Hackaday.io Project

Follow for the 'Hacklet' and latest news about hackaday.io

Follow for the 'Hacklet' and latest news about hackaday.io

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Keep your existing Hackaday.io projects up-to-date with your mobile device and this companion app. Capture photos of your hardware projects, caption them, and log your project progress.

Keeping regular logs of your ongoing hardware projects is the best way to take advantage of the community support and broad visibility provided by the Hackaday.io platform.

Use this app alongside your existing Hackaday.io account. Don’t have an account? Sign up at Hackaday.io.

The app is available for iOS and Android:

Your existing Hackaday.io email and password are required to login. If you signed up with Twitter or Github these options are available at the bottom of the login screen.

If you have forgotten your password you can create a new password here.

On the photo capture screen you can take a new photo or access the photo gallery in the top right. Rotating and crop tools appear after a photo has been captured.

Choose from an existing public or private project. Then select from an existing log or create and title a new log. New projects can be created here.

From the home screen, click on your avatar in the top right to open the user menu. The menu contains a logout link as well as other options.

For general app feedback or questions you can comment below or on the Hackaday.io feedback page.

I start each day checking out the new and updated projects over on Hackaday.io. Each day one can find all manner of projects – from satellites to machine vision to rockets. One type of project which is always present are robots- robot arms, educational ‘bots, autonomous robots, and mobile robots. This week’s Hackaday.io had a few great robot projects show up on the “new and updated” page, so I’m using the Hacklet to take a closer look.

We start with [Jack Qiao] and Autonomous home robot that does things. [Jack] is building a robot that can navigate his home. He’s learned that just creating a robot that can get itself from point A to point B in the average home is a daunting task. To make this happen, he’s using the Simultaneous Localization and Mapping (SLAM) algorithm. He’s implementing SLAM with the help of Robotic Operating System (ROS). The robot started out as a test mule tethered to a laptop. It’s evolved to a wooden base with a mini ITX motherboard. Mapping data comes in through a Kinect V2, which will soon be upgraded to a Neato XV-11 LIDAR system.

We start with [Jack Qiao] and Autonomous home robot that does things. [Jack] is building a robot that can navigate his home. He’s learned that just creating a robot that can get itself from point A to point B in the average home is a daunting task. To make this happen, he’s using the Simultaneous Localization and Mapping (SLAM) algorithm. He’s implementing SLAM with the help of Robotic Operating System (ROS). The robot started out as a test mule tethered to a laptop. It’s evolved to a wooden base with a mini ITX motherboard. Mapping data comes in through a Kinect V2, which will soon be upgraded to a Neato XV-11 LIDAR system.

Next up is [Tyler Spadgenske] with TyroBot. TyroBot is a walking robot with some lofty goals, including walking a mile in a straight line without falling down. [Tyler’s] inspiration comes from robots such as Bob the Biped and Zowi. So far, TyroBot consists of legs and feet printed in PLA. [Tyler] is going to use a 32 bit processor for [TyroBot’s] brain, and wants to avoid the Arduino IDE at any cost (including writing his own IDE from scratch). This project is just getting started, so head on over to theproject page and watch TyroBot’s progress!

Next up is [Tyler Spadgenske] with TyroBot. TyroBot is a walking robot with some lofty goals, including walking a mile in a straight line without falling down. [Tyler’s] inspiration comes from robots such as Bob the Biped and Zowi. So far, TyroBot consists of legs and feet printed in PLA. [Tyler] is going to use a 32 bit processor for [TyroBot’s] brain, and wants to avoid the Arduino IDE at any cost (including writing his own IDE from scratch). This project is just getting started, so head on over to theproject page and watch TyroBot’s progress!

Next is [Mike Rigsby] with Little Friend. Little Friend is a companion robot. [Mike] found that robots spend more time charging batteries than interacting. This wouldn’t do for a companion robot. His solution was to do away with batteries all together. Little Friend is powered by super capacitors. An 8 minute charge will keep this little bot going for 75 minutes. An Arduino with a motor shield controls Little Friend’s DC drive motors, as well as two animated eyes. If you can’t tell, [Mike] used a tomato as his inspiration. This keeps Little Friend in the cute zone, far away from the uncanny valley.

Next is [Mike Rigsby] with Little Friend. Little Friend is a companion robot. [Mike] found that robots spend more time charging batteries than interacting. This wouldn’t do for a companion robot. His solution was to do away with batteries all together. Little Friend is powered by super capacitors. An 8 minute charge will keep this little bot going for 75 minutes. An Arduino with a motor shield controls Little Friend’s DC drive motors, as well as two animated eyes. If you can’t tell, [Mike] used a tomato as his inspiration. This keeps Little Friend in the cute zone, far away from the uncanny valley.

Finally we have the walking robot king, [Radomir Dopieralski], with Logicoma-kun. For the uninitiated, a Logicoma is a robot tank (or “logistics robot”) from the Ghost in the Shell series. [Radomir] decided to bring these cartoon tanks to life – at least in miniature. The bulk of Logicoma-kun is built carefully cut and sculpted acrylic sheet. Movement is via popular 9 gram servos found all over the internet. [Radomir] recently wrote an update outlining his new brain for Logicoma-kun. An Arduino Pro Mini will handle servo control. The main computer will be an ESP8266 running Micropython. I can’t wait to see this little ‘bot take its first steps.

Finally we have the walking robot king, [Radomir Dopieralski], with Logicoma-kun. For the uninitiated, a Logicoma is a robot tank (or “logistics robot”) from the Ghost in the Shell series. [Radomir] decided to bring these cartoon tanks to life – at least in miniature. The bulk of Logicoma-kun is built carefully cut and sculpted acrylic sheet. Movement is via popular 9 gram servos found all over the internet. [Radomir] recently wrote an update outlining his new brain for Logicoma-kun. An Arduino Pro Mini will handle servo control. The main computer will be an ESP8266 running Micropython. I can’t wait to see this little ‘bot take its first steps.

If you want more robotic goodness, check out our brand new mobile robot list! Did I miss your project? Don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet, As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

Skateboarding is a sport that was born of hacking. The identity of the person who first nailed roller skate wheels to a board with a milk crate box is lost to history. Those crate scooters were a staple of the 1940’s and 1950’s neighborhoods. Everyone built their own scooter, so the designs evolved. Eventually the milk crates disappeared. At some point, surfers realized that they could use these wheeled boards to surf the concrete jungle. Things just took off from there. Skateboarding is now a multi-billion dollar industry, but at its heart there are still hackers trying out new designs. This week’s Hacklet is all about skateboarding projects.

