-

1Study of Reference Designs

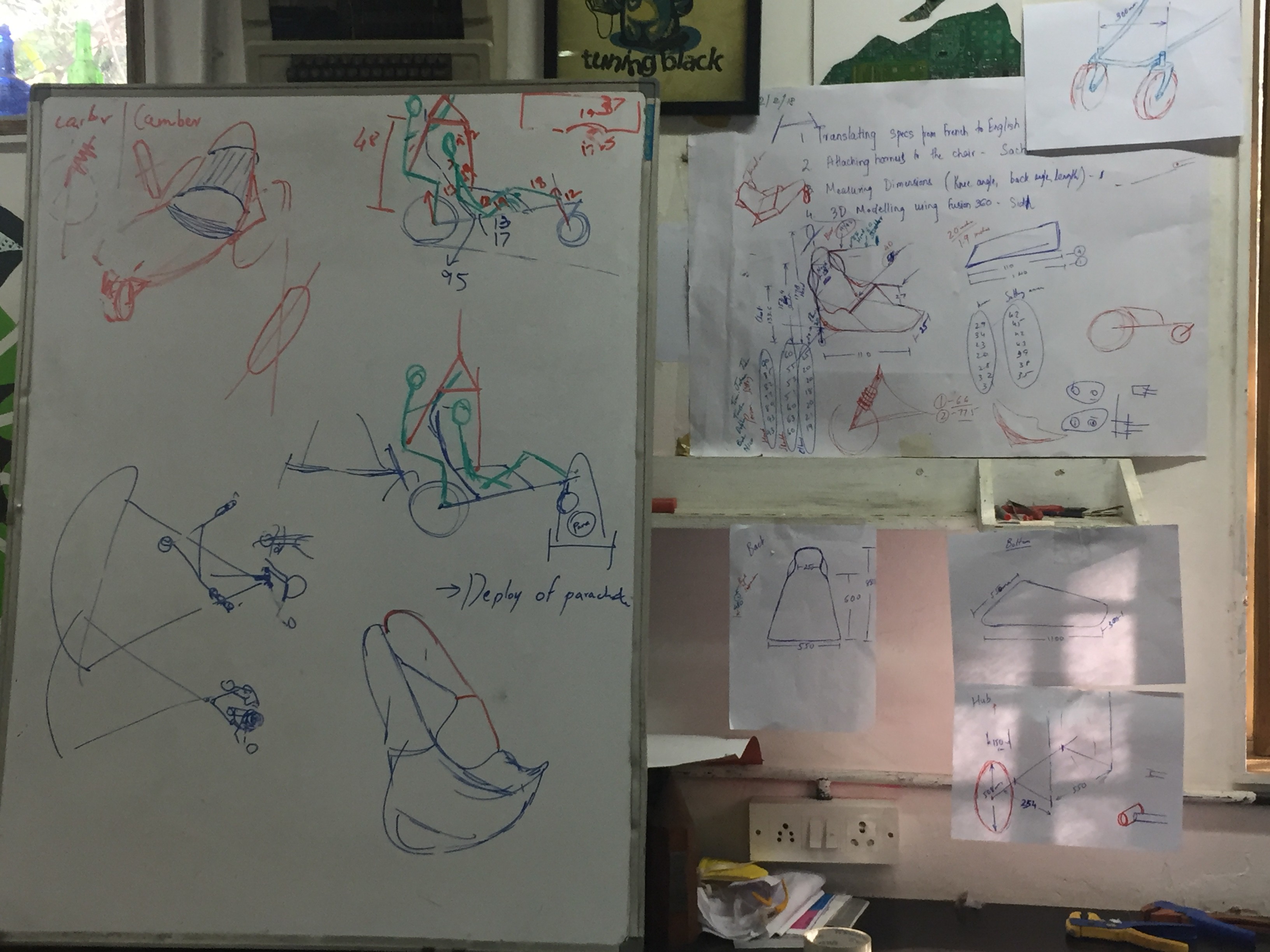

We studied various designs of the existing wheelchair models designed for paragliding, available in the market. We looked at the gliding videos to understand the lift off, gliding and landing stages. We also studied these models to understand the existing chassis structures and suspension models.

