-

Updated components

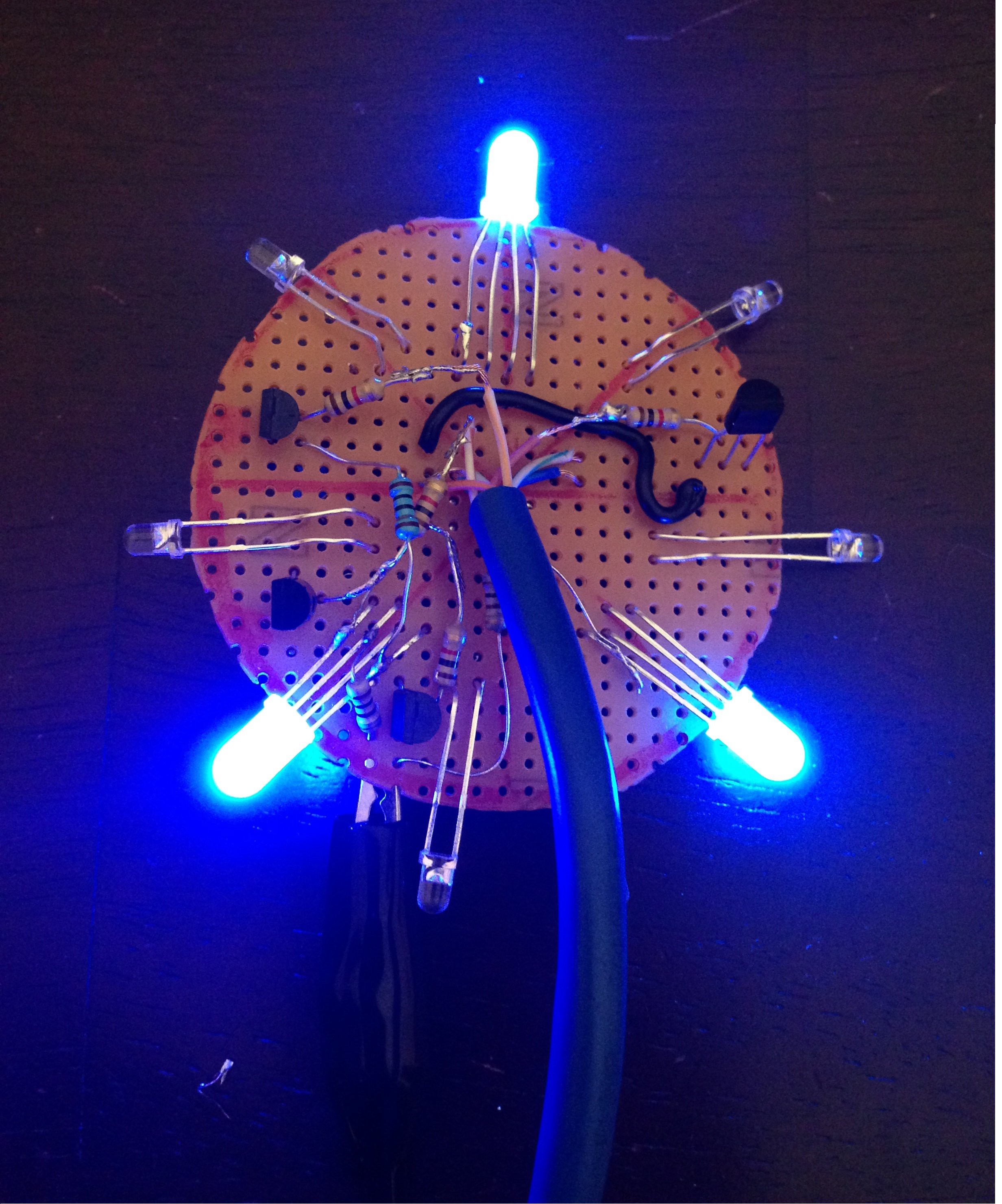

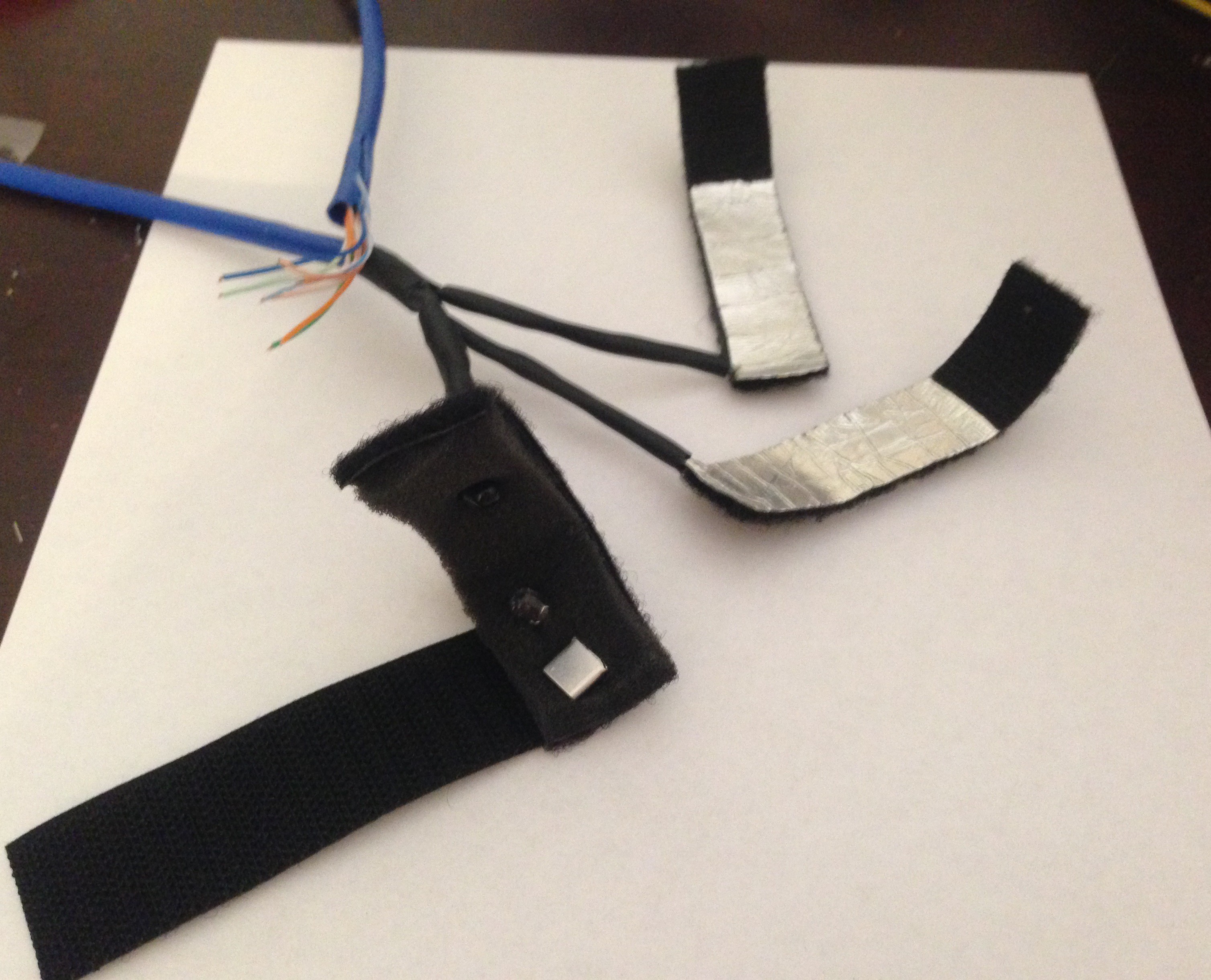

08/21/2014 at 04:25 • 0 commentsMy fourth project journal reflects the sensors that I built. These sensors include: body temperature, galvanic skin conductants, pulse oximter and hand speed sensor. I also built the LED backlight with a driver board.