We start with [brian.rundle] and Electric Longboard. [Brian] built his board using trucks and mechanical parts from a DIY skateboard online shop. The motor is a brushless outrunner R/C plane motor from HobbyKing. Batteries are of the LiPo variety. An Arduino Nano provides the PWM signal which drives the Electronic Speed Control (ESC). Throttle control is via RF link using the popular Nordic Semi NRF2401. [Brian] is focusing on building a safe skateboard. He designed it to carry two batteries, though only one is in use at a time. Rather than use a switch, he’s created a fool-proof system with arming plugs and jumpers. Each battery has its own arming plug. There is one jumper, so only one battery can be connected to the board at a time.

We start with [brian.rundle] and Electric Longboard. [Brian] built his board using trucks and mechanical parts from a DIY skateboard online shop. The motor is a brushless outrunner R/C plane motor from HobbyKing. Batteries are of the LiPo variety. An Arduino Nano provides the PWM signal which drives the Electronic Speed Control (ESC). Throttle control is via RF link using the popular Nordic Semi NRF2401. [Brian] is focusing on building a safe skateboard. He designed it to carry two batteries, though only one is in use at a time. Rather than use a switch, he’s created a fool-proof system with arming plugs and jumpers. Each battery has its own arming plug. There is one jumper, so only one battery can be connected to the board at a time.

Next up is [suiram21] with Longboard Brake. Downhill longboarding can be a dangerous sport. Running downhill at 40MPH or more with no brakes makes for quite an adrenaline rush. [suiram21] loves longboarding but wanted the safety of having a brake if and when he needed it. He started with a Onda board, which is a longboard with large diameter wheels. He 3D printed brackets for a cable actuated braking system. The brake is activated by stepping on a lever at the rear of the board. A lever presses a bicycle brake pad into the inside edge of the tire. This brings the board to a gentle stop. [suiram21] is thinking of adding a second brake to the other wheel to increase braking authority.

Next up is [suiram21] with Longboard Brake. Downhill longboarding can be a dangerous sport. Running downhill at 40MPH or more with no brakes makes for quite an adrenaline rush. [suiram21] loves longboarding but wanted the safety of having a brake if and when he needed it. He started with a Onda board, which is a longboard with large diameter wheels. He 3D printed brackets for a cable actuated braking system. The brake is activated by stepping on a lever at the rear of the board. A lever presses a bicycle brake pad into the inside edge of the tire. This brings the board to a gentle stop. [suiram21] is thinking of adding a second brake to the other wheel to increase braking authority.

Next we have [edbraun] with Skateboard Speedometer by inventED. [edbraun] wanted to know how fast he was going. A GPS would work, but GPS signals are often blocked in cities. A more accurate way to gather speed data is directly from the wheels. Two tiny magnet plugs are placed in holes drilled in the wheel. A hall effect sensor detects the magnets and passes this data on to an Arduino Pro Mini. Once the speed is calculated, it’s sent to a Bluetooth radio. [edbraun’s] Android phone receives the data and displays current speed and total distance traveled. The speedometer and its slick 3D printed case almost hide between the trucks and the board itself. Nice work [edbraun]!

Next we have [edbraun] with Skateboard Speedometer by inventED. [edbraun] wanted to know how fast he was going. A GPS would work, but GPS signals are often blocked in cities. A more accurate way to gather speed data is directly from the wheels. Two tiny magnet plugs are placed in holes drilled in the wheel. A hall effect sensor detects the magnets and passes this data on to an Arduino Pro Mini. Once the speed is calculated, it’s sent to a Bluetooth radio. [edbraun’s] Android phone receives the data and displays current speed and total distance traveled. The speedometer and its slick 3D printed case almost hide between the trucks and the board itself. Nice work [edbraun]!

Finally we have Hackaday alum [Josh Marsh] and EV Commuter Longboard. [Josh] uses an electric longboard for his daily commute. His project is an excellent overview and tutorial on building an electric skateboard from scratch. Like many others, [Josh] utilizes R/C Airplane brushless motors and speed controllers. An Arduino or similar microcontroller is all you need to drive these devices. For batteries, [Josh] loves LiPo packs. Long form six cell affairs provide 22.2 Volts with a capacity of 5000 mAh or more. Plenty of power for carving your way to work!

Finally we have Hackaday alum [Josh Marsh] and EV Commuter Longboard. [Josh] uses an electric longboard for his daily commute. His project is an excellent overview and tutorial on building an electric skateboard from scratch. Like many others, [Josh] utilizes R/C Airplane brushless motors and speed controllers. An Arduino or similar microcontroller is all you need to drive these devices. For batteries, [Josh] loves LiPo packs. Long form six cell affairs provide 22.2 Volts with a capacity of 5000 mAh or more. Plenty of power for carving your way to work!

If you want to see more skateboard projects, check out our new skateboard projects list! If I missed your project, don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet. As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

Last week on the Hacklet we covered optical microscopy projects. Those are the familiar scopes that many of us have at work or even at home on our benches. These are scopes that you typically can use with your eye, or an unmodified camera. This week we’re taking a look at more extreme ways of making small things look big. Electron streams and the forces of a single atom can be used to create incredibly magnified images. So let’s jump right in and check out the best advanced microscopy projects on Hackaday.io!

We start with [andreas.betz] and BluBEAM – a scanning laser microscope. [Andreas] aims to create a scanning confocal microscope. The diffraction limitis the law of the land for standard optical microscopes. While you can’t break the law, you can find ways around it. Confocal microscopy is one technique used quite a bit in medicine and industry. Confocal scopes are generally very expensive, well outside the budget of the average hacker. [Andreas] hopes to break that barrier by creating a scanning confocal microscope using parts from a Playstation 3 BluRay optical drive. Optical drives use voice coils to maintain focus. [Andreas] had to create a custom PCB with a voice coil driver to operate the PS3 optics assembly. He also needed to drive the laser. BluBeam is still very much a work in progress, so keep an eye on it!

We start with [andreas.betz] and BluBEAM – a scanning laser microscope. [Andreas] aims to create a scanning confocal microscope. The diffraction limitis the law of the land for standard optical microscopes. While you can’t break the law, you can find ways around it. Confocal microscopy is one technique used quite a bit in medicine and industry. Confocal scopes are generally very expensive, well outside the budget of the average hacker. [Andreas] hopes to break that barrier by creating a scanning confocal microscope using parts from a Playstation 3 BluRay optical drive. Optical drives use voice coils to maintain focus. [Andreas] had to create a custom PCB with a voice coil driver to operate the PS3 optics assembly. He also needed to drive the laser. BluBeam is still very much a work in progress, so keep an eye on it!

Next up is [MatthiasR.] with DIY Scanning tunneling microscope. Open atmosphere scanning tunneling microscopes are popular on Hackaday.io. I covered [Dan Berard’s] creation in Hacklet 103. Inspired by Dan, [Matthias] is building his own STM.

