-

PCBs with an UV-laser

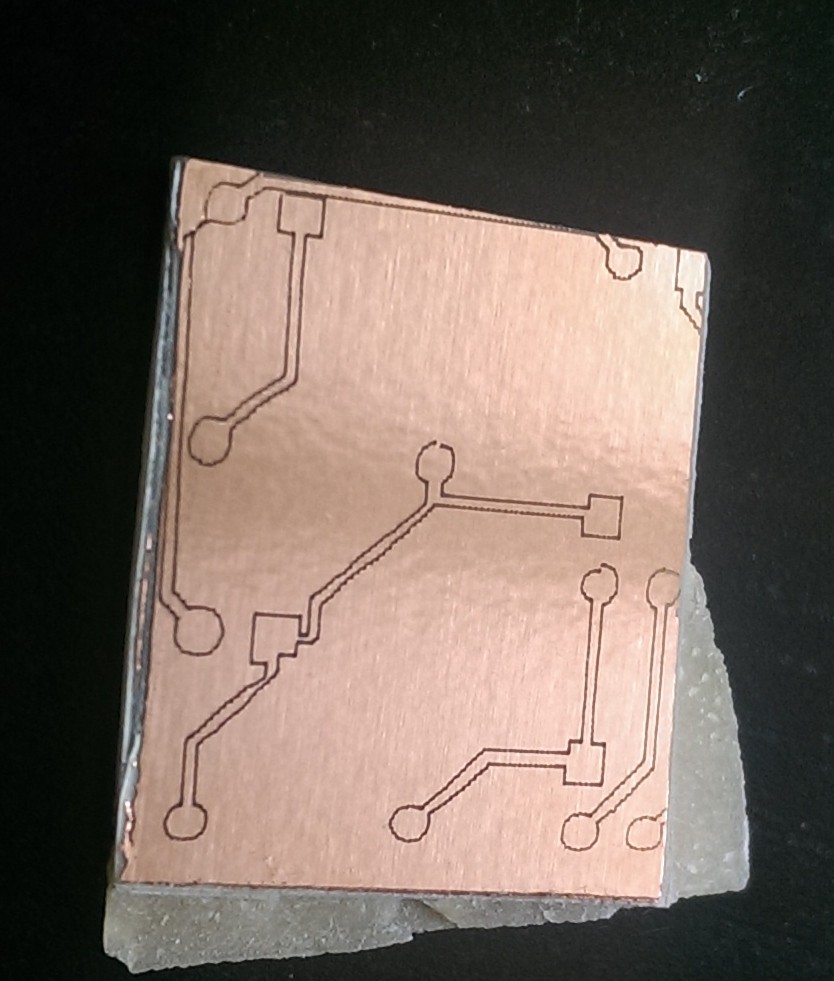

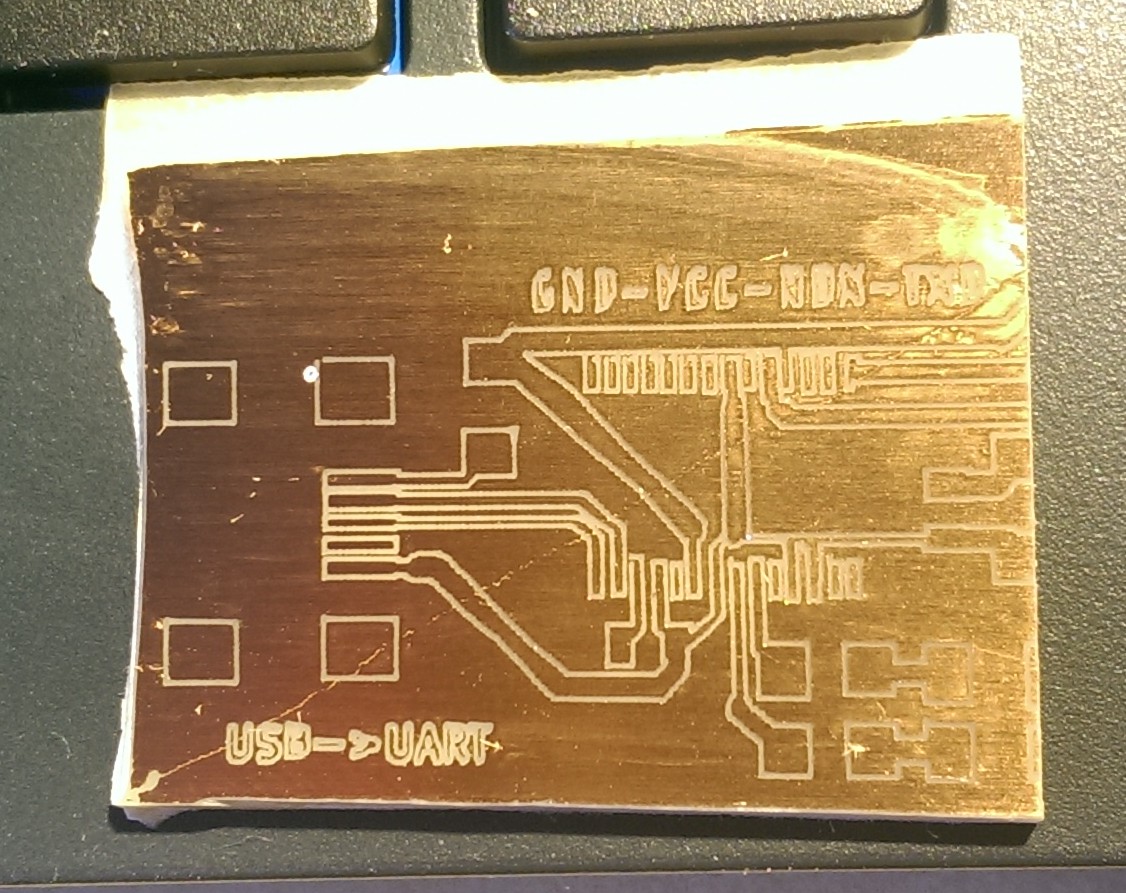

05/02/2016 at 17:46 • 0 commentsRecently I bought a 100 mW UV laser module (405 nm) with power supply (TTL capable) on eBay from laserlands.com to plot PCBs on a printed circuit board with a photo sensitive layer on it. To develop the photosensitive layer 10 - 20 mW of laser power with a feed rate of 300 mm /min is sufficient. I just bought the 100 mW laser because it already came with the TTL-capable power supply.

The first results looked promising: The lines are about 0.2 - 0.4 mm wide after removal of the photo layer with NaOH and etching with HCl / H2O2. But soon I experienced problems when it came to plot very tiny structures.

![]()

![]()

As you can see in the picture on the right, the squares (SMD SOP28 IC, 0.5 mm pitch) are not uniform. This is because my mechanics are to inaccurate / to wobbly. So as a pragmatic person I planed to build a new, more accurate plotter. The process is describes here: yet-another-laser-engraver-cutter-2

This project page will no longer be updated. All new developments will be documented on the new page.

-

The contest is on ! :)

02/22/2016 at 19:10 • 0 commentsJust participated at The best engraving with a diode laser

![]()

-

To little current...

02/08/2016 at 18:34 • 0 commentsWhile I was playing with my laser plotter this weekend and again wondering why some materials were not cut as good as I expected, a thought came into my mind: I should measure the output current of the laser power supply, maybe that is the reason....And then it hit me, the laser diode was running at only 4V and 320 mA instead of 1.4 A ! Shame on me !

I have no idea why the current was so low, I guess I did not remember correctly and assumed that I chose the correct settings when I build it, but apparently I did not.

After I set the current to 1.4 A I realized the real power of this beast !

Fabric, 5 mm felt, paper, 2.5 mm dense cardboard etc. were cut like a hot knife through butter with feed rates up to 500 mm / min ! That is about 5 times faster that before.

With this impressive power in hand I then realized that I have a new problem: All my settings (laser power / feed rate) were wrong (ok ok 1st. world problems ^^).

