-

NOW I can start....

10/07/2018 at 15:05 • 0 comments...I hope.

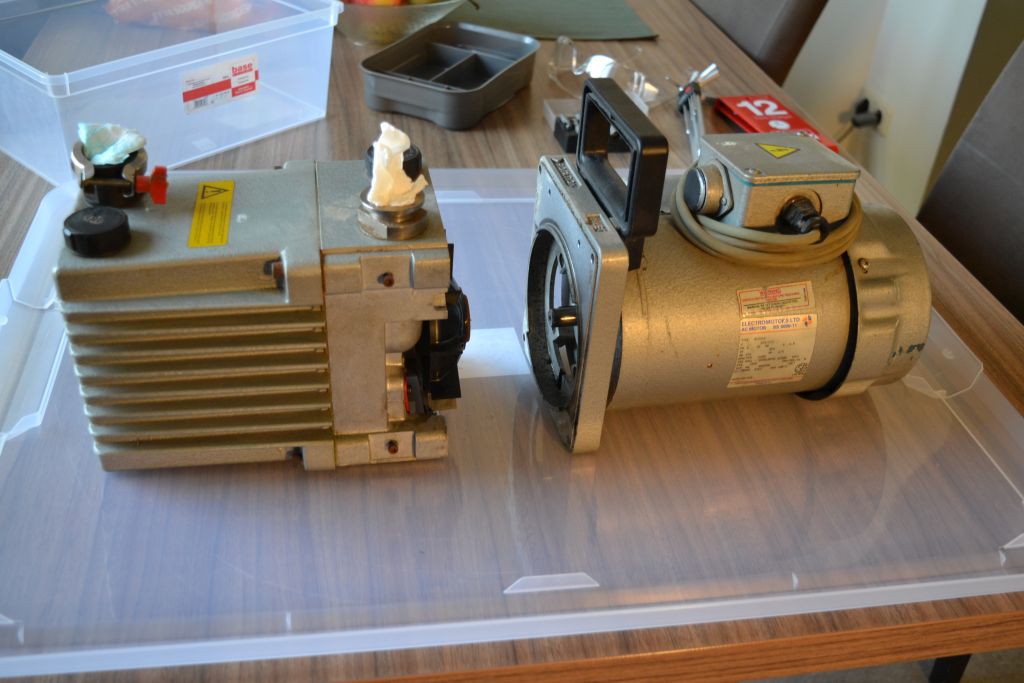

So, the second vacuum pump, which is an Edwards E2M12, just had its maintenance and looks like it also works... kind of.