-

2Ergonomics and Dimensioning of Wheel Chair Chassis

The chassis is designed for 50 percentile male. In order to accommodate different users – we did dimensioning exercise with 7 users of varying body size.

For this we made a jig on wooden table and fitted it with back support at an angle. Then we took measurements for all the users for different knee and ankle positions. The users included 2 Indian male, 2 French male, 2 Indian Female, 1 French Female. We considered the average positions for dimensioning the chassis. -

3Line Drawings

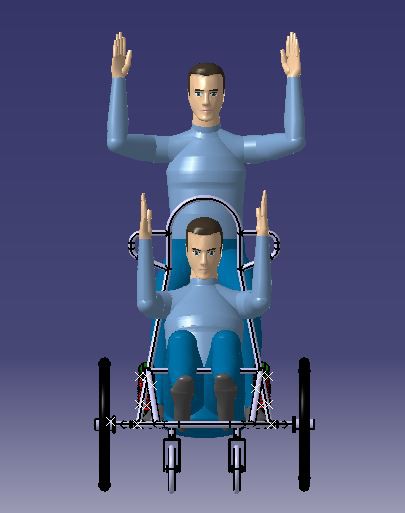

Based on the dimensions finalized, a line drawing of the wheel chair chassis was prepared using Autodesk Fusion 360 in 1:1 scale, with the pilot and the passenger.

-

4Scale Model

Based on the line drawings, a scale model was prepared using 2mm wire. We can use different things to make the scale model such as PVC pipes, electrical conduit or 3D printing.

