-

Conclusion

01/28/2018 at 00:54 • 0 commentsFinishing

I used fiber glass mat and epoxy to make a clean surface. I don't know how the glue will hold up. So over engineer it !

![]()

I sanded it :

![]()

![]()

I painted it in black with paint laying around :

![]()

![]()

![]()

Conclusion :

My drill is working great, has a bit more torque as far as I remember, and use the same battery as the other tools. It's really great !

If I had designed the 3D from scratch I could have used just one 3D printed piece, but less work is better.

Quid of the project 4€ for the glue, the rest was laying around in the workshop.

-

Meeting in the middle

01/28/2018 at 00:38 • 0 commentsThis time we'll assemble both parts.

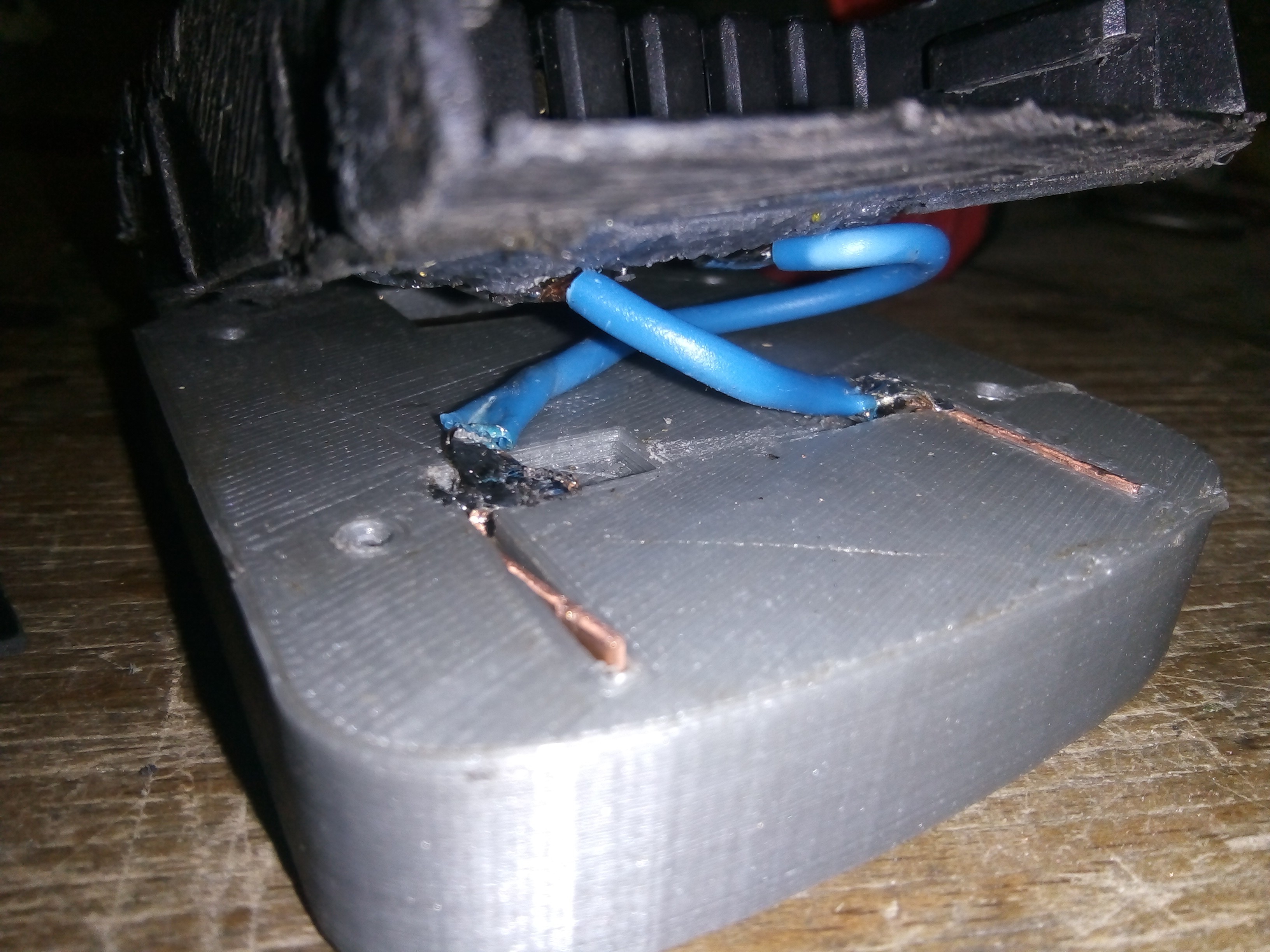

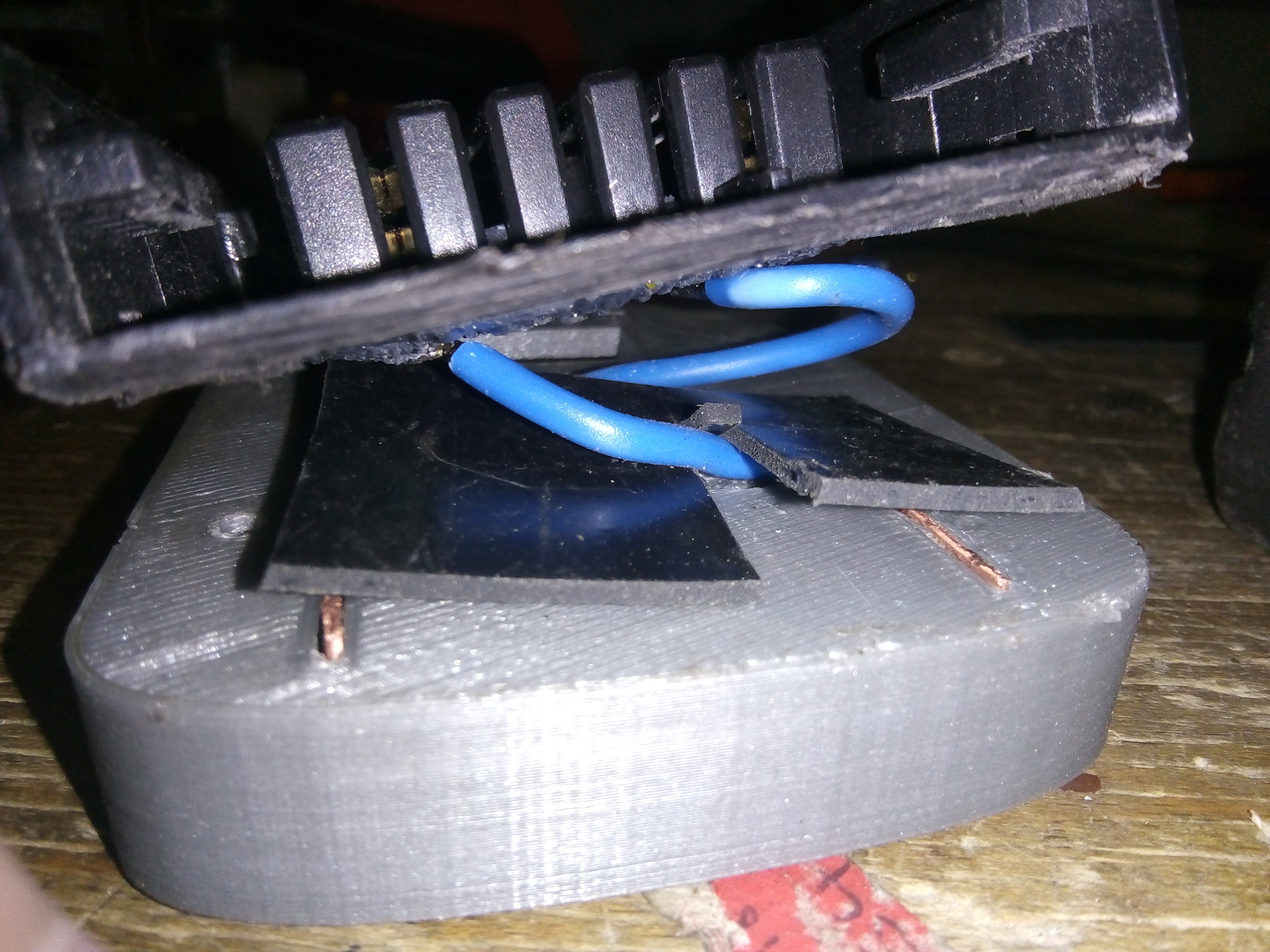

Before soldering check the polarity !

