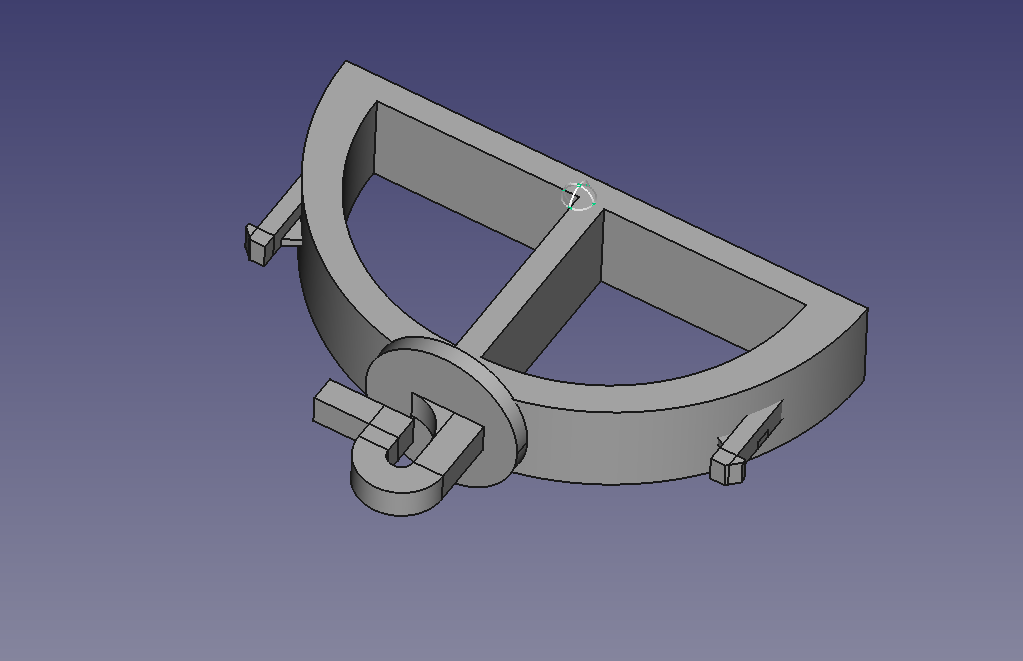

Tupperware Shape'O' ball handle

replacement handle for my sons Shape 'O' ball

replacement handle for my sons Shape 'O' ball

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Ballhandle.stlThe stl file ready fro printingStandard Tesselated Geometry - 72.54 kB - 02/07/2018 at 06:57 |

|

|

ball handle.FCStdThe Free Cad Design filefcstd - 41.76 kB - 02/07/2018 at 06:57 |

|

After designing and building my own 3d printer essentially out of junk I had lying around. Old scanner and a couple of Buble jet printers https://hackaday.io/project/4082-home-made-3d-printer I figgured having a printer was useless unless I had some way of generating the files to print. So imersing myself in the world of cad programs and a minor brain explosion and a distinct dislike for online tools.( I live in a rural town, the best internet we can muster is served up on a couple of barbed wire lines strung betwen the gum trees ) I come accross Free Cad and figgured how hard can ths be...........

The need for the Handle for the Ball was a good motivator to sit down and have a go.

To start with I took the remianing handle and took some measurements and made a bit of sketch on paper and set out to duplicate what I saw.

Bubling along with my first attempt at using a 3d CAD tool I started out with the biggest bit first a circle that defined the outer edge of the handle. The rest is "blending" adding and subtracting a series of circles (or segments of circles) and rectanfgles to build up the shape.

While I got the critical dimensions pretty well right I struggled to get the cut outs for the handle section quiet right. The end result was a vairiation in the thickness of the handle as it curved from the hook to the flat face. This was due to using different origins for the cutouts and the outer circle. While this is quiet obvious in the drawings in reality it makes no difference to the opperation and is barely noticable.

Dont be woos!

anybody can lay down a couple of hundred bucks and buy a printer be daring scratch through your junk box and see what you can come up with.

slap it together, youll be supprised how well it work

The stl file is posted HERE. Down load it

I use slic3r it works for me but use what ever floats your baot - I use a .4mm nozel and .2mm layer height

PLA works fine - just dont leave it in a car on a hot day

Print it on its side with supports

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates