-

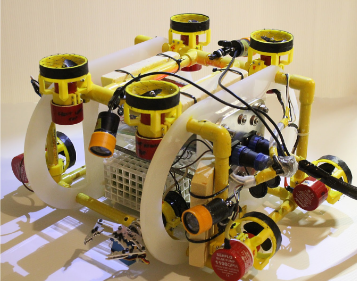

Finished ROV!

07/24/2017 at 03:10 • 0 commentsWe finally finished the Archelon ROV!

It has the following capabilities:

- Has 8 motors to...

- go up/down

- move forward/backward

- turn

- Grab and release objects with claw

- Collect agar for analysis

- Send live camera feedback to human controller

- Can be controlled with web interface

It can solve the following problems

- Help with maritime trade

- Clean contaminated areas

- Robot can accomplish tasks underwater previously done by humans

- Has 8 motors to...

-

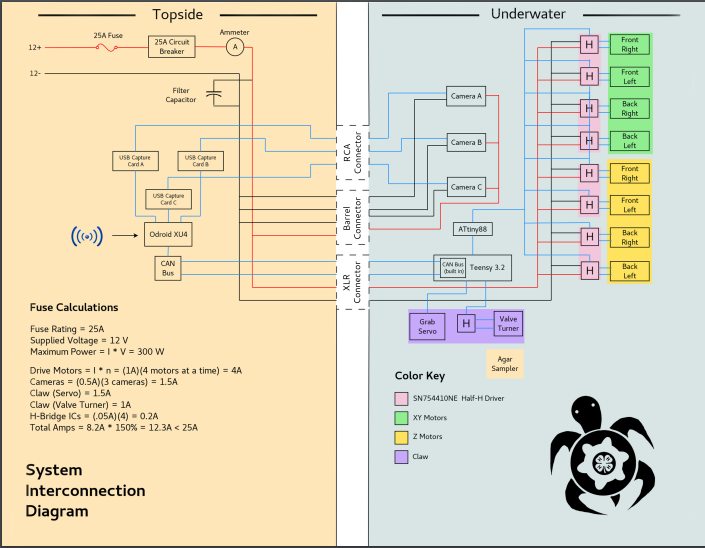

Topside Electronics

07/24/2017 at 03:01 • 0 commentsThe topside electronics is above the water and gives the human the ability to receive feedback from cameras and sensors and respond appropriately with a web-based interface. It has the following capabilities:

- Receive input from 3 cameras

- Communicate with bottomside

- Send signals to and receive feedback from web interface on tablet/laptop

- Monitor voltage and current usage

- Use fuses to prevent short circuits

![]()

