-

PCB Connector Testing

12/31/2017 at 17:15 • 0 comments![]()

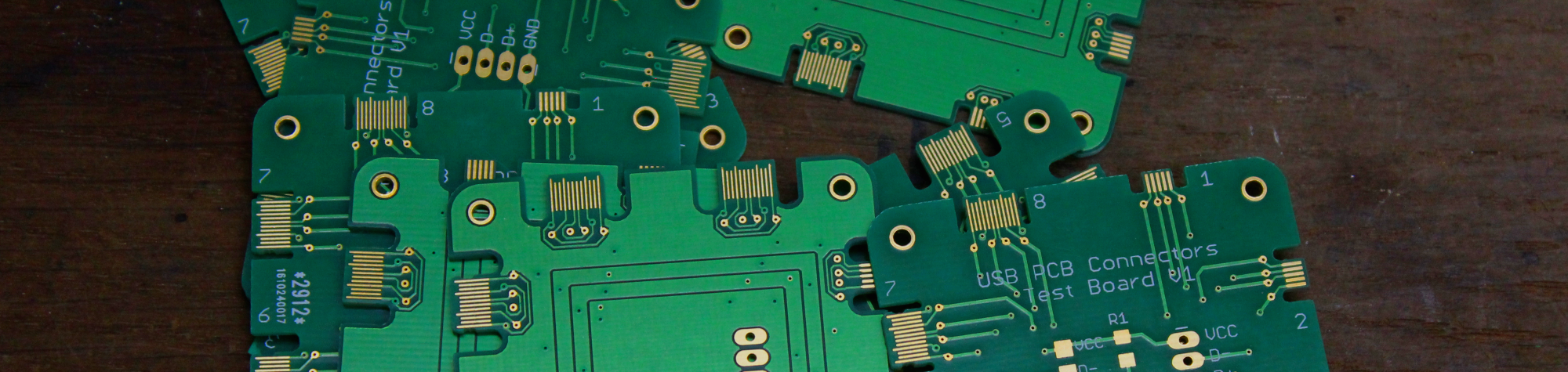

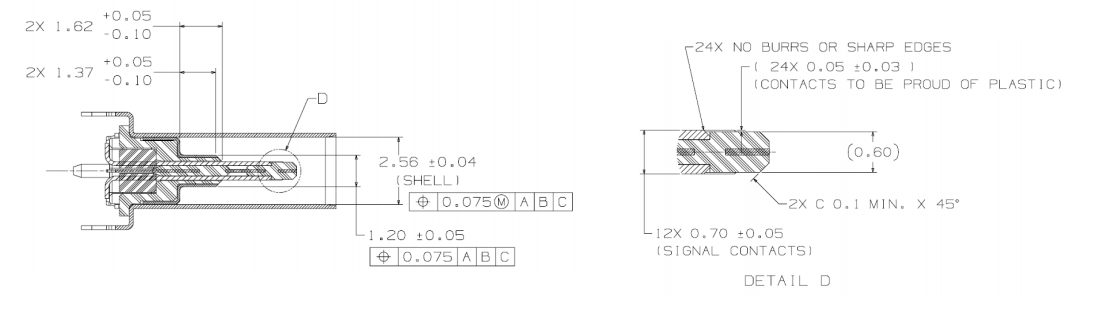

Before prototyping I wanted to test the PCB connectors first, because I have some footprint variants and I didn't know which one was the best.

For that reason I made a test PCB with 8 footprint variants, 3 for the micro b connector and 5 for the type c connector.

I ordered it from a very cheap PCB manufacturer, I had some problems with their web, and I had to do the order it 2 times. Because i was in a hurry the second time, I used the wrong PCB thickness of the board and ordered 1.2 mm PCBs.

I realized it when the PCBs come, two weeks later, so I was a little bit annoyed. The whole point of making the PCBs was to test the connectors, and with a PCB thickness of 1.2 mm I could not do anything.

