-

Final product design outline

09/28/2014 at 04:15 • 0 commentsThe goal of my project is to provide a system that consists of a docking cone with wires that your batteries including their respective balance leads will be connected to that mounts to the bottom of multirotors. Inside the cone there will be a wide angle webcam, sonar and a single board computer. Onboard computer connects to a flight controller over UART using mavlink packets and it is expected that the flight controller is using the arducopter firmware version 3.1 rc7 (or a version that has sonar support for your chosen flight controller).

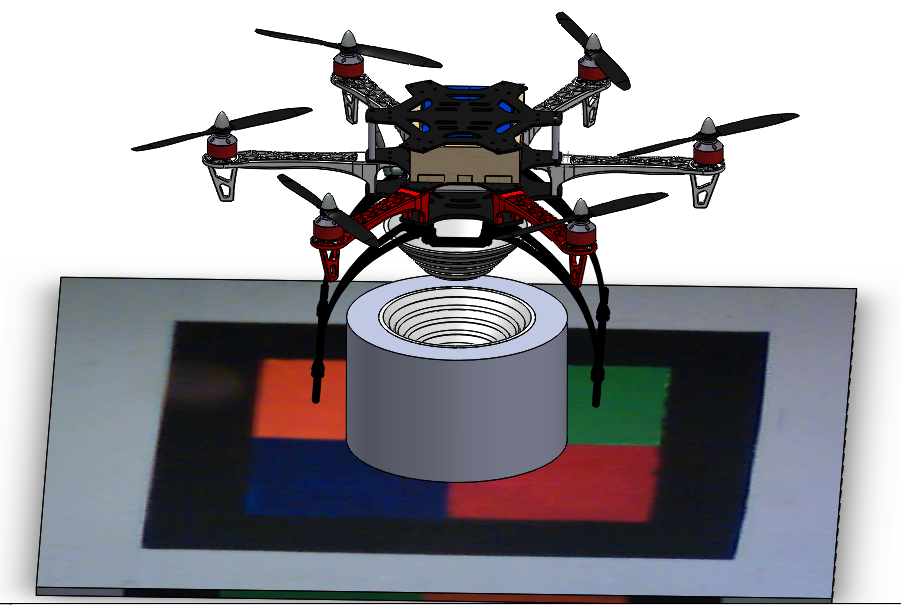

(Prototype rendering of the system)

Currently I am designing it for the F550 frame from hobbyking which is a knock off of the DJI H550 frame with a set of tall springy landing skids (they are useful for rough landings and have saved my hex a few times) ,but the design can be easily adjusted to fit other frames by changing the parameters(height, width, angle and spacing of connection rings) of the docking cones.

The system may not be suitable for small multirotors as it weighs approximately 500g, but this weight could be reduced in later versions as I am not optimizing for weight due to tight time constraints and prototyping.Integration with arducopter

At a later date when the project is more mature I am going to make further modifications to the arducopter software to add in configurations to allow easier external control and integrate my offboard controller more into the firmware to allow easier integration for people who want to use this system.

-

Current testing progress and results!

09/28/2014 at 04:13 • 0 commentsAs part of my testing a rig has been set up in the front yard involving a rope between the roof and a tree in the yard which allowed me to test the copter repeatedly and ensure that any changes I made don't destabilize the craft or cause fly aways. Once the software has been proven to not cause problems and the copter had managed to perform its task while tethered a few untethered flights were performed in a reserve far away from people, power lines and buildings.

It has been a slow and long process ,but finally I have managed to achieve a set of results that can be considered a working prototype system. The copter has been able to reliably detect and center itself over the target them bring itself down onto the target with a 10cm error outdoors which should be fine as the docking station is being designed to deal with that much error. Currently the system is a little slow with actuating itself over the target but this is past of slowly building up confidence in the system and taking it slow for safety reasons both for the copter and myself.Possible improvements:

I can also improve my results when I switch over to a better state estimation when I can finish off the EKF design and I think velocity based control for the positional control will work better than attitude based. As well as implementing a sliding mode controller rather than cascaded PID loops -

Prototype docking station design

09/28/2014 at 04:04 • 0 commentsIn order to achieve the task of docking a multirotor for recharging a custom docking station had to be designed. Several designs were considered against the requirements in order to select the most appropriate.

