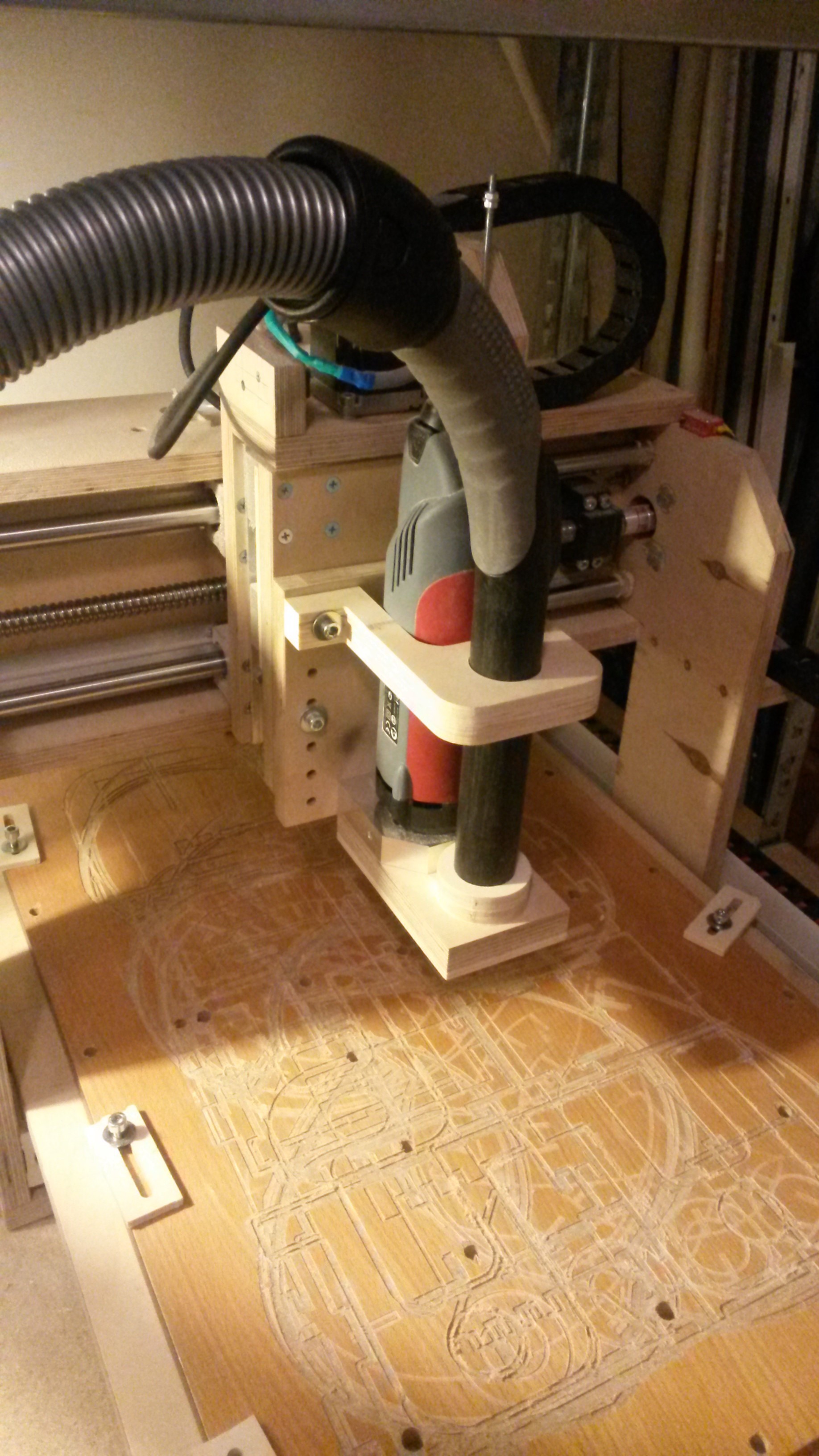

- working area 350 x 600 x 90 mm (x;y;z)