(Luckily for me, this mistake save me from a possible laptop destruction, you will see why)

![]()

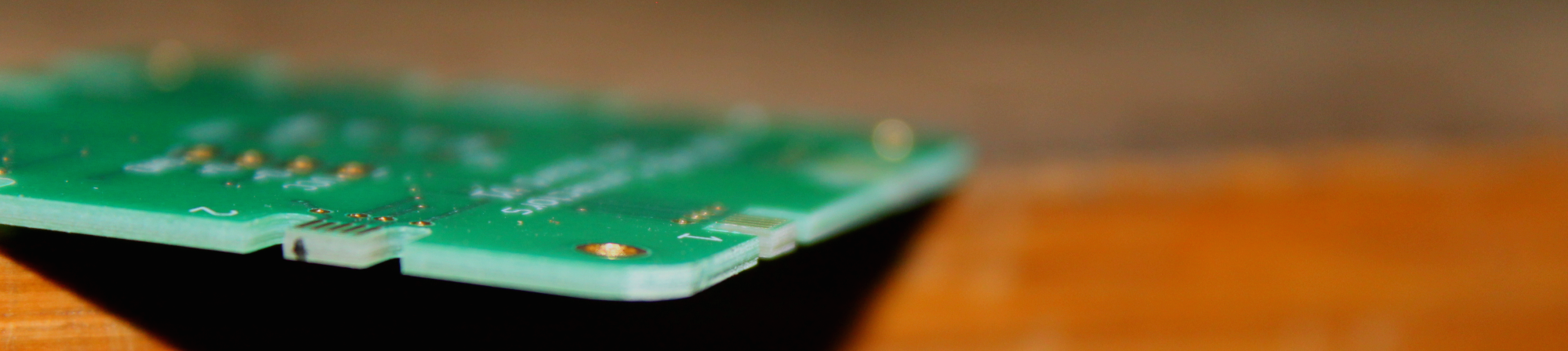

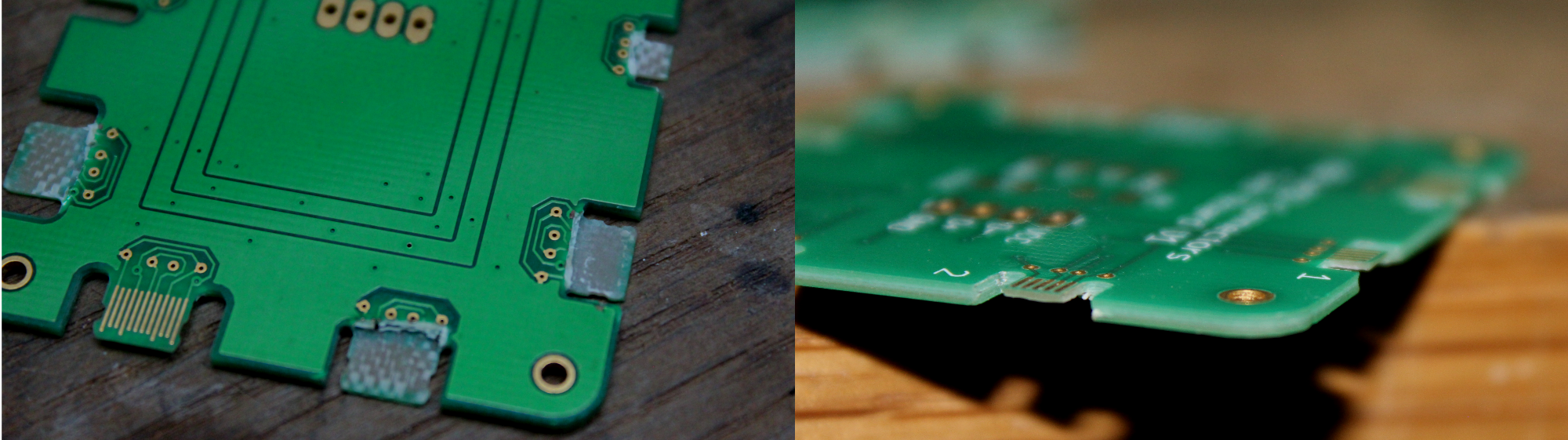

I don't want this PCB to waste so I tried to modify the PCB to make, at least, a rough test of the connector. Thankfully, those PCBs are made of FR4 material, and the way it is made is from thin layers of glass fiber, this make easy to scrap some layers to achieve the right thickness of 0.6mm (with the help of a caliper).

The footprint for the PCB connector type C is two sided, because the reversibility of the real connector, you can plug it either way. On the other hand, the real USB micro b is only one way, but my first footprint for that connector were two sided, that means that if you connect a USB micro b cable to that connector, in one side it does connect with the pads of the connector, but on the other side, the plug has a metallic surface, so all the pads are shorted together. That means that it could short circuited the USB supply and if there is no overcurrent protection it can potentially destroy my laptop (I seen some example of that).

I was scraping the PCB, thinking that I could not prove the reversibility of the connectors when I realized that it could cause the short circuit. of the USB, so my annoyance turned into happiness. I still could not test the reversibility of the connectors, but at least my laptop was safe. And at the end the test was successful and i was prepared to do the real prototype.

![]()