In my case reversed from Bosch to Parkside : (see the wires crossed)

![]()

If the polarities are not on the same side it will need some electrical insulation :

![]()

Place glue and let it cure :

![]()

![]()

First test :

it's a WIN !

![]()

-

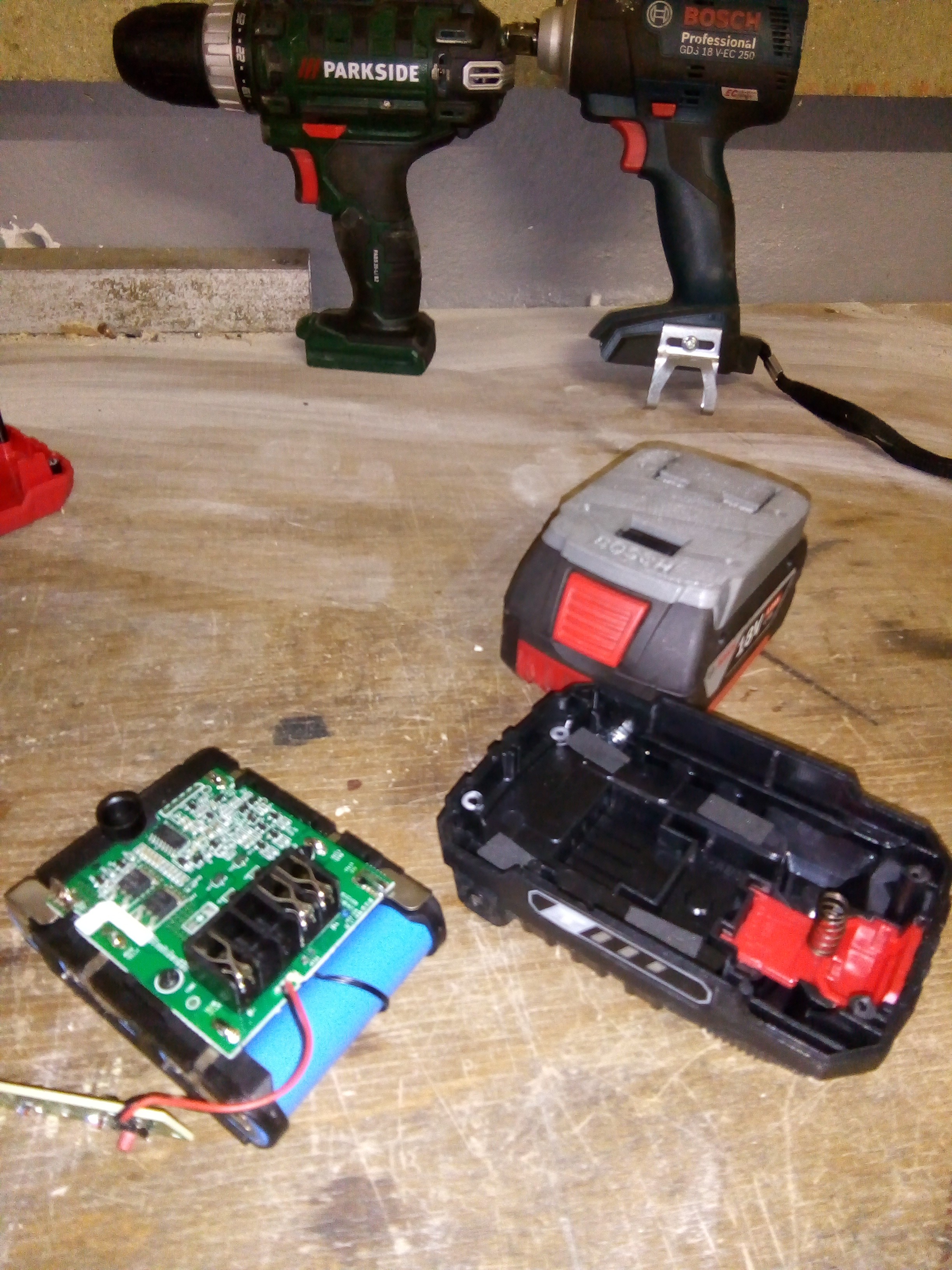

The Parkside side

01/28/2018 at 00:27 • 0 commentsIt's time to release your anger !