-

Components

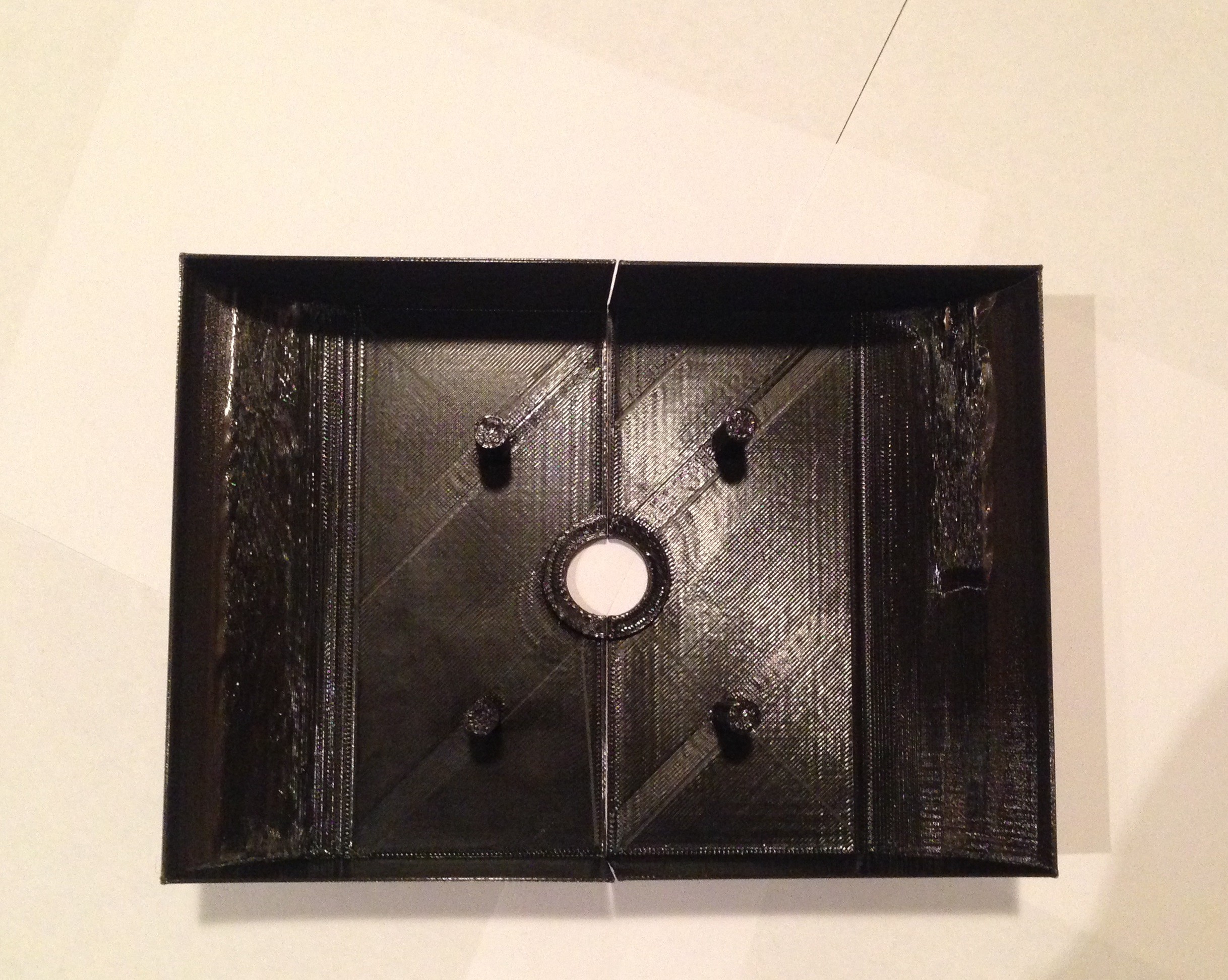

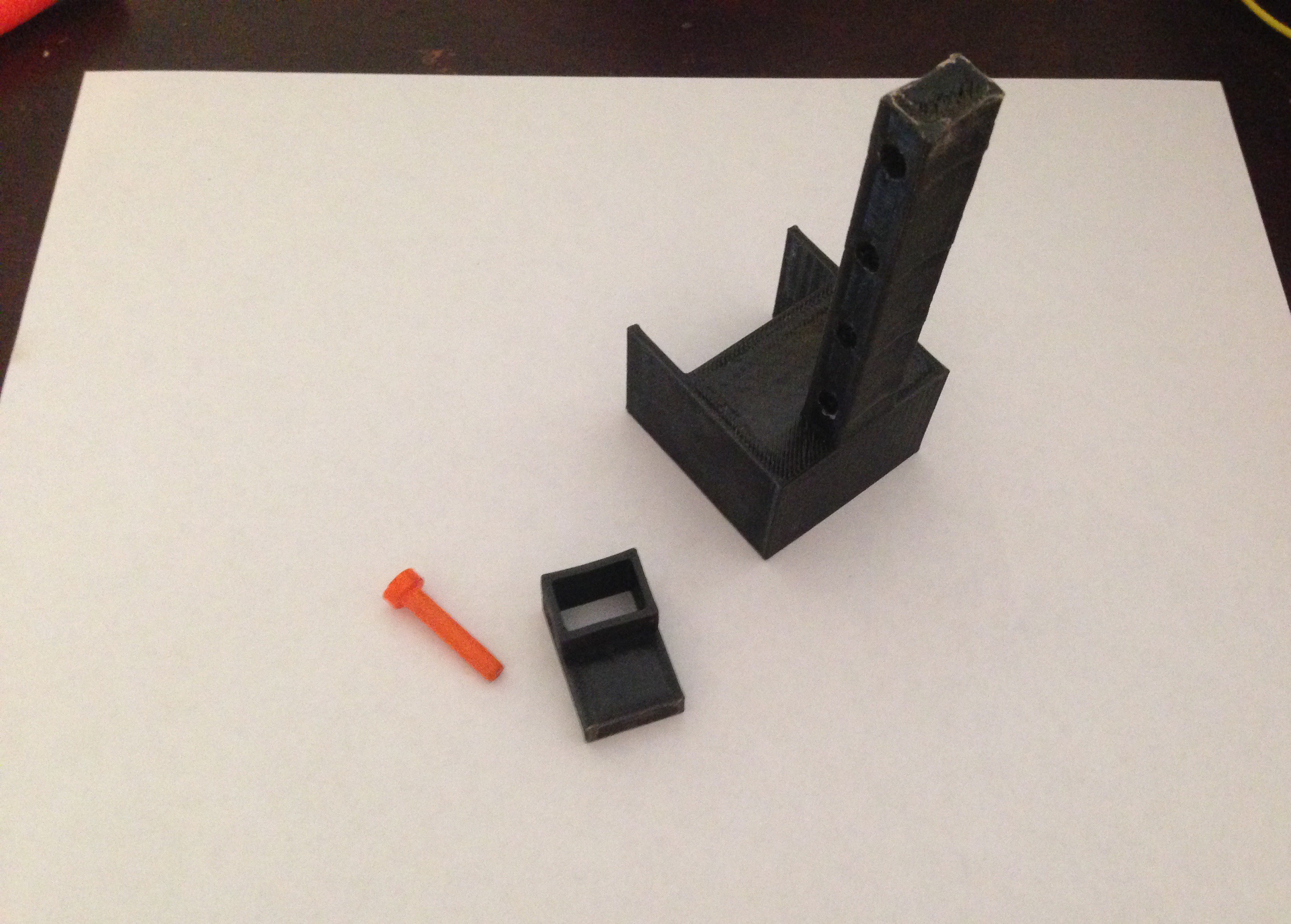

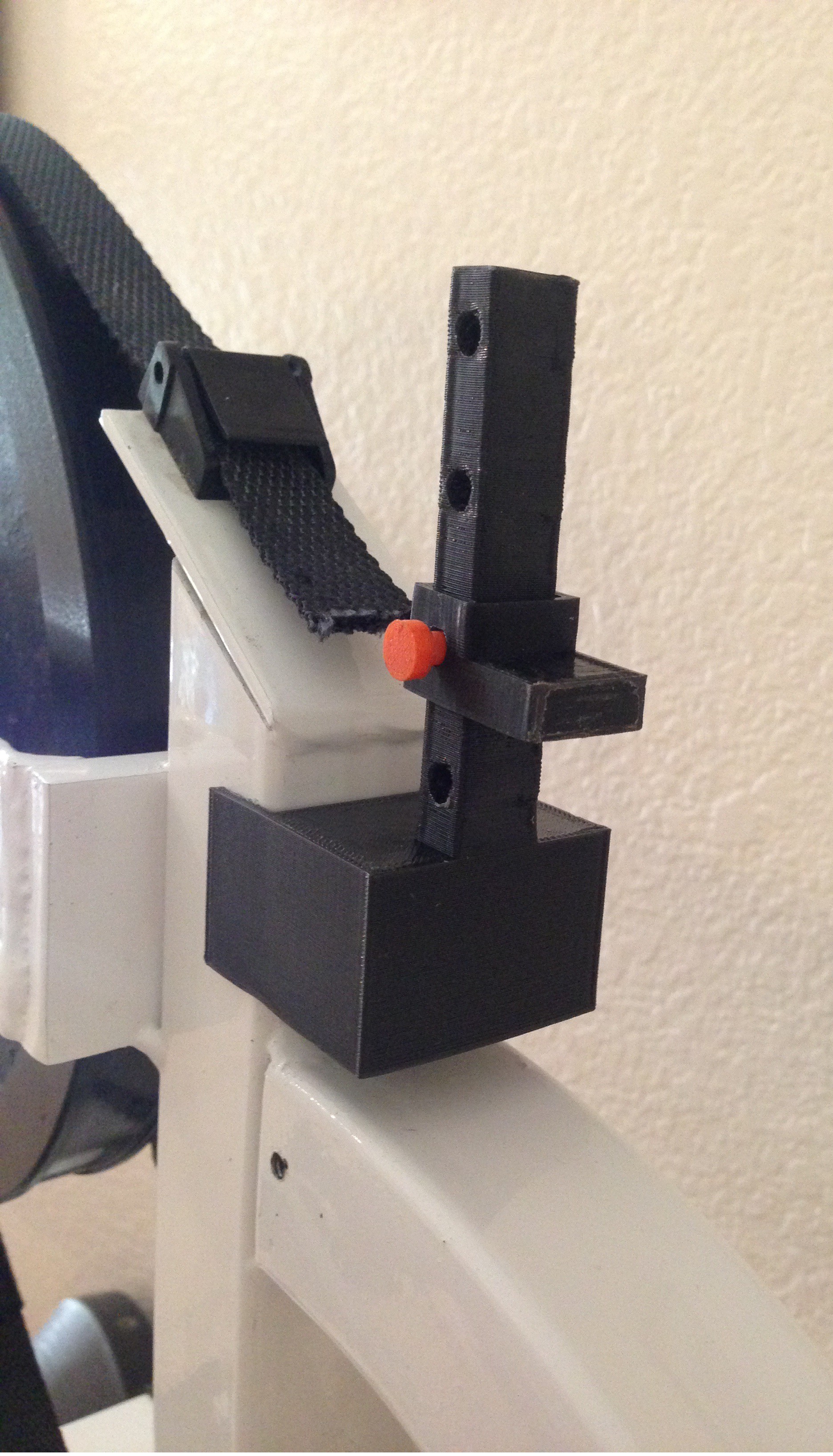

08/21/2014 at 04:24 • 0 commentsMy third project journal reflects the 3D printed parts I made using my 3D printer. These parts include: servo mount, display holder with integrated tablet holder, and adjustable display mount.

-

Close-up Examination

08/18/2014 at 03:46 • 0 commentsThis is a detailed examination of the components of the hand cycle. I found the RPM sensor to be in functional condition. The tensioning strap was in good physical condition. There was very little play in the hand crank and fly wheel bearings. I used my digital multimeter to assess the functionality of the RPM sensor and determined that once every rotation the sensor will momentarily ground itself and the rest of the time it will be open. The original hand cycle had a display that broke off several years ago. It never functioned properly but was suppose to display pulse rate, time, distance, speed and calories. Ideally the placement of the Android display would fit where the previous one was located.