Next up is [MatthiasR.] with DIY Scanning tunneling microscope. Open atmosphere scanning tunneling microscopes are popular on Hackaday.io. I covered [Dan Berard’s] creation in Hacklet 103. Inspired by Dan, [Matthias] is building his own STM.

Environmental vibration is a huge problem with high magnification microscopes. [Matthias] is combating this by building a vibration isolation platform using extruded aluminum. He’s currently working on the STM preamplifier, which amplifies and converts the nano amp STM values to voltages which can be read by a digital to analog converter. [Matthias] is using the venerable Analog ADA4530 for this task. With an input bias of 20 femtoamps (!) it should be up to the task.

Next we have [Jerry Biehler] with Hitachi S-450 Scanning Electron Microscope. Scanning electron microscopes have to be the top of the microscopy food chain. Jerry got his hands on a 1980’s vintage Hitachi SEM which was no longer working. The problem turned out to be a dodgy repair made years earlier with electrical tape. Fast forward a couple of years of use, and [Jerry] has done quite a lot to his old machine. He’s learned how to make his own filaments from tungsten wire. The slow oil diffusion vacuum pump has been replaced with a turbomolecular pump. The SEM now resides in [Jerry’s] living room, which keeps it at a relatively constant temperature.

Next we have [Jerry Biehler] with Hitachi S-450 Scanning Electron Microscope. Scanning electron microscopes have to be the top of the microscopy food chain. Jerry got his hands on a 1980’s vintage Hitachi SEM which was no longer working. The problem turned out to be a dodgy repair made years earlier with electrical tape. Fast forward a couple of years of use, and [Jerry] has done quite a lot to his old machine. He’s learned how to make his own filaments from tungsten wire. The slow oil diffusion vacuum pump has been replaced with a turbomolecular pump. The SEM now resides in [Jerry’s] living room, which keeps it at a relatively constant temperature.

Finally, we have [beniroquai] with Holoscope – Superresolution Holographic Microscope. Holoscope is a device which increases the resolution of a standard camera by using the physical properties of light to its advantage. Precise tiny shifts of the object being magnified cause minute changes in a reflected image, which is captured by a Raspberry Pi camera. The Pi can then reconstruct a higher resolution image using the phase data. [Beniroquai] has put a lot of time into this project, even sacrificing an expensive Sony connected camera to the ESD gods. I’m following along with this one. I can’t wait to see [beniroquai’s] first few images.

Finally, we have [beniroquai] with Holoscope – Superresolution Holographic Microscope. Holoscope is a device which increases the resolution of a standard camera by using the physical properties of light to its advantage. Precise tiny shifts of the object being magnified cause minute changes in a reflected image, which is captured by a Raspberry Pi camera. The Pi can then reconstruct a higher resolution image using the phase data. [Beniroquai] has put a lot of time into this project, even sacrificing an expensive Sony connected camera to the ESD gods. I’m following along with this one. I can’t wait to see [beniroquai’s] first few images.

If you want to see more advanced microscopy projects, check out our new advanced microscope projects list! If I missed your project, don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet. As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

Humans have always wanted to make small things bigger. To see that which is unseen with the naked eye. The inventor of the original microscope happened sometime in the 1600’s, though the inventor is still contested. Some say it was Cornelis Drebbel, while others say Hans Lippershey. Galileo Galilei’s compound microscope is probably the most well-known ancient magnifier. Regardless of who created the device, hackers, makers, engineers, and scientists have used microscopes to study mysteries of biology, geology, electronics, and just about anything else you can imagine.

This is a fitting topic for this week’s Hacklet at is aligns well with the Citizen Scientist challenge round of the Hackaday Prize which began on Monday. Making quality microscopes more widely available is one of many great starting ideas for an entry. Let’s take a look at some of the best microscopy projects on Hackaday.io!

We start with [J. Kha] and Armed Microscope. [J. Kha] was one of the backers of the original uArm over at Kickstarter. He also does quite a bit of work with electronics. After fighting with a cheap USB microscope, he realized he had the perfect platform to control it. Microscopes usually are stationary, with the object being viewed moved on a stage. [J. Kha] turned things upside down by mounting the microscope on his uArm. An Arduino Yun controls the system. The Yun also allows him to stream the microscope’s video over the internet using the mjpg-streamer library. [J. Kha] did have some power issues at first, but he’s got his regulators all sorted out now.

We start with [J. Kha] and Armed Microscope. [J. Kha] was one of the backers of the original uArm over at Kickstarter. He also does quite a bit of work with electronics. After fighting with a cheap USB microscope, he realized he had the perfect platform to control it. Microscopes usually are stationary, with the object being viewed moved on a stage. [J. Kha] turned things upside down by mounting the microscope on his uArm. An Arduino Yun controls the system. The Yun also allows him to stream the microscope’s video over the internet using the mjpg-streamer library. [J. Kha] did have some power issues at first, but he’s got his regulators all sorted out now.

Next we have [andyhull] with Adding a light touch to a “classic” microscope. A lucky dumpster find netted [Andy] a pile of old broken microscopes. From this he was able to build a working classic stereo scope. This was a Gillet & Sibert stereo compound scope. Like most microscopes of its time, the old GS used standard incandescent or halogen lights for illumination. The old bulbs were long gone, and would have been a pain to replace. [Andy] switched his scope over to LED illumination. He ended up using a commercially available LED “bulb” designed to replace type 1157 automotive tail light bulbs. This type of LED is designed to run on 12 volt power which simplifies the wiring. The small LED flashlight in a custom mount also provides a bit of help for opaque subjects.

Next we have [andyhull] with Adding a light touch to a “classic” microscope. A lucky dumpster find netted [Andy] a pile of old broken microscopes. From this he was able to build a working classic stereo scope. This was a Gillet & Sibert stereo compound scope. Like most microscopes of its time, the old GS used standard incandescent or halogen lights for illumination. The old bulbs were long gone, and would have been a pain to replace. [Andy] switched his scope over to LED illumination. He ended up using a commercially available LED “bulb” designed to replace type 1157 automotive tail light bulbs. This type of LED is designed to run on 12 volt power which simplifies the wiring. The small LED flashlight in a custom mount also provides a bit of help for opaque subjects.

Next up is [Andre Maia Chagas] with Flypi – cheap microscope/experimental setup. Flypi is [Andre’s] entry in the 2106 Hackaday Prize. Flypi is more than just a microscope, it’s a 3D printed data collection and image analysis device for hackers and scientists alike. A Raspberry Pi 2 or 3 controls the show. Images come in through Pi Camera with an M12 lens. The Pi runs some open source Python code allowing it to acquire and analyze images. It also has an Arduino as a co-processor to handle anything a particular experiment may need – like RGB LEDs, heaters, manipulators, you name it. Andre sees Flypi as having uses in everything from fluorescence imaging to optogenetics and thermogenetics.