By the way, the test results were that the tighter the connector the better. So my conclusion was to make the cutout for the connector as small as possible to add more grip to the plug and maintain the cable attached to the PCB, and also make the cutouts a little bit longer considering that the drill doing the cutouts is round and can not do perfect corners.

-

Free USB Connectors!

12/24/2017 at 20:14 • 1 comment![]()

One of the main features of this project is the PCB USB connector that makes the interface between the business card and the computer.

As I said, I wanted a very thin card so the use the USB type A PCB connector was descarded (you need are least 2.4mm thickness for a good grip).

Another reason for not choosing the USB type A PCB connector is that this PCB connector was made simulating the USB type A plug, so you have to connect it directly to the PC, and this is not good for a gamepad, is really difficult to play videogames with a game pad with no cable. You can find one of those USB plug/USB receptacle cables, but those are not very common.

So I thought, what is the USB cable that we all have around? And the answer was the USB to micro USB cable.

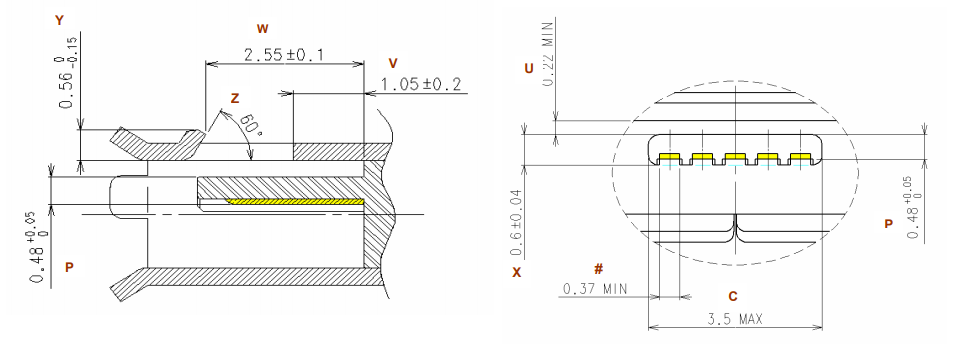

I searched for the specification of the USB micro B cables and connectors to look at the dimensions of the connectors, and find a way to create a PCB micro USB connector.

One of the restrictions of the PCB connector is that the thickness of the PCB has to be one of the commonly used thickness: 0.6mm, 0.8mm, 1mm, 1.2mm, 1.6mm, 2mm.

