-

1Step 1

The drive gears are made of 1" nylatron plastic. A very strong material with a lubricant impregnated into it. Here is the blank : 8 inches in diameter.

-

2Step 2

Using a 1" wood drill bit and hack saw and a belt sander I formed the main drive gear. Several hours of work and viola a gear.

-

3Step 3

The Track was split down the middle. Using a zip cut disk and lots of time I was able to produce two mirrored tracks.

-

4Step 4

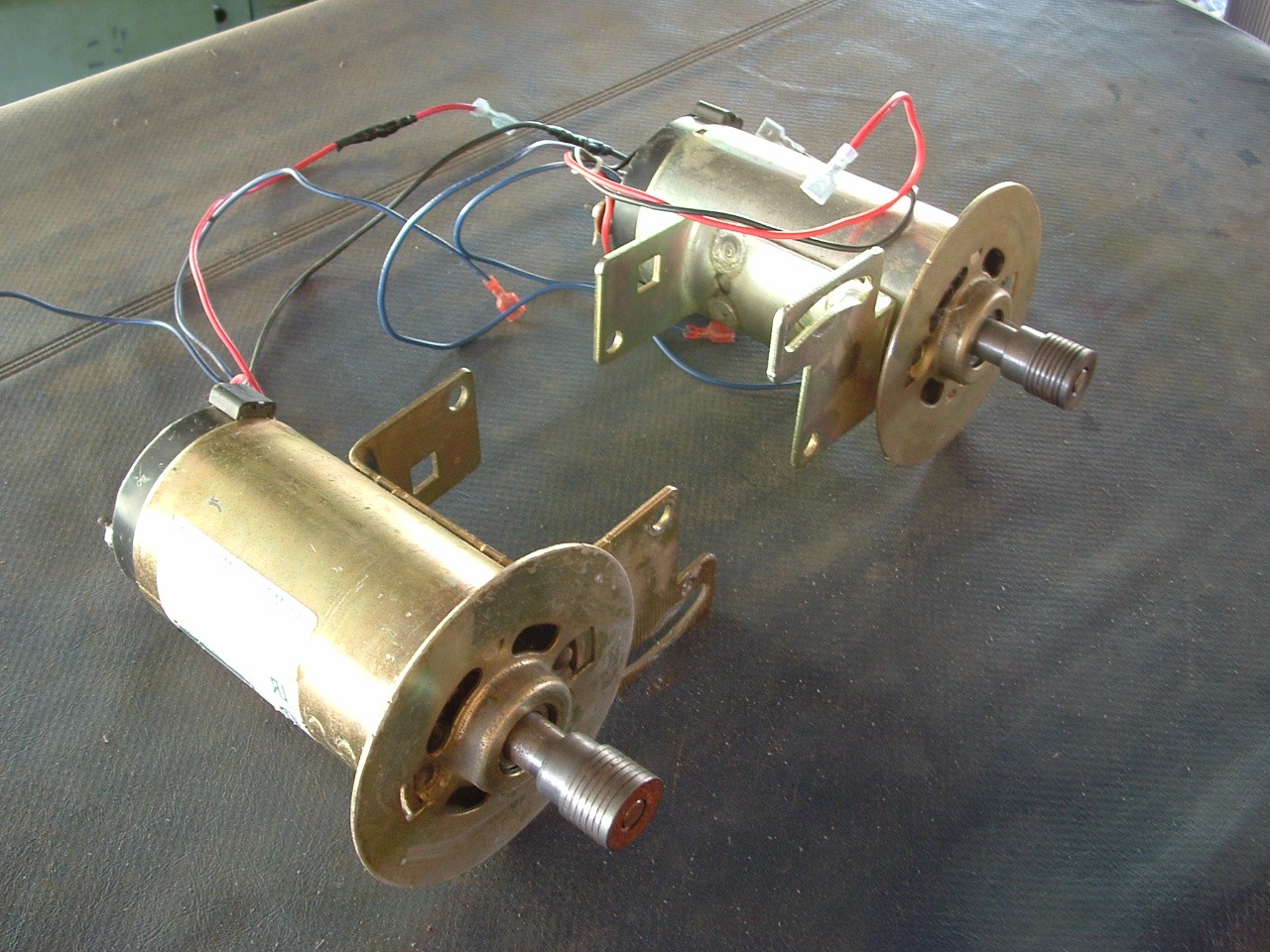

I will start with two modified treadmill motors to power the mover. The cooling of the motors is important and the fans, flywheels will be replaced with a better system.