Next up is [Andre Maia Chagas] with Flypi – cheap microscope/experimental setup. Flypi is [Andre’s] entry in the 2106 Hackaday Prize. Flypi is more than just a microscope, it’s a 3D printed data collection and image analysis device for hackers and scientists alike. A Raspberry Pi 2 or 3 controls the show. Images come in through Pi Camera with an M12 lens. The Pi runs some open source Python code allowing it to acquire and analyze images. It also has an Arduino as a co-processor to handle anything a particular experiment may need – like RGB LEDs, heaters, manipulators, you name it. Andre sees Flypi as having uses in everything from fluorescence imaging to optogenetics and thermogenetics.

Finally we have [Jarred Heinrich] with Stagmo: Microscope Stage Automator. Positioning samples under high magnification requires a steady hand. Trying to image them makes things even harder. To help with this, microscopes have stages. Fine lead screws manually controlled by knobs allow the user to precisely position any subject. Automated stages are available as well, but they can get quite expensive. [Jarred] recognized that the microscope stage is an X-Y platform like any CNC, laser, or 3D printer. He used an Arduino and a motor shield to control a couple of stepper motors. The motors are coupled to the stage knobs with rubber belts. While the mounting system looks a little wobbly, but it got the job done, and didn’t require any modifications to the microscope itself.

Finally we have [Jarred Heinrich] with Stagmo: Microscope Stage Automator. Positioning samples under high magnification requires a steady hand. Trying to image them makes things even harder. To help with this, microscopes have stages. Fine lead screws manually controlled by knobs allow the user to precisely position any subject. Automated stages are available as well, but they can get quite expensive. [Jarred] recognized that the microscope stage is an X-Y platform like any CNC, laser, or 3D printer. He used an Arduino and a motor shield to control a couple of stepper motors. The motors are coupled to the stage knobs with rubber belts. While the mounting system looks a little wobbly, but it got the job done, and didn’t require any modifications to the microscope itself.

Optical microscopes are just one type of scope you’ll find on Hackaday.io. There are also atomic force microscopes, scanning electron microscopes, and more!...

Read more »If you can’t tell, we’re on a roll with 3D printers and printed projects this month. So far, we’ve covered printers, andsimple functional 3D prints. This week we’re taking a look at some of the awesome complex 3D printed projects on Hackaday.io.

Complex 3D printed projects are things like robots, quadcopters, satellite tracking systems, and more. So let’s jump in and look at some of the best complex 3D printed projects on Hackaday.io!

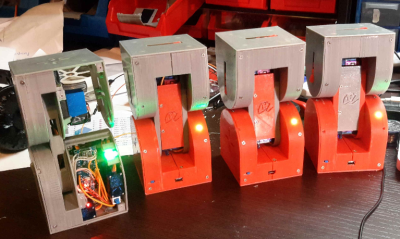

We start with [Alberto] and Dtto v1.0 Modular Robot. Dtto is [Alberto’s] entry in the 2016 Hackaday Prize. Inspired by Bruce Lee’s famous water quote, Dtto is a modular snake-like robot. Each section of Dtto is a double hinged joint. When two sections come together, magnets help them align. A servo controlled latch solidly docks the sections, which then work in unison. Dtto can connect and separate segments autonomously – no human required. [Alberto] sees applications for a robot like [Dtto] in search and rescue and space operations.

We start with [Alberto] and Dtto v1.0 Modular Robot. Dtto is [Alberto’s] entry in the 2016 Hackaday Prize. Inspired by Bruce Lee’s famous water quote, Dtto is a modular snake-like robot. Each section of Dtto is a double hinged joint. When two sections come together, magnets help them align. A servo controlled latch solidly docks the sections, which then work in unison. Dtto can connect and separate segments autonomously – no human required. [Alberto] sees applications for a robot like [Dtto] in search and rescue and space operations.

Next up is [Szabolcs Lőrincz] with Broke Hackers’ Model Railway. Anyone who’s read Steven Levy’s classic book ‘Hackers’ knows that model trains and hardware hacking go hand in hand. Unfortunately, model trains have gotten prohibitively expensive. Broke hackers’ model railway is the perfect solution. Nearly every part is 3D printed. The tracks are 3D printed sections with copper tape conductors. The locomotive has a 3D printed frame. Automated track switches use hand wound coils on 3D printed bobbins. This isn’t a dumb railway either – a Raspberry Pi controls the action, making sure the trains stay on time.

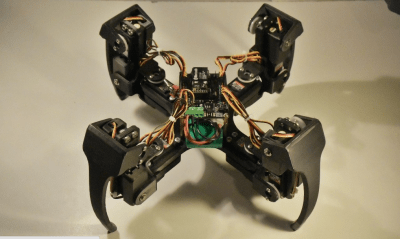

Next we have [Rob] with Quadrup3D, his 3D printed quadruped robot. Quadrup3D uses 12 beefy R/C style servos to move its four legs. An Arduino with a Bluetooth handles on-board processing. This robot is built from 25 individual 3D printed parts. From the center frame to the legs, just about every major structural piece has been spit out by an FDM desktop printer. [Rob] uses his SpaceMouse Pro as a remote control unit. A laptop processes commands from the mouse and sends them to the robot. Using a control scheme like this allows [Rob] to quickly and easily experiment with different gaits and stances for his four legged friend.

Next we have [Rob] with Quadrup3D, his 3D printed quadruped robot. Quadrup3D uses 12 beefy R/C style servos to move its four legs. An Arduino with a Bluetooth handles on-board processing. This robot is built from 25 individual 3D printed parts. From the center frame to the legs, just about every major structural piece has been spit out by an FDM desktop printer. [Rob] uses his SpaceMouse Pro as a remote control unit. A laptop processes commands from the mouse and sends them to the robot. Using a control scheme like this allows [Rob] to quickly and easily experiment with different gaits and stances for his four legged friend.

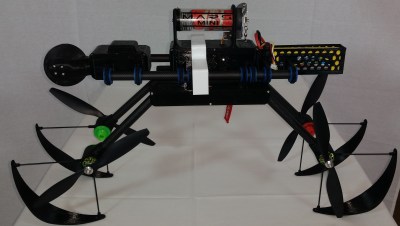

Finally we have [tlankford01] with LOKI 4G (Locate Observe Krack Isolate) 4th Gen. Who says you can’t 3D print your own drone? LOKI uses 3D printed parts for most of its major components. Carbon fiber rods act as the quad’s spine. Riding on these rods are 3D printed propeller guards, battery holder, and electronic enclosures. One of the most interesting parts is the 3D printed gimbal, used to stabilize aerial video. LOKI was used as a test mule for Project ICARUS, [tlankford01’s] poacher hunting 3D printed fixed wing drone.