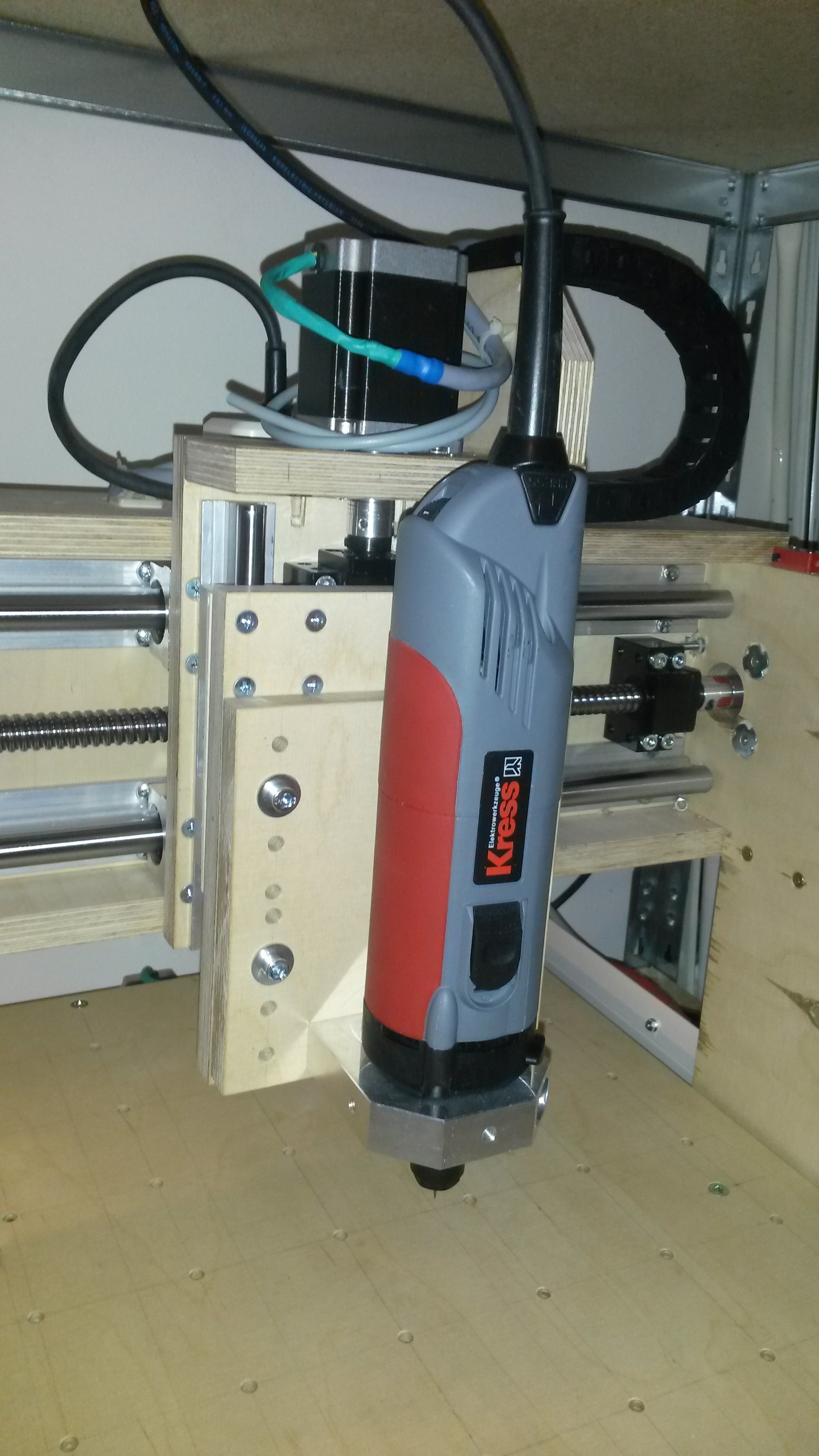

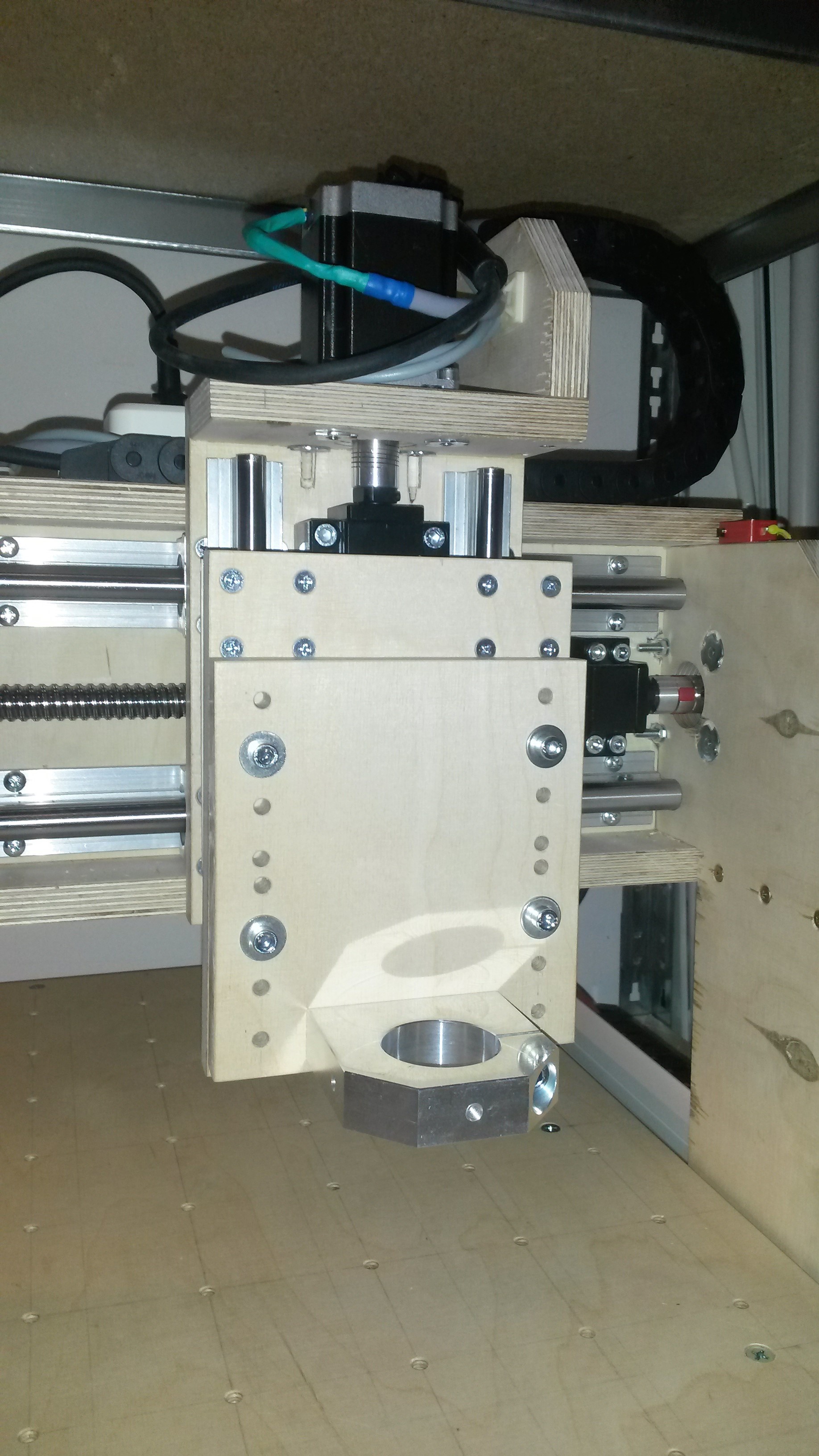

- 1050 W Kress spindle

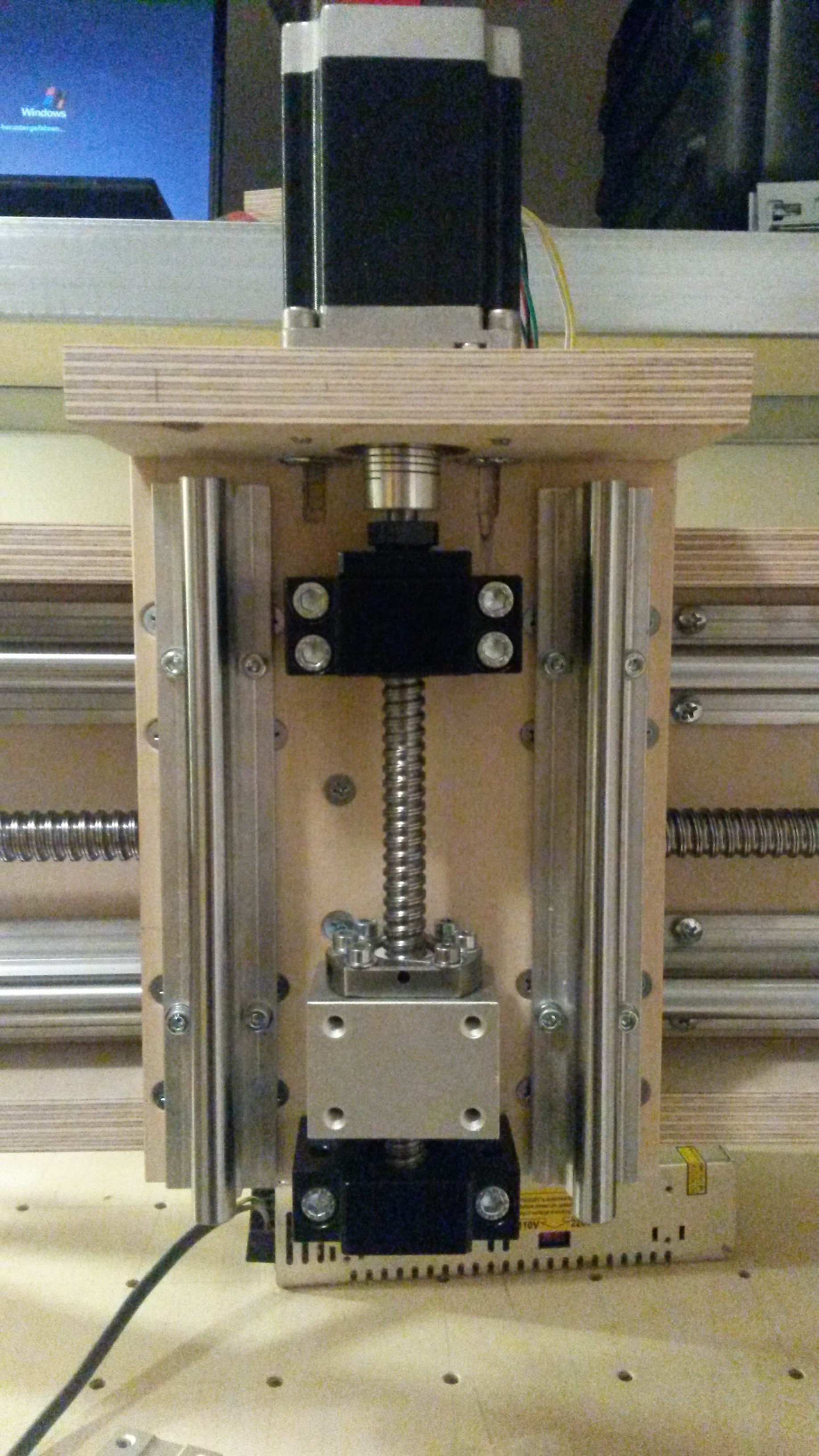

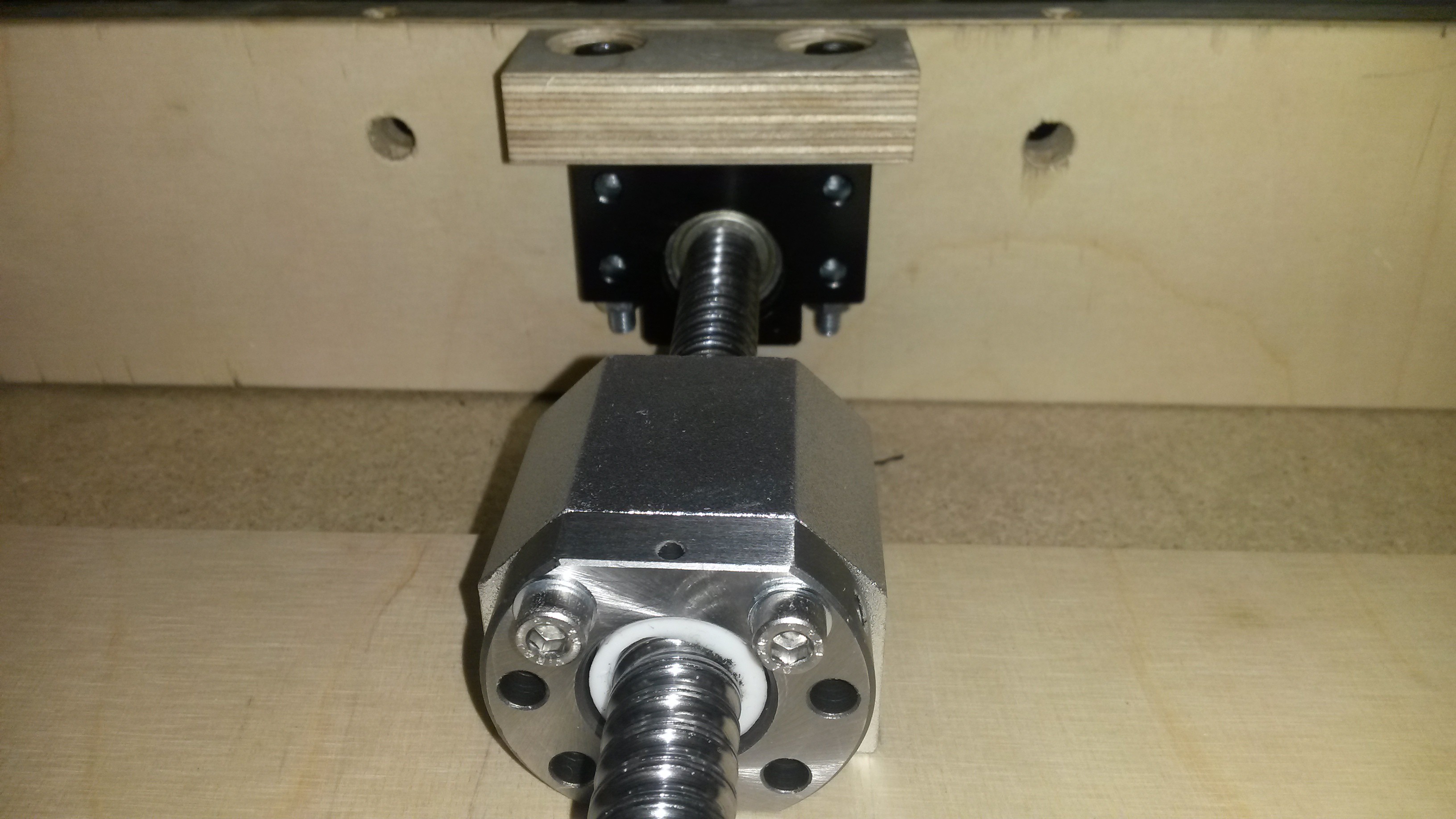

- 3A NEMA 23 stepper

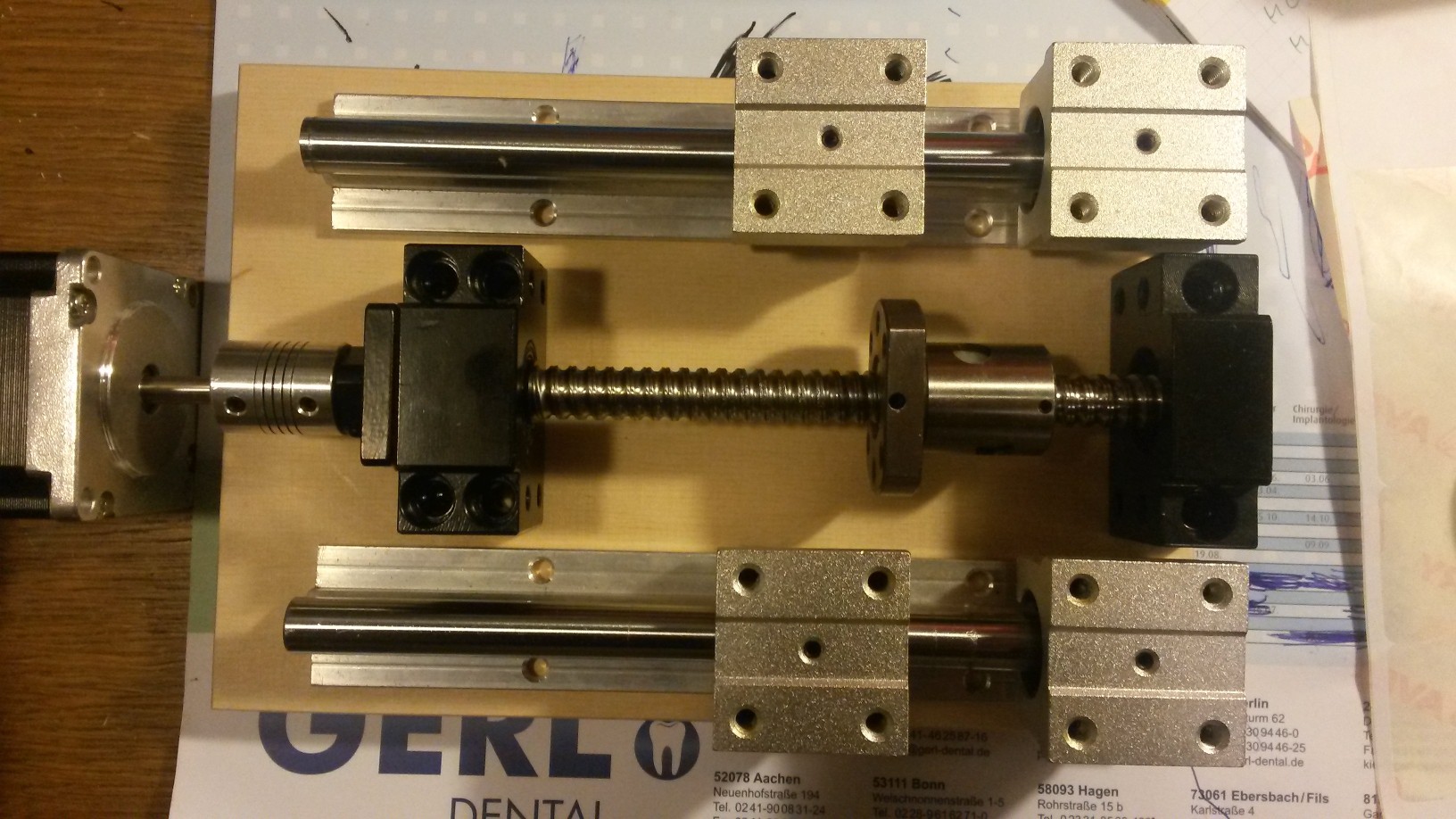

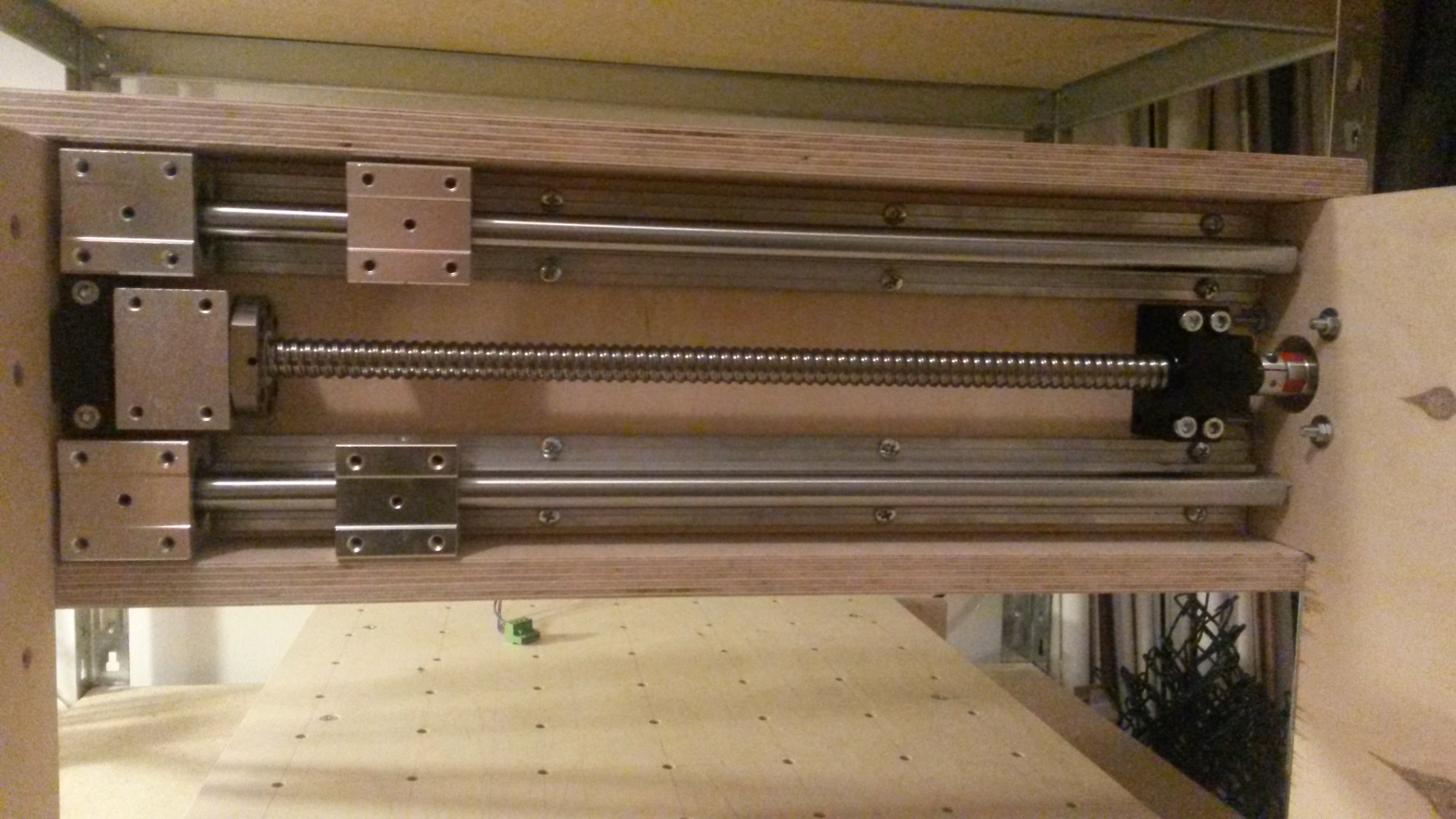

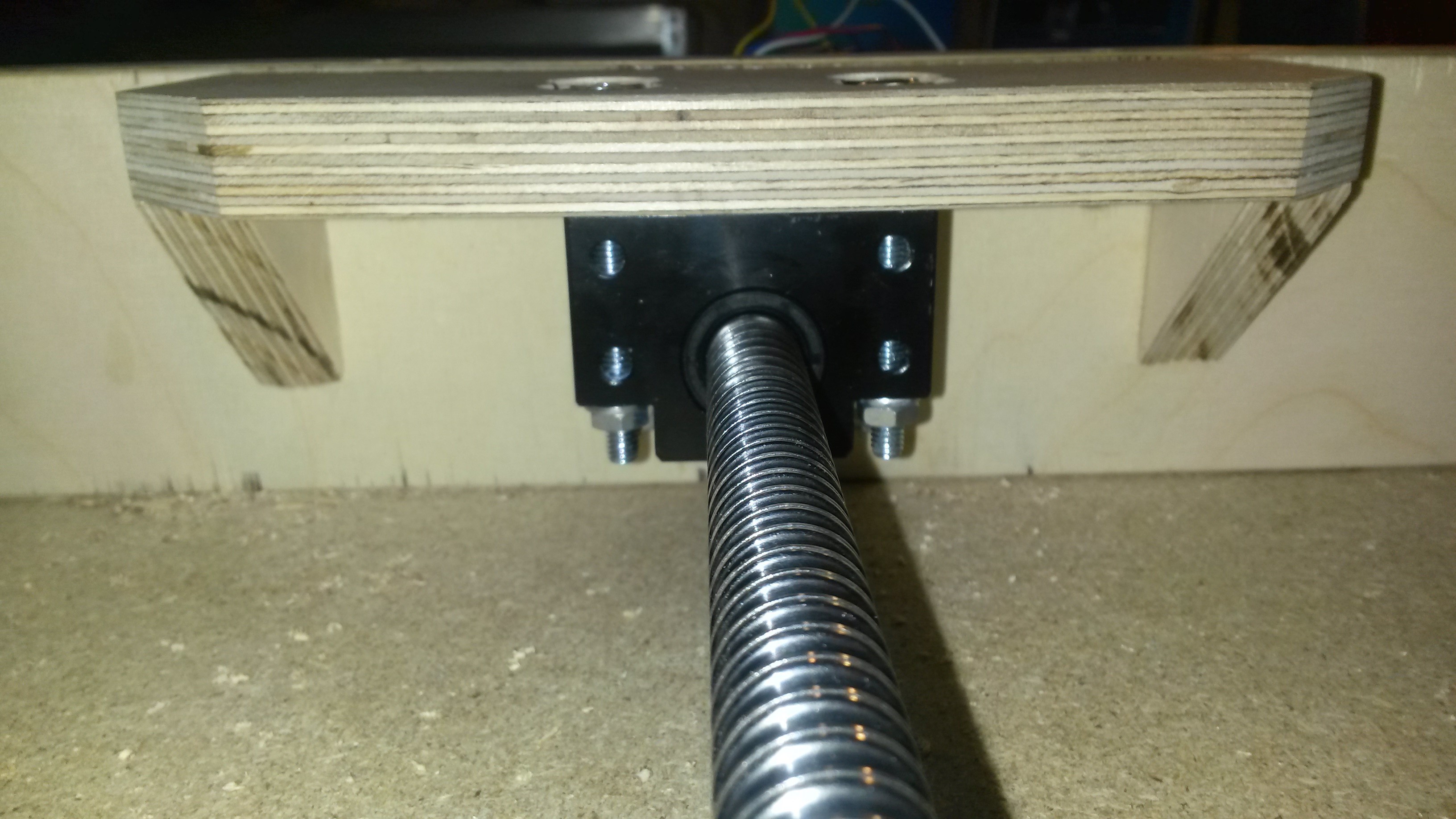

- ball screws

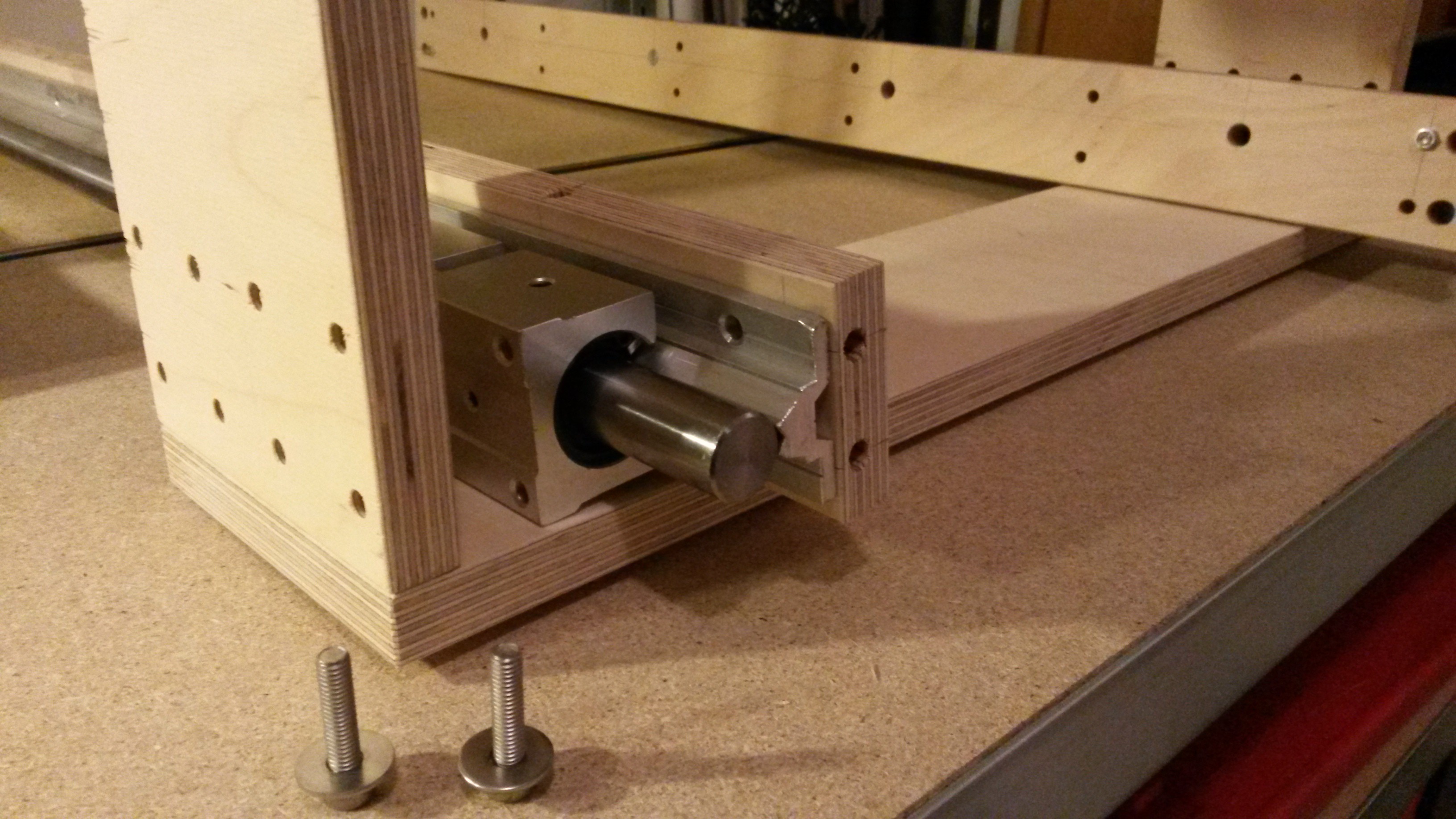

- supported rails

- automatic dust extraction

DIY Multiplex Plywood CNC Router

My first self made CNC router!

My first self made CNC router!

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Portalfräse.FCStdFreeCAD plan.fcstd - 377.66 kB - 02/20/2016 at 23:08 |

|

My suction works well so far but it should work even better with a brush!

It´s been a while since my last log entry. I had a lot of work with different CNC projects. During this time the router had blow out a lot of dust in my workshop. Of course I have a "manual dust suction" with a vacuum cleaner but this works not good enough.

So I decided to upgrade my router with an automatic dust suction which is always available!

