-

HAD.com

10/01/2015 at 14:30 • 0 commentsBrian Benchoff has wrote a small article about our project on HAD.com go check it out!

http://hackaday.com/2015/09/28/hackaday-prize-semifinalist-cnc-becomes-pick-and-place/

-

Improvements

09/30/2015 at 17:39 • 0 commentsWe are back to work! We have a lot of people interested one of which requires us to prove our worth, and we always like a good challenge! To meet the expectations of the customer we have to add several new features. These new features will include the ability to place double sided boards and to have a "vibrafeed" for parts that come in tube trays.

We are working on getting this done ASAP! We are also making improvements to the error detection. We will now be able to tell very quickly if we had a part pick up failure.

Lastly, we are making changes to some areas of our computer vision. When all of this is done we will be able to reduce set up times drastically. Setting up these machines has always been the biggest headache, and we think we have the solution for it.

Stay tuned as the updates roll through!

-

Back from the Faire!

09/29/2015 at 14:10 • 0 commentsWe had a great time at the World Maker Faire! NYC was so much fun. We met a lot of great people and great makers. One thing that we ran into is that there are a lot of people who want the machine, but aren't able to back KickStarters. We've been reached out to by several academic institutions, small businesses, and large companies that want our PnP, but are not allowed to fund a KickStarter campaign.

Because we have had so much interest in our machine we will be selling it as a product weather or not the KickStarter gets funded.

If you have interest in the machine and are unable to pledge toward the KS campaign we ask that you please email us at ryan.riegel@protovoltaics.com

Thanks!

-

New York!

09/24/2015 at 14:51 • 2 commentsPacking up to leave for NYC today. If you have a chance to attend the World Maker Faire please do! Hope to see you there :D

-

01005 parts?

09/18/2015 at 23:11 • 0 commentsJust a quick update. We were testing the limitations of the machine and sucessfully placed an 01005! We will continue to test the limitations through the weeks to come. Also, we will be posting video of the machine placing 0402's, 0201's, and 01005's!

-

Hackaday prize semifinalist, possible finalist?

09/17/2015 at 18:20 • 0 commentsIt would be great to be a finalist. We know there are a lot of great projects this year! Also, we know that because we aren't fully Open Source we are at a disadvantage. However, we aren't throwing in the towel! There are several points the judges will be looking at to make their selections for the 10 finalists.

1. How open is it?

Everything but the head design and software are open currently. We might end up making the head open source, but we are at a stage where we are changing the design of the head so much it doesn't make sense to yet. As for the software the machine could easily work with OpenPNP software available now.

2. Wow factor.

I look at what is currently available on the market today, and at the cost of those machines. Then, I look at what we have done, and how fast it has come along. I'm definitely wow'd by our progress and the machine, and I hope you all are too. Remember we have been working on this project on and off only since January. We finally started really hammering down long hours on the machine in mid April!

3. Does it solve a wide range of problem?

As of now we are working very hard on the Pick and Place aspect of this machine, and this is our main focus, but we have some family in the medical field who have shown interest in the machine. The idea is they would use this machine in their medical lab to prepare samples for testing. Their are machines available currently now that can do this, but much the same reason we took on this PnP project is that these machines are very expensive.

4. Is the project reproducible and could the work be extended for other uses?

The hardware is very much all reproducible, there is readily available software, and as we said in point 3, there are other applications we will be looking into.

5. Is it innovative.

It is a Pick and Place, and these have been available for some time now, but we do believe it is still innovative. We are always introducing new features to the machine. Currently I believe we are the only PnP with 2 downward facing cameras.

6. Is it usable in the real world?

Absolutely! We were actually the first customer for this machine. We use it everyday to build the boards we currently sell on our website.

7. Will others want to continue perfecting on this well-documented idea?

We are using closed source software currently, but I don't think this will stop others from wanting to help perfect our product. We are always looking for ways to gather feedback from the community and implement ideas and features they want for the machine.

It's a great honor just being a semifinalist. To have a group such as Hackaday acknowledge your work, and tell you they think it's great, is an amazing thing. We are extremely thankful for all of those almost 150 makers who have followed our project and over 50 makers who have given us a skull!

Back to work!

