-

Whats new? 7 Watts !

03/16/2016 at 16:05 • 5 commentsThe device actually makes electricity !.

7 Watts.

That might not sound like a lot but in the land of the blind the one eyed man is king. If you happen to be on a deep space mission & have 7 Watts instead of zero watts you would be a very happy person.

Similarly, for the 'prepper' community, 7 Watts, 24 hours a day from any heat source will be very useful.

But 7 Watts is just the start. This was the first trial run with a basic magnetic assembly. The displacement is small at about 2mm. We are looking at ways to multiply this by orders or magnitude.

We have a friend who happens to have a suitable solar collector. We are now just waiting for some decent sunny weather to see how the solar version works.

I think this has definite commercial possibilities. Once you know how, it is easy to make. It is entirely maintenance free. There is no doubt that it will eventually make a lot more than 7 Watts. It would even make an excellent executive toy..

Noise is something of an issue but we can solve that with a clever casing..

This particular project is badly written up but I will fix that (in the very distant future). This device is beyond cool. Shocking that NASA gave up on it. The potential is huge.

-

Update Feb 2016

02/26/2016 at 13:21 • 1 commentWe finally got the device to work.

The problems identified were rather simple. We made the hot cap & Displacer ourselves. They never felt correct. We eventually sourced some off the shelf parts on amazon that were perfect for this purpose. With the new hot cap & Displacer we got some movement. We then made the grooves in the Beryllium copper membrane bigger & this got us proper movement...

Just now, we are making the magnet assembly so we can convert the movement into electricity. We will then run tests to see how efficient the unit is.

After that, we will add a solar collector.

When complete, the device will be wonderful because it can run on solar power during the day & any heat source during the night. What we have is a device that solves the problems of overcapacity caused by solar panels, windmills etc..

The device can produce electricity 24 hours a day simply by switching the heat source from solar to gas, a simple flick of a switch..

The elephant in the room is efficiency. I expect we will only be around 5% efficient now. However, I will not worry about that until we have measured efficiency, hopefully in March. Pics do not really show anything about the device. Things become more clear with a video. I will post one once we have added the magnet assembly on the top..

Very happy we finally got this thing to work, it has been very channenging...

-

January 2016

01/16/2016 at 11:42 • 0 commentsI had very little time to work on the device but finally made some progress last week.

2 fundamental problems were identified.

The engine is mounted to the frame via springs. As vibration is important to the entire device, we realized that this connection via the springs needed to be firm & tight. That was fixed.

The second problem is with the hot cap & displacer. The gap between the two should be small. However, our gap is far too small. The way we fabricated the devices was also poor. With a bit of online shopping, we discovered we can buy ideal cans off the shelf to use as the hot cap & displacer.

Now, we just have to wait for the parts to arrive. We will try to do a bit of work on the magnet assy to go on top of the device while we wait for the parts. Fixing these 2 basic things should tell us if the hard things we make like the planar spring & beryllium copper plate are good or bad.

This thing is simultaneously amazingly simple & deeply complex. I will be very happy if we ever get it to function.

This note is just to say the project is ongoing

-

Still not working

09/08/2015 at 11:57 • 0 commentsWe tested the device again using the new Planar spring & new gaskets. Unfortunately, it still does not work.

The Planar spring is connected to the displacer using 3 screws. Unfortunately, the heads of these screws are too big. When the displacer pushes the spring upwards, the heads of the screws touch the bottom of the sealed chamber... This is a very precise device, any slight touching like this causes it not to work at all.

The problem is easily fixed (screws with a smaller head). However, I fear this is not the only problem. It seems likely that each time we fix one problem we may identify a new problem. But, eventually, we will get there !..

-

Free Movement

08/24/2015 at 23:27 • 0 commentsWe have reworked the displacer & hot cap so we now have free movement.

The reason for filling with water is to ensure both are airtight & that we did not have any little holes left from welding.

We need some new rubber gaskets as the ones we are using are not perfect. Once we get them, we should be able to test the device...

-

New Planar Spring

08/22/2015 at 16:01 • 0 commentsOur first attempt at a planar spring resulted in a bent & warped effort.

