-

S I M P L I F I E D

09/16/2017 at 21:02 • 0 comments---------- more ----------S I M P L I F I E D

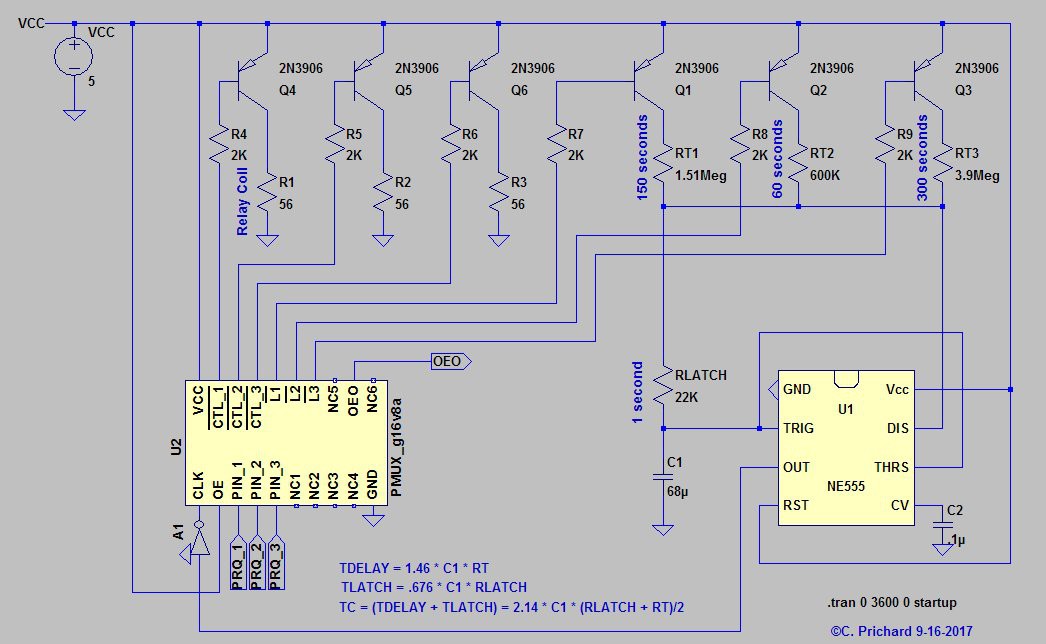

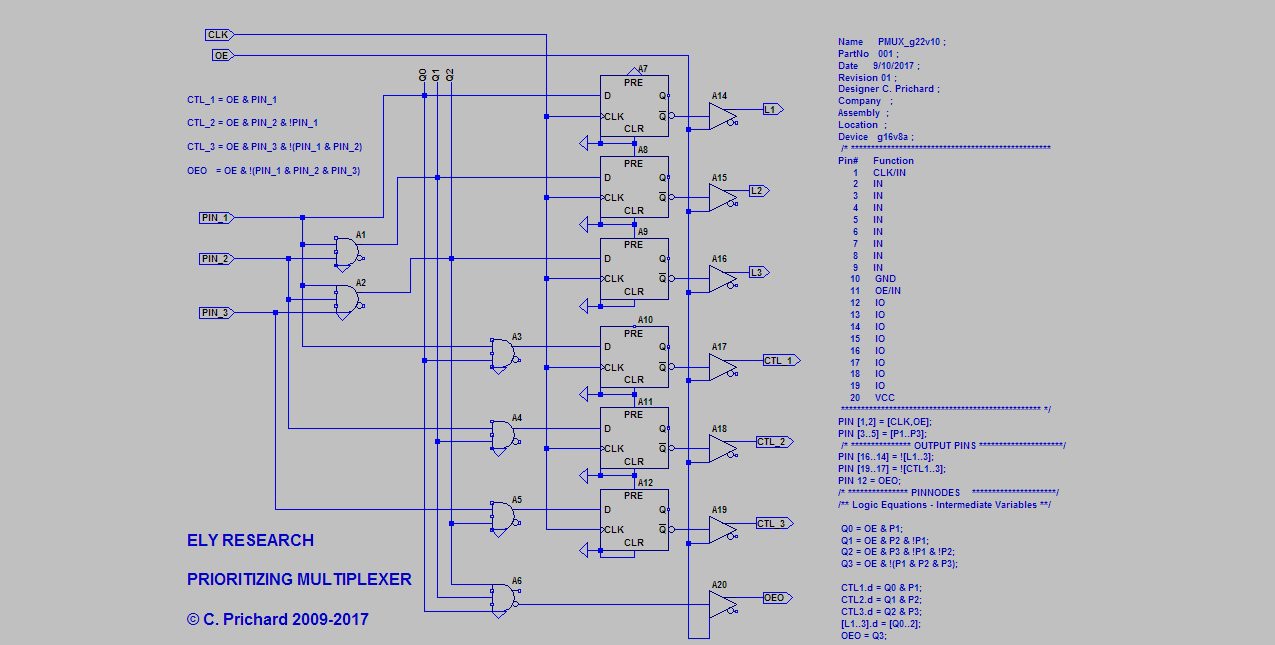

g16v8a PLD makes this a much easier project.

![]()

![]()

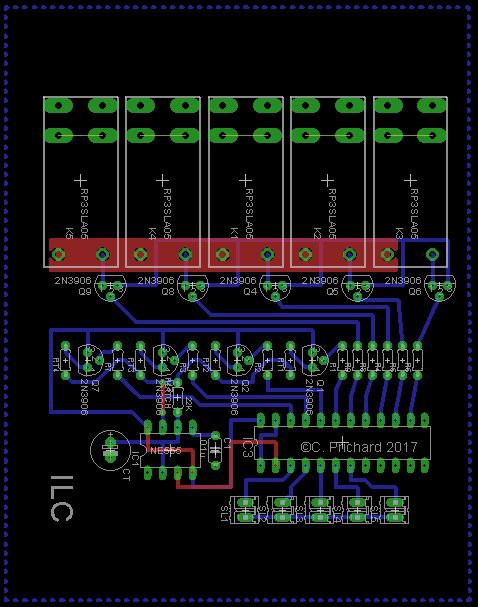

New layout coming...

![]()