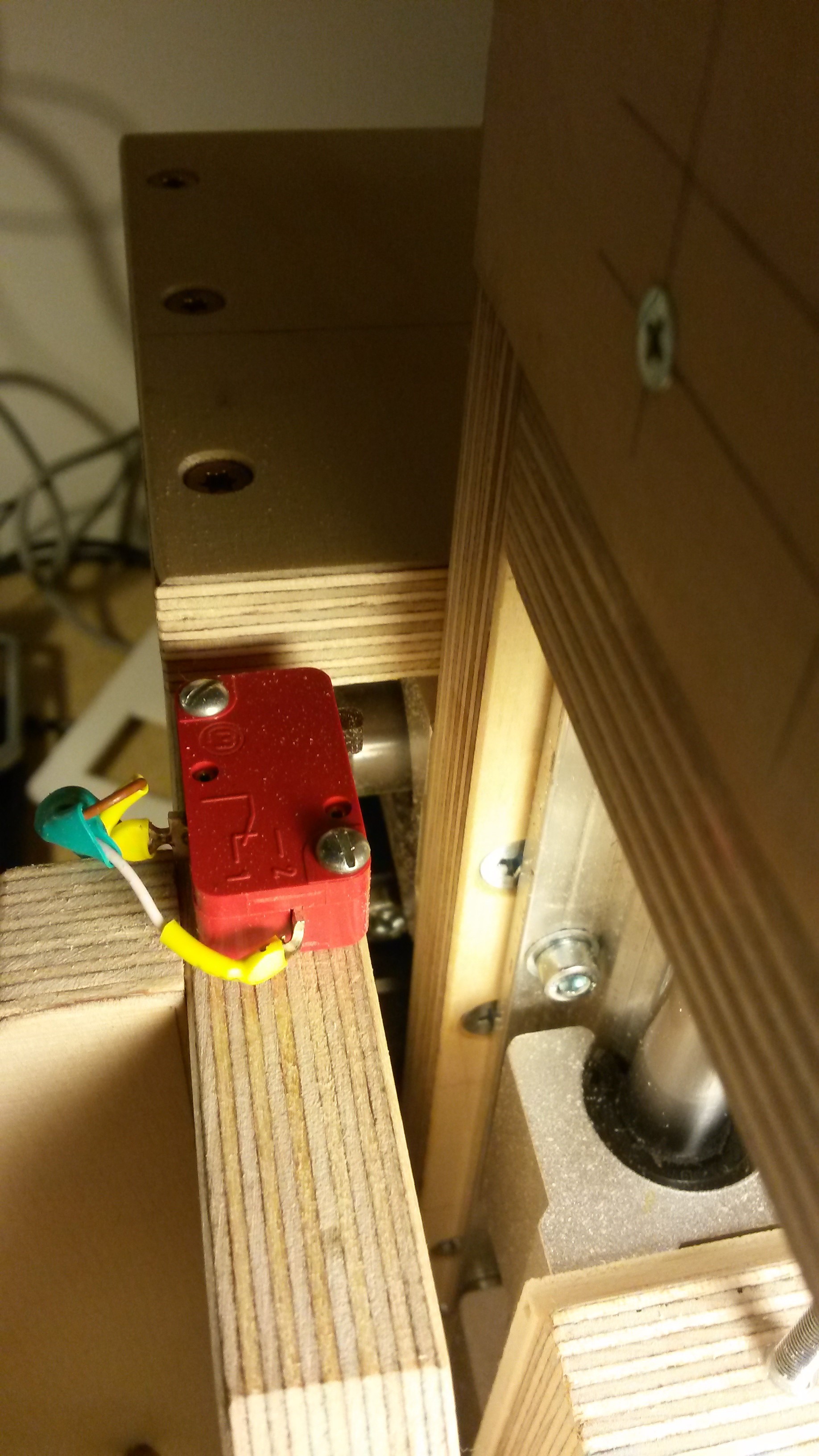

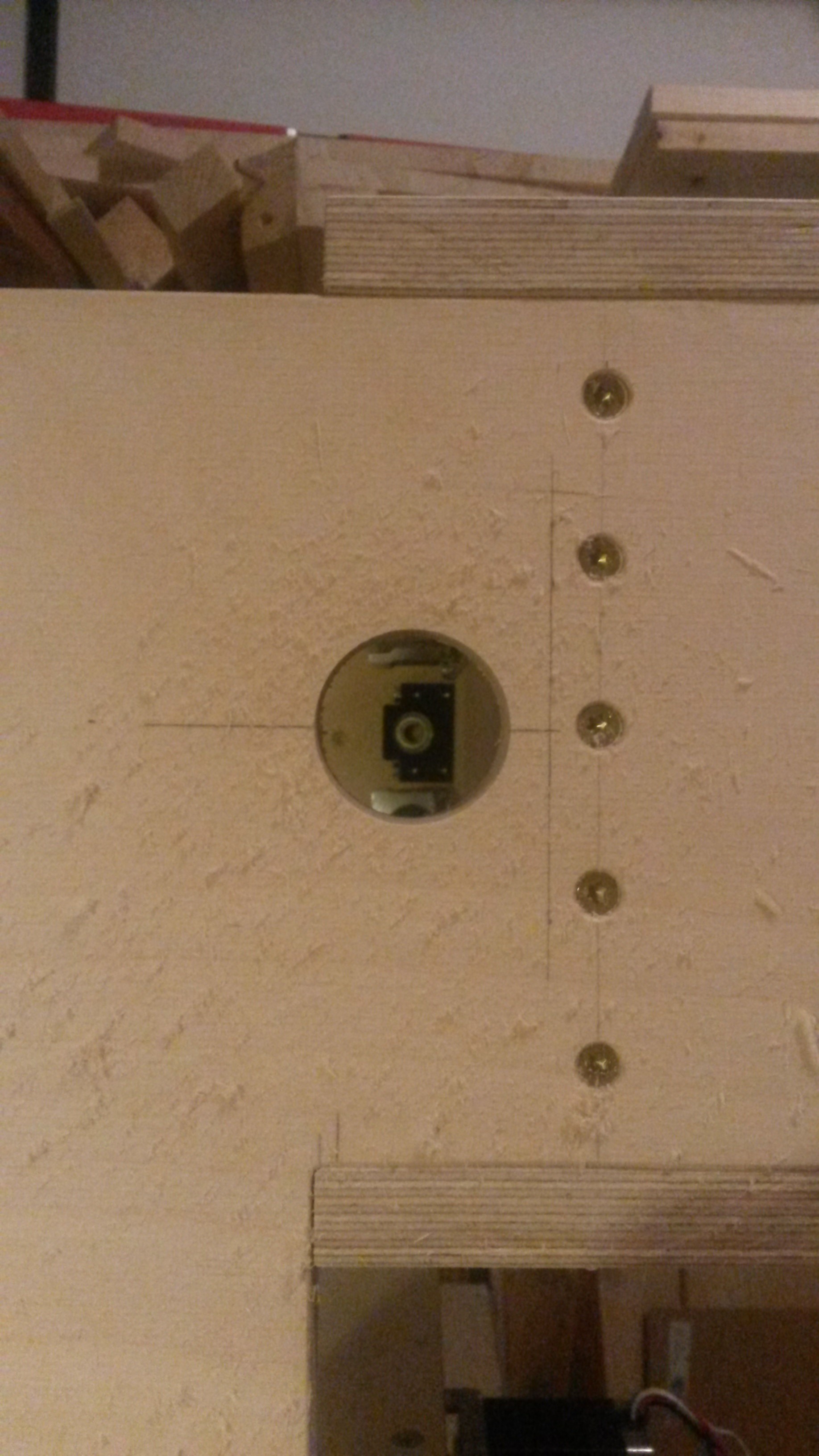

Y axis limit switch

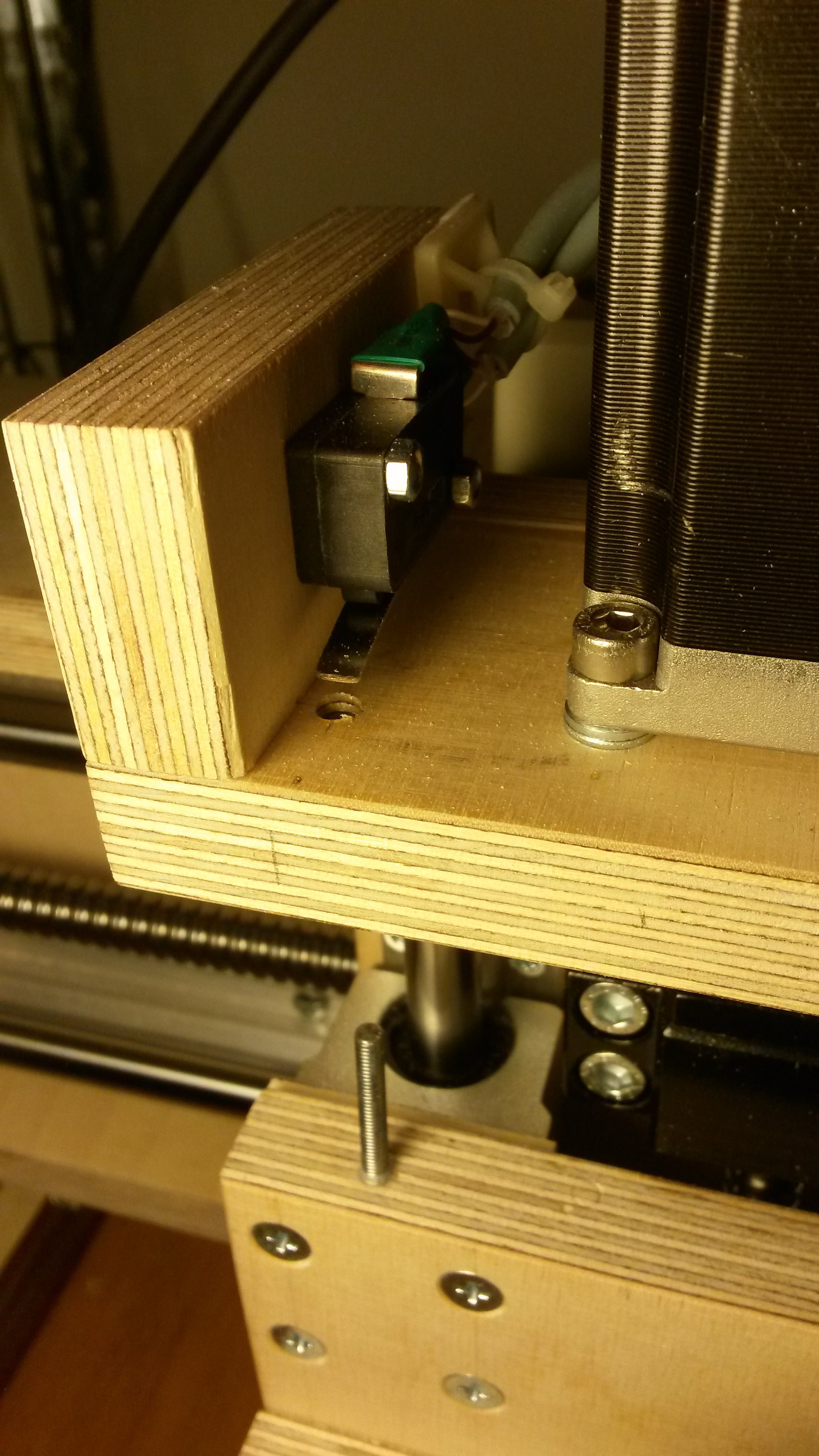

Z axis limit switch down direction

Y axis limit switch