Here you can see the heavy flywheels have been machined off.

-

5Step 5

These motors combined will develop 3 hp at 3600 rpm.

-

6Step 6

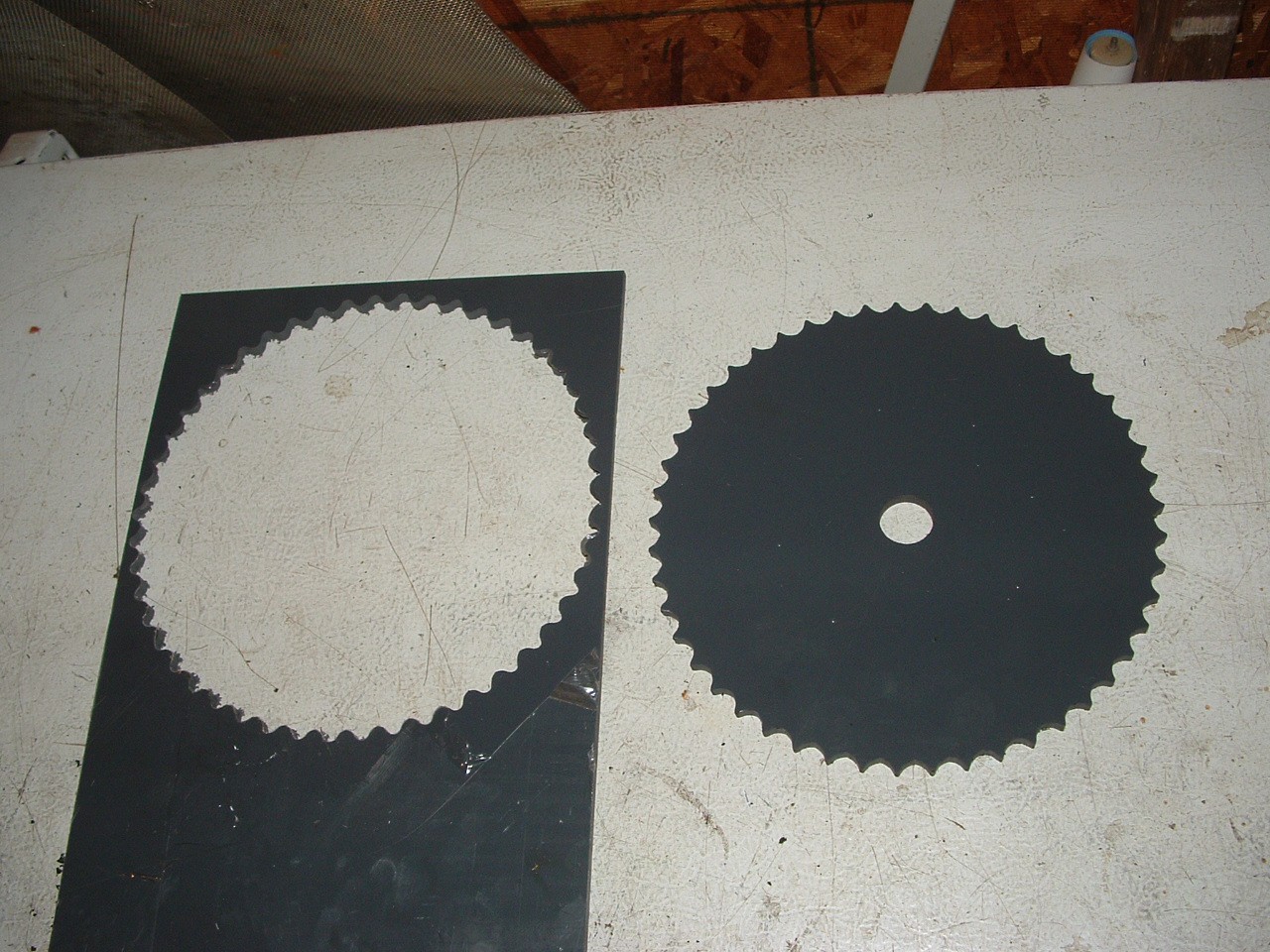

The drive motors will be connected to the main gear by a 15.9 to 1 reduction. Here is the first cut done on my cnc machine.

Here the machine is cutting a 40A49 sprocket from 1/4 " nylatron flat stock. This material is strong and cuts easily at low speed. I am using a 2mil end mill cutter.

