Since the design of the socket and the connector is completed, it can now be attached to complete the bionic leg. The whole setup is very simple and it consists mainly 3 parts.

- The Socket

A simple cast/mold is made from silicone rubber after measuring the dimensions of the knee region. Later we would attach a vacuum suction material so as to perfectly attach the amputated part with the bionic leg. The cost of 1kg of silicone rubber is approximately 15$.

- The Lower Leg imitator

A customized light weight stainless steel rod was designed and was fixed to the lower region of the socket and the other end being connected to a prosthetic foot/shoe. Make sure the base of the shoe is cushioned enough to withstand the stress during movements and is attached to the steel section tightly. The upper part of this is connected to the socket by means of a rotary coupler. This can be adjusted to make the leg move in desired ways. The cost of steel rod is 7$ and that of rotary coupler is 8$.

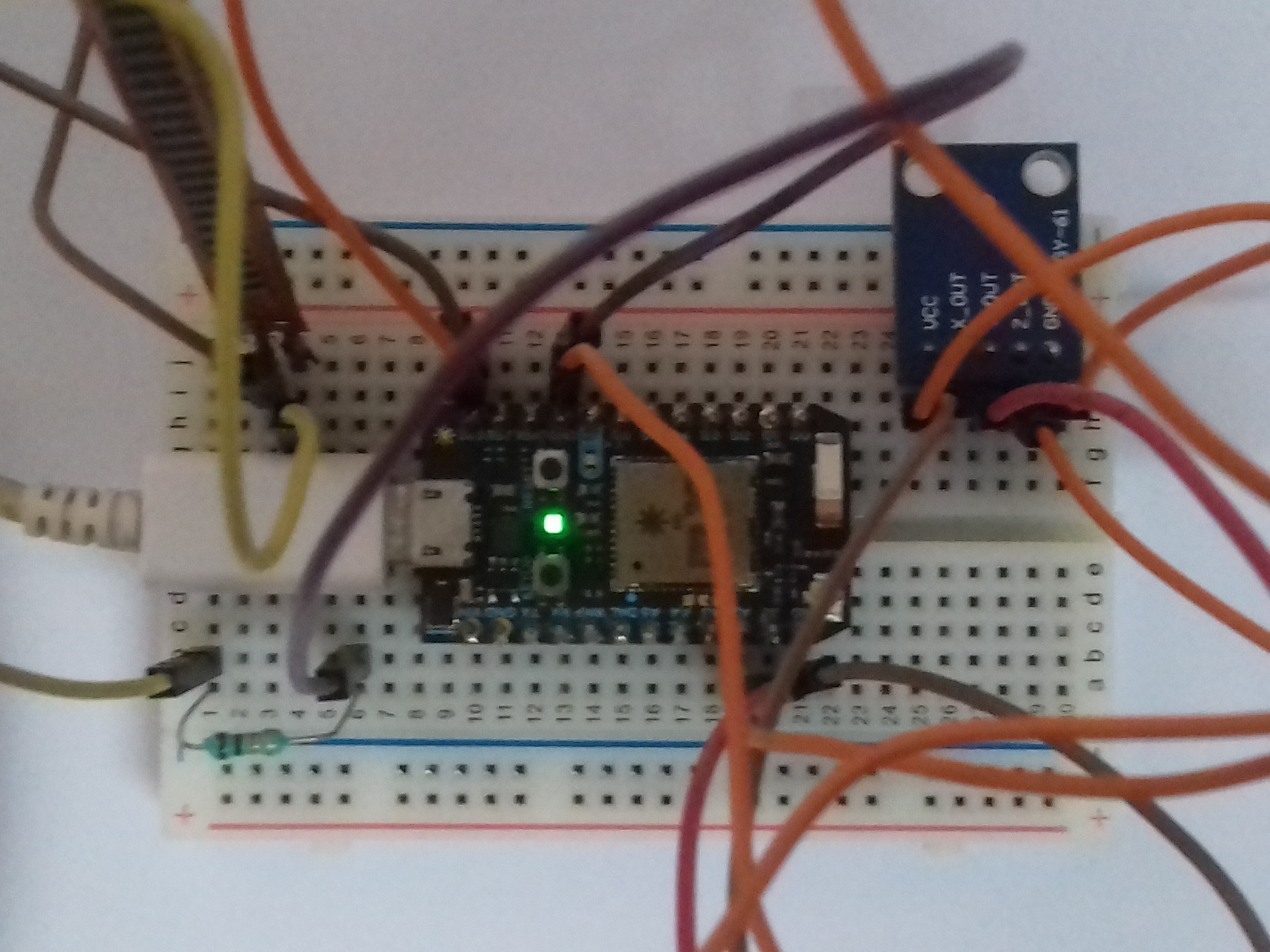

- Sensor Module

It consists of a small plastic box that incorporates particle photon, accelerometer, flex sensor and a battery. It is attached to the stainless steel rod region present in the bionic leg. The cost of photon is 20$ and the sensors are about 10$ in total.

The total cost for design is approximately equal to 60$.

Below is an image that we expected to bring out of our design.

We obtained a similar kind of model and will be updating this with improvements and ways to reduce the cost further.

G.Vignesh

G.Vignesh

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.