Finally we have [tlankford01] with LOKI 4G (Locate Observe Krack Isolate) 4th Gen. Who says you can’t 3D print your own drone? LOKI uses 3D printed parts for most of its major components. Carbon fiber rods act as the quad’s spine. Riding on these rods are 3D printed propeller guards, battery holder, and electronic enclosures. One of the most interesting parts is the 3D printed gimbal, used to stabilize aerial video. LOKI was used as a test mule for Project ICARUS, [tlankford01’s] poacher hunting 3D printed fixed wing drone.

If you want to see more awesome complex 3D printed projects, check out our new complex 3D printed projects list! If I missed your project, don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet. As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

We featured 3D printer projects on last week’s Hacklet. This week, we’re looking at a few awesome projects created with those printers. Trying to pick great 3D printed projects on Hackaday.io is a bit like staring at the sun. There are just way too many to choose from. To make things a bit easier, I’ve broken things down into categories. There are artistic prints, complex mechanical or electronic prints, and then there are simple functional prints, which is the topic we’re featuring today. Simple functional prints are designs which perform some function in the world. By simple, I mean they have only a few moving parts or electronic components. Let’s get right to it!

We start with [Scott] and L Extrusion Endcaps. Every Home Depot, Lowes, or hardware store has a selection of extruded aluminum. Typically there are a few flat bars, and some L brackets. L brackets are great, but they can be a pain to work with. Most of us don’t have the skills or the tools to weld aluminum, so nuts and bolts are the only way to go. [Scott’s] given us another option. He’s designed a set of 3D printable brackets that slip onto the ends of the brackets. The brackets make quick work of building boxes, racks, or anything with 90° or 45° angles.

We start with [Scott] and L Extrusion Endcaps. Every Home Depot, Lowes, or hardware store has a selection of extruded aluminum. Typically there are a few flat bars, and some L brackets. L brackets are great, but they can be a pain to work with. Most of us don’t have the skills or the tools to weld aluminum, so nuts and bolts are the only way to go. [Scott’s] given us another option. He’s designed a set of 3D printable brackets that slip onto the ends of the brackets. The brackets make quick work of building boxes, racks, or anything with 90° or 45° angles.

Next up is [Joe M] with 3D Printed Molds: Custom Silicone Earbuds. [Joe] had a set of Bluetooth earbuds he enjoyed, but the rubber tips left a bit to be desired. Not a problem when you have a 3D printer on hand. [Joe] measured the plastic part of his earbuds and the rubber tips from a different set he liked. A bit of CAD magic later, and he had a model for the perfect earbud tip. While he could have directly printed the tip in a flexible filament like NinjaFlex, [Joe] opted for a pure silicone tip. He printed molds, then mixed silicone caulk with cornstarch (as a catalyst). The resulting earbuds sound and feel great!

Next up is [Joe M] with 3D Printed Molds: Custom Silicone Earbuds. [Joe] had a set of Bluetooth earbuds he enjoyed, but the rubber tips left a bit to be desired. Not a problem when you have a 3D printer on hand. [Joe] measured the plastic part of his earbuds and the rubber tips from a different set he liked. A bit of CAD magic later, and he had a model for the perfect earbud tip. While he could have directly printed the tip in a flexible filament like NinjaFlex, [Joe] opted for a pure silicone tip. He printed molds, then mixed silicone caulk with cornstarch (as a catalyst). The resulting earbuds sound and feel great!

Next we have [Jetty] with Highly Configurable 3D Printed Helmholtz Coil. Helmholtz coils are used to create uniform magnetic fields. Why would you want to do that? It could be anything from measuring magnets to cancelling out the effect of the earth’s magnetic field on a device being tested. [Jetty’s] wrote an OpenScad program which allows the user to enter parameters for their coil. [Jetty’s] program then calculates the coil’s magnetic properties, and outputs a printable .stl file. Building the coil is as simple as printing it and wrapping some copper wire. [Jetty] found that his coil was within 60nT (nanoTesla) of the expected value. Not bad for a bit of plastic and wire!

Next we have [Jetty] with Highly Configurable 3D Printed Helmholtz Coil. Helmholtz coils are used to create uniform magnetic fields. Why would you want to do that? It could be anything from measuring magnets to cancelling out the effect of the earth’s magnetic field on a device being tested. [Jetty’s] wrote an OpenScad program which allows the user to enter parameters for their coil. [Jetty’s] program then calculates the coil’s magnetic properties, and outputs a printable .stl file. Building the coil is as simple as printing it and wrapping some copper wire. [Jetty] found that his coil was within 60nT (nanoTesla) of the expected value. Not bad for a bit of plastic and wire!

Finally we have StickScope, [SUF’s] entry in the 2016 Hackaday Prize. Like many of us, [SUF] loves his StickVise. Sometimes you need a bit of magnification to see those tiny 0201 resistors though. [SUF] had a cheap USB microscope on hand, so he designed StickScope, a USB microscope mount designed especially for the StickVise. Two 6mm steel rods are the backbone of the design. 3D printed clamps hold the system together like a miniature boom microscope. This is actually the third revision of the design. [SUF] found that the original design couldn’t be used with parts close to the bar which holds the microscope. A small jaw extender was the perfect tweak.

Finally we have StickScope, [SUF’s] entry in the 2016 Hackaday Prize. Like many of us, [SUF] loves his StickVise. Sometimes you need a bit of magnification to see those tiny 0201 resistors though. [SUF] had a cheap USB microscope on hand, so he designed StickScope, a USB microscope mount designed especially for the StickVise. Two 6mm steel rods are the backbone of the design. 3D printed clamps hold the system together like a miniature boom microscope. This is actually the third revision of the design. [SUF] found that the original design couldn’t be used with parts close to the bar which holds the microscope. A small jaw extender was the perfect tweak.

If you want to see more simple functional 3D printed projects, check out our new simple functional 3D prints list! If I missed your project, don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet. As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

3D printers have forever changed the hardware hacker movement. From the original RepRap project on up through current commercial offerings, 3D printers have become an indispensable tool for hackers, makers, and engineers. While printers may not have started a desktop manufacturing revolution, they are a desktop prototyping evolution. It’s rare for a day to go by on Hackaday without a project that uses a 3D printed part in some way shape or form. These printers also continue to evolve, with new projects pushing the technology ever forward. This week’s Hacklet is all about some of the best 3D printer projects onHackaday.io!