I then tested the diode with a new material I came in touch with at the Makerfair in Munich: Kraftplex It is a 'wooden sheeting' made entirely out of wood. I got the business card of one of the inventors (which was made out of Kraftplex 1.5 mm) and tried to cut a square out of it (S100;F40) and it worked like a charm ! The other business card with 0.8 mm thickness worked even better.

![]() Top: 0.8 mm Kraftplex, bottom: 1.5 mm. The second burned in square is from the first attempt to cut it with the lower current.

Top: 0.8 mm Kraftplex, bottom: 1.5 mm. The second burned in square is from the first attempt to cut it with the lower current. -

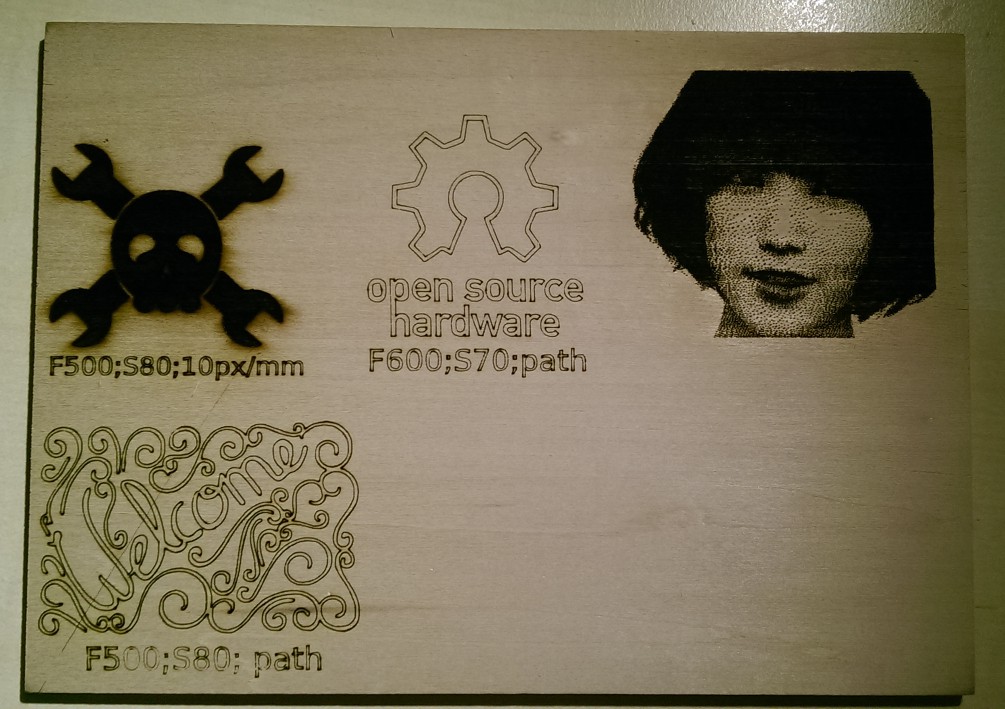

Yet another laser plotter meets Raster 2 Laser GCode generator

12/14/2015 at 20:26 • 0 commentsA view days back I found again a plugin here on hackaday.io, the "Raster 2 Laser GCode generator". It is a plugin for Inkscape to generate Gcode from images files like jpg, svg and png in different styles for laser engraving !