Requirements

- Shall allow a +- 5cm tolerance on landing

- Shall be able to connect to at least a single lipo(4s) and the corresponding balance connections

- Should be capable of allowing a +- 15 deg orientation misalignment

- Should allow a range of multirotor sizes and configurations

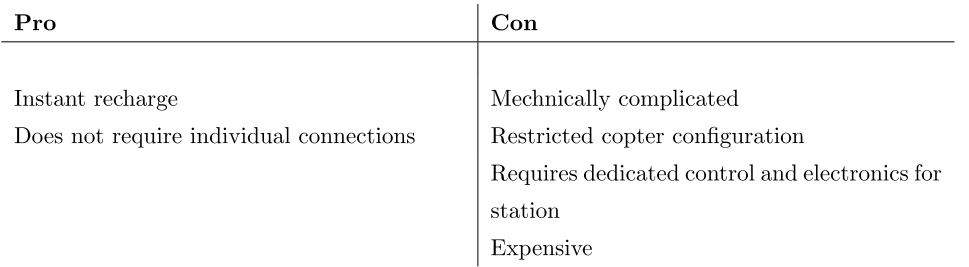

Mechanical battery swap

For this design the copter lands and a mechanism removes the battery from the copter and then switches in a fresh one from a cartridge

Mechanical gantry for alignment

For this design the copter lands on the target in the approximate area then an arm sweeps it to an appropriate position.

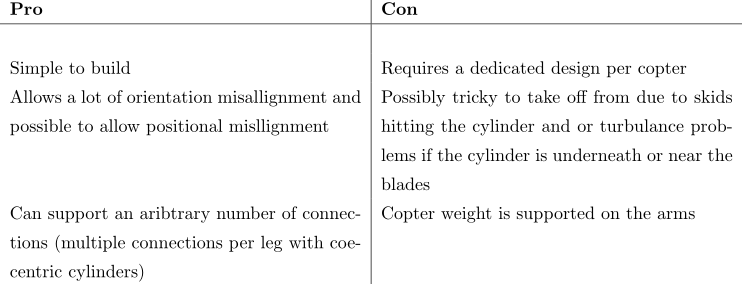

Big cylinder with notches

For this design the copter has contacts on the arms and lands into a cylinder with triangular notches to guide it into a resting position

Guiding cones

This system is based off satellite style docking mechanisms with one side active and the other passive. The cone system fits over the camera and sonar assembly at the base of the copter and a cylinder with a raised section and a mating cone is placed on the landing target in such a way that the docking is complete when the landing skids barely touch the target.

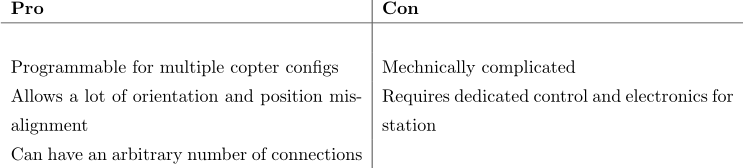

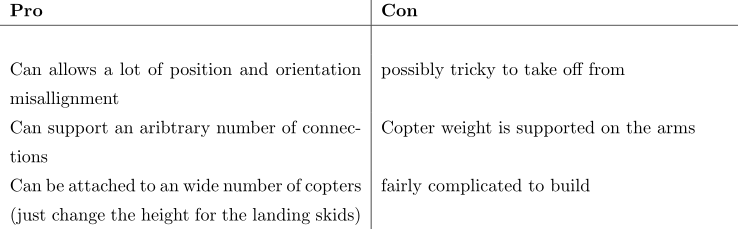

Arbitrary contact grid

This system is based off the idea of having metal contacts placed on the landing skids and a landing on a target with a number of contacts in a pattern that maximize misalignment

– Therefore be capable of 2 + 5 connections(power and balance) to 4+10 connections (for 2 4s lipos in parallel)

