-

Experiments with Polyethylene Dielectric

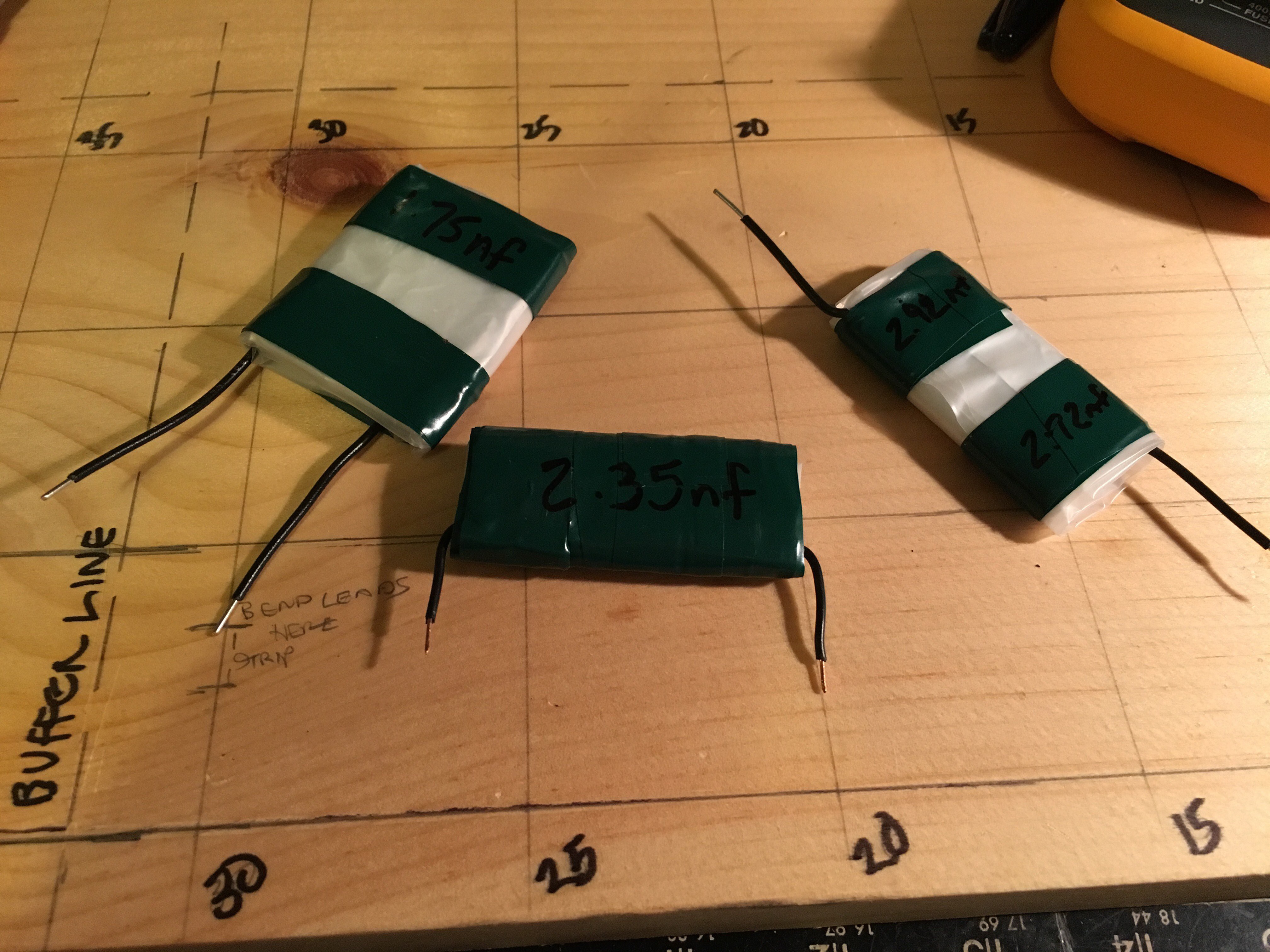

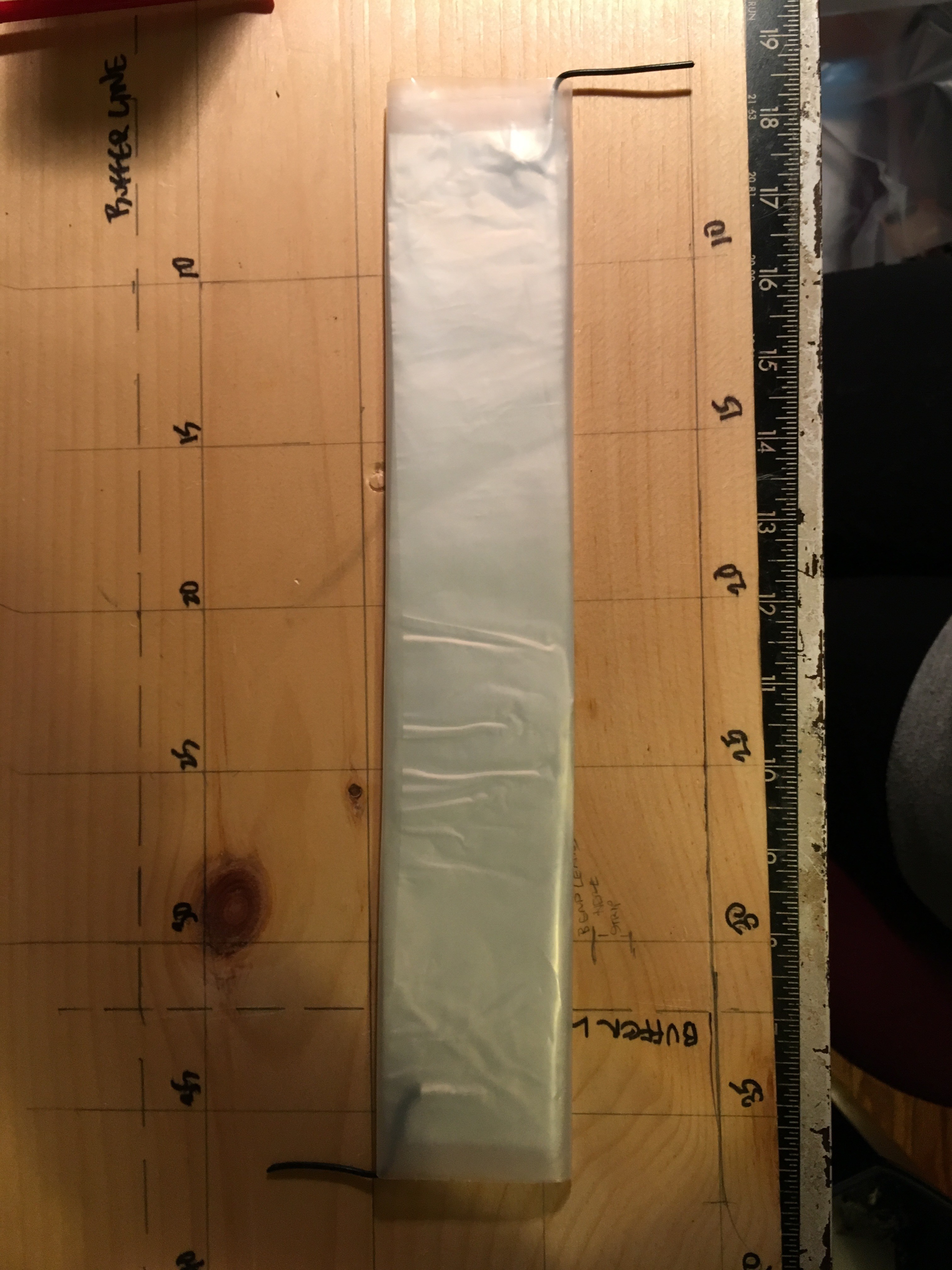

11/08/2017 at 15:34 • 0 commentsAlong with working out processes for fabricating capacitors, I created some tests with aluminum tape and polyethylene dielectric (of varying thicknesses.) Capacitance measured between 2 and 3 nanofarads.