We start with [TTN] and Icepick Delta. [TTN’s] passion is creating 3D printers as cheaply as possible. The Icepick definitely succeeds at this. Icepick’s frame is made of wood. The motors are commodity steppers. Control is via the long proven Ramps 1.4 board, which can be picked up with drivers and an Arduino Mega clone for under $35 these days. A few ball bearings and metal parts fill out the vitamins of this design. Just about everything else is 3D printed in true RepRap style. The printer is currently running Marlin firmware, but [TTN] plans to move to Repetier in the future.

We start with [TTN] and Icepick Delta. [TTN’s] passion is creating 3D printers as cheaply as possible. The Icepick definitely succeeds at this. Icepick’s frame is made of wood. The motors are commodity steppers. Control is via the long proven Ramps 1.4 board, which can be picked up with drivers and an Arduino Mega clone for under $35 these days. A few ball bearings and metal parts fill out the vitamins of this design. Just about everything else is 3D printed in true RepRap style. The printer is currently running Marlin firmware, but [TTN] plans to move to Repetier in the future.

Even with these humble origins, Icepick manages to print at a very respectable 50 mm/s before frame flex becomes a problem. Prints at 0.1mm layer height look great, on par with any current commercial printer.

Next up is [Machinist] with 3D printer brain retrofit. Commercial 3D printers have been available for decades now. This means some of the older models are getting a bit long in the tooth. [Machinist] has a very tired 15 year old Stratasys Dimension 768. The mechanics of the Dimension are still in good shape, but the electronics have seen better days. [Machinist] is ditching all the old electronic hardware (and the DRM which goes with it) and setting this machine up with a Smoothieboard 5X. So far the Dimension has been gutted, and [Machinist] has gotten the monster stepper motors playing sweet music with his new control board. I can’t wait to see how this project progresses.

Next up is [Machinist] with 3D printer brain retrofit. Commercial 3D printers have been available for decades now. This means some of the older models are getting a bit long in the tooth. [Machinist] has a very tired 15 year old Stratasys Dimension 768. The mechanics of the Dimension are still in good shape, but the electronics have seen better days. [Machinist] is ditching all the old electronic hardware (and the DRM which goes with it) and setting this machine up with a Smoothieboard 5X. So far the Dimension has been gutted, and [Machinist] has gotten the monster stepper motors playing sweet music with his new control board. I can’t wait to see how this project progresses.

Next we have [jcchurch’s] Coffee Maker Delta 3D Printer. [jcchurch] has managed to convert an old Norelco coffee maker into a mini sized 3D printer. The warmer plate has even become a heated bed for ABS prints. Unlike Icepick up top, the aim of this design is to use as few 3D printed parts as possible. The idea is that this would be the first printer to build when you don’t have another printer handy. Think of it as a caffeinated RepStrap. According to [jcchurch], this printer has been running strong at Tropical Labs for over a year. You can even pull the delta assembly off and make a pot of coffee! The coffee maker printer is still somewhat of a teaser project. If you see [jcchurch] online, tell him to head over and give us more details!

Next we have [jcchurch’s] Coffee Maker Delta 3D Printer. [jcchurch] has managed to convert an old Norelco coffee maker into a mini sized 3D printer. The warmer plate has even become a heated bed for ABS prints. Unlike Icepick up top, the aim of this design is to use as few 3D printed parts as possible. The idea is that this would be the first printer to build when you don’t have another printer handy. Think of it as a caffeinated RepStrap. According to [jcchurch], this printer has been running strong at Tropical Labs for over a year. You can even pull the delta assembly off and make a pot of coffee! The coffee maker printer is still somewhat of a teaser project. If you see [jcchurch] online, tell him to head over and give us more details!

Finally, we have [DeepSOIC] with linear stepper motor 3d printer. 3D printers all use good old fashioned rotary stepper motors. [DeepSOIC] is trying to eliminate all that rotary motion, along with the belts and pulleys required to convert to linear motion. Linear stepper motors can be thought of as regular stepper motors, just unrolled. They tend to be very expensive though, so [DeepSOIC] is building DIY versions. His first attempt was to print motor parts using BlackMagic3D’s ferromagnetic filament. This lead to a whole separate project to measure the permeability of the filament. Unfortunately, the filament isn’t permeable enough to act as a motor for a printer. [DeepSOIC] hasn’t given up though. This is the type of project we love – one that might not work out, but really gets people thinking. Check out the comment thread on the project to see Hackaday.io collaboration at work!

Finally, we have [DeepSOIC] with linear stepper motor 3d printer. 3D printers all use good old fashioned rotary stepper motors. [DeepSOIC] is trying to eliminate all that rotary motion, along with the belts and pulleys required to convert to linear motion. Linear stepper motors can be thought of as regular stepper motors, just unrolled. They tend to be very expensive though, so [DeepSOIC] is building DIY versions. His first attempt was to print motor parts using BlackMagic3D’s ferromagnetic filament. This lead to a whole separate project to measure the permeability of the filament. Unfortunately, the filament isn’t permeable enough to act as a motor for a printer. [DeepSOIC] hasn’t given up though. This is the type of project we love – one that might not work out, but really gets people thinking. Check out the comment thread on the project to see Hackaday.io collaboration at work!

If you want to see more 3D printer projects, check out our updated 3D printer list! If I didn’t wake up early enough to catch your project, don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet. As always, see you next week....

Read more »One of the best ways to teach electronics and programming is with hands-on learning. Get the concepts off the computer screen and out into the real world. Students of all ages have been learning with robots for decades. Many older Hackaday readers will remember the turtle robots. These little ‘bots would drive around drawing shapes created in the logo programming language. This week’s Hacklet is all about the next generation of robots that teach electronics, mechanics, programming, and of course, hacking. So let’s check out some of the best educational robot projects on Hackaday.io!

We start with [Tom Van den Bon] and Edubot Controller (Benny). Buying one or two robots can get expensive. Equipping a classroom full of them can break the bank. [Tom] is hoping to make robots cheaper and more accessible with Edubot, his entry in the 2016 Hackaday prize. Edubot rides on a 3D printed frame with low-cost gear motors for a drive system. Edubot’s brain is an STM32F042, a low-cost ARM processor from ST micro. The micro and motor drives are integrated into a custom board [Tom] designed. He’s has even begun creating lesson plans so students of various ages and skill levels can participate and learn.

We start with [Tom Van den Bon] and Edubot Controller (Benny). Buying one or two robots can get expensive. Equipping a classroom full of them can break the bank. [Tom] is hoping to make robots cheaper and more accessible with Edubot, his entry in the 2016 Hackaday prize. Edubot rides on a 3D printed frame with low-cost gear motors for a drive system. Edubot’s brain is an STM32F042, a low-cost ARM processor from ST micro. The micro and motor drives are integrated into a custom board [Tom] designed. He’s has even begun creating lesson plans so students of various ages and skill levels can participate and learn.