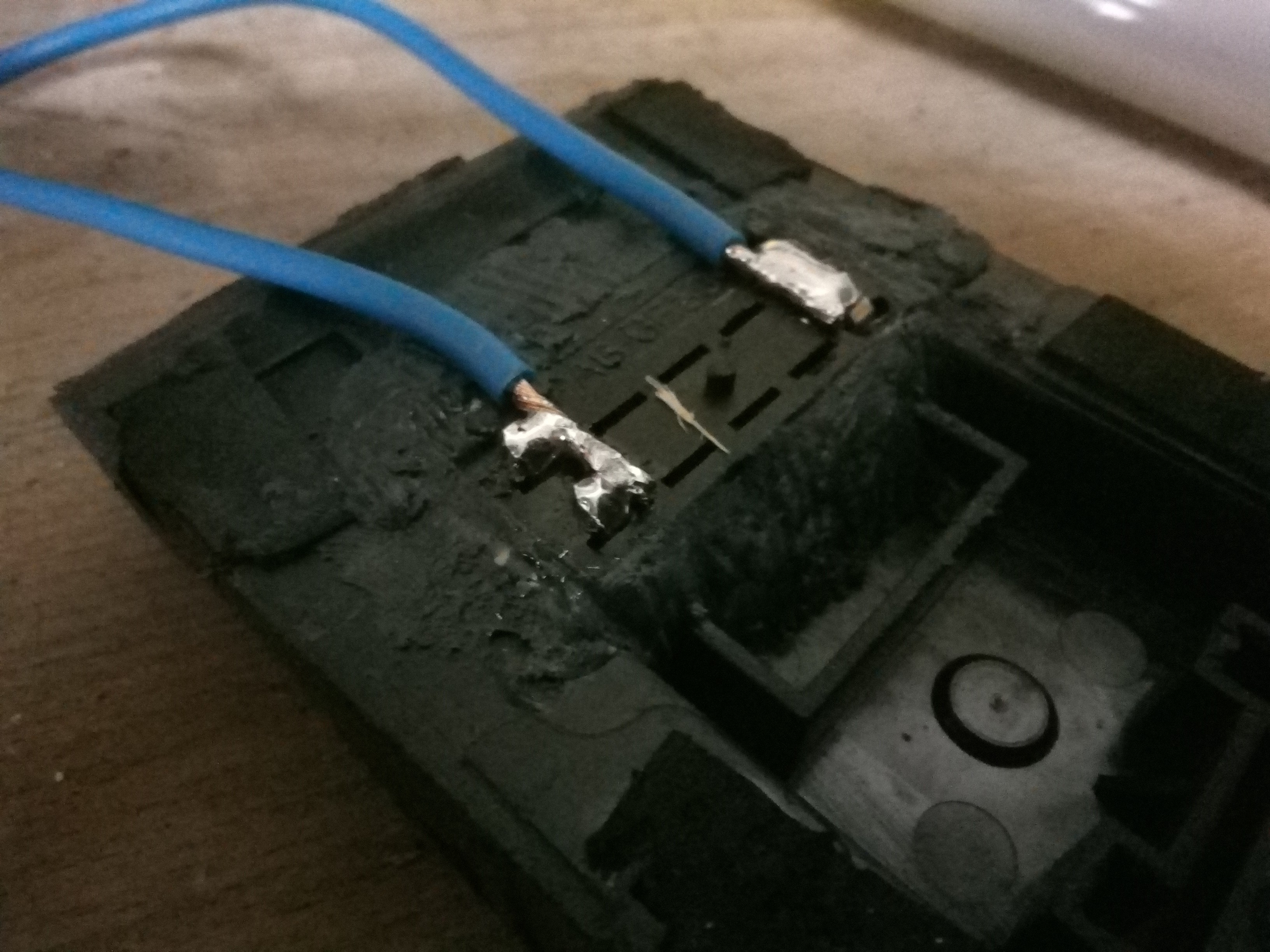

Open the old battery (I had screws). ACT WITH CARE : the battery, even weak, has some energy left and could arc with a watch, ring, bracelet ... and burn you.

![]()

Fit test :

![]()

Hack it up! :

I cut the edges keeping the electrical connector interface.

