Table of contents

1. Introduction

2. Description

3. Team

4. Goals

5. Design consideration

6. Requirements

7. Block Diagram

8. Hardware

9. Software

10. Firmware

11. Documentation

12. Prototypes

13. Market comparison

14. Media

15. Launching

16. Timeline

17. Tools

18. Testing

19. Production

20. Open Source Licence

21. BOM (Bill of materials)

1. Introduction

The rangefinder is a tool that allows you to determine the distance to obstacles and walls in order to avoid them. The rangefinder is perfect in robotic applications where the robot needs to move and go to a determined position in unknown territory. This sensor is great to determine the distance to the walls .The design was started in 2010 and continued on and off until present. It went over through three prototypes which tried to improve the design.

2. Description

The rangefinder has two sensors placed at 90 degrees that read the distances simultaneously.

Here are some of the unit details:

- detectable range: 200 mm to 1500 mm (7 to 60 inches )

- 7.5 degrees angular resolution

- 2 scans per second

- 180 degrees view

- easy readable output data in text format

- easy interface with other boards

- it comes pre-calibrated

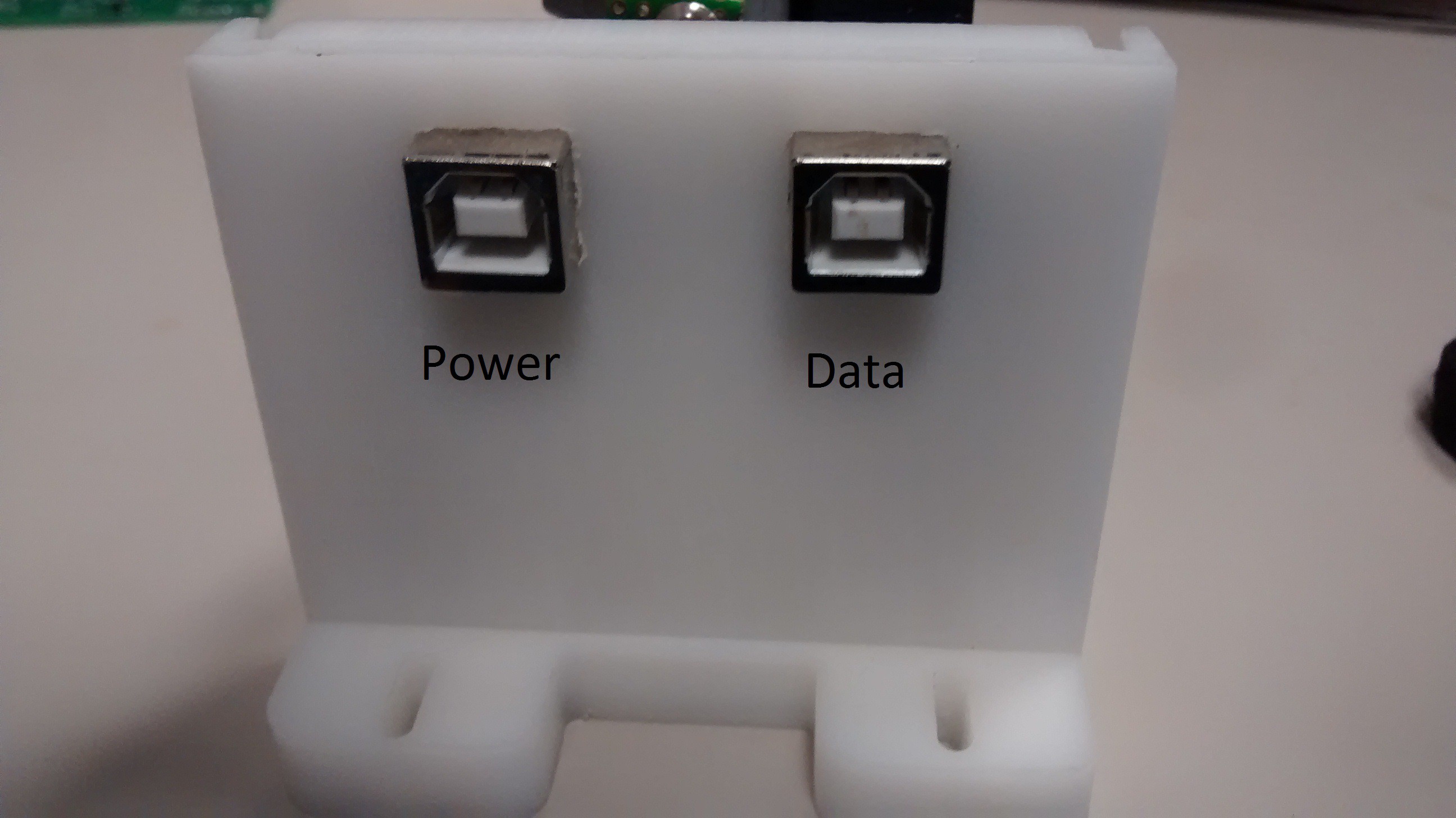

- USB interface power and data

3. Team

We are a small team of engineers from Cleveland and we like to tinker with stuff and work on all kinds of interesting projects. In the past we participated twice at Centennial Regolith Challenge, a competition organized by NASA and California Space Authority. This is where we came with the idea of creating a cheap obstacle detection unit. Since we payed all the costs for the robot, transportation, and the competition fee, we did not have a lot of money to spend and we lacked proper sensors. The obstacle detection units that are on the market today start at more than a thousand dollars, which we could not afford. Also Kinect would be great if it would work reliably in daylight.

4. Goals

Our goal is to create a cheap 2D obstacle sensor that could be used in robotics.

5. Design consideration

a. Choosing plastic for enclosure

The enclosure has to provide some rigidity.