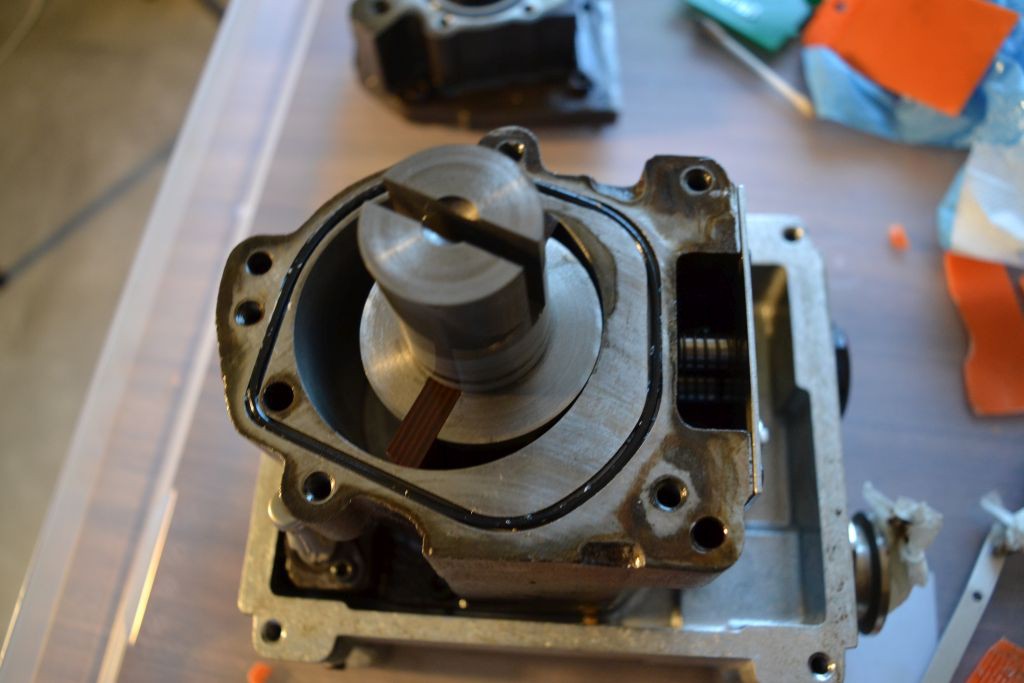

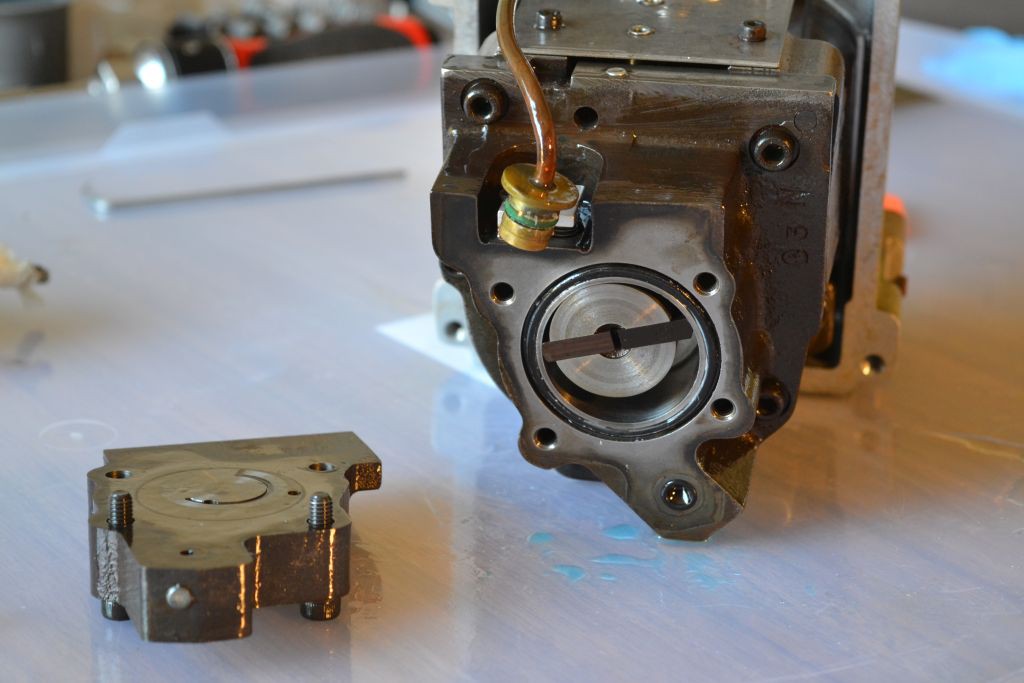

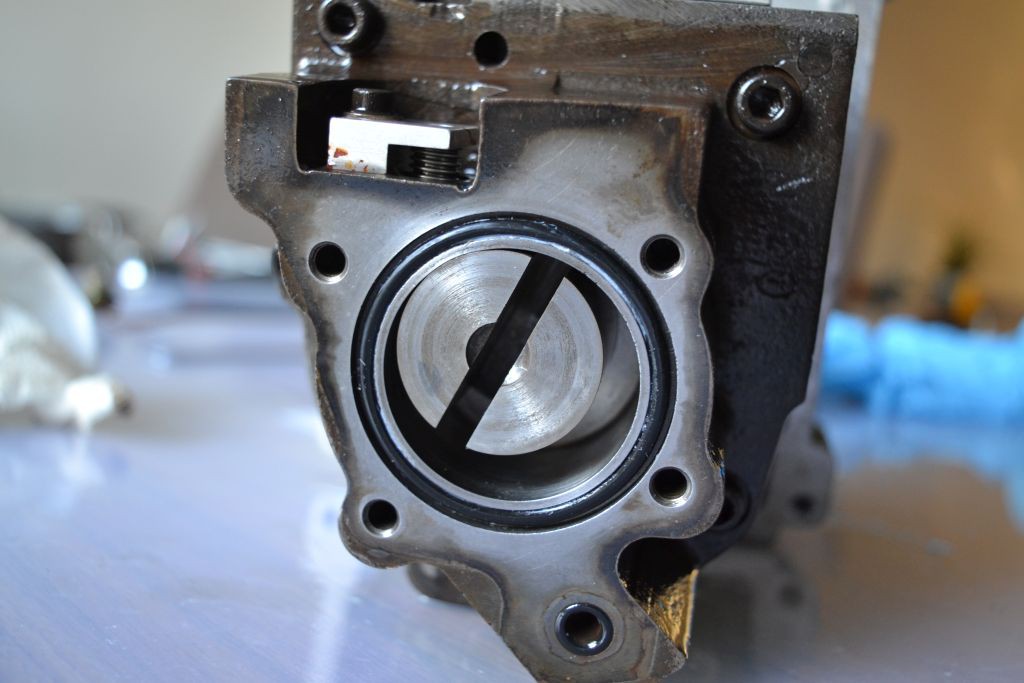

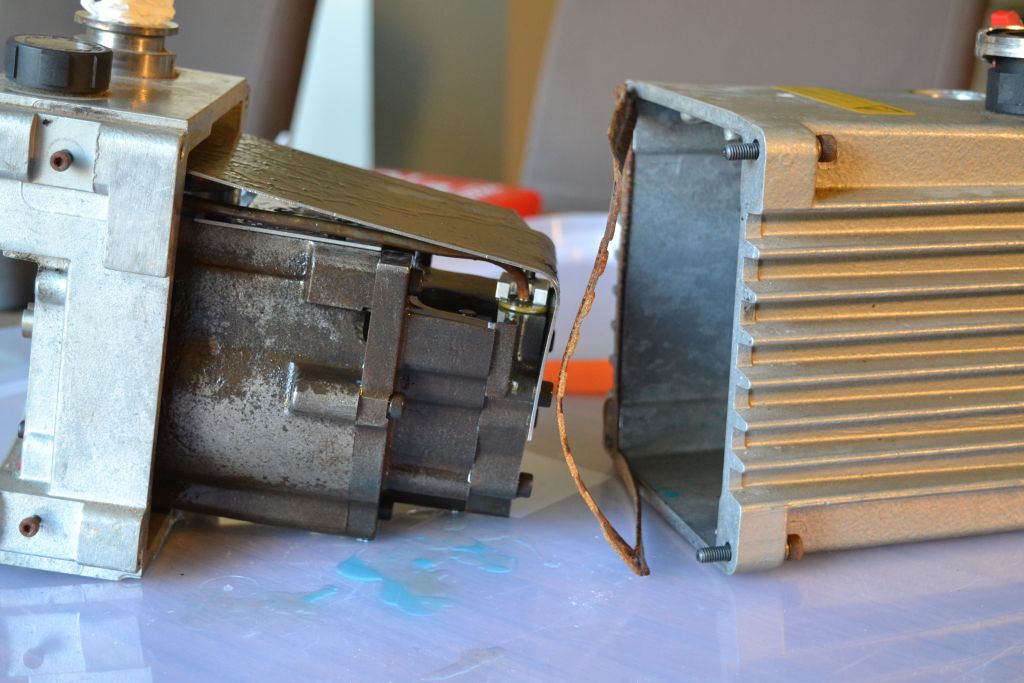

Before I explain, here's a few pics of the weekend-long overhaul process:

There's a lot of rust gathered at the bottom of the gas ballast valce (where a ball bearing sits) and the ultimate vacuum I can reach right now is ~ 1 x 10e-2 mbar, which is pathetic. But at least it's enough for the X-ray experiment....just barely. I'll have to take the pump apart again and try to see if I can do something about that.

Alsom this has been a nightmare, from finding and getting the overhaul kit to getting the Pirani gauge. But at least the pump is back together and it works.

Next thing is to think about a small vacuum enclosure to put the crystal in and how to make some isolated feedthroughs for powering the TEC inside the vacuum chamber.