![]()

![]() In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :

In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :![]()

Glue the connector to the case and solder wires ;

![]()

We are done here ! Next comes the assembly.

-

The Bosch side

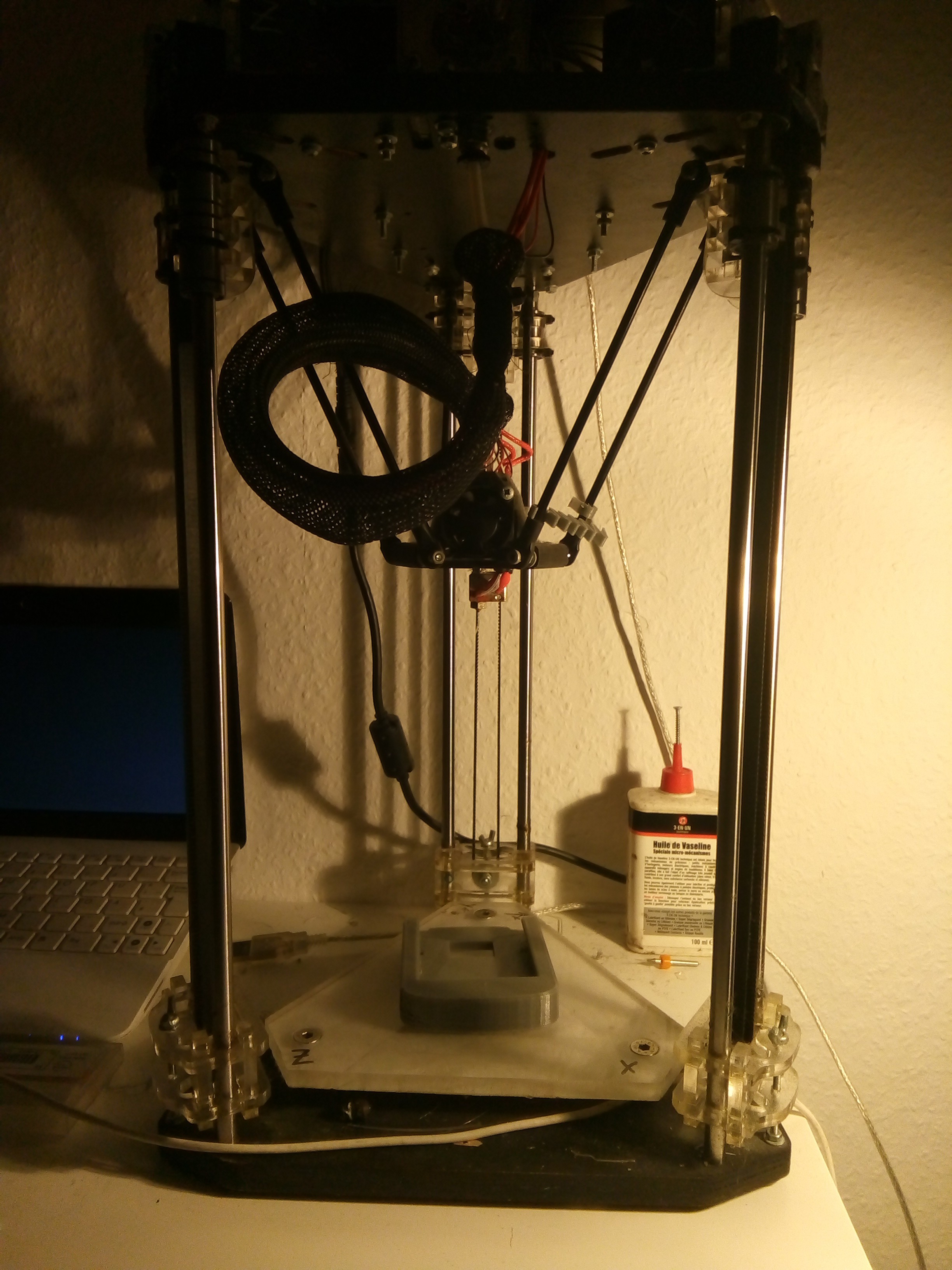

01/28/2018 at 00:01 • 0 commentsThanks to Simhopp : https://www.thingiverse.com/thing:1815758.