Next up is [Joshua Elsdon] with Micro Robots for Education. Big robots can be intimidating. They can also cause some damage when hardware and software created by budding engineers doesn’t operate as expected. Tiny robots though, are much easier to wrangle. [Joshua ] may have taken tiny to an extreme with these robots. Each robot is under 2 cm square. The goal is for each one to cost less than £10 to produce. These micro bots have big brains with their ATmega328P micro controllers. [Joshua] is currently trying to figure out a low-cost way to produce wheels for these robots.

Next up is [Joshua Elsdon] with Micro Robots for Education. Big robots can be intimidating. They can also cause some damage when hardware and software created by budding engineers doesn’t operate as expected. Tiny robots though, are much easier to wrangle. [Joshua ] may have taken tiny to an extreme with these robots. Each robot is under 2 cm square. The goal is for each one to cost less than £10 to produce. These micro bots have big brains with their ATmega328P micro controllers. [Joshua] is currently trying to figure out a low-cost way to produce wheels for these robots.

Next we have [shamylmansoor] with 3D printed mobile robot for STEM education. Robots are expensive, and international shipping can make them even more expensive. [Shamyl] is shooting for a robot which can be made locally in Pakistan. 3D printing is the answer. The robot’s chassis can be printed on any FDM printer. Wheels,and tires are low-cost units. Motors are RC servos modified for continuous rotation. The brains of the robot is an Arduino Mega 2560, which should provide plenty of inputs for sensors. [Shamyl] even included a solderless breadboard so students can prototype circuits and sensors right on the robot’s body.

Finally we have [Rodolfo] with Plobot. Plobot is a robot designed for the youngest hackers – those from four to seven years old. [Rodolfo] designed Plobot to be programmed with RFID cards. Each card contains a command such as move forward, turn, start, and reset. Many of the language mechanics are inspired by the Scratch programming language. Plobot’s processor is a Sanguino, running [Rodolfo’s] custom code. An ESP8266 allows Plobot to be connected to the outside world via WiFi. [Rodolfo] has even created a custom over the air update system for Plobot’s firmware. Plobot has already been tested with students, where it made a great showing. We’re hoping both [Rodolfo] and Plobot do well in the 2016 Hackaday Prize!

Finally we have [Rodolfo] with Plobot. Plobot is a robot designed for the youngest hackers – those from four to seven years old. [Rodolfo] designed Plobot to be programmed with RFID cards. Each card contains a command such as move forward, turn, start, and reset. Many of the language mechanics are inspired by the Scratch programming language. Plobot’s processor is a Sanguino, running [Rodolfo’s] custom code. An ESP8266 allows Plobot to be connected to the outside world via WiFi. [Rodolfo] has even created a custom over the air update system for Plobot’s firmware. Plobot has already been tested with students, where it made a great showing. We’re hoping both [Rodolfo] and Plobot do well in the 2016 Hackaday Prize!

If you want more mind hacking goodness, check out our brand new educational robot list! Did I miss your project? Don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet, As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

A mind is a terrible thing to waste – but an awesome thing to hack. We last visited brain hacks back in July of 2015. Things happen fast on Hackaday.io. Miss a couple of days, and you’ll miss a bunch of great new projects, including some awesome new biotech hacks. This week, we’re checking out some of the best new mind and brain hacks on Hackaday.io

We start with [Daniel Felipe Valencia V] and Brainmotic. Brainmotic is [Daniel’s] entry in the 2016 Hackaday Prize. Smart homes and the Internet of Things are huge buzzwords these days. [Daniel’s] project aims to meld this technology with electroencephalogram (EEG). Your mind will be able to control your home. This would be great for anyone, but it’s especially important for the handicapped. Brainmotic’s interface is using the open hardware OpenBCI as the brain interface. [Daniel’s] software and hardware will create a bridge between this interface and the user’s home.

We start with [Daniel Felipe Valencia V] and Brainmotic. Brainmotic is [Daniel’s] entry in the 2016 Hackaday Prize. Smart homes and the Internet of Things are huge buzzwords these days. [Daniel’s] project aims to meld this technology with electroencephalogram (EEG). Your mind will be able to control your home. This would be great for anyone, but it’s especially important for the handicapped. Brainmotic’s interface is using the open hardware OpenBCI as the brain interface. [Daniel’s] software and hardware will create a bridge between this interface and the user’s home.

Next we have [Angeliki Beyko] with Serial / Wireless Brainwave Biofeedback. EEG used to be very expensive to implement. Things have gotten cheap enough that we now have brain controlled toys on the market. [Angeliki] is hacking these toys into useful biofeedback tools. These tools can be used to visualize, and even control the user’s state of mind. [Angeliki’s] weapon of choice is the MindFlex series of toys. With the help of a PunchThrouch LightBlue Bean she was able to get the EEG headsets talking on Bluetooth. A bit of fancy software on the PC side allows the brainwave signals relieved by the MindFlex to be interpreted as simple graphs. [Angeliki] even went on to create a Mind-Controlled Robotic Xylophone based on this project.

Next we have [Angeliki Beyko] with Serial / Wireless Brainwave Biofeedback. EEG used to be very expensive to implement. Things have gotten cheap enough that we now have brain controlled toys on the market. [Angeliki] is hacking these toys into useful biofeedback tools. These tools can be used to visualize, and even control the user’s state of mind. [Angeliki’s] weapon of choice is the MindFlex series of toys. With the help of a PunchThrouch LightBlue Bean she was able to get the EEG headsets talking on Bluetooth. A bit of fancy software on the PC side allows the brainwave signals relieved by the MindFlex to be interpreted as simple graphs. [Angeliki] even went on to create a Mind-Controlled Robotic Xylophone based on this project.

Next is [Stuart Longland] who hopes to protect brains with Improved Helmets. Traumatic Brain Injury (TBI) is in the spotlight of medical technology these days. As bad as it may be, TBI is just one of several types of head and neck injuries one may sustain when in a bicycle or motorcycle accident. Technology exists to reduce injury, and is included with some new helmets. Many of these technologies, such as MIPS, are patented. [Stuart] is working to create a more accurate model of the head within the helmet, and the brain within the skull. From this data he intends to create a license free protection system which can be used with new helmets as well as retrofitted to existing hardware.

Next is [Stuart Longland] who hopes to protect brains with Improved Helmets. Traumatic Brain Injury (TBI) is in the spotlight of medical technology these days. As bad as it may be, TBI is just one of several types of head and neck injuries one may sustain when in a bicycle or motorcycle accident. Technology exists to reduce injury, and is included with some new helmets. Many of these technologies, such as MIPS, are patented. [Stuart] is working to create a more accurate model of the head within the helmet, and the brain within the skull. From this data he intends to create a license free protection system which can be used with new helmets as well as retrofitted to existing hardware.