This is gonna be fun :D

Will update things as they progress, of course. Oh, and I'll do a separate thread about how I took apart the pump and changed some O-rings and seals.

-

Yep, still here

09/14/2018 at 17:22 • 0 commentsAnd no, I haven't lost interest in this or moved to something else.

The vacuum pump I previously mentioned... it sucked. No, I mean it really sucked... as in it didn;t do much in terms of vacuum. FLushed it a couple of times, put fresh oil in it....still not much "suck" from it.

I wanted a new pump, something more professional, like...

Like the Edwards EM12 pump that I bought about two weeks ago.

Hold you horses..... there's still some ways to go until I can call this project wrapped up.

I want to buy a set of replacement parts for the pump (O-rings and seals) then I want to buy a Pirahni gause so I can acurately measure the vacuum levels. Also, I need vacuum fittings, and those don;t gro on trees... and neither do money. So I;m going to be on this for a while.

Will keep updating this as work progesses. Right now, the only thing arrived for the pump is a set of couplings. The Pirahni gauge went tits up because the guy on eBay didn;t ship the item so I asked for a refund. And the O-ring kit seems to be a pain to get because companies will only sell to other companies. B.S. policies....

Oh well....

-

"On Track"

10/15/2017 at 09:13 • 0 commentsOk, so things so far have been going exactly as I figured......that is painully slow.

I received the vacuum pump and as luck would have it, it's a total piece of garbage.

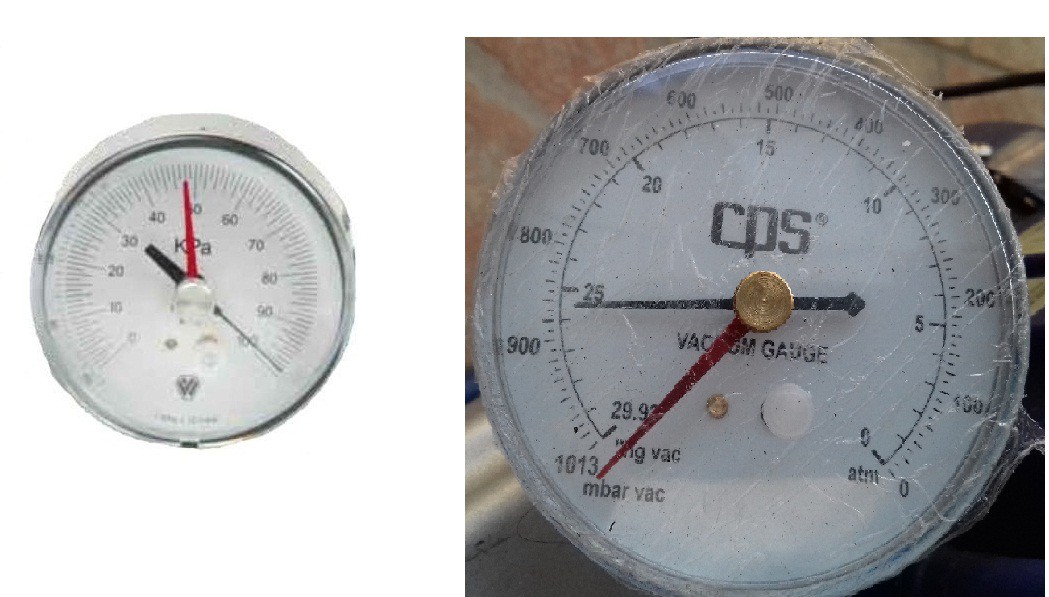

The vacuum gauge on it when it came looke like it had a rough life, so I had to replace it. Turns out that a vacuum gauge witht he correct scale is kind of hard to get in my country. Only 1 or 2 online shops that have it in stock.

This is how the original gauge looked. No glass on it and the indicator needle buggered off to some better place.

![]()

This is the pump I got. It's from ITE (german-chineseium grade vacuum pump, from what I can gather from the datasheet) and it's a Blue-Tec MK-60.

![]()

Here's the specs on it

![]()

So after about a week, the new vacuum gauge came and lowe and behold....it was nothing like the description.

