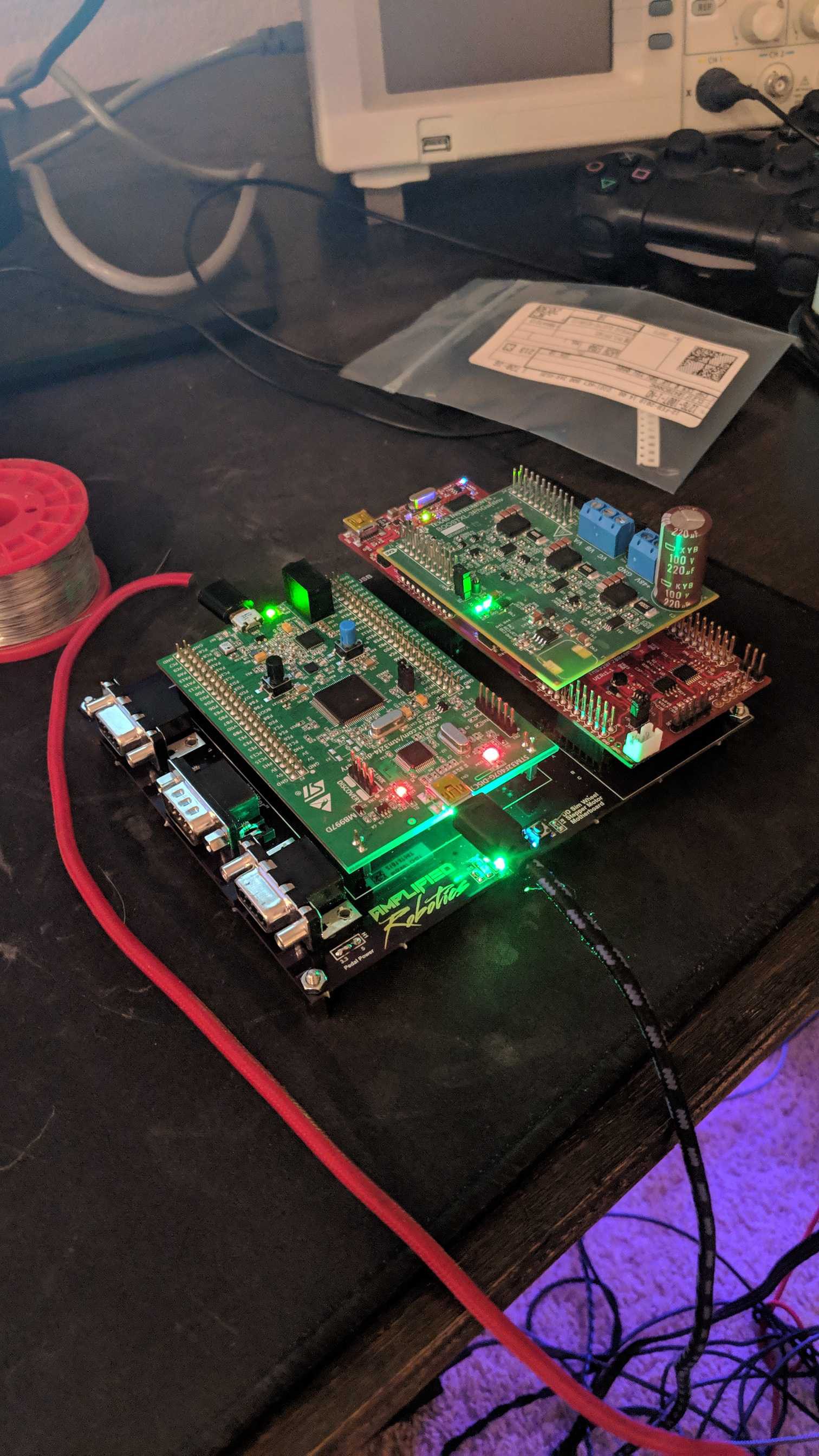

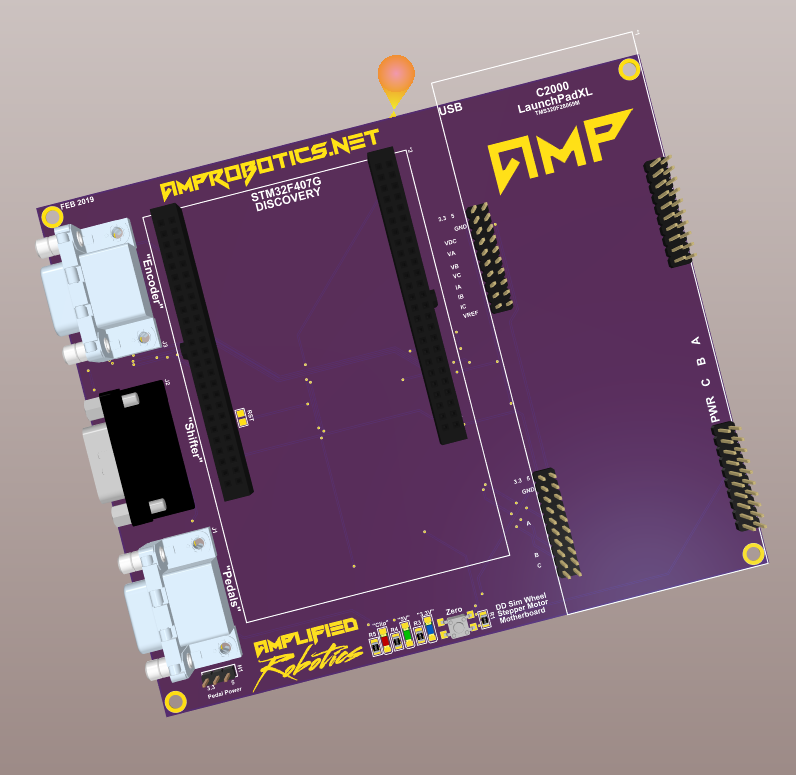