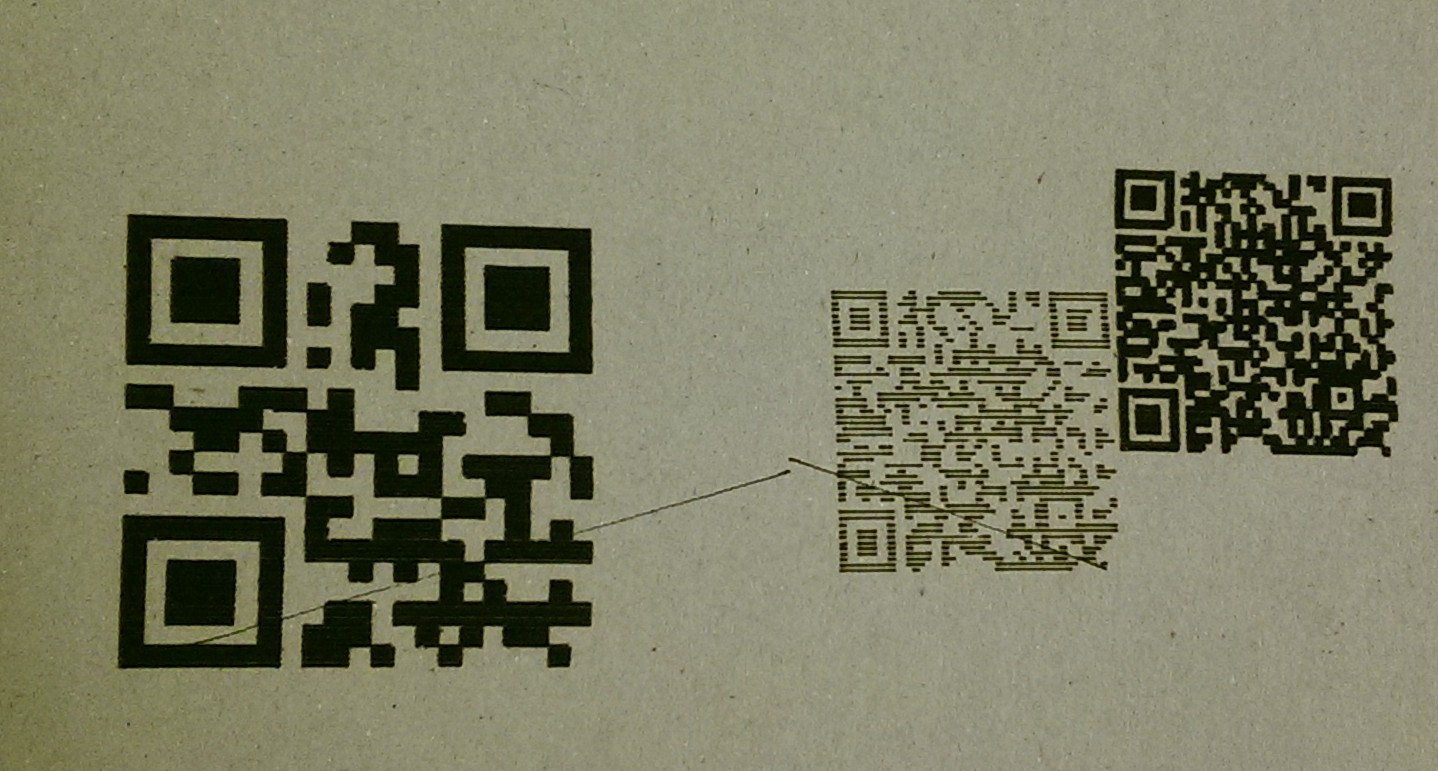

I testet it with some QRcode-images, and here are the results:

![]()

I engraved them on very thick and dense cupboard:

From left to right (1: 50 x 50 mm, 5 px / mm, S100, F200; 2: 30 x 30 mm, 2 px / mm, S100, F250; 3: 30 x 30 mm, 5 px / mm, S100, F250; 3)

As you can see, the 5 px / mm setting results in nice dark blocks. The lower setting on the other hand gives visible spaces in the dark blocks. This QRcode could not be read by my smart phone. The other two work nicely.

In the next tests I will attempt to make tiny (10 x 10 mm) codes on cupboard or wood...

-

Creative weekend

04/27/2015 at 20:05 • 0 commentsThis was a quite creative weekend. I experimented a bit with thick felt (4 mm, S100, <= F50) and cut some flowers for decoration from it :)

![]()

A nice engraving on a birthday card for little princesses ^^

![]()