-

New Head

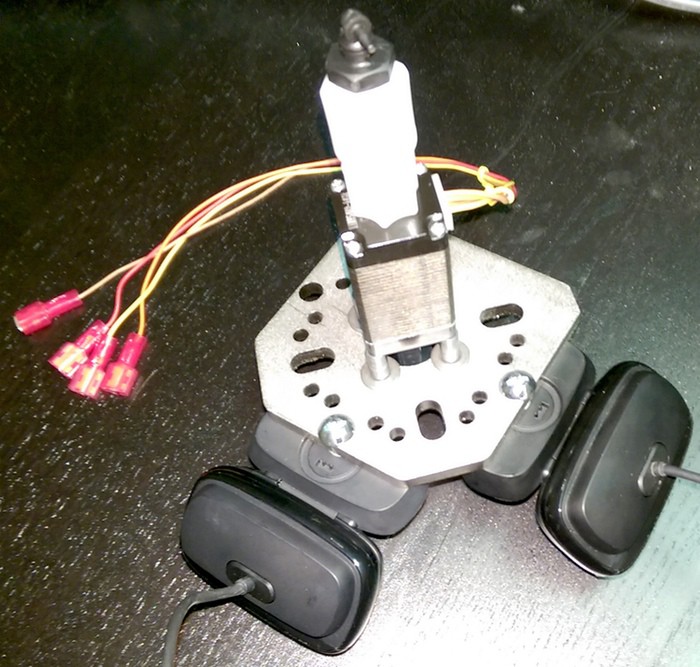

09/16/2015 at 00:00 • 0 comments![]()

This new head design will eliminate all of the backlash that we currently have. It also brings rigidly mounted cameras that will allow us to move faster. Previously, we had to run slower than top speed just so our cameras wouldn't move off target due to rapid accelerations and decelerations.

Right now we have to waste a bunch of time over the upward looking camera while we confirm that our rotational correction has been applied. This is because of the backlash in the system. The computer vision tells us that we have to rotate, say 5 degrees, to have the part properly aligned, however when we tell the motor to turn by 5 degrees it really doesn't turn 5 degrees because our belt system has slack in it. Some of the motor's movement is just to take up the slack in the belt instead of actually rotating the part. We end up needing to use the computer vision to confirm that the part was actually rotated correctly and this means having to hang out over the upward camera until the part is actually fully rotated to the proper orientation.

The new head will eliminate all of this wasted time. The new design has no belt, so we'll be able to take an image of the part, and then immediately start flying to the place location. On our way there we should get the feedback from the computer vision saying what the angular offset is, and we can correct it on the fly. This is the first major step to getting us to over 1000 cph (components per hour).

The new head has been mounted on our prototype, but we need a bracket to mount a limit switch to so that we know when we make contact with the pick-up tip. We have time scheduled late tomorrow with the laser cutter, so we should be able to start running trials with the new head design on Thursday.

We're also trying a NEMA 23 motor on the z-axis to see if there's any speed difference versus the old NEMA 17.

The last change we applied today was a new feeder divider that will allow us to reconfigure the incoming feeders for the various types of SMT reels out there from 8mm to 44mm.

-

KickStarter, KickStarted!

09/15/2015 at 11:57 • 0 commentsThe KickStarter is now live! We had a lot of interest at the Orlando Maker Faire so we decided to go ahead a launch our KickStarter and let it run through the remaining Maker Faires we will be attending.

https://www.kickstarter.com/projects/protovoltaics/pick-and-place-machine-by-protovoltaicsWe are now making the changes to increase operating speed of the PnP. We believe this will get us up above 1000 components per hour. The biggest change we are making is with the rotational alignment. We are currently rotating the parts with a stepper motor and belt. The problem is the belt has slack in it, so when we say rotate 3 degrees it might rotate 2 degrees. Due to this we have to remain over the upward looking camera to double/triple check to make sure the part got rotated properly. With the new way we will be doing this we will know the part is going to rotate 3 degrees, and we will not have to sit over the camera. We can apply the correct on the fly over to the place location.

-

Month of Maker Faires!

09/10/2015 at 18:28 • 0 commentsWe will be be leaving today for the Orlando Maker Faire which starts on the 12th! We will be attending a Maker Faire every weekend from now till Mid-October! If you have a chance to go to any please stop by!

Orlando Maker Faire --- Sept 12th, 13th http://www.makerfaireorlando.com/

Maryland Maker Faire --- Sept 20th http://makerfairesilverspring.com/

New York World Maker Faire --- Sept 26th, 27th http://makerfaire.com/

Atlanta maker Faire --- October 3rd, 4th http://makerfaireatl.com/

Pitssburgh Maker Faire --- October 10th, 11th http://makerfairepittsburgh.com/

-

Release Video

09/08/2015 at 12:07 • 2 commentsHere is our official project video! You can see it all here! Auto tool changing, multi-board placement, IC placement, small part placement, placement of caps, Software/UI, computer vision, and more. Please take some time to watch the video and let us know what you think. This is only the beginning! This is a product we will be using ourselves and we will be continuously updating the software and hardware to keep the machine as awesome as possible!

ProtoVoltaics

ProtoVoltaics