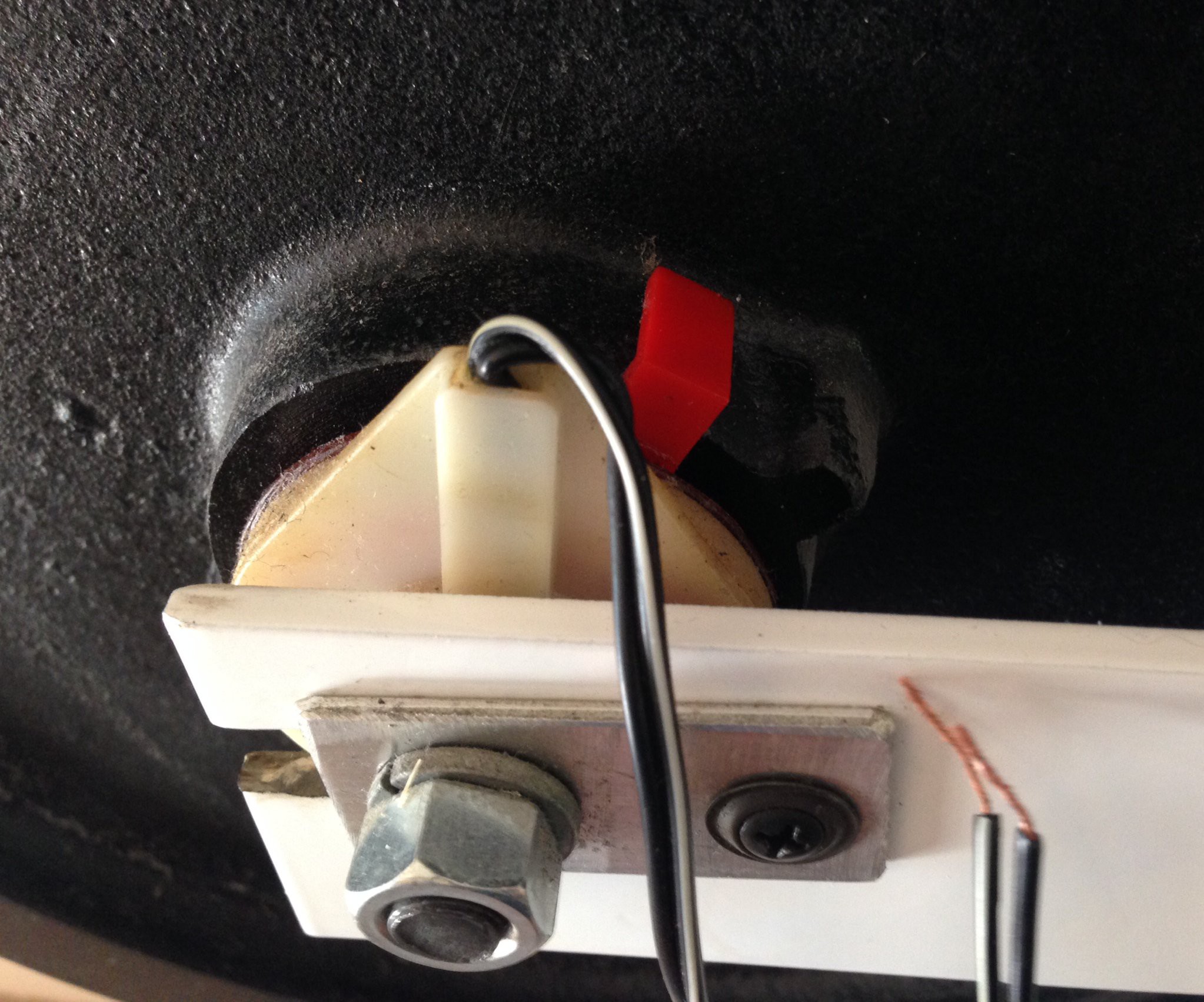

The above image is the tensioning mechanism for the hand cycle. Below is the RPM sensor in verified working condition.