-

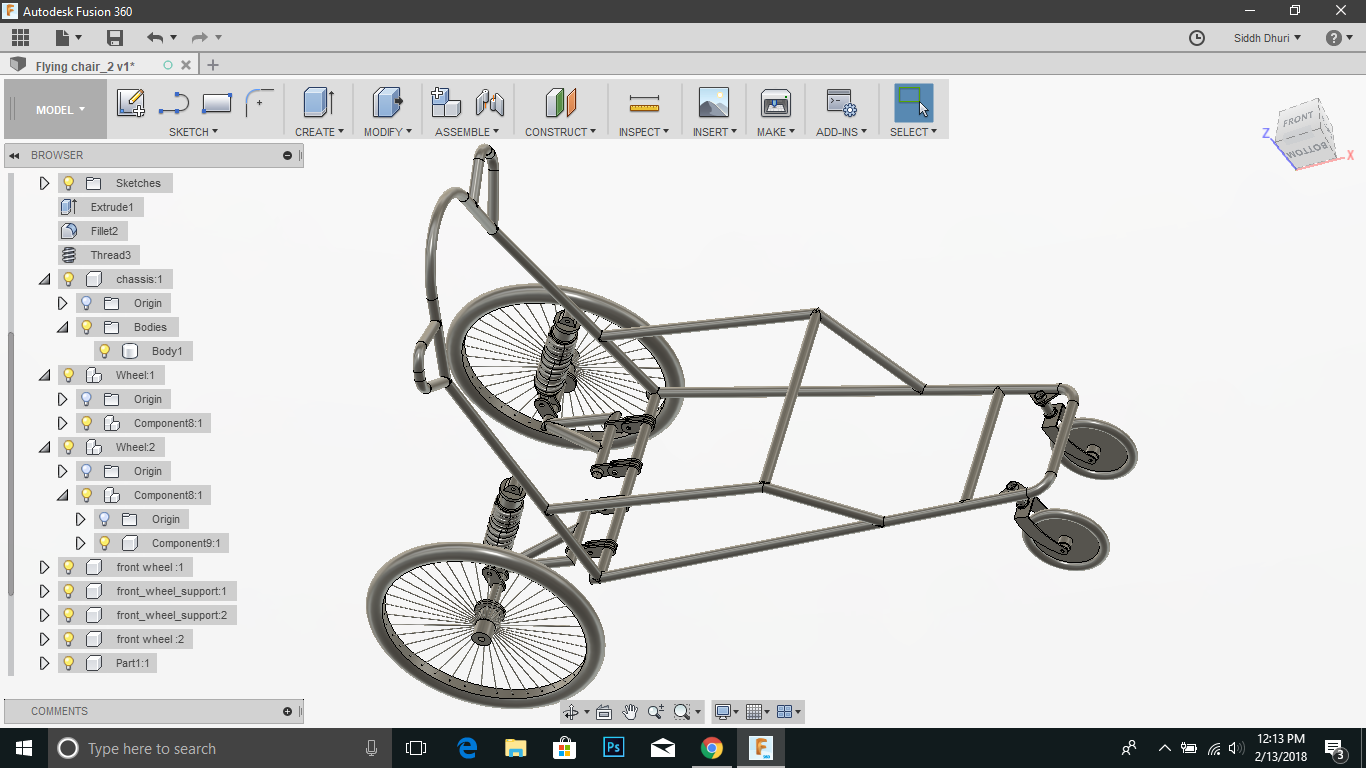

53D Model

Detailed 3D models were prepared using Autodesk Fusion 360, mentioning details about the chassis design, hubs, wheels, suspension, various joints and bends. For the 3D model we used the dimensions of the wheels [rear and front] and suspension [shock absorbers] that were available locally in the market.

We made iterations to the model to accommodate certain anomalies that were highlighted such as ensuring sufficient space for the model to spread the arms while flying; sufficient space for him to shift his weight by moving the chest and the hands; comfortable space for the pilot to keep his legs on the back side of the chassis.![]()

-

6Sourcing of components

We prepared the Bill of Material basis the components required as per the 3D model. We sourced the wheels as per the following dimensions:

Rear Wheels – 2 Wheels with Air tube each of size 20 inches

Front Wheel – 1 Wheel of 8 inches

MS seamless pipes were used for the chassisSuspension – Independent Suspension system from Bajaj Pulsor 150cc motorbike were used – 2 shock absorbers for each rear wheel.

-

7Fabrication

MS round pipes were bent as per the angle required for forming the base and back of the chassis. The MS pipes were then cut on the metal cutter as per the dimensions required and were grinded to give them curvature so as to fit on the other round pipes.

We first welded the basic chassis structure together using arc welding for MS.

In parallel to this, another team worked on the brackets which were cut as per the dimensions and attached to the chassis for mounting of the suspension. Another set of 6 brackets were placed on the side bars [2] for attaching the paraglider’s spreader bar onto the chassis. Having 3 positions allow for changing the flying wheel chair mode from tandem to solo or vice versa.

Wheel hubs were created from metal plates for front and rear and were welded to the MS pipes. The wheels were attached to these hubs using nuts and bolts. Post this, the suspension points were located and the suspension was mounted onto the chassis. With these the chassis was ready along with the wheels and suspension system -