-

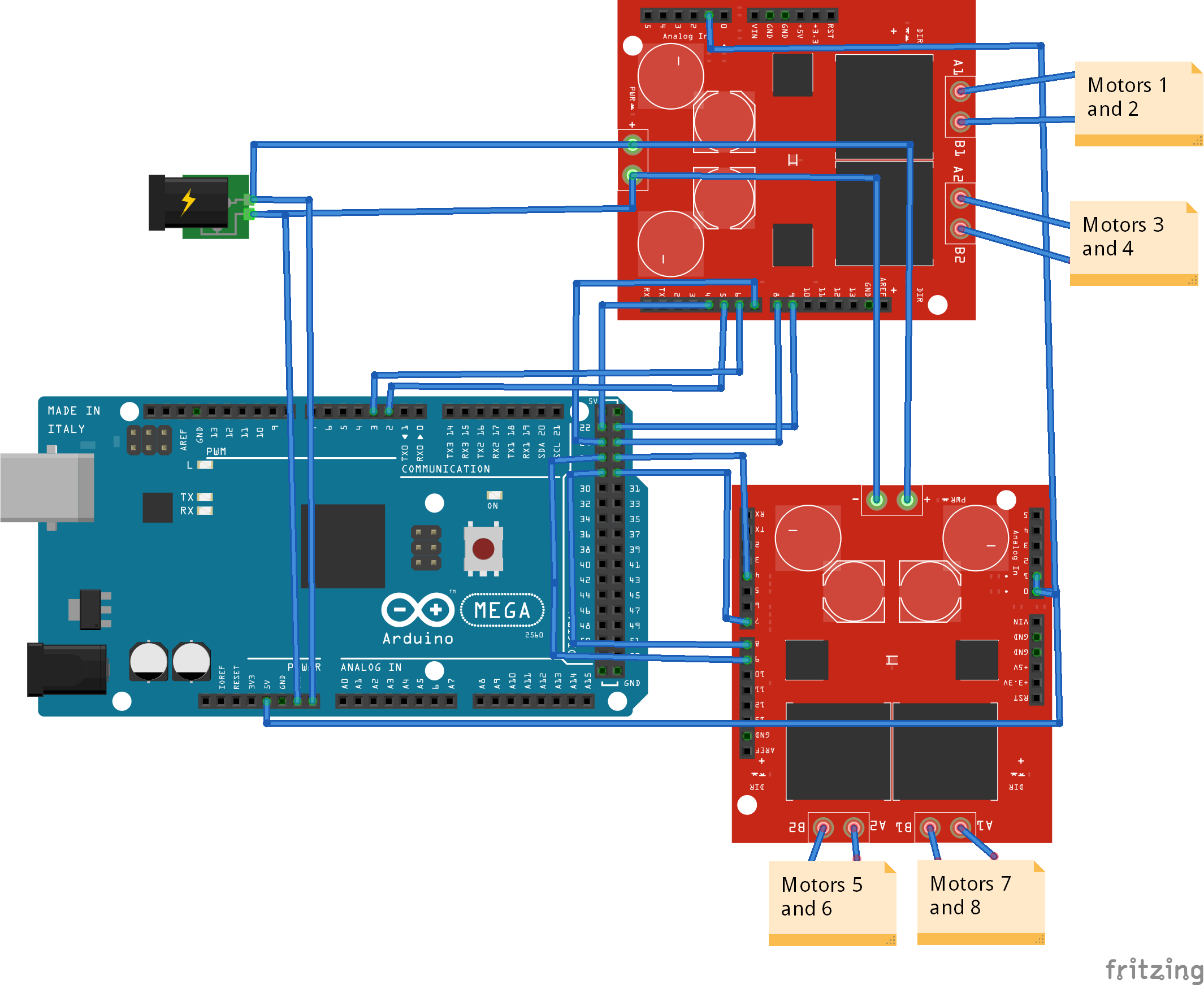

Bottomside Electronics

07/24/2017 at 01:22 • 0 comments![]()

The electronics that go in the acrylic tube that goes underwater are called bottomside electronics. Their function is to control the motors, any sensors, and any attachments. The bottomside electronics need to be able to control the motor's direction and speed. To accomplish this difficult task we used two monster moto boards that control the 8 motors in pairs. They receive a PWM input from an Arduino Mega and 12 volts from the tether. The robot also uses a teensy for communication. The underwater electronics are also capable of controlling the servo motor and the stepper motor that turns the servo motor.

-

Claw Design/Modifications

07/22/2017 at 16:51 • 0 comments![]()

In previous years, AscendTech's predecessors would design and build their own claw out of various materials to serve as an end effector for our ROVs. Last year, our developmental team decided to explore a different route for the claw, as the previous designs were frequently bulky and unreliable. Instead of building a claw from scratch, our build team instead modified a commercial claw that was guaranteed to work by its manufacturers. Our modified claw uses a 500 GPH bilge pump motor connected to a waterproof servomotor to operate the claw. This modification allows the claw to move on 360 degrees in rotation, a feature not included in the commercial claw's design.

Archelon ROV

The Archelon ROV is a low-cost, environmentally friendly Remotely Operated Vehicle (ROV) that helps to alleviate marine contamination.

ascendtech.robotics

ascendtech.robotics