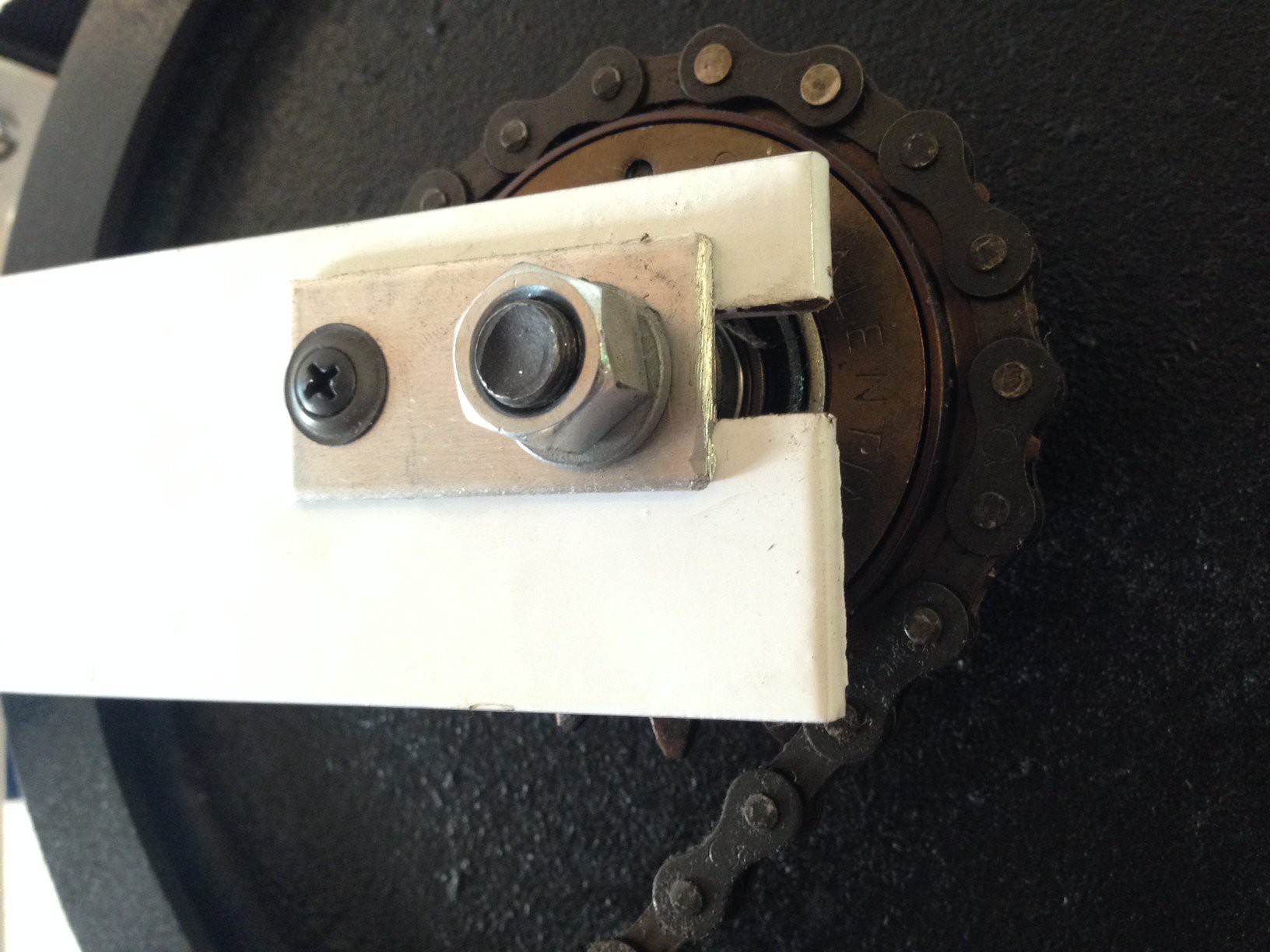

The above photograph shows the sprocket and chain assembly on the hand cycle. The image below shows the spring used to connect the tensioning strap to the adjustable mechanical tensioner.

The image above shows the support frame for the hand cycle. The placement of the Android display will be in the upper left hand corner at the end of the tensioning strap.

-

Teardown and Assessment of Hand Cycle

08/17/2014 at 23:42 • 0 commentsTo start the project, I first dismantled a hand cycle and determined the best way to digitally control the tension and assess the viability of the project. Upon visual inspection the therapy machine was in good working condition and has enough space for components inside bicycle casing.

This is an Endorphin Hand Cycle Model EN-300 disassembled. Below shows close-up of hand cycle.

The top image shows the hand cycle without plastic cover and displays the hand crank, sprocket, fly wheel, spring and support structure. The bottom image shows a close up of the RPM sensor attached to the flywheel. This picture also displays a clear view of the tensioning mechanism which I will modify to allow the Arduino to control the tension via a Servo motor.

Connected Hand Cycling for the 21st Century

Upgraded physical therapy hand cycle featuring an Arduino and connected vitals recording with monitoring and feedback adjustments

Hebrewhammer130

Hebrewhammer130

The image above shows the support frame for the hand cycle. The placement of the Android display will be in the upper left hand corner at the end of the tensioning strap.

The image above shows the support frame for the hand cycle. The placement of the Android display will be in the upper left hand corner at the end of the tensioning strap.