Still working out lead placement, orientation, etc.

![]()

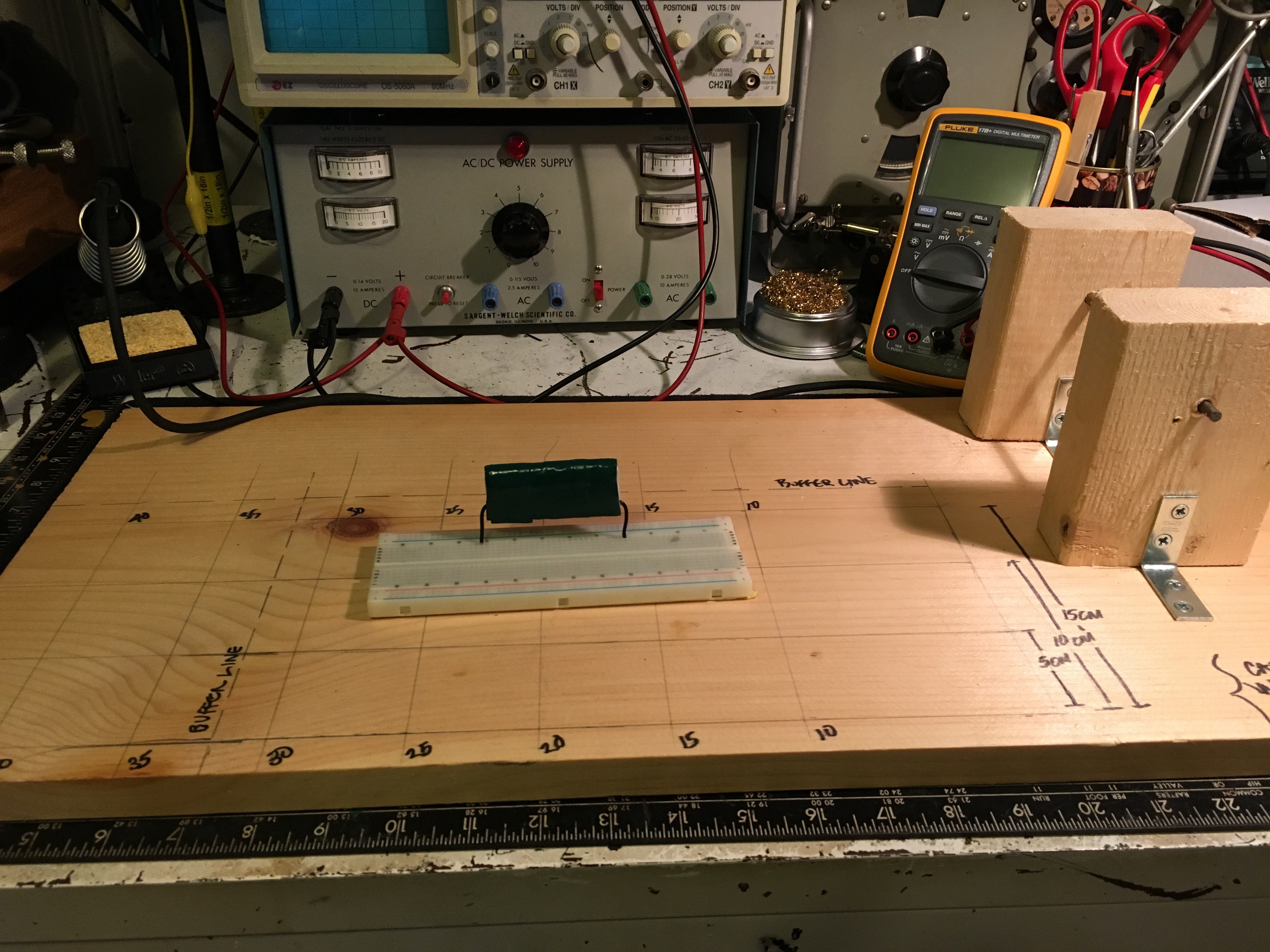

Along the way, I created a little jig to assist with creation. Right now I'm just using the measurement sections, but I've been working on a tool at the top to assist with wrapping capacitors on the top left. Not sure if it will be hand wound or motorized.

![]()

Still trying to find the best way to affix the leads. Solder connections on the aluminum tape are not great. May be solved by dipping in sealant (wax, epoxy, resin) and drawing a vacuum on it to get rid of air.

