-

Assembly

06/01/2017 at 09:07 • 0 commentsAfter receiving PCB, it was time to assemble all components : the PCB, Stepper Motor Drivers and Solid State Rely.

My current CNC is an Openbuild OX, which needs 4 motor-drivers (2*Y, X Z) and the Spindle is a simple Makita RT0700, so I only need 1 peripheral driven by a Solid State relay.

I made a layout in Fusion360 and cut a baseboard out of 5 mm plexiglass (Polymethylmethacrylaat (PMMA))

All components are mounted with M4 bolts and nuts. The head of the bolt is recessed in the baseboard, so it can be mounted flush under the machine.

Next step is to do all the wiring between the motherboard and the motor drivers - TBC

-

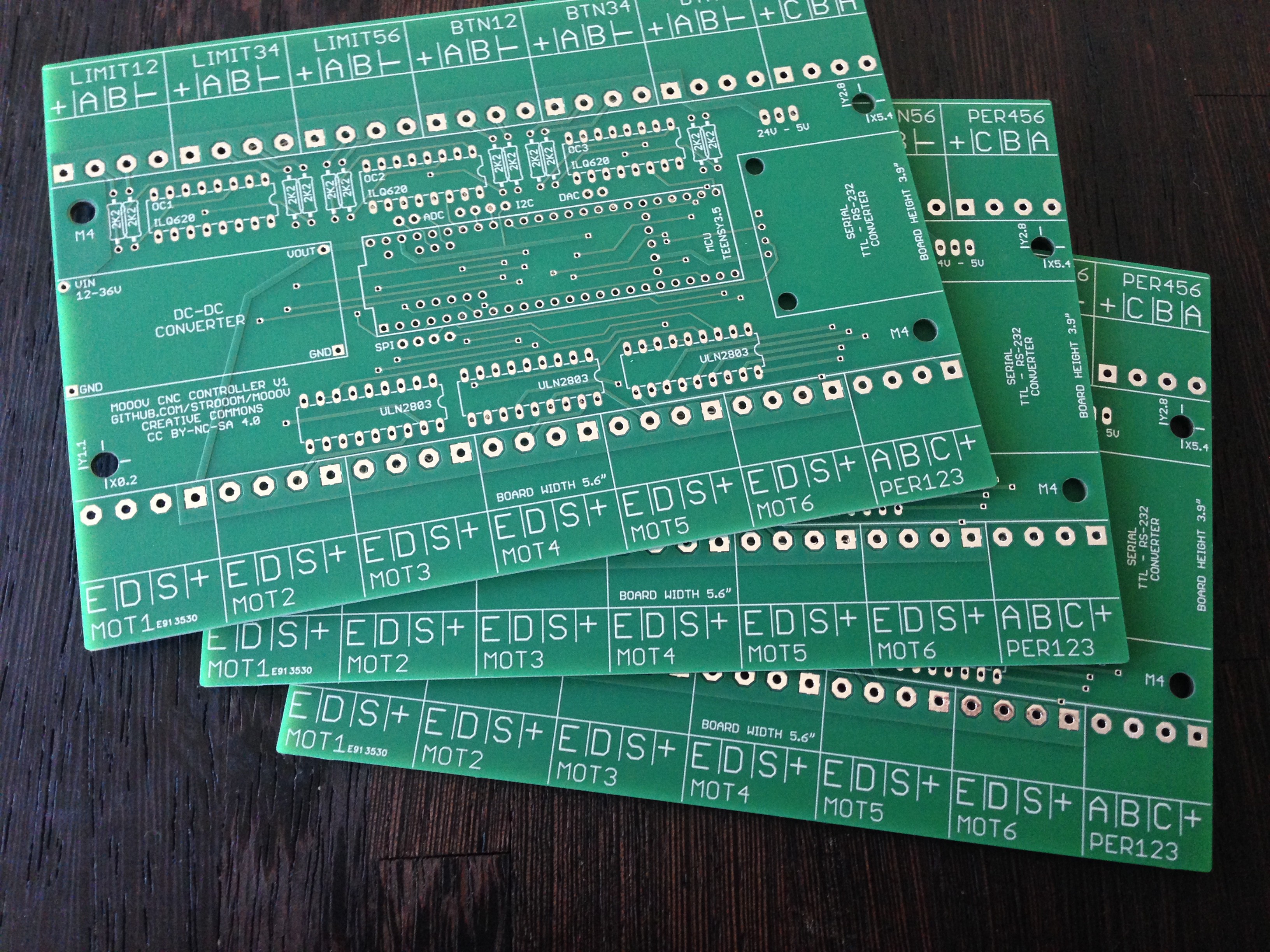

Motherboard PCB

06/01/2017 at 08:22 • 0 commentsConnecting the Teensy to (up to) 6 Motor Drivers, (up to) 6 peripherals Solid State Relays and (up to) 12 input switches, involves a lot of wiring. Furthermore all inputs are opto-coupled and all outputs are open-collector drivers, allowing any type of motor drivers to be used.

So I decided to design a PCB to keep al this clean. Turns out I needed about 100 * 140 mm.

PCB was designed in Autodesk Eagle, schematics and layout files are available on Github.

During assembly I noticesd a few mistakes : basically the serial port and USB port connector are hard to reach because other components are obstructing it. This will need to be solved in the next version.

I had the PCB manufactured at Euro-Circuits.

![]()

Mooov Motion Controller

ARM based Motion Controller for CNC, 3D-printer, Laser-cutter,.. 6 Axis, Helical, S-Profile

Pascal Roobrouck

Pascal Roobrouck