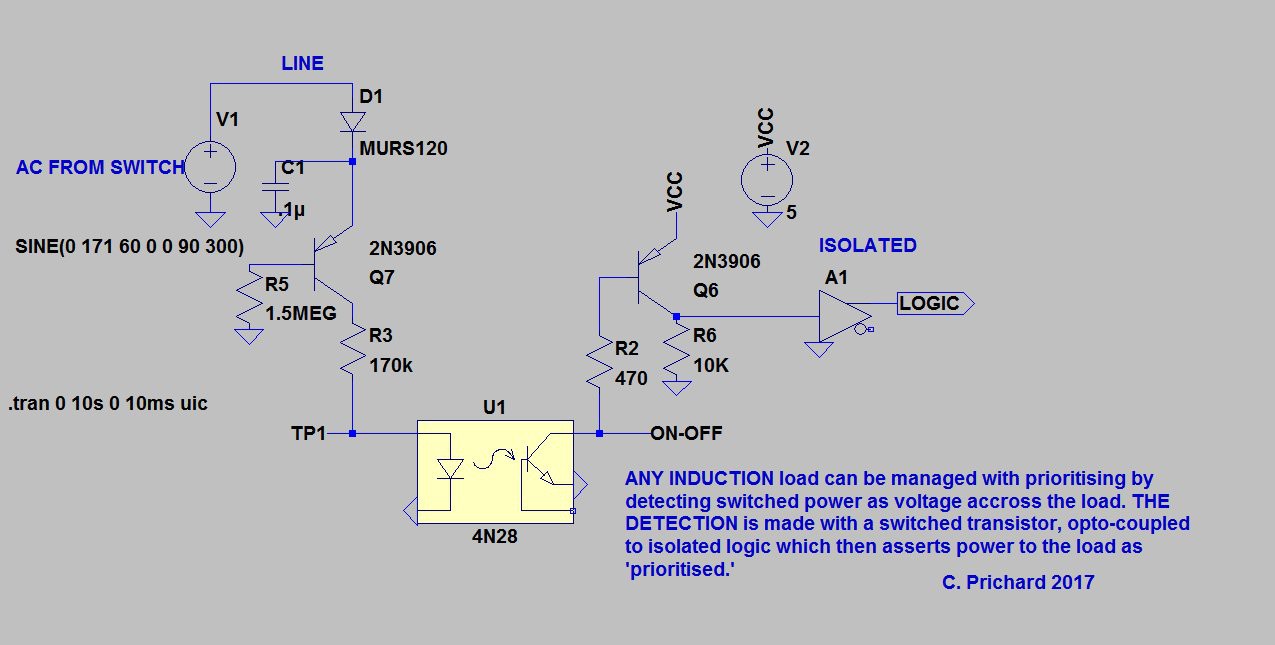

ISOLATED INPUTS to logic component. A REFRIGERATOR, septic pump, well pump, ... dedicated devices can all be handled in this manner, intercepting the switched AC as a signal, asserting logic to then determine the demand is valid & the highest priority made at a given time.

![]()

SHOWN IS my #1 prototype candidate, using the 22V10 PLD. CLOCKING ALLOWS low priority tasks to be completed without interruption.

-

Dual Purpose Circuit

08/14/2015 at 17:34 • 0 commentsUPDATE: 9-11-15

Prioritized Production, or processing of any kind can possibly benefit by using a controller to automate which "jobs" are placed into sequence. In this application, the processing is limited, filling in low priority "jobs" even as higher priority "on demand job processing" is most profitable. The circuit for the Inductive Load Center can be applied to control automated gates to a conveyor system...

Prioritized Zonal Heating seems a perfect second application for the circuit that prevents concurrent switching of inductive loads..

Prioritization can restrict power to manage slab heat, circulating glycol where needed. Winter heating of the insulated garage can be minimal, low priority. A basement, and two other areas can be prioritized. Using one circulating pump, valves can be controlled to save energy.

The Zonal Heating application application would use the same circuit, easily configured for different delays.

An interesting possibility could be explored in programming, considering the temperature differential between the desired value, and actual. Controller response might vary with deviation from settings to put actual temperature back within tolerances. This would only be possible if adequate heat source is available. Software can expand on prioritization, to provide improvement. If this the Zonal Heating application can be improved with programming, it may be easier to find additional applications, approaching them similarly.

-

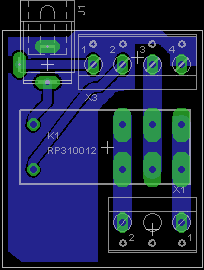

Schematic and Board

06/23/2015 at 14:32 • 0 comments![]()

![]()