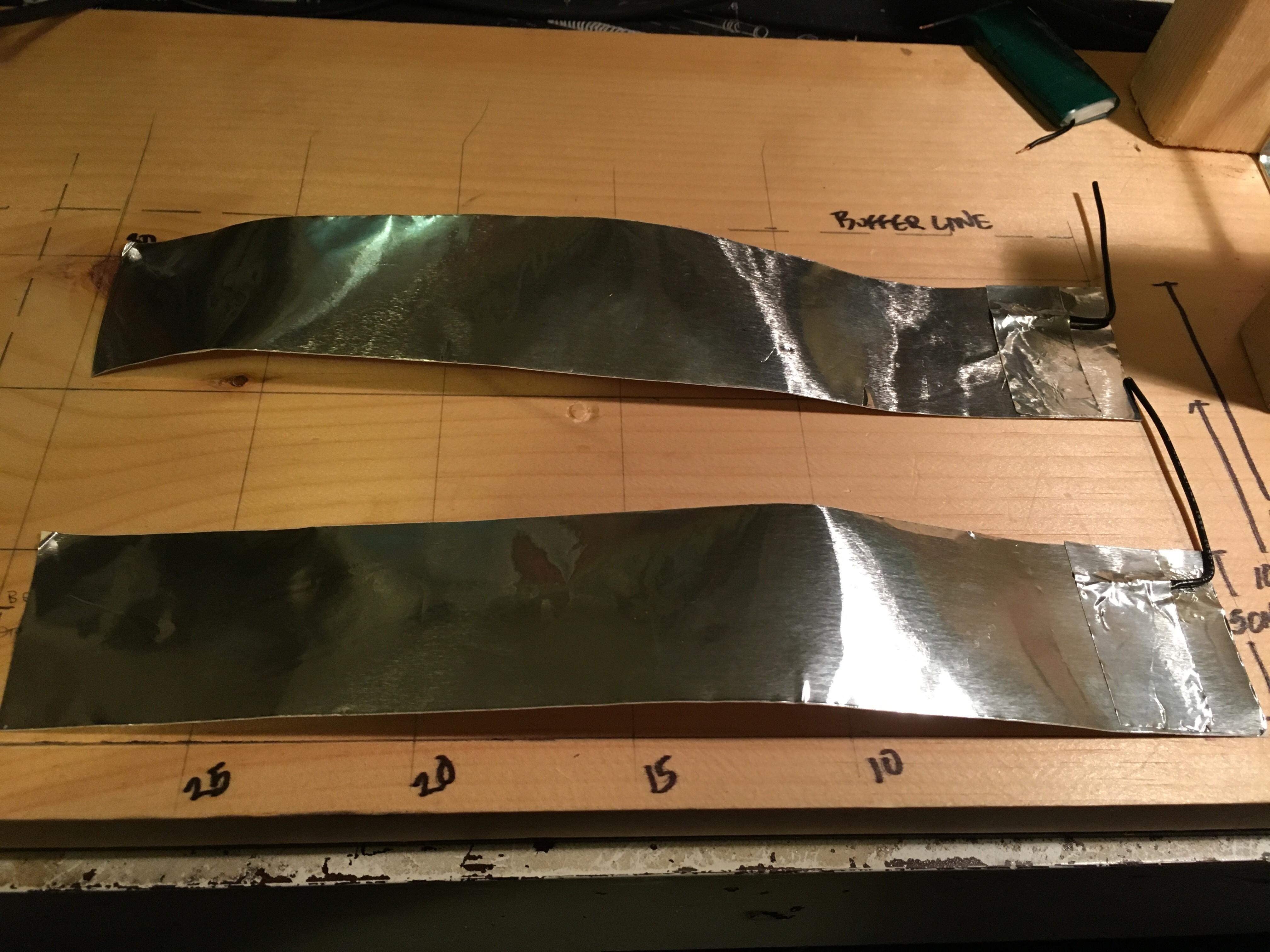

I'll wrap up with some process pics.

![]()

Connections soldered and then covered in metal tape.