On the left is the gauge from the store's pic. On the right is the very one that I got. But, ignoring my frustration, at least I was closer to testing my pump.

![]()

The next thing that got in my way of firing up the pump was a lack of proper fittings. After being delayed 1 week because of my half-arsery and ordering the wrong kind of fitting (Ordered by mistake a 1/8 NPT fitting instead of a 1/4 NPT), when I actually got to order the right one, it never came. No one phoned me to say if they have it in stock or not, no mails, no nothing.

Because my frustration grew eve more, I decided to go at it caveman style and plug the pump's inlet with what I hoped to be and airtight seal made from a small round piece of rubber gasket, wide enought to cover the 1/4 hole of the fitting.

And, of course, when you're on a roll, why stop, right? Turns out that the vacuum pump doesn't go all the way down to the specified vacuum.

I bought some vacuum pump oil and flushed the pump twice (the old oil was OK, but it looked more like motor oil than vacuum pump oil) but still it only went down to about 250 mbar, which is way more that the required 0.05 mbar. Also, the oil that came with the pump had some grime in it, probably because the pump inlet was left open in a shop somewhere.

So, as of now, I either have a leak in the system (probably the rubber is not sealing well) or the pump is actually FUBAR from being run with the wrong kind of oil and/or because of debris still inside it. I can only verify this by actually putting a 1/8 NPT plug on the inlet and running it like that but alas. these seem to be as rare as hen's teeth.

To be continued.....

-

Still on it

09/15/2017 at 13:21 • 0 commentsI haven't done any work on this because I'm stuck looking for a suitable vacuum pump that doesn't cost an arm and a leg.

The vacuum level isn't that high, but most chinesium-grade pumps I've seen don't look that promising.

I may have found one that fits the bill, both in price and performance. It's a second hand, 2 stage pump. Hope it also works. Sometime next week I'll find out if this is really the case or I just threw away 50 Euros.

I've also been thinking about the set-up and fittings I'm going to use. I basically want a set-up that's easy to disassemble and also holds a vacuum. Kind of much for them, but I'll test this out once I have the pump (if it works)

-

The game plan

08/19/2017 at 12:04 • 1 commentTesting the basic concept

To get the for factor as small as possible, the only way to go, as far as I've seen or read is by using a pyroelectric crystal. This has the advantage of taking up a few cubic centimeters of space and uses voltages somewhere between 5 and 12 V. Perfect!

Ok, so what is a pyroelectric crystlal, I hear you ask? Well, it's a crystal (most common ones are Lithium Niobate or Lithium Tantalate) that when subjected to a temperature differential, charges inside the crystal matrix start wandering about and elctrons wil be emmited from the Z-plane of the crystal matrix. In other words, you heat up the crystal from the bottom, for example, electrons gather to the top of the crystal and will be emitted outwards. Without any additional acceleration voltage.