Z axis limit switch up direction

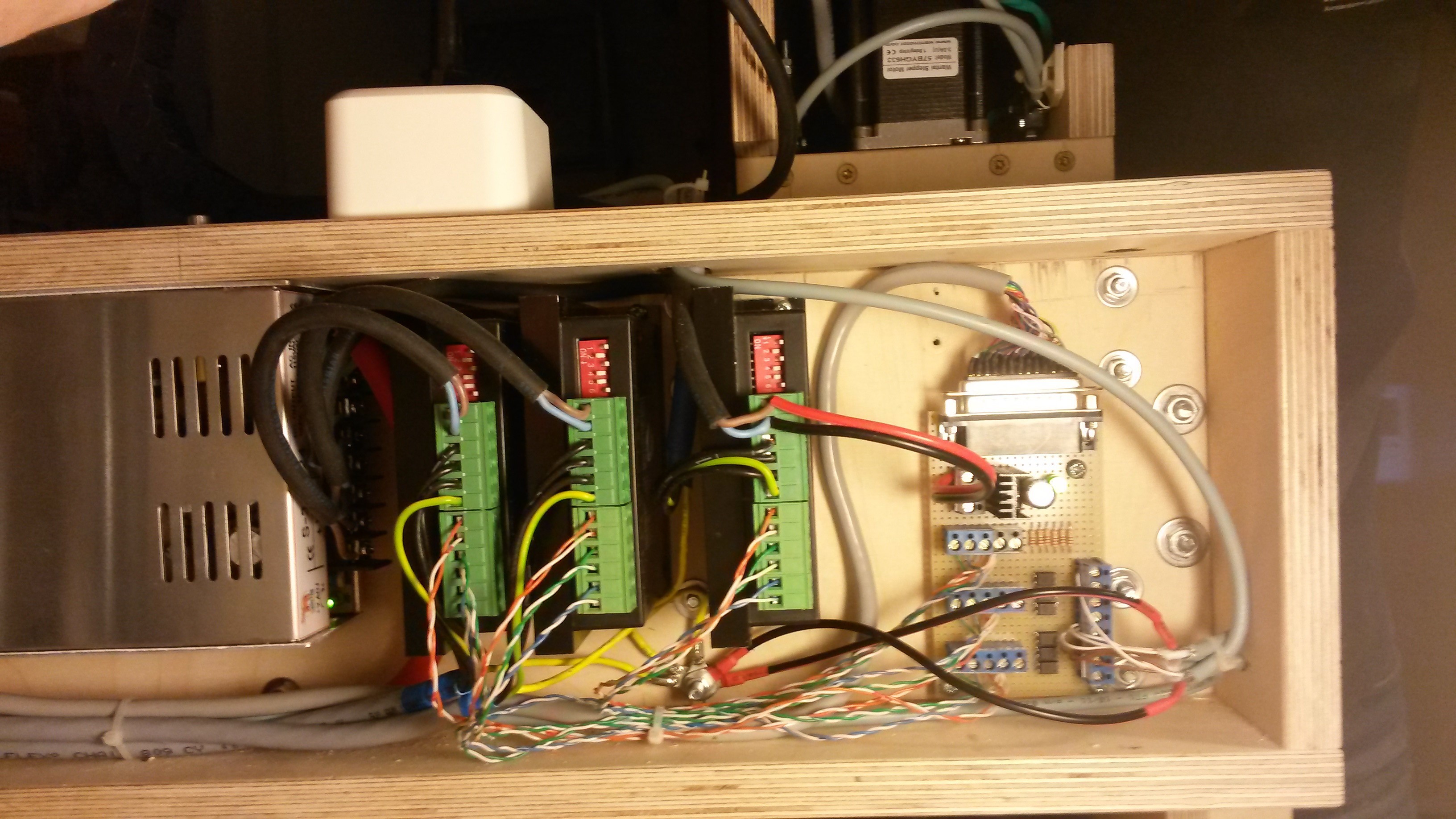

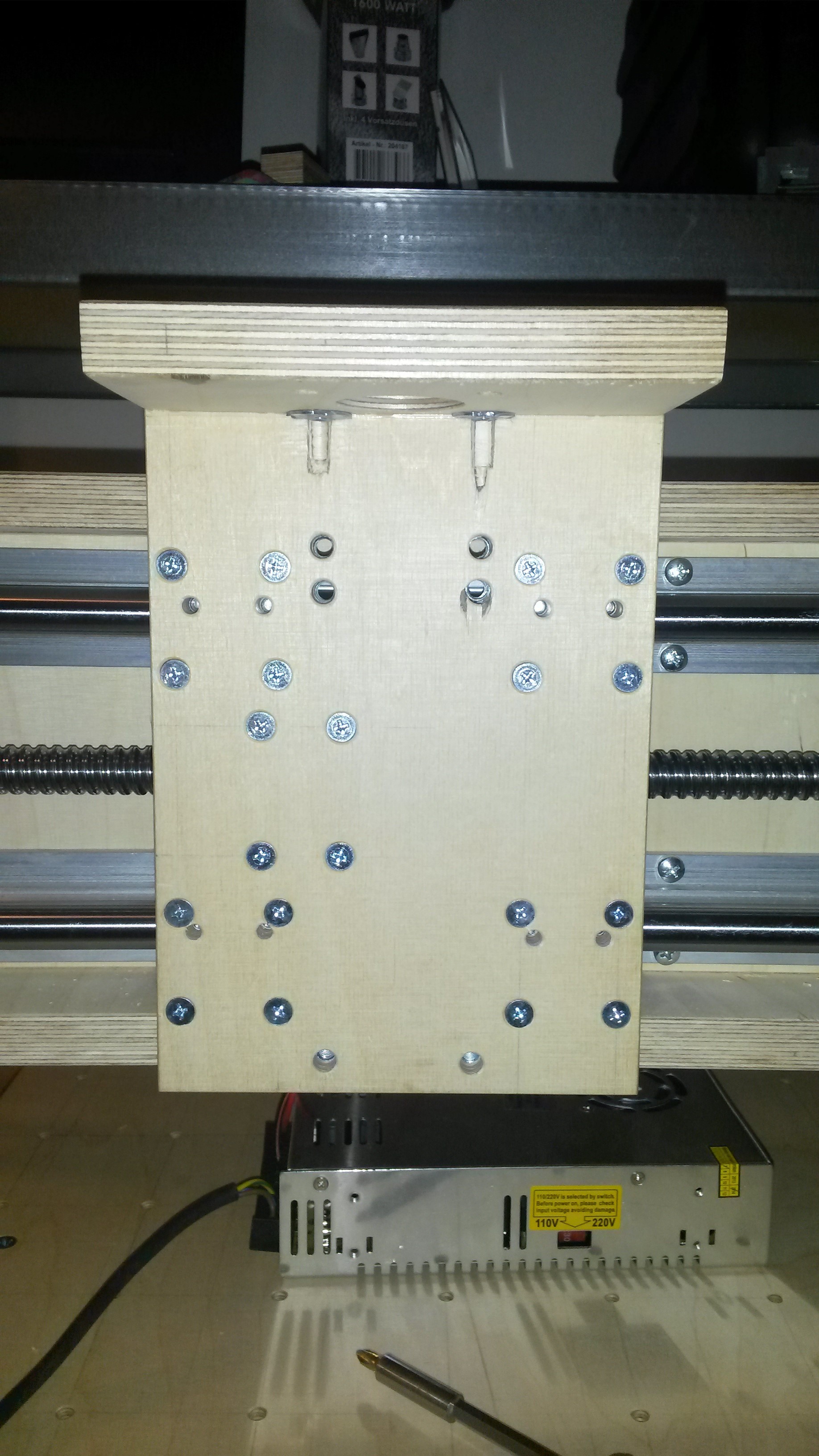

The complete electronics are housed in the backside of the portal

The complete electronics are housed in the backside of the portal