Giovanni Durso

Giovanni Durso

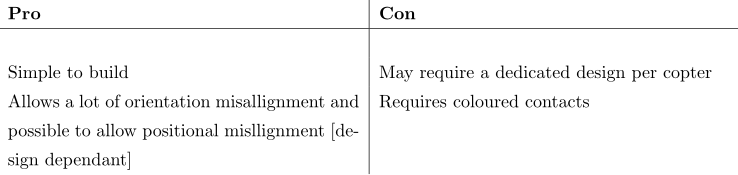

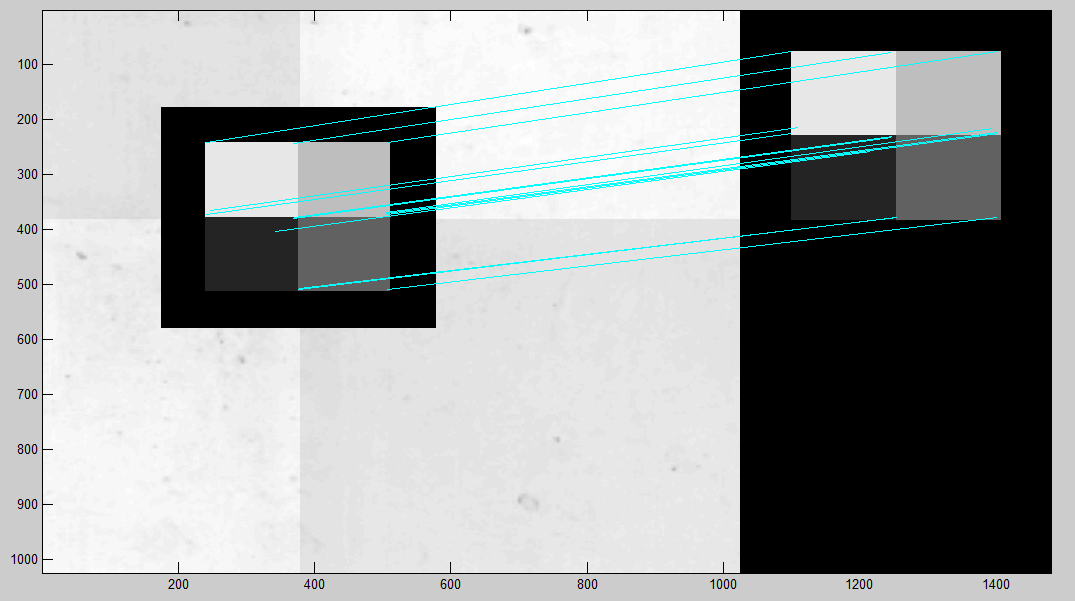

Example of breakdown of blob detection

Example of breakdown of blob detection

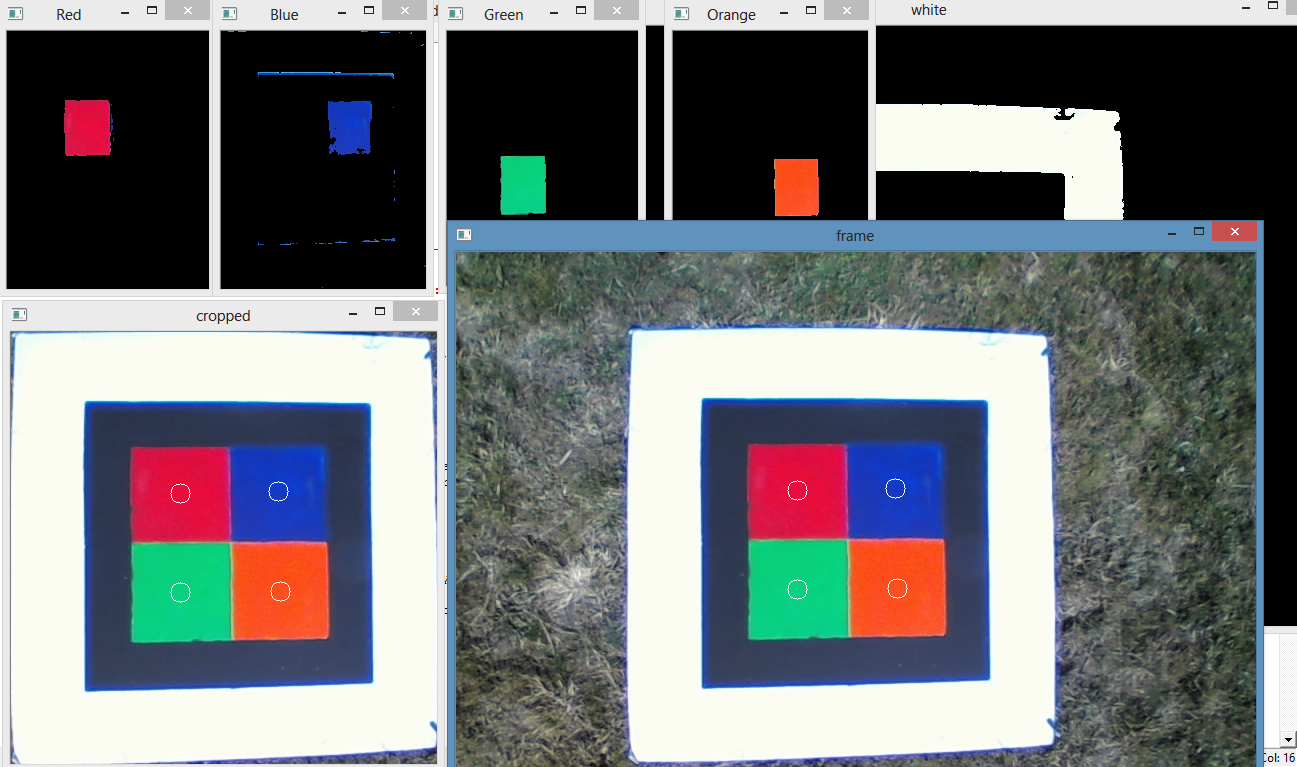

Output from CMT outdoors with hexacopter 15 meters above the ground

Output from CMT outdoors with hexacopter 15 meters above the ground