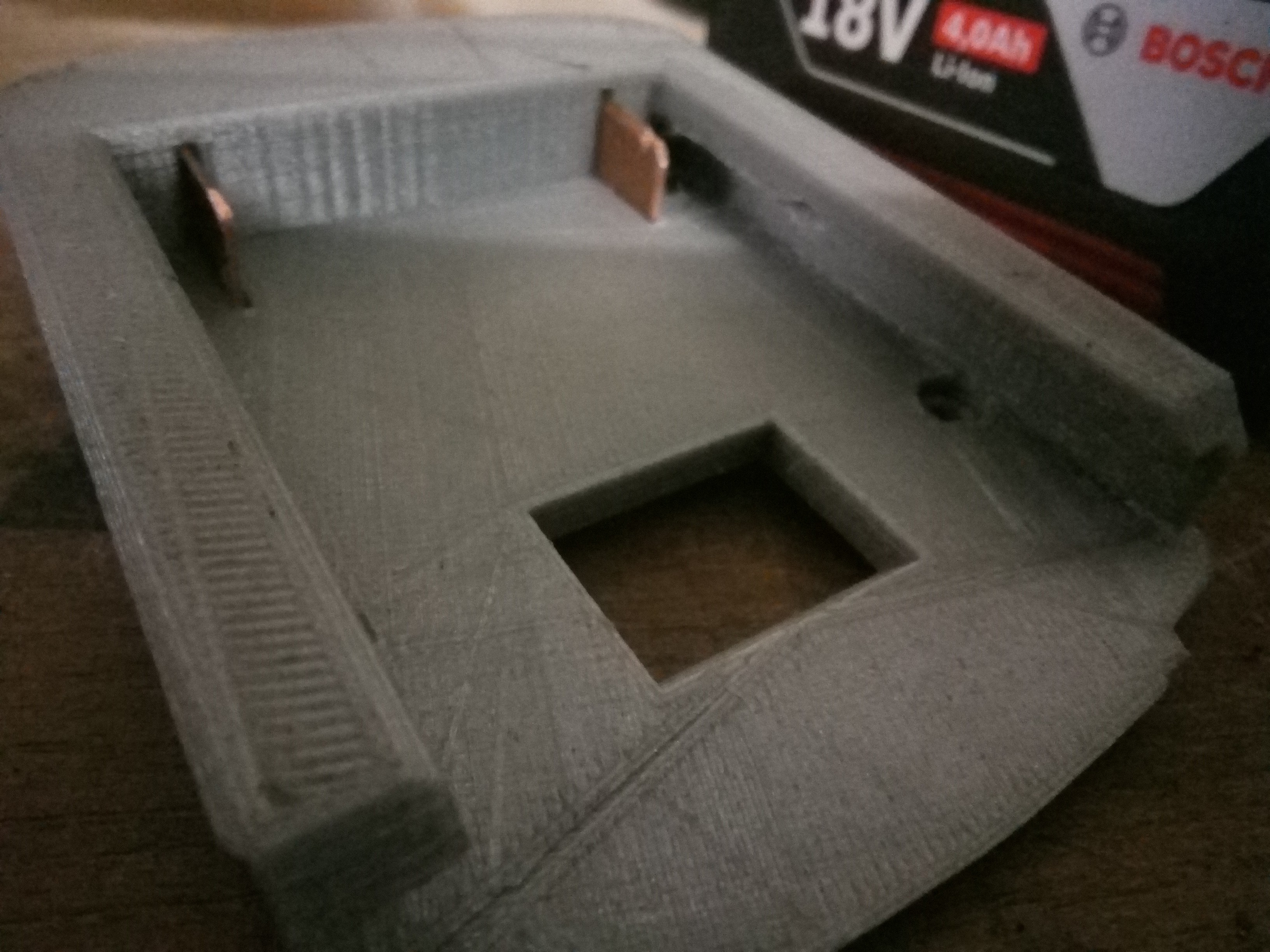

I printed the Bosch Pro 18v battery socket with my RepRap Emotion µDelta.

Printing parameters : 95% infill at 50mm/s, 0.2mm layer height and support.