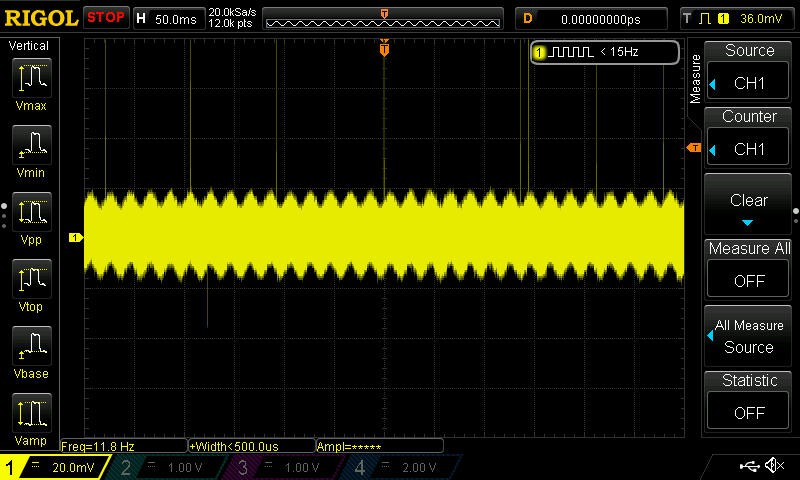

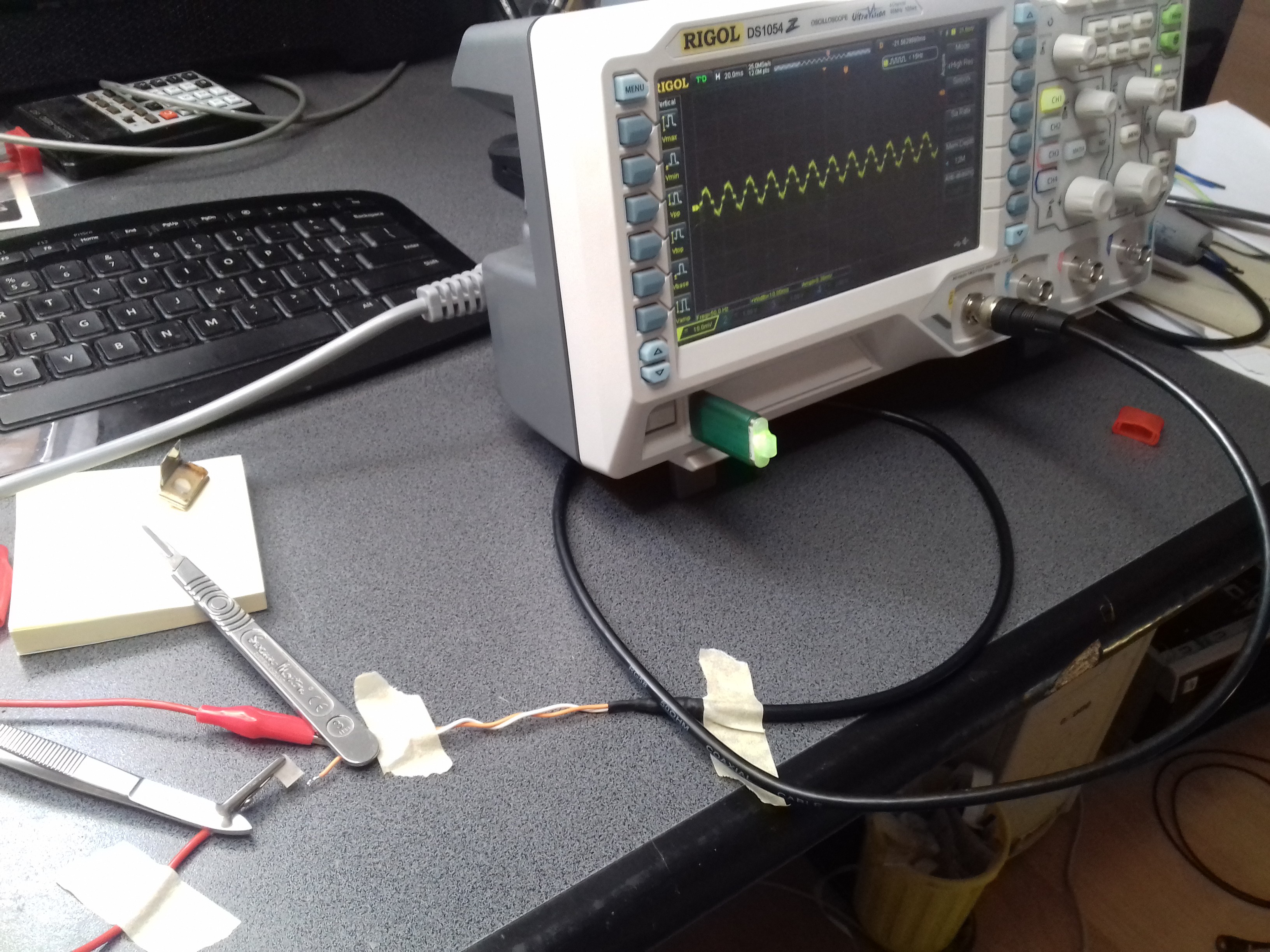

If you don't believe me, (and it's understandable, because I didn't until I tried it) here's a scope shot of a quick experiment I did.

![]()

![]()

The set-up is pretty simple. I took a slither of Lithium Niobate crystal, hooked one end to the ground of a scope and I left the the top of it floating near the positive of the scope's input (just a straight BNC cable, attenuation X1).

