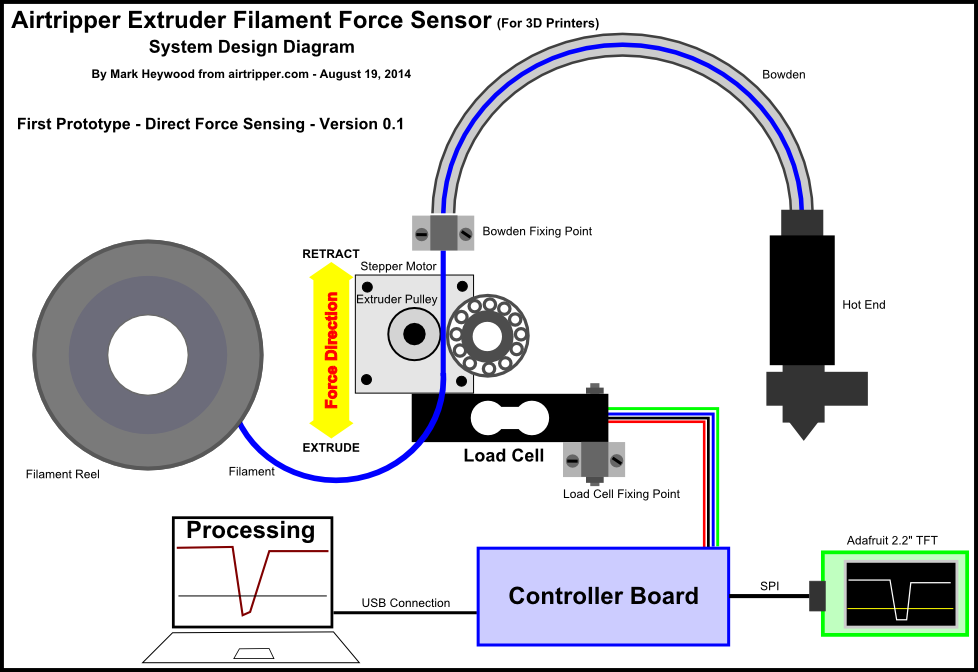

08/19/2014 at 20:28 • 0 commentsHere is the system design diagram for the current Airtripper Extruder Filament Force Sensor set-up. The diagram shows direct force sensing where all the forces generated by the stepper motor is transferred to the load cell.

An amended system design diagram is coming up that shows indirect force sensing. This diagram will show how the force sensor can be applied to existing extruder systems. Should be a lot easier to set up than the current extruder force sensor design.

![]()

The direct force sensing set up is ideal for testing and benchmarking existing and new hot end designs, stepper motors and drive gear filament pulleys.

-

Do I have to use your extruder?

08/17/2014 at 01:07 • 0 commentsJust added two updates to the project details:

Nice Project! - Do I need this? - How will this project benefit the average 3d printer user?

I Love My Extruder! Do I have to use yours? - Explains that a compact design is an option that will fit in an existing bowden extruder system.

Processing sketch for graphing the force sensor outputs on a computer is ready to publish, just got to set-up Github for it. Should be useful for projects other than this. -

Left it till late!

08/16/2014 at 01:05 • 0 commentsWith only five days to go, I've decided to get my entry in for the hackaday prize. I should make the entry requirements before closing, with the 2 minute video taking the most effort to produce.

Much of this project is very well documented on my blog, but what is lacking, is a detailed summary of the build process from start to finish, hopefully, this project page will provide that summary, and the hackaday prize will be the boot up the backside to get it done.

3D Printer Extruder Remote Health Monitoring

Receive force sensor reports from the 3d printer extruder at regular intervals on your mobile device.

Mark Heywood

Mark Heywood