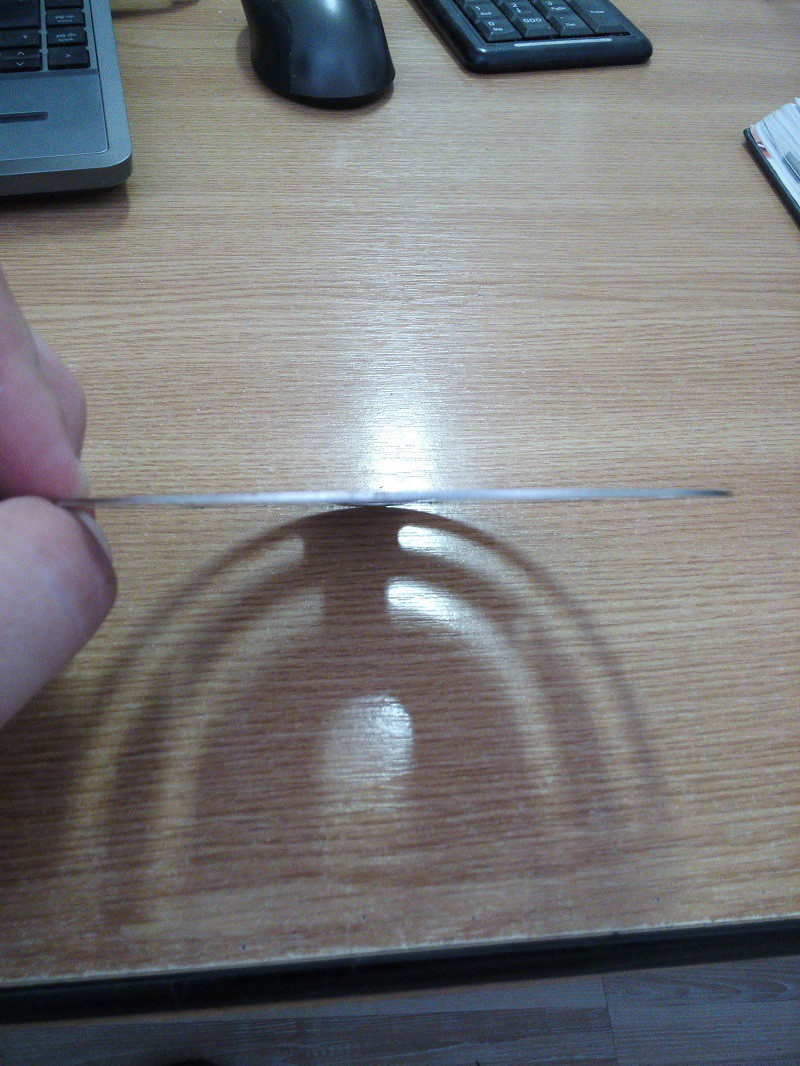

The new spring is fabricated using a water cutter from CS80 hardened & tempered spring steel strip, 1mm thick. On the Rockwell scale, the material is rated 42/44

![]()

![]()

As can be seen in the pics, the new spring is completely flat.

Next, we will fix the issue of free movement of the displacer & post a video..

-

August 12th 2015

08/12/2015 at 12:27 • 0 commentsThe project to date is very poorly described. We have been working to fabricate the parts. For such an apparently simple device, fabrication has been very difficult. Parts can be seen in the video below.

There is a strong metal ring. You can see that this has 3 springs attached. These 3 springs sit on a frame. The frame is visible at about the 30 second point in the video. At about the 4 second point, you can see we also have a regulator attached to the big structural ring.

You can see the hot cap & this is screwed to the ring with 12 screws.

On the reverse side, there are 24 screws holding the beryllium copper membrane in place (sourcing Beryllium copper is hard, we found some at a very specialist UK online shop). Forming the Beryllium copper to the correct shape is even harder but that is for a different project log.

At about 35 secs, we have removed the 12 screws so we can take away the hot cap (outer Can). We can now see the displacer (inner can). The outer can has a metal ring & a seal to keep it in place & to keep the device air tight.

At 52 secs, when we remove the displacer, you can see the planar spring. This is screwed to the top of the displacer by 3 screws. For the device to function, the planar spring must be completely straight. Our spring is not straight, hence the device does not work. Forming a planar spring is far from easy. Using any normal methods, the spring will warp. We now know that the only realistic way to make a straight spring is to use a water cutter. Thankfully, we know someone who has one of these so a new spring is on the way.