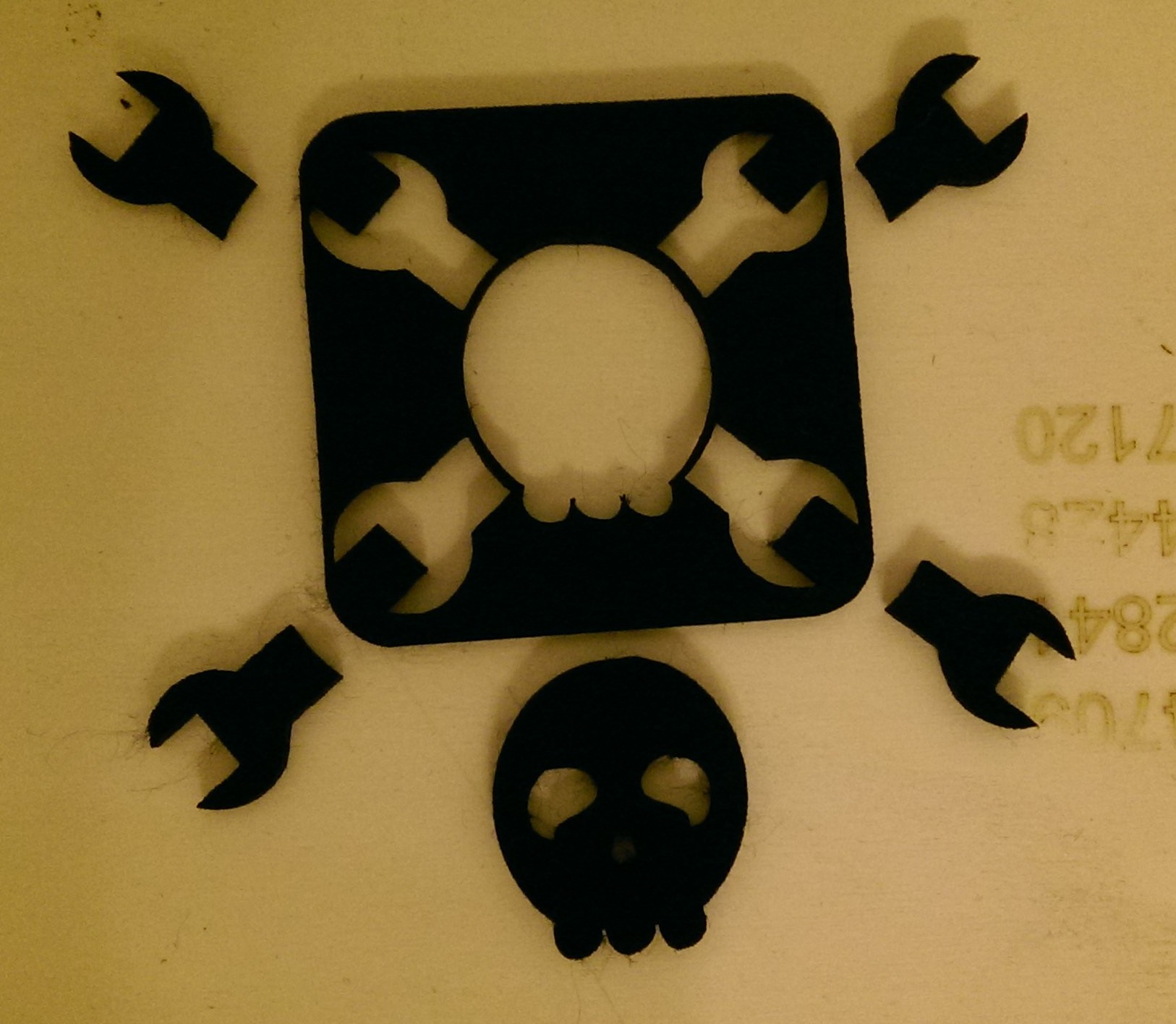

And finall the logo out of 4 mm black felt (S100, F30) we all blog and build for HACKADAY !

![]()

I added a metal elbow at the 0/0 position to have a easier alignment of the workpiece on my plotter.

![]()

Yet another laser engraver / cutter

I build a 1.6 W 450 nm laser cutter / engraver mostly from China parts.

Top: 0.8 mm Kraftplex, bottom: 1.5 mm. The second burned in square is from the first attempt to cut it with the lower current.

Top: 0.8 mm Kraftplex, bottom: 1.5 mm. The second burned in square is from the first attempt to cut it with the lower current.