-

7Step 7

The finished sprocket finished in 23 minutes.

Two sprockets and I move on.

-

8Step 8

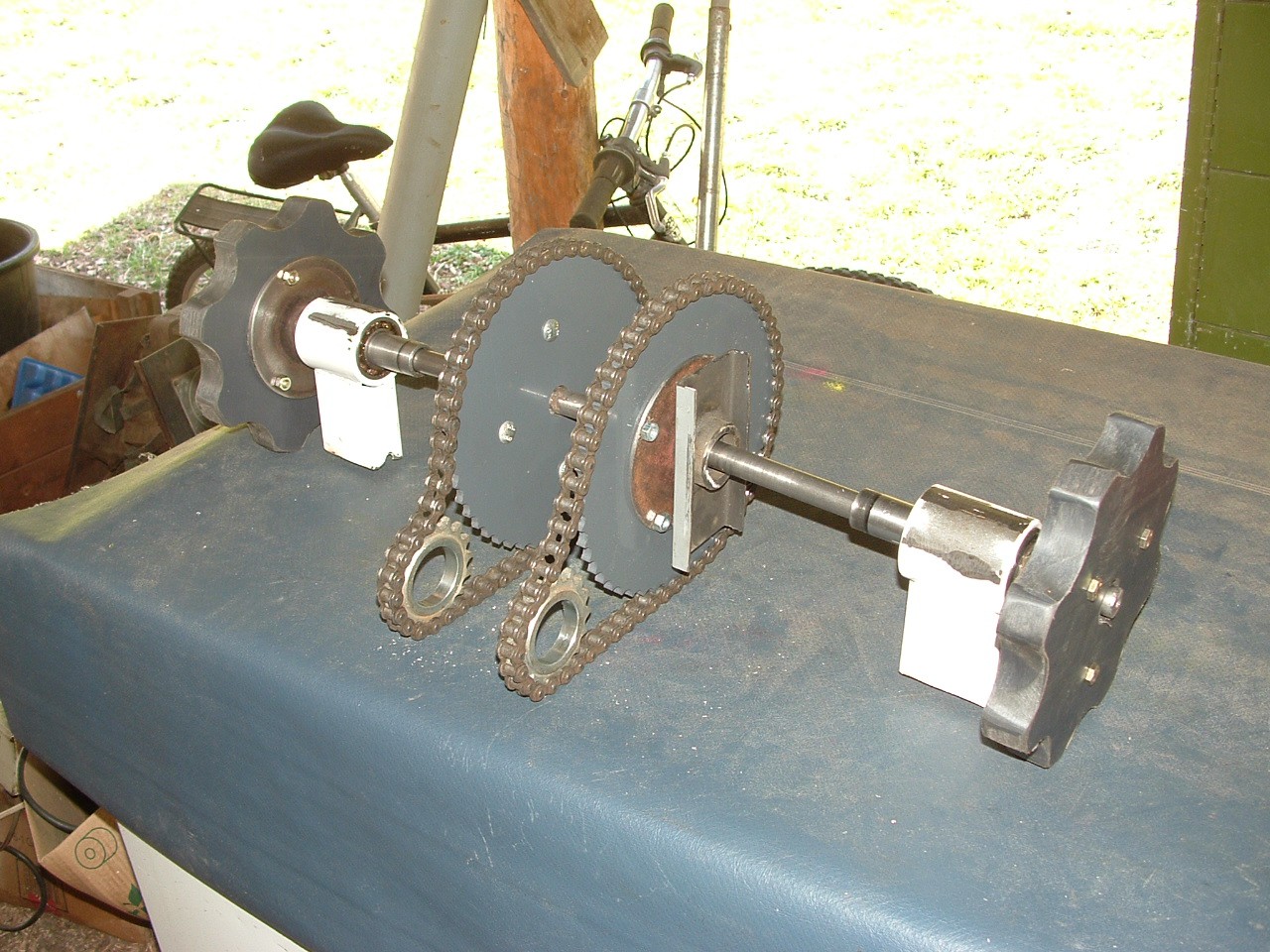

The are the hubs partially assembled.