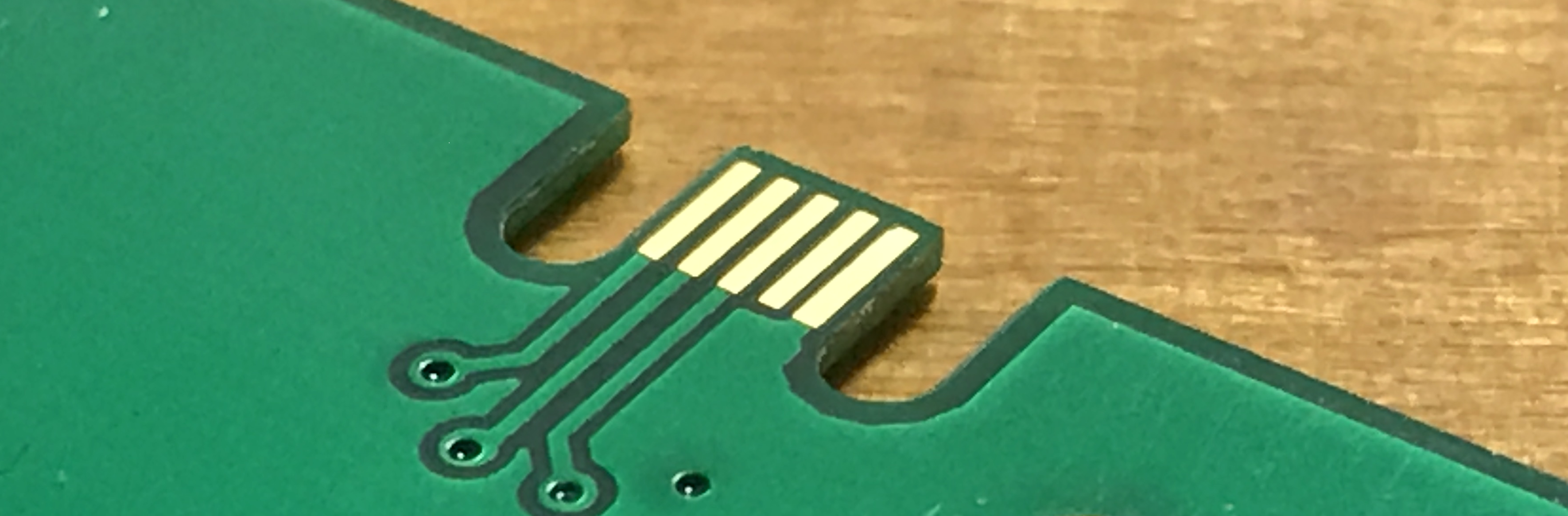

To my surprise the mid plate of the USB micro B is around 0.6 mm (the majority of the cheap PCB manufacturers can do 0.6mm PCBs, with little or no extra cost), the contacts are a bit below the surface but the other side of the connector is spring loaded, so you can have a a bit of slack. Copying the pads pattern of the mid plate was all i needed to create a footprint in Eagle.

![]()

For getting extra points I also investigated about the "new" USB type C, and looking at the specification it also uses a mid plate of around 0.6mm thickness. It has much more pads and unlike the micro B, it can be used either way. So i created another top and bottom layer footprint for the USB C connector.

![]()

I put together those footprints with some variations and even a USB type C connector USB 2.0 compatible in a single Eagle library.

Those types of connector are not bullet proof, obviosuly it can not be used for a lot of pulgs and unplugs and the fit is not 100% perfect. But if you have a project that needs a USB connector, and you don't mind to use a 0.6 mm thickness PCB, you can use it and have a free, low profile connector.

-

A bit of background and research

12/20/2017 at 22:13 • 2 commentsBefore I started this project I searched how other people made his own PCB business cards to find ideas and possible problems that they encountered to help me make my card.