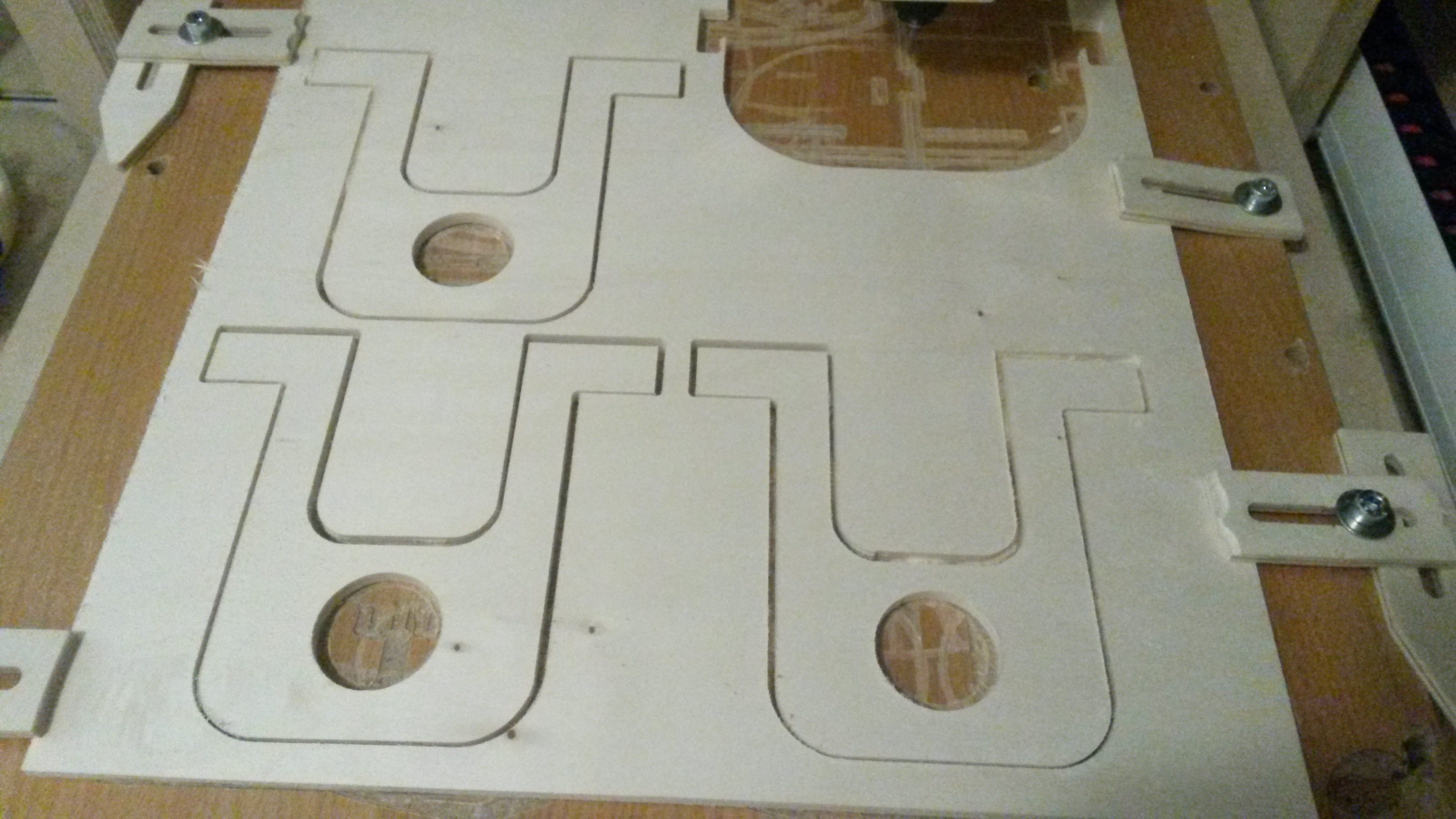

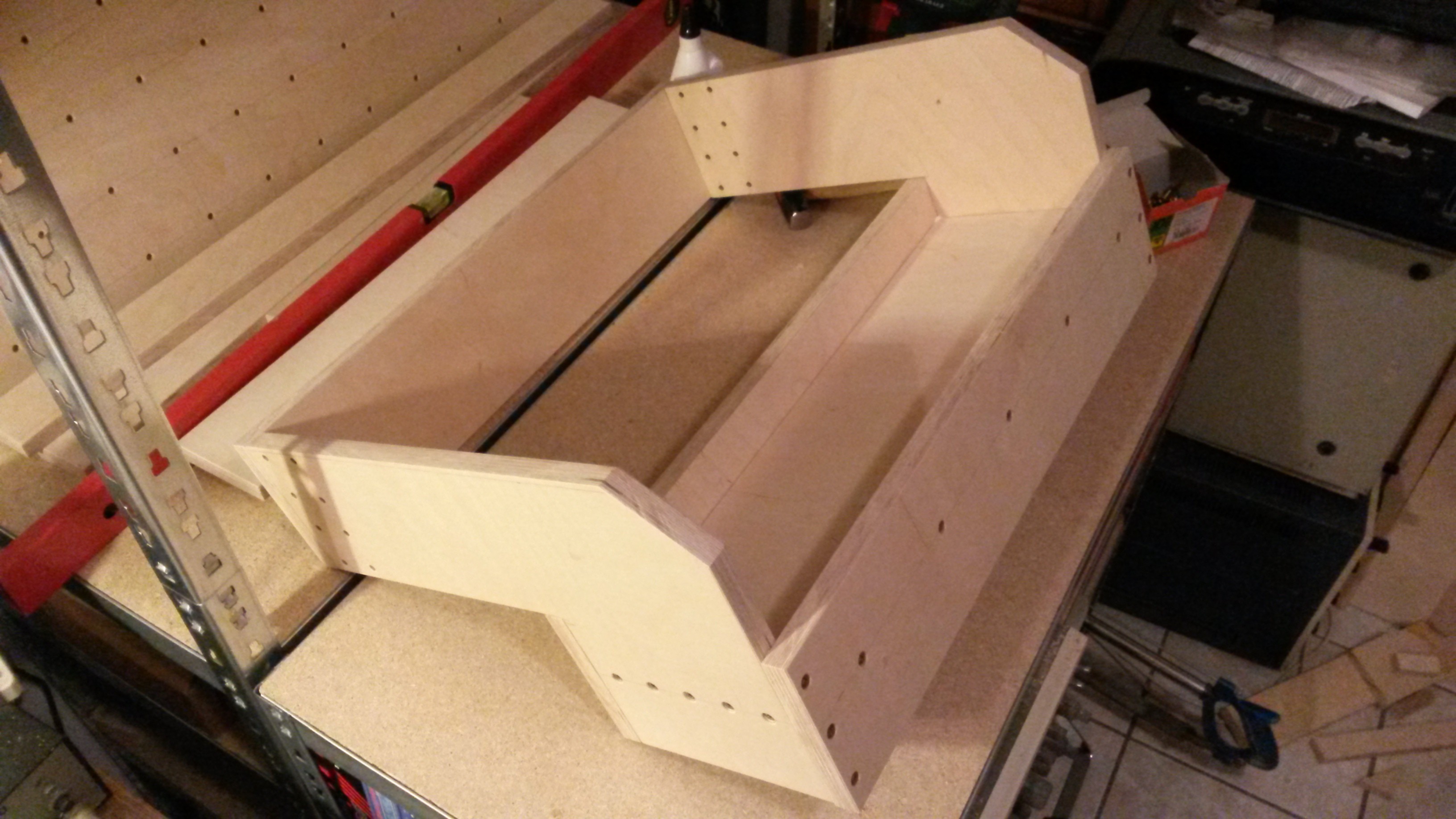

Y axis.

X axis

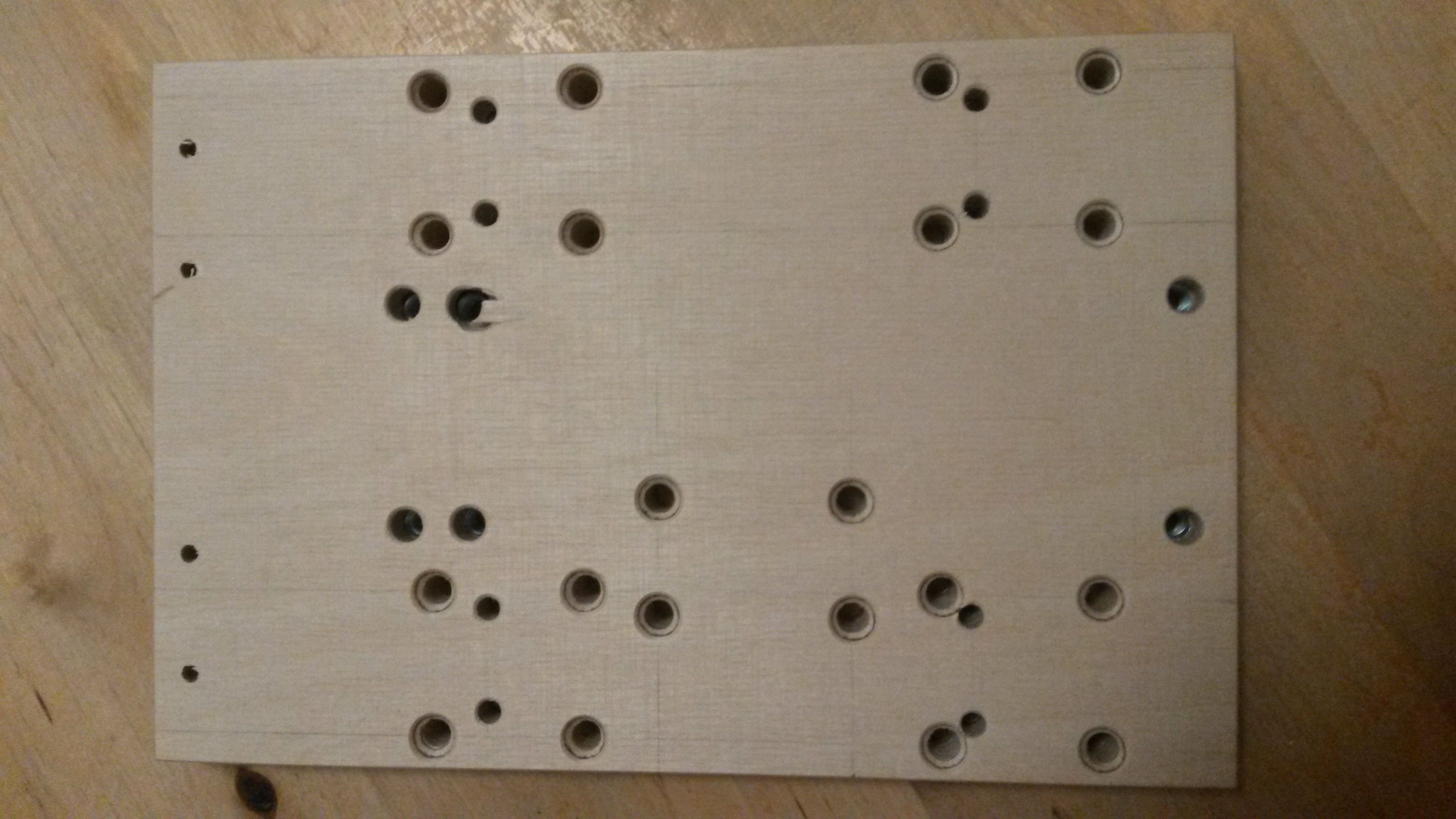

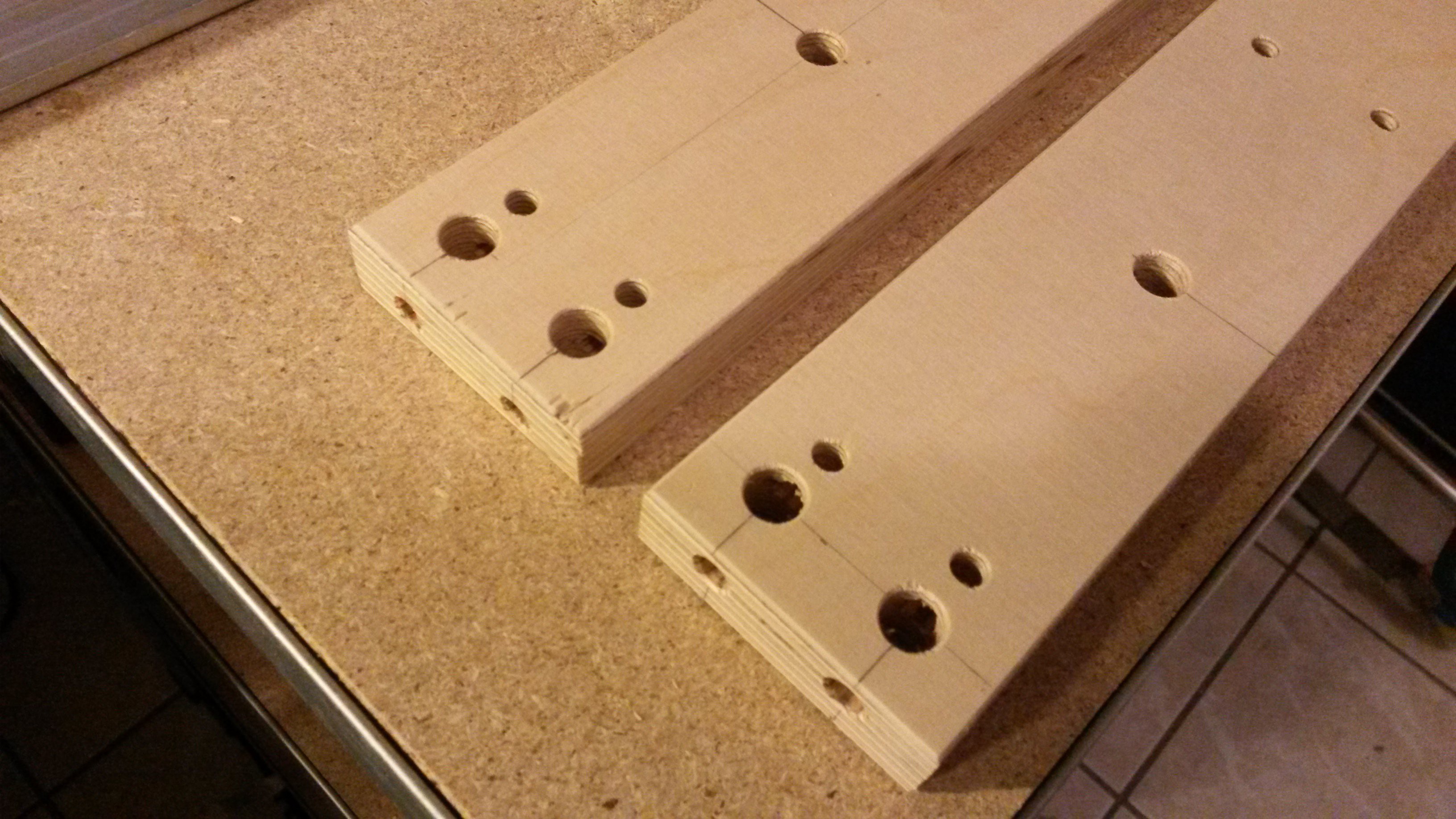

A lot of screws...