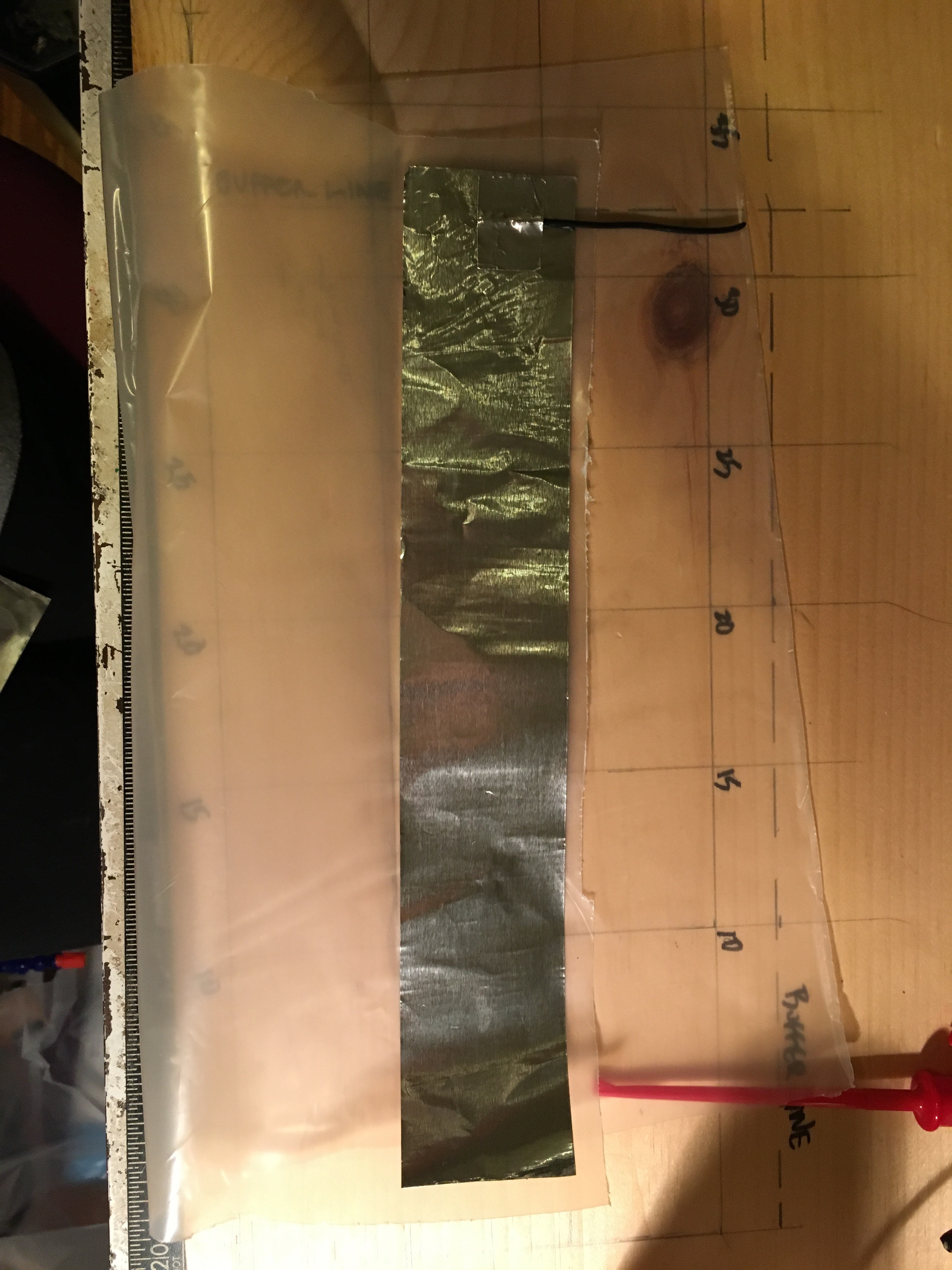

![]()

Both layers on polyethylene.

![]()

Wrapped up before being rolled.

-

Useful Table of Dielectric Strength

11/07/2017 at 19:04 • 0 commentsFound a useful table of dielectric strengths for various materials over on 4HV.

-

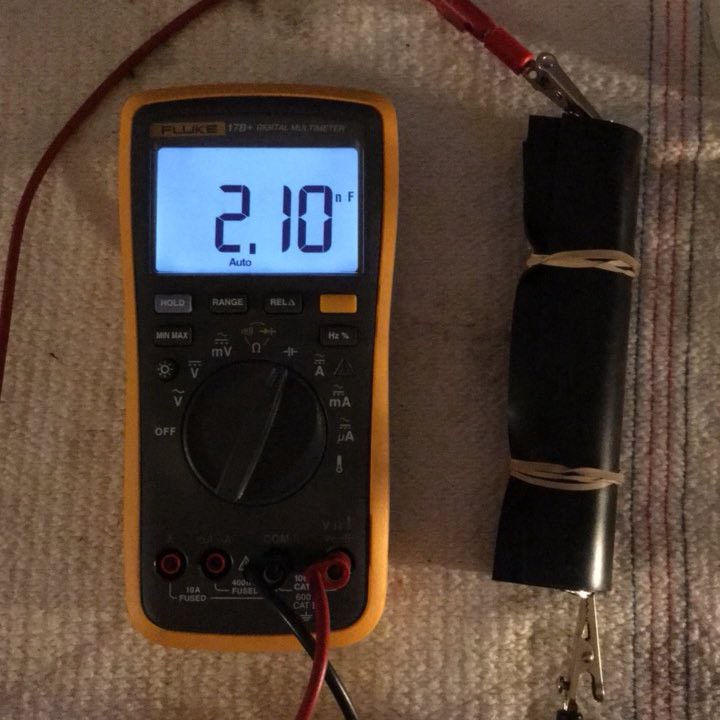

Proof of Concept - 2.10nf 25kv Capacitor (Rubber Dielectric)

11/07/2017 at 16:15 • 0 commentsAs a proof of concept, I decided to try making a foil capacitor with a rubber dielectric. The plates were rolled together and secured with rubber bands to keep everything snug.

Specifications

Width: 15mm

Height: 15mm

Dielectric: Neoprene Rubber

Dielectric Thickness: 1.5875mm

Conductor: Aluminum foil

Leads: Aluminum foil tabs

Capacitance, 2.10nf (2,100pf)

Breakdown Voltage: ~25kv

Capacitance was read by connecting leads to aluminum tabs extruding from opposite ends of the capacitor. A Fluke 17B+ was used for measurements.

Wikipedia lists the dielectric strength of neoprene rubber between 15.7 - 26.7 MV/m which gives us a minimum breakdown voltage of around 24,923 volts and a maximum of 42,386 volts.

![]()

High Voltage Capacitors

Creating tooling and techniques for making high voltage capacitors.

anotheremily

anotheremily