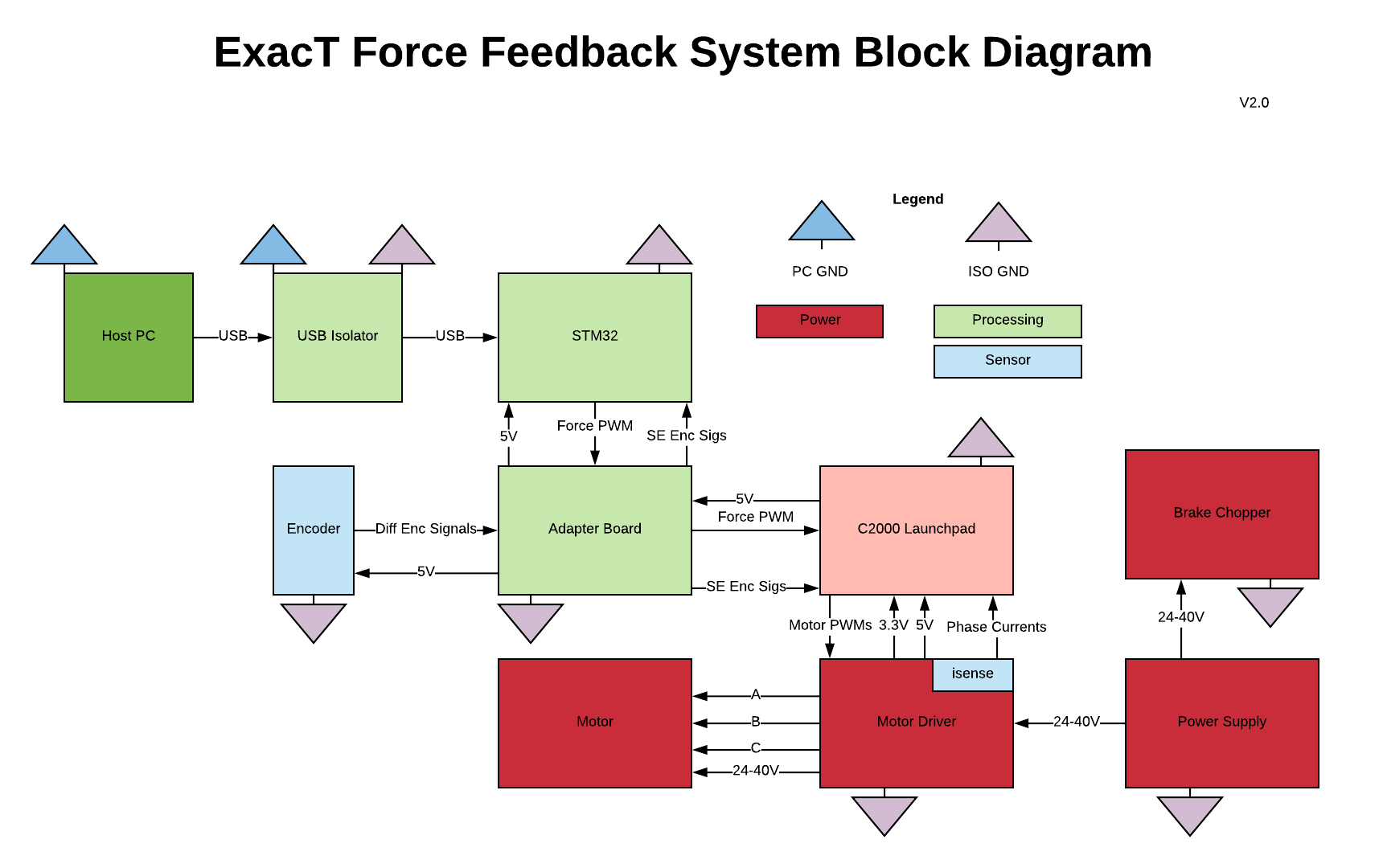

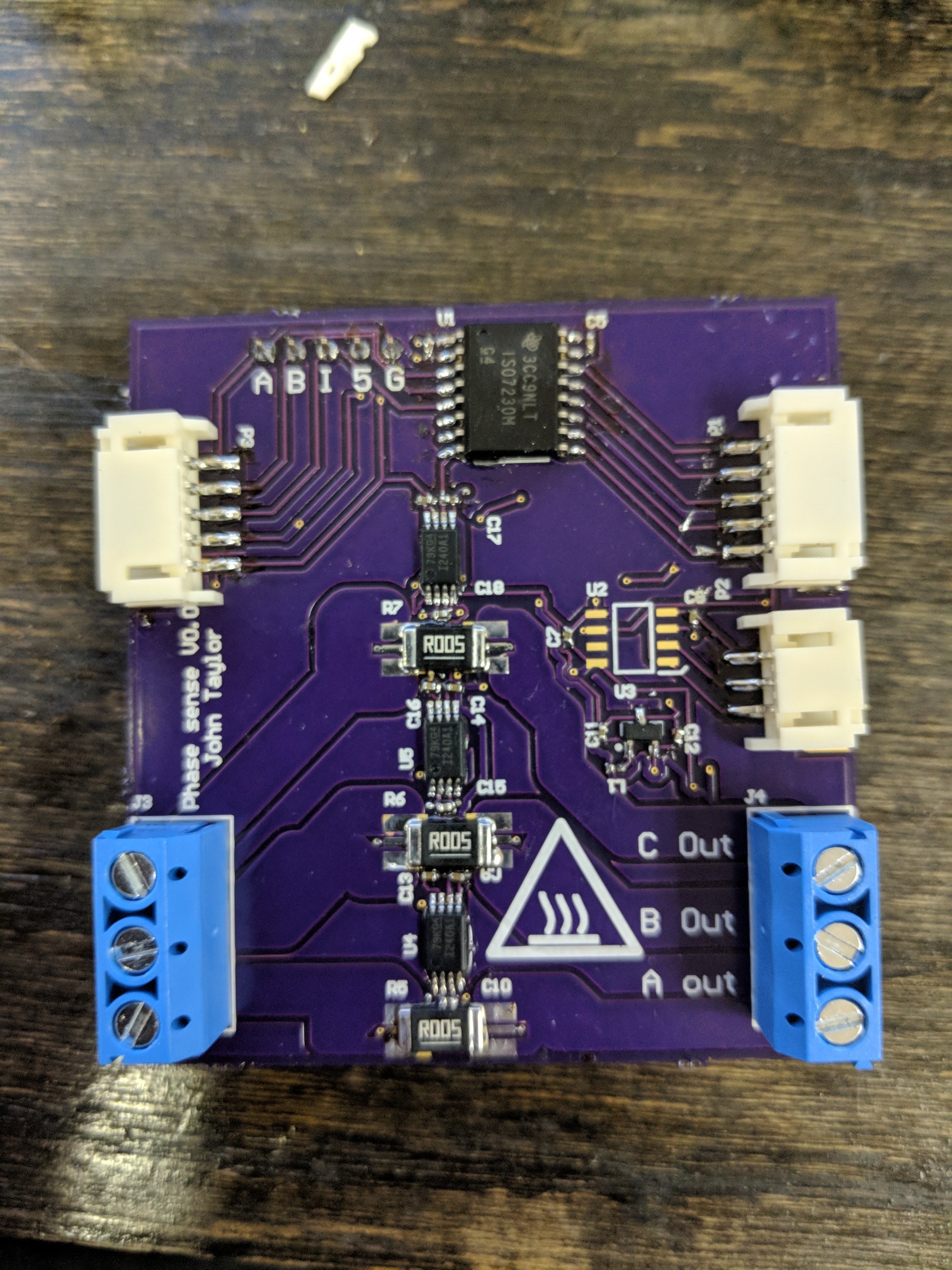