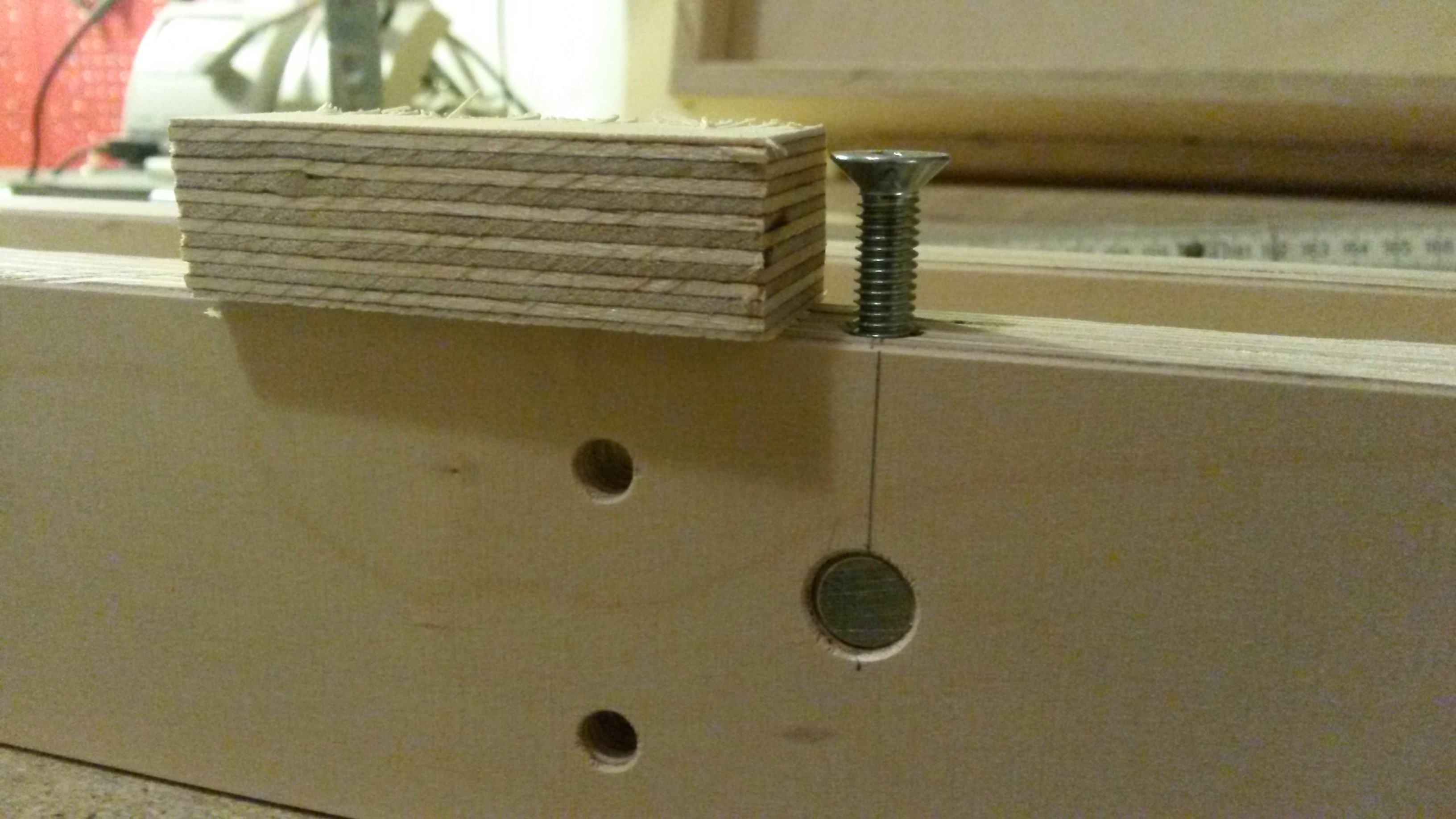

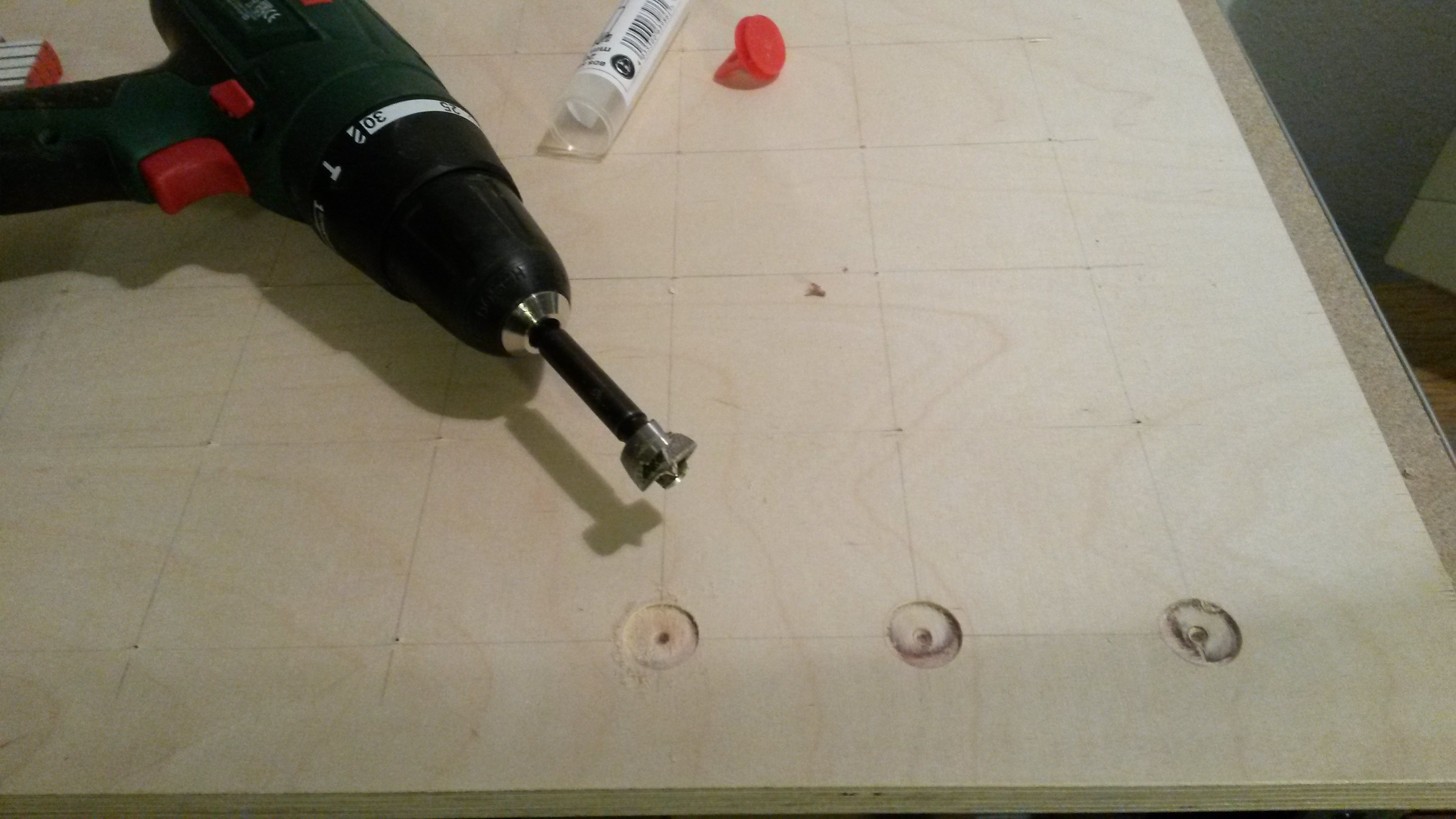

The raw material. 18 mm birch multiplex ply wood.