![]()

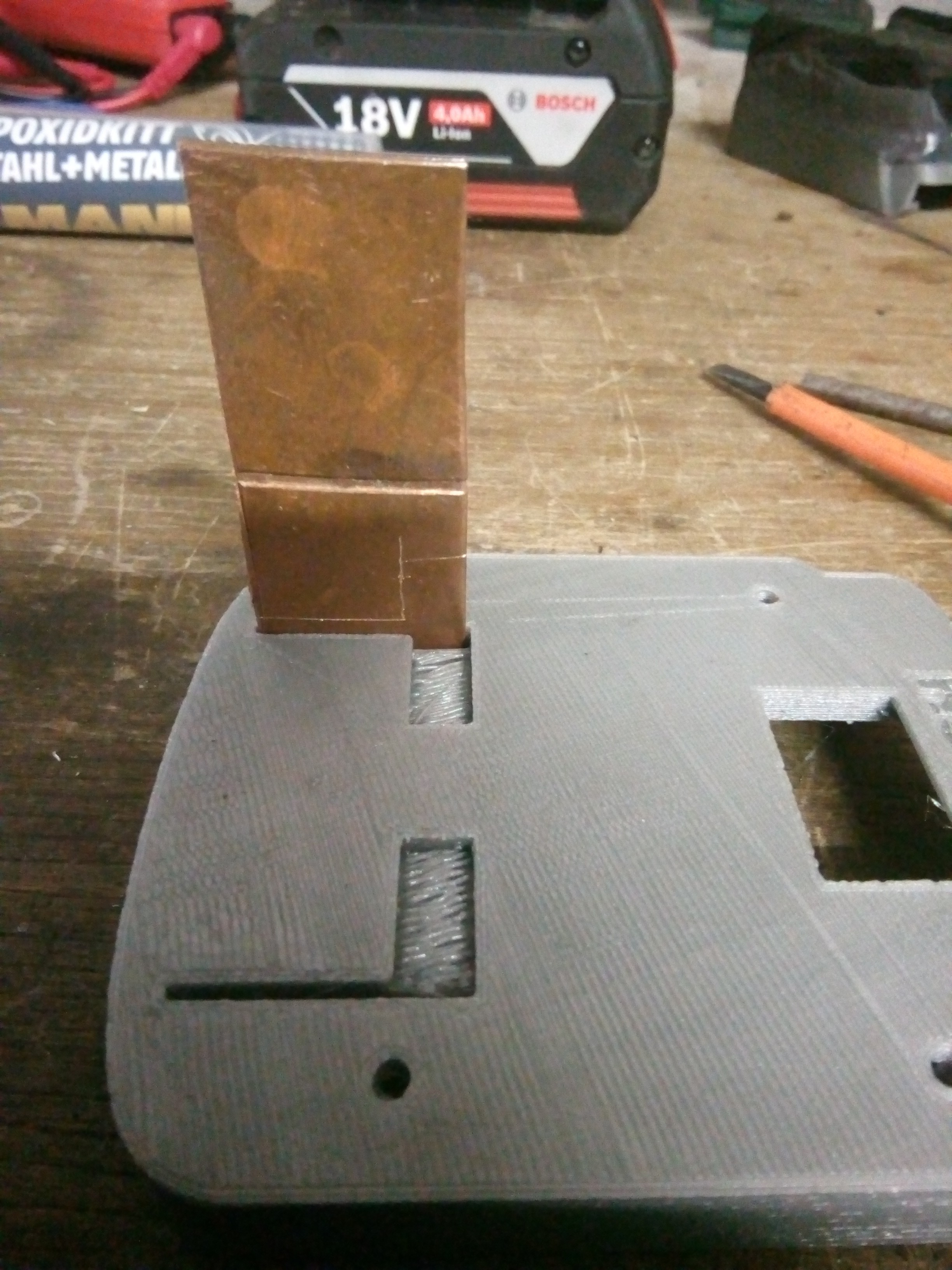

Then make the electrical connection :

The pads are made from a flattened copper plumbing tube with a thickness of 2mm. It will most certainly corrode so remember to later use electrical grease on the pads.

Cut a piece that will fit tightly in the gap then mark the piece with the line you need to cut :

![]()

Cut following the lines (hacksaw would also work) :

![]()

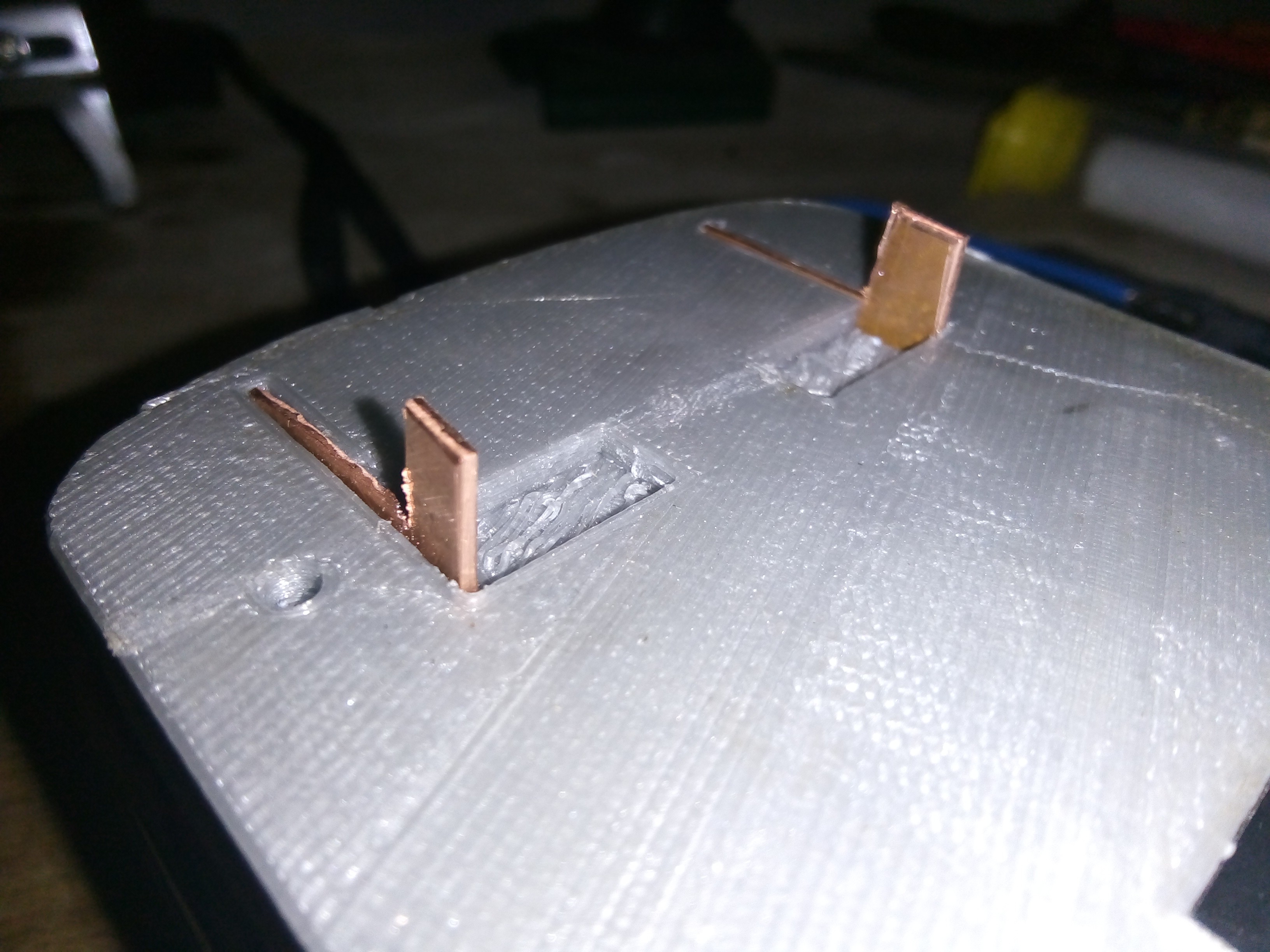

Install them in the groove :

![]()

![]()

![]()

Test the voltage between connectors with a voltmeter :

![]()

Bend the tabs flush :

![]()

Electrical connectors are in place, socket is ready for soldering.

The Long Legged Drill

Mix-mash of an old battery case and and 3d printed part gued together to get a cheap Parkside Drill to serve again

NPN

NPN

In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :

In my case the connector was soldered to the board (the black piece on the PCB), so I de-soldered the board from the cells and then de-soldered the connector from the board's underside :