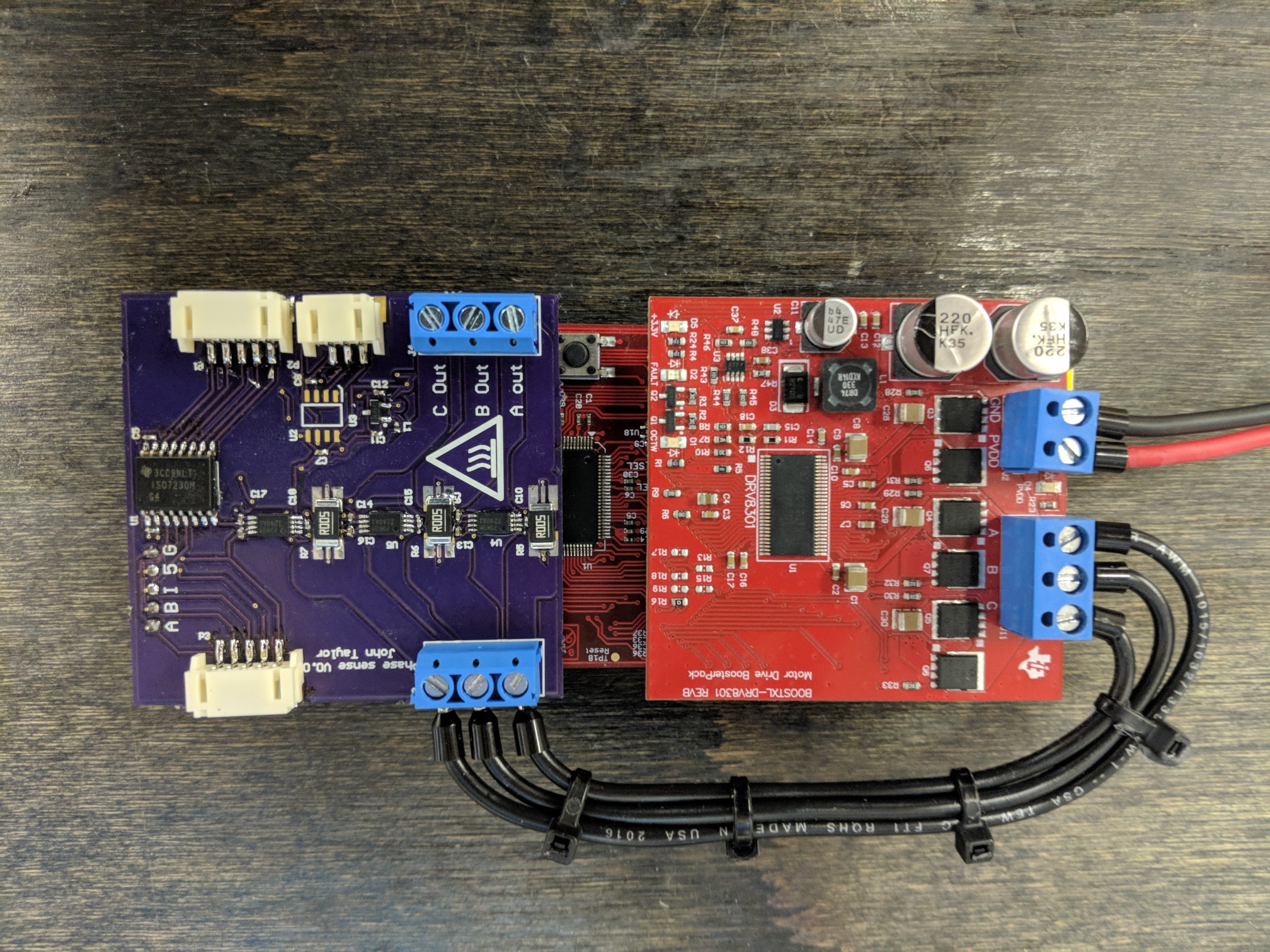

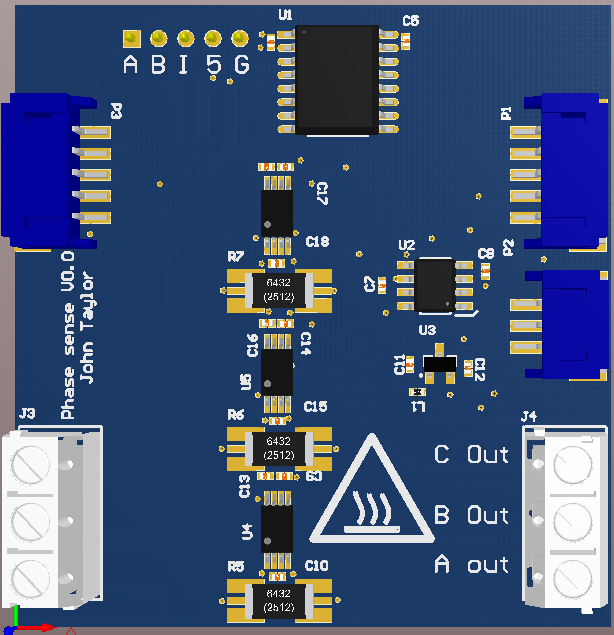

The motor drive system is composed of a 14NM NEMA32 stepper motor.,off the shelf TI development boards, custom firmware, and a 5000 PPR (20000 CPR) Differential encoder.