With a fast search on google you find a lot of projects with PCB business cards, some of them are just business cards with no other purpose than that. But the vast majority of these projects have another use for the cards. Those are some examples:

- Ilia Baranov's useful card. Nice card to have around, it has a ruler, hole sizes, and footprints of commonly used components.

- Here it is a flamethrower business card! awesome!

- POV business card. I really like the way the routing has been done, it looks futuristic.

- Brian McEvoy and his blinky cards. Simple, beautiful, and functional. The free battery holder just blows my mind, awesome idea.

- Logical Card. How many logic gates does it take to change a light bulb?

Because I wanted to connect my card to a PC I searched for business cards that had PC connectivity. Those are some examples.

- Brian Carrigan business cards versions 1 and 2.

- Mathieu Stephan right thickness card.

- Corey Harding development board card. It acts as a keyboard to write his contact info in any text editor.

- Ch00ftech paint Card. It acts like a mouse and draws in paint his logo, very cool!

The problem with all those cards is that they used the old fashioned USB type A connector. In order to use this connector you need a PCB thickness of 2.4 mm for a good connection. There is not a simple way to achieve this, some uses extra solder on the USB connector pads, some use tape on the back of the connector, and my favorite one (The Mathieu Stephen business card), uses a 2 PCB stack (1.6 + 0.8) to achieve the exact thickness. But with this thickness the card is not usable for a normal wallet. it is very rigid and fat to be inserted into the wallet.

With this information i had 3 or 4 ideas of what i wanted for my card, but finally I decided to do a gamepad business card, because it was something I didn't see and i like to play old video games.

Later I found that someone had the same idea before me, but I don't know if he really finishes the project.

-

What I want in a business card

12/12/2017 at 21:41 • 0 comments![]()

Features i'm looking for:

- Use: A business card is something you take, use one or two times and through it away or store it in some dark drawer for the rest of the eternity. I want to give it a second life, a use for something else.

- Design: “Design is not just what it looks like and feels like. Design is how it works.” –Steve Jobs

- Innovation: Innovation is always good, or so the news says.

- Price: A business card can't be expensive, you are giving it away for free!

- Thickness: I don't want to have a wallet about to explode in my pocket, i want a slim card.

- Coolness: If it has an use and also looks cool, what more do you need?

And with those features in mind, I designed my business card.

Use

i had some ideas. First, i wanted to use it as a memory storage device to store my CV, but Mathiew Stephan already did a nice work with the two versions of his business card. So not to leave the innovation aside, I wanted to make something different. I was between two ideas, in one hand I wanted to use it as a USB midi device (a piano was my first approach) and in the other hand a gamepad controller. Gamepad sound a lot cooler, so we have the use!

Design

I'm not a very good designer, but as the quote I wrote before, i tried to focus on the simplicity and the usefulness of the card.

Innovation

The most difficult part. Luckily for me this project started not only because I wanted my own business card, but also because I have an idea of a USB PCB connector. So my contribution to the world is a new type of PCB connector. Free connectors for everyone!

Price

One microcontroller, one crystal (needed for the USB timing), ten passive components, a PCB. USB PCB connector: free, PCB touch buttons: free. Can it be cheaper?, maybe, but not much more.

Thickness

0.6 mm looks thick to you? most RFID cards are 0.8mm ;). Due to the USB micro B PCB connector it uses, the thickness of the PCB must be 0.6 mm to assure a good fit of the plug, that makes a very thin card. Is true that you need to account also the thickness of the components once soldered to the PCB, that makes the card a little bit thicker, but hey!, is a 1 mm gamepad, what more do you need?

Coolness

Gamepad... in your wallet... When your wallet gets stolen on the way to work, you are going to be sad, not for the money, or the photos of your family, you are gonna be sad because today you are not going to be able play old video games when your boss is not looking :_(.

Business Card Gamepad

Bussines Card with PC interface via Micro USB Type B PCB connector that acts like a gamepad. USB connectors for FREE!!!