-

9Step 9

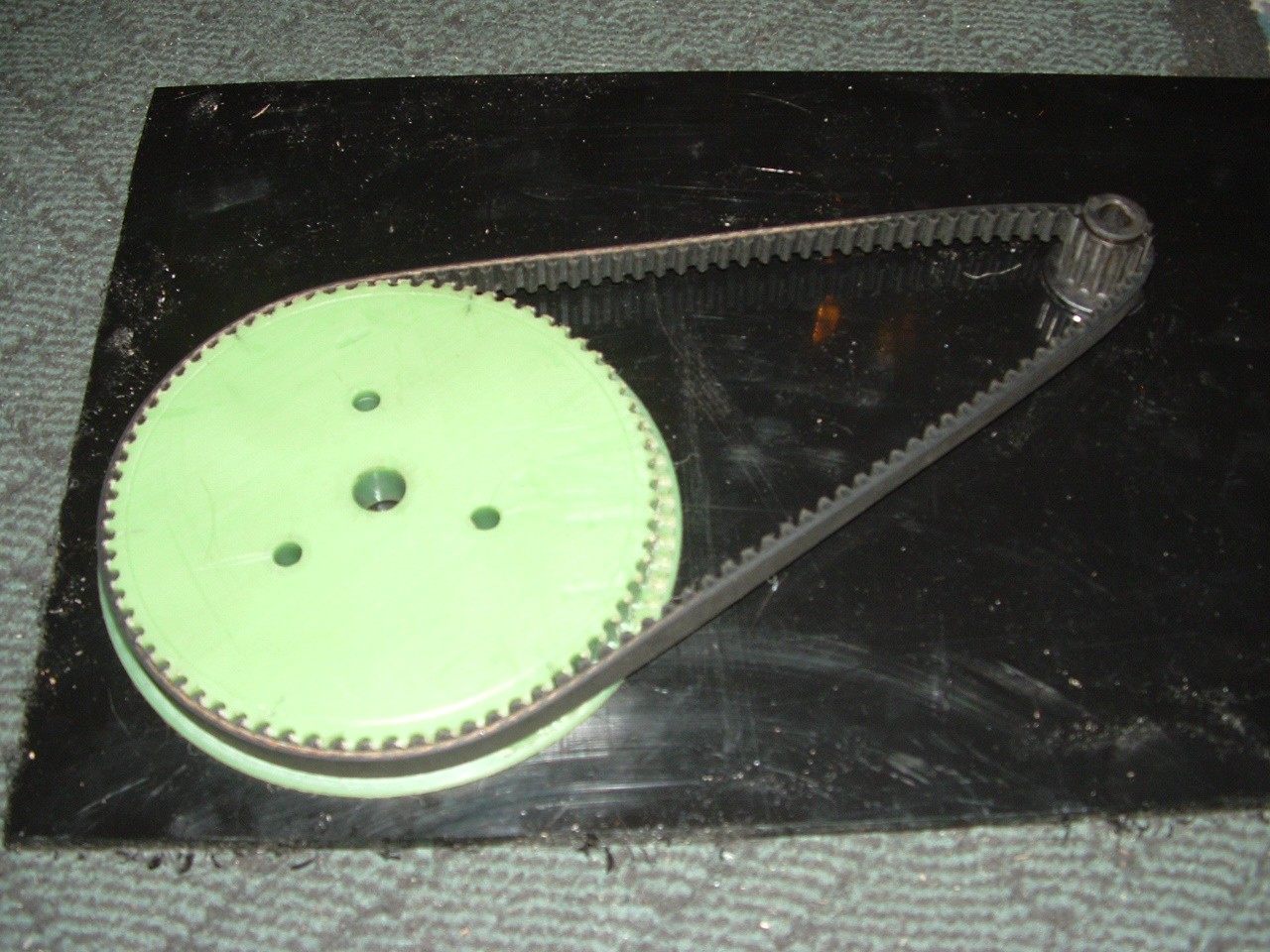

Here is the second reduction gear assembly. The motor pinion has 13 teeth and the green nylatron has 72 teeth. This reduction is ~ 5.54. Total 5.54 X 2.88 = 15.9 : 1 .

-

10Step 10

Track Mover Speed Estimated:

0 to 7.386 MPH

6200 Motor RPM / 15.9 gear reduction = 390 RPM Main Drive Cog.

390 RPM / 60 = 6.5 RPS

6.5 RPS X 20 " Cog diameter = 130 Inches per second

130 inches per second of the track = 7.386 MPH

Average walking speed = 3 MPH

Track mover

This project will use old arctic cat parts to evolve into a personal tracked mover..

Joseph Lavoie

Joseph Lavoie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.