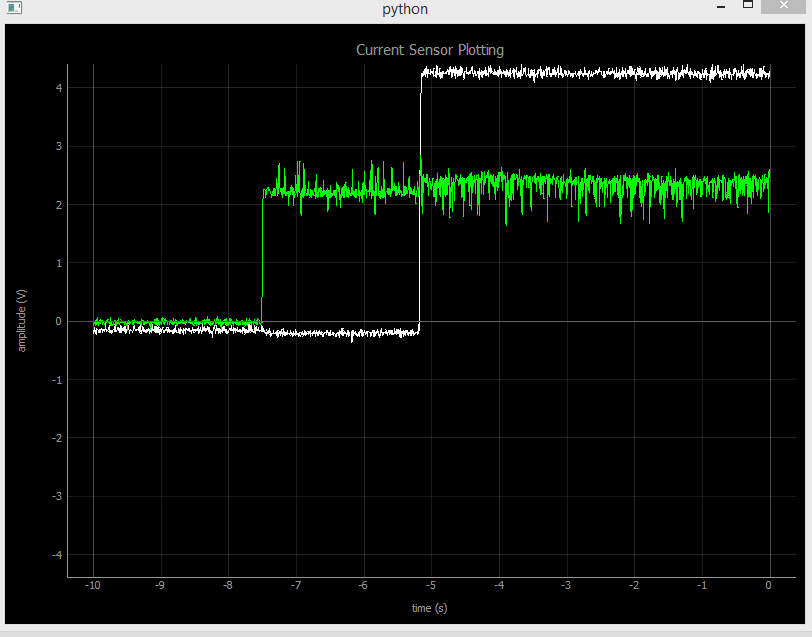

The software uses Field-Oriented Control to, with the help of the encoder, precisely control the magnetic flux vector so that maximum torque with minimal ripple is achieved.

Disclaimer

THE USE OF SmoothStep IS AT THE YOUR SOLE RISK. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, AND PERFORMANCE OF SmoothStep IS WITH YOU, THE USER OF SmoothStep. TO THE MAXIMUM EXTENT PERMITTED BY LAW, SmoothStep IS PROVIDED "AS IS" WITH ALL FAULTS AND WITHOUT WARRANTY OF ANY KIND. John Taylor DISCLAIMS ALL WARRANTIES AND CONDITIONS WITH RESPECT TO SmoothStep. NO USE OF SmoothStep IS AUTHORIZED EXCEPT UNDER THIS.

YOU, THE USER OF SmoothStep, MAY NOT USE SmoothStep:

- UNLESS YOU HAVE AGREED TO THIS DISCLAIMER

- IN ANY JURISDICTION THAT WILL NOT RECOGNIZE AND ENFORCE THE DISCLAIMER OF WARRANTIES, LIMITATION OF LIABILITY, YOU ARE SOLELY RESPONSIBLE TO DETERMINE WHETHER YOUR JURISDICTION WILL RECOGNIZE AND ENFORCE THESE TERMS.

YOU, THE USER OF SmoothStep, ARE FULLY AWARE THAT:

SmoothStep based Force Feedback systems (FFB) pose high mechanical danger that may cause serious injuries to living beings, cause damage to external property, or loss of profits. Always operate SmoothStep based systems with maximum caution.

- Beware of very high sudden torques or vibrations produced by motor attached to SmoothStep - these are expected even in normal operating conditions.

- Be aware that malfunction of misconfiguration may cause uncontrolled or higher than normal motor rotation or torques.

- End-user's responsibility is to ensure that motor, or items connected to the motor can not cause damage due to rotation, torque or vibration.

- Always be ready to let go of the motor or parts connected to it (i.e. take hands off the simulator wheel)

- Make sure that a reliable stopping method is available and user reachable at all times (reliable method: unplugging AC power). Note that unplugging power might not stop motor immediately.

- Do not try to stop spinning motor by hands or other mechanical means as injury could occur.

- Note that wheel, cables or other items attached to motor could become dislodged and hit objects or living beings with damaging effects. User's responsibility is to control this danger and take responsibility of the possible consequences caused by moving items.

- Ensure that motor and items attached to the motor are rigidly fixed to avoid becoming loose under extreme vibrations and rotations.

- Commonly used motors may exceed torque of 30 Newton meters and rotation speed of 1000 rpm when attached to SmoothStep.

- Due to high electric currents, motor, cables or SmoothStep drive may get dangerously hot. (skin burns, fire hazard)

- For your own safety, do not operate SmoothStep if you don't understand these dangers

John Taylor

John Taylor

Can you share schematic for the baraking resistor