Whenever the crystal was exposed toa temperature differential, electrons started spewing from it and would appear on the scope as soem very narrow pulses. The slither was heated using a regulat heat gun, set to about 100 degrees C. A few 2 second shots of hot air on the crystal generated the scope shot you see.

Now, please take into account that what I've done here is just proof of concept (for myself at least) to see if I have something tangible here.

As you can see from the scope shot, a lot of pulses show up, so tht means that indeed, electrons do indeed escape from the crystal. No, these are not X-rays. At least not yet. These are just run of the mill electrons :D. For the actual X-rays, a few more things are needed.

Also, bear in mind that electrons are only emitted when the crystal has a tempeerature differential across it. Once the crystal uniformly heats up, there are no more emmisions from it.

Ok, so now that I have some proof that I'm not just chasing green unicorns, I can get on to bigger and better things.

Let's get to work on those X-rays

X-rays are actually generated when an electron collides with another material (i.e. the atoms inside that material). So, basically, if I take the slither of crystal and put it in a medium where electrons can travel unimpeeded (say, in a vacuum) then have those electrons slam into something, X-rays will be genrated.

Granted, those will be some very low energy X-rays, but hey.... if you want to go handheld, it's better than lugging a whole grandma's basket filled with tubes and tranformers.

What I want to do next is build a vacuum enclosure, stick the crystal in it , get some vaccum inside it then have a small window where X-rays can escape from.

I figured that aluminium foil, copper foil and mica are some good candidates for the window material.

I know it doesn't look like much, but hopefully those fittings are going to be my vacuum chamber. Why go for those, instead of a glass envelope? because I wnt to experiment with this, meaning I might want to try different crystal orientations and different window materials, therefore I want something that seals adequately under vacuum and can be easily taken apart. Will it really work ? I don;t have a clue, but I hope it does. All I can do i just hope and speculate, as at the moment I don't have a vacuum pump.

Speaking of vacuum, there seems to be a sweet spot for the vacuum level for this thing. That seems to be somewhere between 1-10 Pa of pressure (or 10^-2 to 10^-3 Torr). I'll try to aim for anything under 5 Pa, but as I'm a noob regarding this kind of stuff, again, I can only hoep for the best right now.

So, where can one get those crystals?

The most expensive thing about this build is actually the crystal itself. Somthing like a Z-cut Lithium Niobate slither 2mm x 2mm x 5mm is somewhere around 200 $. And it's not like you can just walk into your closest store and take one off the shelf.

So, like any mad scientist, I had to do some research, to see where I can get one for cheap.

I scrounged the net for any information I could find, and only came across 2 other sources attempting the same thing as me:

1. http://www.rapp-instruments.de/index5.htm

2. https://www.intechopen.com/books/scanning-electron-microscopy/palmtop-epma

The most important information I came scross was that LiNbO3 or LiTaO3 are, or more accurately were used in some high bandwidth SAW filters.

With this in hand, I searched the interweb high and low for any reference of a SAW filter that used these materials as a substrate. Also, very few manufacturers actually write in the datasheet the substrate material, so it was a very frustrating search.

The reason they are not used today as a substrate i SAW filters is exactly the reason I wanted them in the first place: their pyroelectric properties. Meaning that for a few degrees of temperature change, theyradically changed their SAW characteristics.

Asking around on the EEVBlog forum, I got a hit on some old SAW filters. The company that manufactured them was C-Tech and the part number for the one I got was 312991. It was only about 20 $, which is perfect for a proof of concept experiment. They also seem to have a LiTaO3 substrate filter available. Jackpot!

What I want to do isn't by any chance new. mptek have the Cool-X generatos, that works on exactly the same principle. Except they want to charge about 2500 $ for it. Naa, I'll pass.

That's pretty much it for now. I got a Peltier module with which Im going to heat and cool the crystal and next step should be getting a vacuum pump that can do 5 Pa or less. Some eBay ones are advertised as beig capable of that, but if they really deliver... I have no idea.

Low Voltage Pyroelectric X-ray Generator

Trying to develop an X-ray generator using a pyroelectric crystal, for less than 100$

Razvan Caldararu

Razvan Caldararu