Pins 1, 2 are used to loop the ground connection from the 12V power input to pressure switch contacts, and back to the relay. When the pressure switch closes, and relay is energized, AC power switches from Pin 3 to PUMP 1 connected to X1 - 1.

The device, approximately 1.5x1.5 inches can be encapsulated with pigtails, or made in such a way it can be mounted on/in an electrical enclosure commonly used in construction.

A version with softstart may be useful, guaranteeing the relay cannot operate for a period of time, or until an input enable signal is received.

I could call it an "EXCLUSIVITY POWER SWITCH" or "NON-CONCURRENCY SWITCH." The switch shown is rated for 16 amps.

-

Simplification

06/22/2015 at 16:57 • 0 commentsWiring my cabin for state inspection, I realized AC neutral will be bonded at Earth potential. Design simplification will be to connect the AC neutral wires, and switch only the 120VAC power (black,) lines. The switch component can be an SPDT switch, the normally closed side connected to my septic pump. This will simplify the design, and installation.

That AC neutral is bonded to Earth for safety anyway, precludes thinking there may be a "safety reason" to switch BOTH hot and neutral lines as in pump switches...

I guess it is useful to look at connecting the deep well pressure switch directly to the SPDT relay. When triggered ON, the well pump operates. Otherwise, power is connected through the normally closed connection to the other (septic pump and sensor,) pump. This design uses no logic, or one-shot timing pulse and will mimic functionality of a grid-tied system that allows both pumps to operate simultaneously. One will hardly notice any difference.

I'll try this first, as it is simple, and it may be in existence in some form. I'll draw the schematic in EAGLE and look at doing the board. An ample 12V wall wart supply could be used to provide power for the SPDT relay which will also be wired directly to the pressure switch.

Right now, my new installation has each pump connected to its own 15-amp breaker in my main panel of six. Simplification, and use of my idea to wire the SPDT switch will allow use of a single breaker, and eliminate having to pay attention, keeping the water switched off to avoid startup conflicts.

C. Prichard

C. Prichard