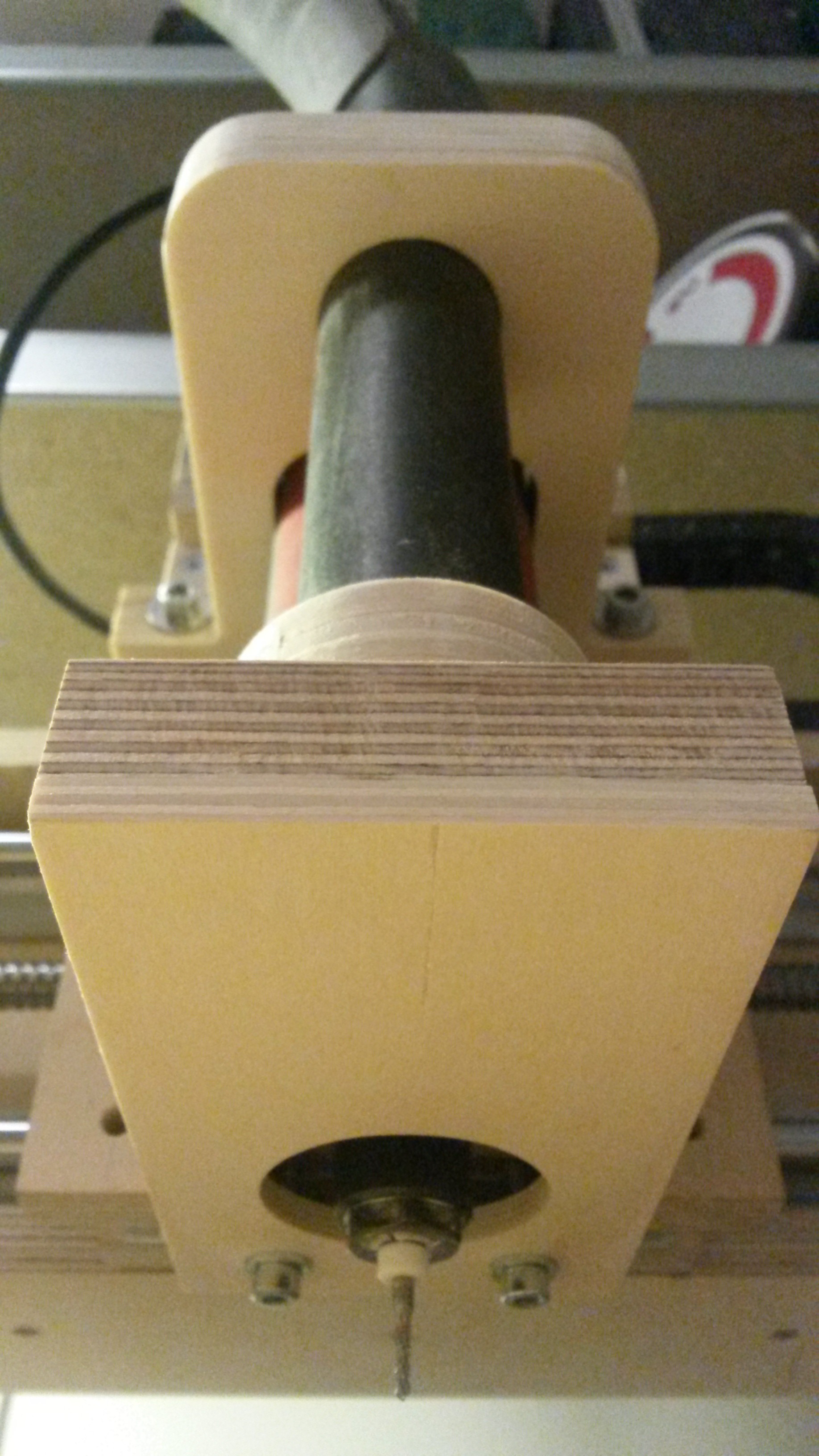

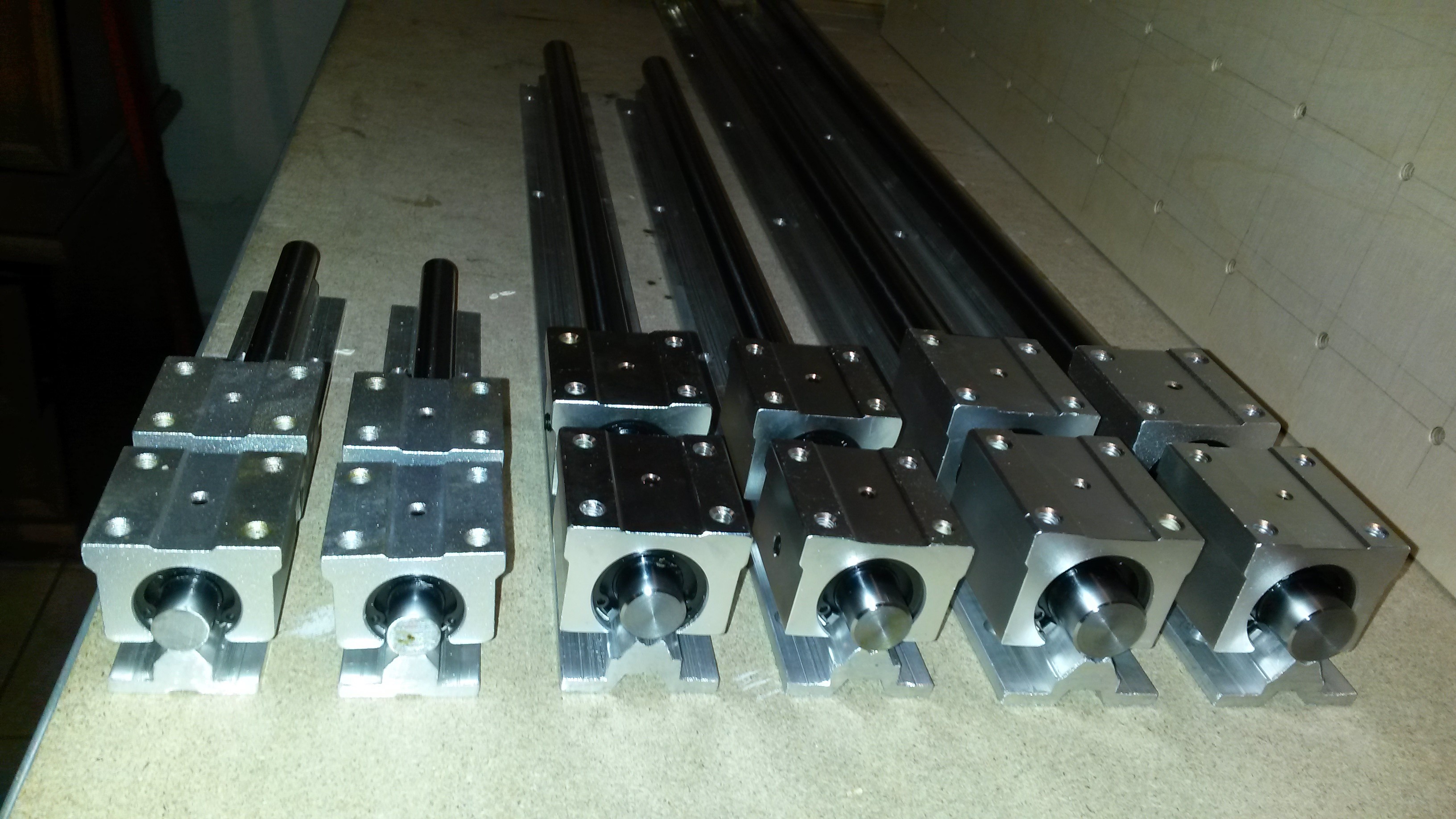

Supported rails. 20 x 800, 16 x 500, 12 x 200 mm

Nema 23 stepper motors, TBA6560 stepper driver, 300W power supply

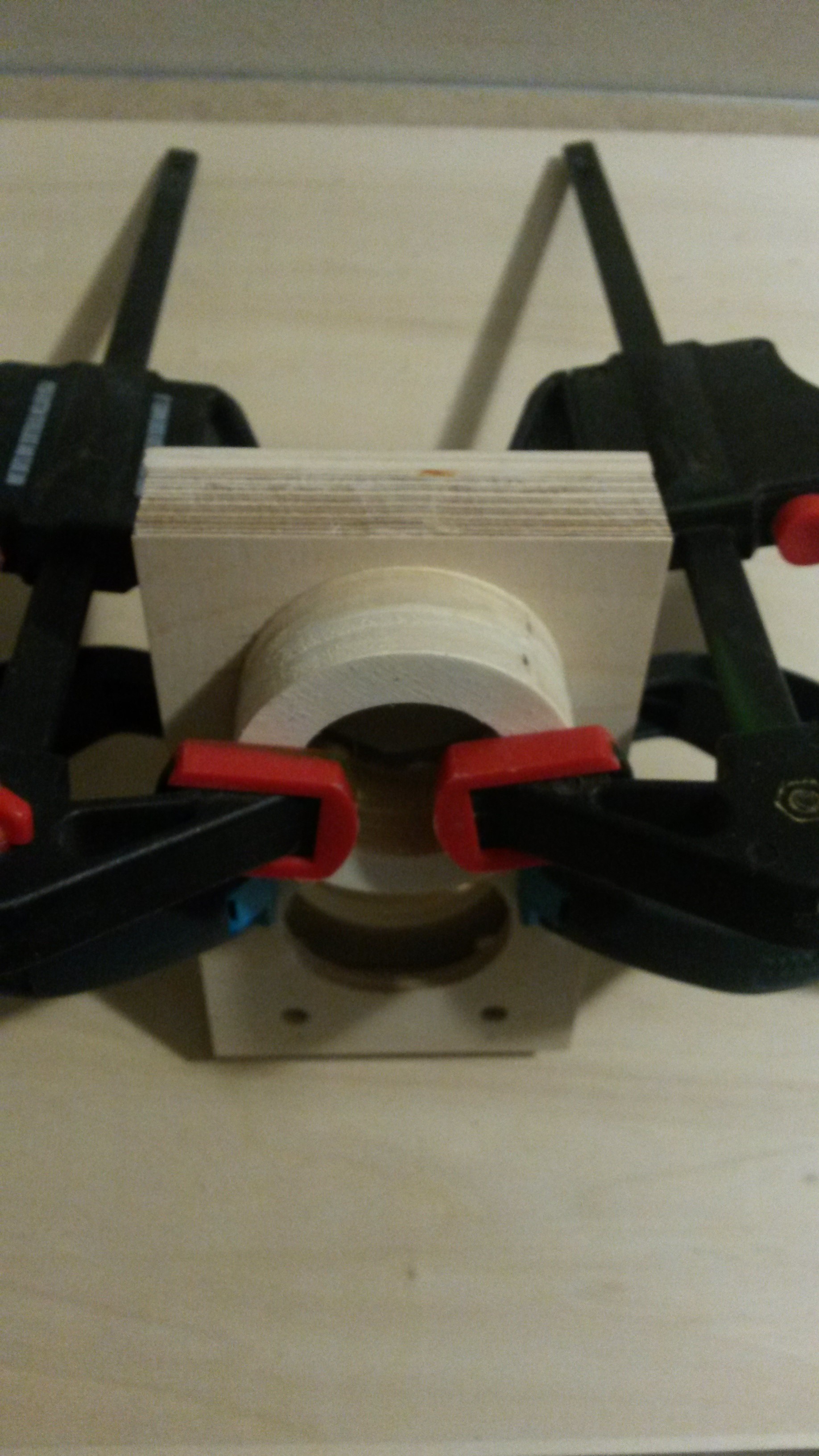

Ball screws. 16 x 800, 16 x 500, 12 x 200 mm

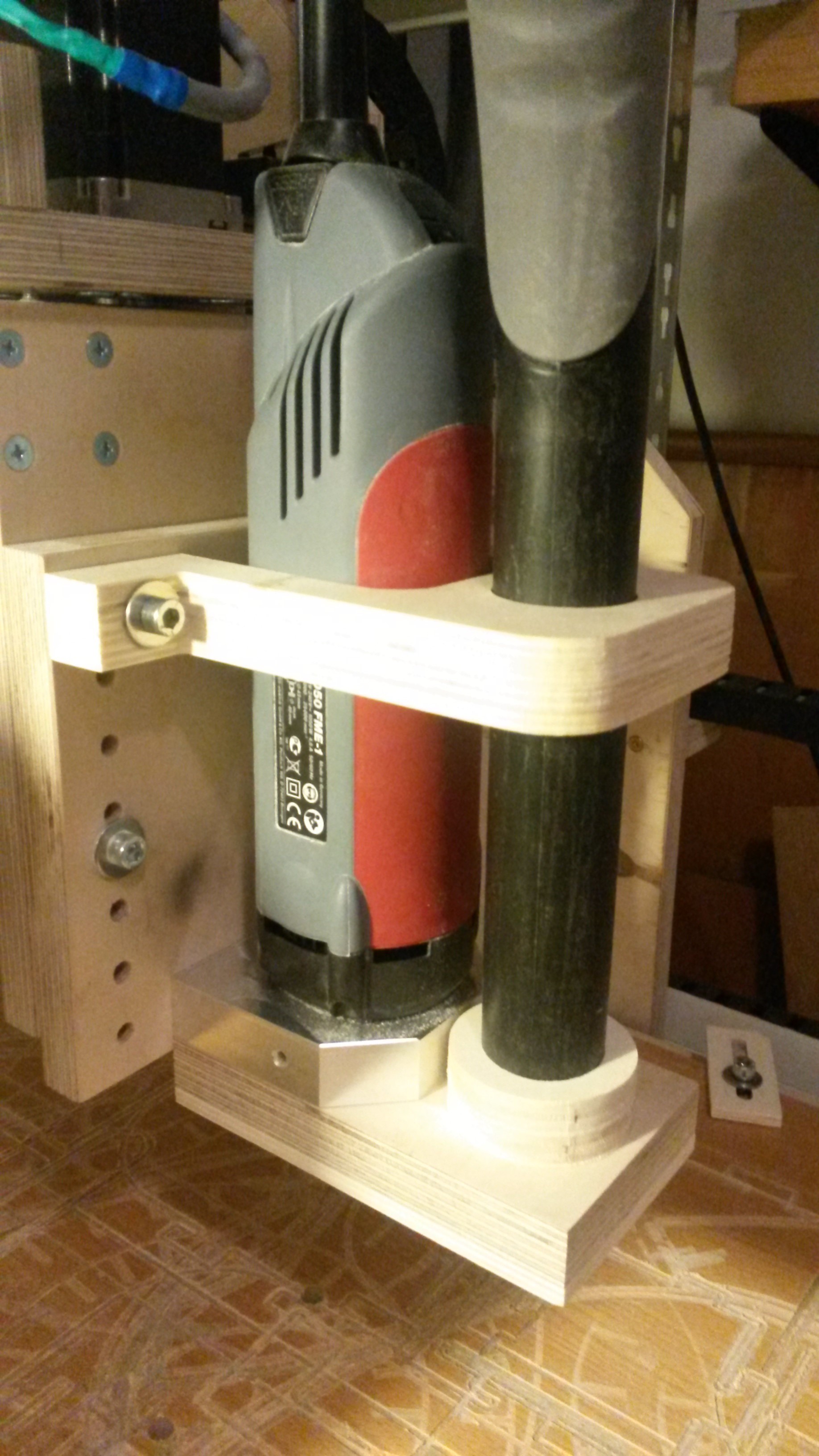

The Kress 1050 FME-1, 1050 Watts, 5000 - 25000 rpm

The Eurohals holder.

Create an account to leave a comment. Already have an account? Log In.

If you want to build a desktop sized CNC router, check out this article: http://diyprojectchannel.com/reviews/diy-smart-saw/. There is no need for expensive tools to build this machine.

^^^ $39.00 ^^^ Too many free ones out there IMHO. No need to buy.

Hi Chris, thank you for the hint with the moving-knot ! You're right. The gantry wobbles a bit about the central axis. This looks like great idea and I think i will steal it. ;-)

I have built a couple of similar machines. I like your choice of linear slides. With the bearings so close together on the longest (assuming X) axis, you may experience "racking" of the gantry. I had this issue for a long time and solved it with a moving-knot system and documented it on my website: http://cockrum.net/cnc.html

Your build looks clean - hope it works well for you.

Chris

Become a member to follow this project and never miss any updates

Great project really I like this idea and also working on it you can see here how we both are working on a similar and unique Ideas.