8Harness Mounting & Simulator

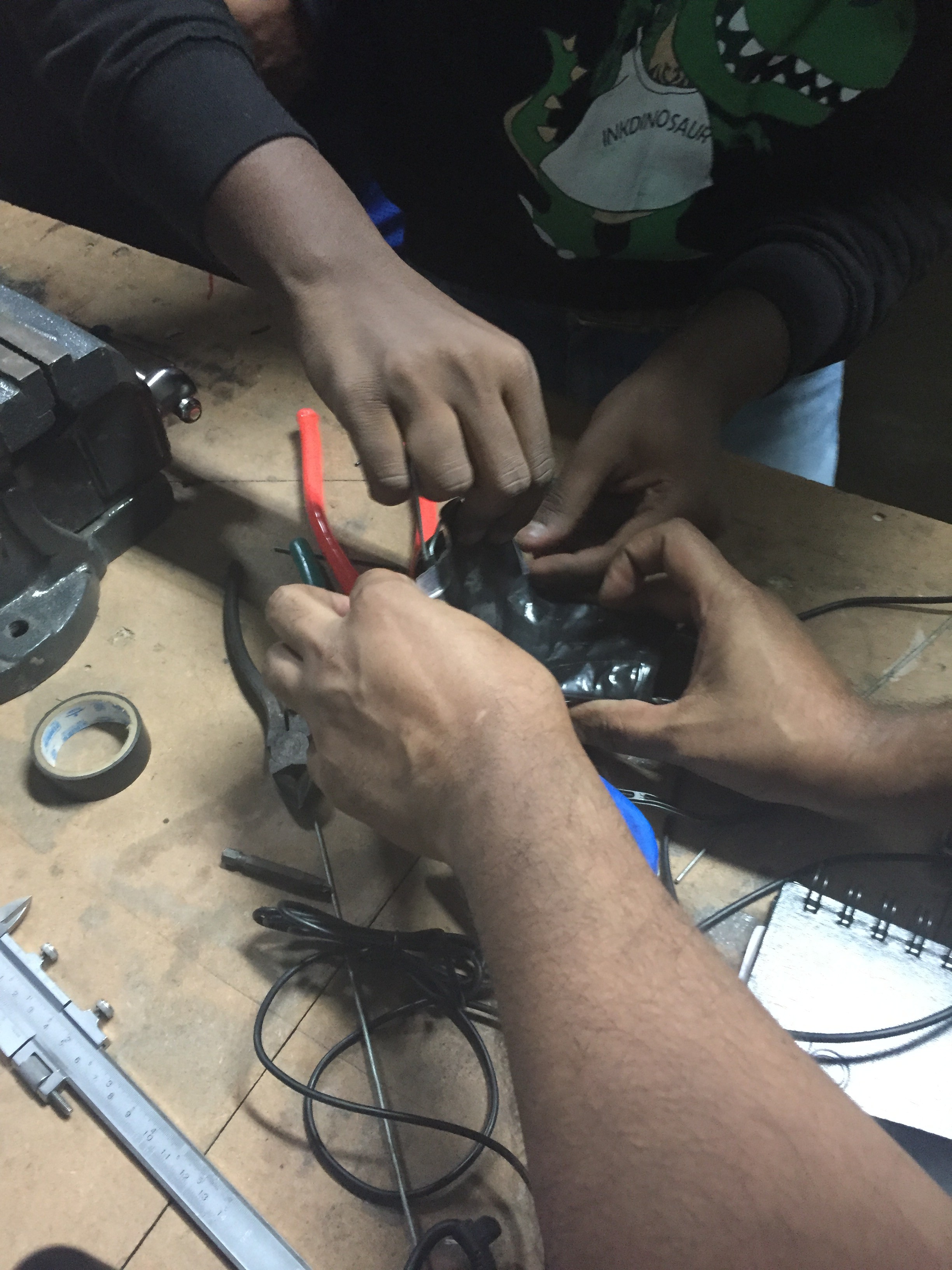

With the wheel chair ready, we placed the harness onto it and secured it by tying it with strong ropes to the chassis. We provided additional support by using short bungee cords with hooks at the ends. These cords were put from the backside of the chassis to the bottom so that it provides support to the passenger when he/she is sitting in the flying wheel chair.

Simulator: We attached 2 ropes to the ceiling to create a simulator to help us identify the exact points on the chassis where the carbineer would be attached [points from where the chassis will be suspended to the paraglider]

The chassis fitted with the harness was mounted onto this simulator and we did testing of the flying wheel chair with the passenger seated.

Fl'Air

This project will involve creating a wheelchair that is capable of sliding right into a paraglider!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.