| Name | Rigidity | Machinability | Problems |

| Nylon | Medium | Medium | The finishing after machining is not so great |

| 3D Printer Thermoplastic | Good | N/A | Finishing is not so great |

| Delrin | Good | Good | Finish acceptable |

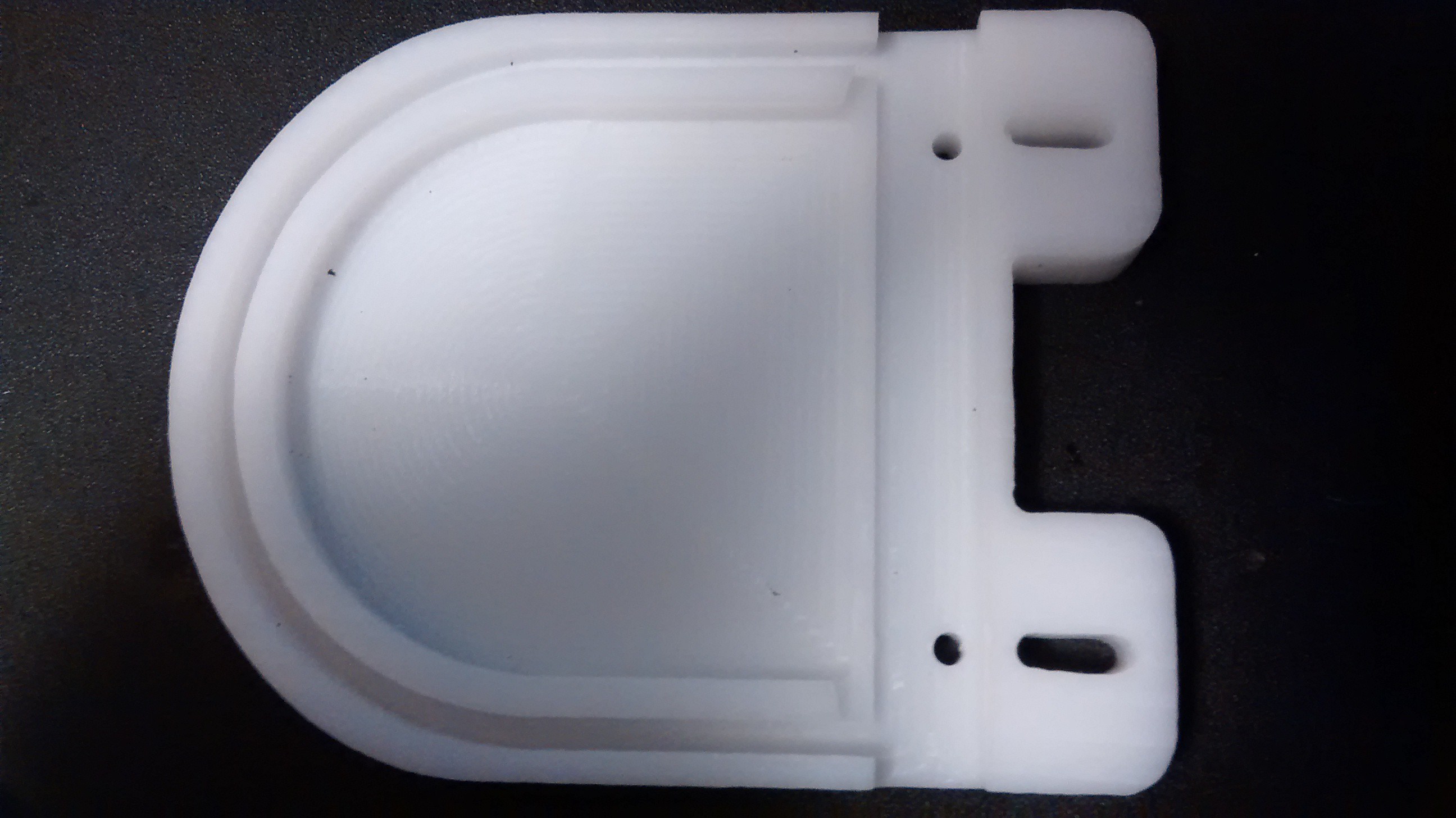

Almost the whole enclosure is made from a single piece of plastic.

We choose 3/8 in Delrin which has very good rigidity.