Finally we have [Tom Meehan], whose entry in the 2016 Hackaday Prize is Train Your Brain with Neurofeedback. [Tom] is hoping to improve quality of life for people suffering from Epilepsy, Autism, ADHD, and other conditions with the use of neurofeedback. Like [Angeliki ] up above, [Tom] is hacking hardware from NeuroSky. In this case it’s the MindWave headset. [Tom’s] current goal is to pull data from the TAGM1 board inside the MindWave. Once he obtains EEG data, a Java application running on the PC side will allow him to display users EEG information. This is a brand new project with updates coming quickly – so it’s definitely one to watch!

Finally we have [Tom Meehan], whose entry in the 2016 Hackaday Prize is Train Your Brain with Neurofeedback. [Tom] is hoping to improve quality of life for people suffering from Epilepsy, Autism, ADHD, and other conditions with the use of neurofeedback. Like [Angeliki ] up above, [Tom] is hacking hardware from NeuroSky. In this case it’s the MindWave headset. [Tom’s] current goal is to pull data from the TAGM1 board inside the MindWave. Once he obtains EEG data, a Java application running on the PC side will allow him to display users EEG information. This is a brand new project with updates coming quickly – so it’s definitely one to watch!

If you want more mind hacking goodness, check out our freshly updated brain hacking project list! Did I miss your project? Don’t be shy, just drop me a message on Hackaday.io. That’s it for this week’s Hacklet, As always, see you next week. Same hack time, same hack channel, bringing you the best of Hackaday.io!

Create an account to leave a comment. Already have an account? Log In.

Hi, I found a scooter in the trash Augment ES210. It is a littler damaged. but not much. Problem is the display. I called the company and it turns out that the former owner forgot to pay a few payments! The company has therefore canceled his subscription, so that the scooter cannot run. They wont let me take over the subscription, as it is slightly damaged. Shit happens.

any recommended projects for hacking or hacking tool?

whats the best wifi deauther project for esp32&esp8266?also any good other projects? thanks

I tried this in the past: https://hackaday.io/project/9865-hackadayio-cover-photo-template it did work perfectly but it's a good starting point

If you've been thinking about hosting a Hack Chat, here's your chance. Do you work in an interesting field that people would love to hear about? Do you have a cool project you're working on? Or maybe there's just something you'd like to discuss? Then host a Hack Chat! Check out our FAQ for all the details.

And if there's someone you're just dying to see on the Hack Chat, let us know and we'll try to make it happen. Send us your ideas and we'll see what we can do.

During the account creation process, it recommends projects and profiles to follow.

https://hackaday.io/page/9226-electronics-microcontrollers-for-absolute-beginners-part-9

Can't find recommended aspect ratio (size) for project's background image. Any suggestions?

The banner image at the top? It is set to cover so it will always fill the space, some of the image will be cropped, and because it is a fixed height but variable width, the aspect ratio changes. Generally a wide image works better, from 16:9 and up.

The recommended <a href="http://gulfexpatsguide.com/">aspect ratio</a>or size for a project's background image can depend on several factors,...

I tried this in the past: https://hackaday.io/project/9865-hackadayio-cover-photo-template it did work perfectly but it's a good starting point.

The LaTeX renderer seems to have some bugs. The LaTeX in this project entry no longer renders: https://hackaday.io/project/12989-thor/log/44018-inverse-kinematics

I'll try to see if I can find out why these last few failed to render.

You could upload an image with some numbers and lines in it to quickly figure it out.

Is there a way to unsubmit a project page from the Hackaday Prize? I'd submitted a project for the Reactivate Wildcard Round, but things went south and now it won't be ready, but I'd like to see if I can submit it for next year if it fits.

Hi @Peter McCloud - If you make a project 'Private", it will be removed from all lists you submitted it to. You can make it public afterward.

What's the recommended aspect ratio (size) for the Project "background image" ?

I tried looking around but couldn't find the answer.

I don't know, but you could upload an image with some numbers and lines in it to quickly figure it out.

There isn't any. The height of the background is fixed, but the width depends on the width of the users display/window. The image is clipped to match the required aspect ratio.

So you may want to choose an image that has the object of interest in the center, and has some margin around it, so it doesn't get clipped on wide screens.

Notifications seem to work with Firefox (86.0.1) now! I accidentally clicked on them and was stunned to see them work. Super great to see things improve, well done team. My excitement is immeasurable and my day is made.

I just posted Part 9 of my "Electronics & Microcontrollers for Absolute Beginners" series. I'm quite proud of the initial analogy. Would love to hear your comments.

https://hackaday.io/page/9226-electronics-microcontrollers-for-absolute-beginners-part-9 Regards, Max (1/2 man. 1/2 beast. 1/2 wit)

Can people who join up just to insert links to their own businesses be deleted?

They join, like a few projects, have no projects of their on and only the hackaday robot as a follower. Especially referring to dry wall installation, appliance repair, business loans, fish tank cleaning, gutter cleaning and dumps (whatever they are).

Yeah it's spam. For any that makes it through the automated channels, we have an open issue to reduce how much is shown before it can be moderated.

Just interested, where are you seeing it the most? Stack or new profiles?

I just noticed it on this page. A series of vague comments like "thanks, great project" with URLs to non-geeky sites. There seem to be many 'members' with no projects of their own. I get such people liking my projects and I wonder if they are real. My girlfriend recently joined and I saw she liked projects way outside her interest zone. I asked if she had really understood those projects and she said no, those are just what were suggested to me by Hackaday.io. So maybe many likes are just from spammers trying not to look too fake.

Spammer likes might explain why some projects had more likes than visits.

https://hackaday.io/jgibbard has > 39k followers and only one project.

I looked at the followers in order of number of projects, and found 911 with 1 or more projects, thus the remaining 38122 have zero. Seems odd to have over 41 times more lookers than makers. I'll be a bit down if many of the people liking my projects were just made by spambots. James is a real guy and says he has no idea why it is. When people join, does the hackaday bot automatically give them projects to follow? Some dating site bots send fake 'likes' to make people think they are getting interest for their money, but I can't see why hackaday would want to create such an illusion.

Yes it does recommend projects and profiles to follow on account creation.

Without giving too much away (details), the moderation stuff might be an interesting writeup.

I haven't had to deal with comment spam in a decade but I remember using email scoring filters as part of it (SpamAssassin, and in particular: URI blacklists and IP address scoring).

Become a member to follow this project and never miss any updates

Greg Kennedy

Greg Kennedy

zakqwy

zakqwy

Sophi Kravitz

Sophi Kravitz

Jasmine Brackett

Jasmine Brackett

Zraveite bihte li mi kazali kak da si odkluca skuterat (motorniqt kontroler)Lime gen 3