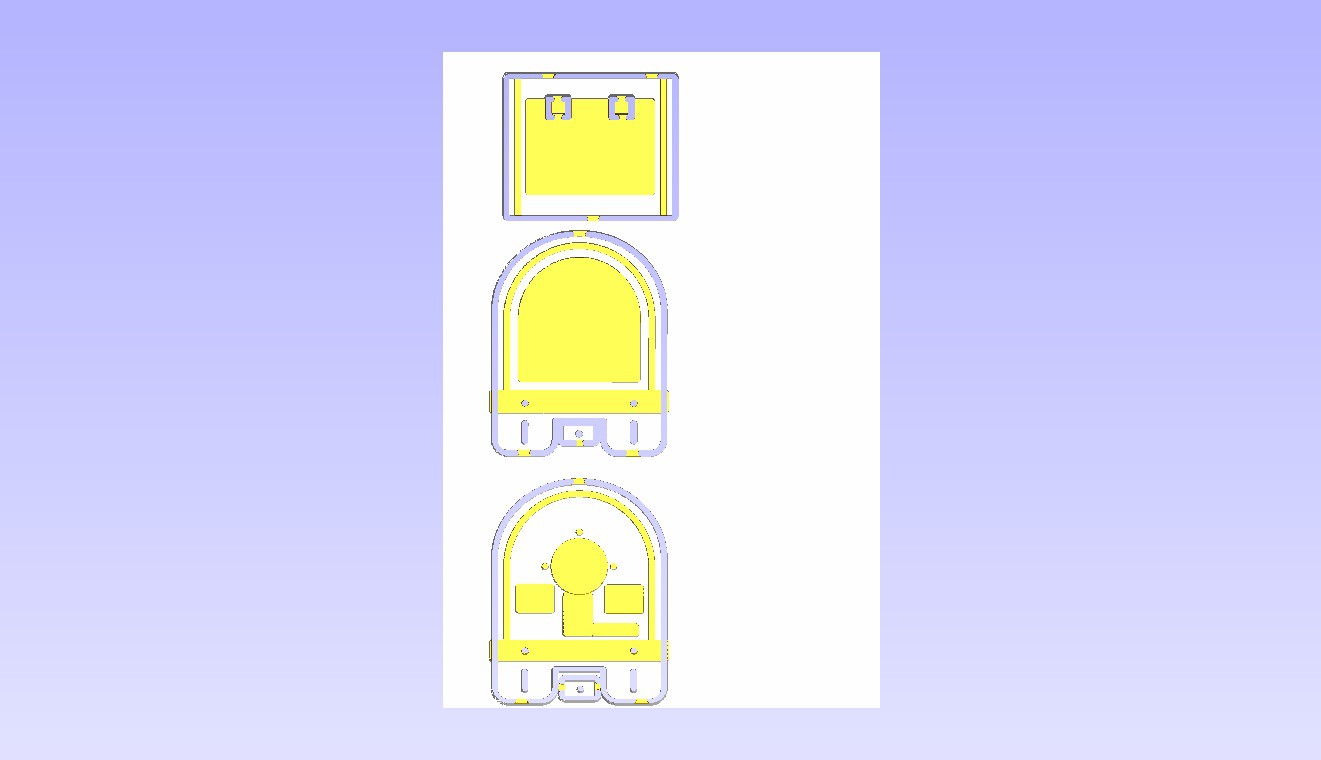

Nylon CNC part

The 3D printed part

The Delrin part

The enclosure has to provide some rigidity in order to hold the screen.

b. Choosing the microcontroller

Some of our requirements for the microcontroller were 12 ADC resolution, UART interface, a good API, familiarity, and price. Those are the choices we had at the design time and the choices might be different today.

We decided to go with STM32100 which has an ARM Cortex core at 24MHZ. It provides some very good performances and low power for a low price.

c. Choosing the stepper motor

The goal was to choose a cheap stepper motor with enough steps /revolution to give enough readings. Also the supply voltage and the price came to consideration.

d. Choosing the sensor

The idea was to use a sensor that can be used outside and be affordable

The Sharp sensors are notoriously noisy. One way to mitigate this is to add a capacitor very close to the sensor between Vcc and ground.

Also the sensor can provide about 50 readings per second or about 40 ms per reading.

e. Power

Since the unit will use more than 500 mA (which is the USB standard and also it cold be used with smaller boards such as Raspberry Pi, we decided to use 2 USB connectors . One is strictly for data and the other one is for Power.

6. Requirements

a. Easiness of manufacturing

We compared between a CNC Machine and a 3D printing machine for manufacturing the enclosure

| Name | Price | Materials | Problems |

| CNC Machine | $1600 | Wood, Plastic, Metal | Not very Complicated 3D forms |

| 3D Printer | $500 | Plastic | Warping |

b. Simple interface

The unit is seen as a Serial port by the host computer.

It can be queried directly from command line and the commands and...

Read more » harry.olar

harry.olar

oneohm

oneohm

Kuldeep Singh Dhaka

Kuldeep Singh Dhaka

Anshul Sanamvenkata

Anshul Sanamvenkata

It's nice to see some neat stuff coming out from Ohio! I use the VCNL4010 from Vishay for my distance sensing as I needed something much smaller than what Sharp offers. They don't seem to offer anything that can go past 200mm which is a bummer because they have really good performance (~.0001mm variance and ~.01mm std deviation) and are really small (2mmx2mm package). Anyways, nice project! :)