When heat is added to the hot cap, the displacer acts on the planar spring. The spring acts on the 'chamber". You can see slight movement on the chamber at about 1 min 30 secs (before we remove it as at this time we have already removed the 24 screws from the other side.). Movement of the sealed chamber is critical !.

At about 2 mins, you see inside the displacer. The component inside ensures that the displacer does not lose its shape when heat is applied to the outer can..

At 3 minutes, we are trying to show the 'free movement' of the displacer inside the outer can. Obviously, we do not have free movement. Without free movement, the device will not work... The gap between the displacer & outer Can is supposed to be as small as possible (like 1mm) but still allow free movement. We are going to rework the inner & outer cans to get the required free movement.. Honestly, even making the inner & outer Cans to this degree of accuracy is challenging. The gap has to be uniform. We do not know any easy way to make these things. We just got some metal & bent is as best we could. To add to the complexity, the bottom of each Can needs to be slightly curved as the device will not work with a flat bottom.. The curves on both have to be the same.. It is just a matter of fiddling around with the metal, cutting it accurately & welding it. But expect to have a good few goes before you get it even half right.

At about 5 minutes, we remove the sealed chamber containing the beryllium copper membrane. You can also see a rubber gasket. At 5.40 the basic idea is that the planar spring should touch the sealed chamber. This does not happen for us because the spring is warped. The sealed chamber has divots for the screw tops as the spring, not the screw tops should act on the chamber..

The sealed chamber holding the inner part of the membrane is sealed using a single central screw. Both sides of the sealed chamber have rubber gaskets (it is hard to see these in this video)..

What is visible in this video is only half the device. On top of this, we need to place a magnet & coil contraption. The magnet & coil will turn the motion into electricity. The 'motion' in this device is movement of possibly 1mm. We will be able to detect the motion when we get it working & the magnet assy being attached or not should not effect functionality of this half of the device..

So, there we have it. A badly described device that does not work !. But, if we can make it work, it will be an amazingly elegant electricity generating device. It should work from any heat source. This leads to the tantalizing possibility of running it on solar power during the day & gas at night. That would be a biggie, meaning that a solar device does not have to do noting when the sun does not shine... & even NASA could use solar power when their plutonium runs out in deep space..

“Course heading, Captain?”. “…Second star to the right — and straight on 'til morning.”

More updates to follow....

-

How the thing is supposed to work

07/09/2015 at 21:25 • 0 commentsSomewhat dreading this but here we go.

The Stirling cycle is well described all over the net so lets not go there. I believe our device is best described as working on a free piston Stirling cycle. In our engine, the piston is replaced by a diaphragm. In addition to a free piston, the engine also has a free displacer. The diaphragm & the displacer will work out of phase (by 90 degrees).

OUTER CAN / HOT CAP

Heat from any source is applied to the bottom end of the "hot cap" or outer can (green in diagram). The bottom of this is the hot end of the device. The top is the cold end. The outer can serves to heat & cool the gas & keep the gas in place.

We have choice with gas. The choices are as follows.

A. Normal air as normal or high pressure.

B. Helium at normal or high pressure.

C. Hydrogen at normal or high pressure.

We are likely to start with air at normal pressure then migrate to helium at normal pressure & then helium at high pressure. The choice of gas & the pressure of gas will only effect efficiency, it will not interfere with the basic workings of the device.

INNER CAN / DISPLACER (shown in Blue)

Inside the outer can is an inner can. The inner can is the DISPLACER This hollow can is the same as the outer can, just 1 mm smaller. Enough to allow for free movement of the inner can. It should be a snug fit but have the ability to move freely. The bottoms of both cans should be slightly rounded as flat surfaces are prone to deformation. The displacer moves back & forth moving the gas from the hot end to the cold end.

The inner surface of the outer can and the outer surface of the displacer also act as a regenerator. This is important for efficiency but less important for understanding.

All the gas would stay at the same temperature if the displacer was static. (Well, if it were an ideal gas with zero viscosity & ours is not). The temperature variance happens because the displacer is moving.

PLANAR SPRING (Shown is Yellow)

The displacer is mounted underneath the planar spring. The spring keeps the displacer in the correct position & allows the displacer to move to its own rhythm

DIAPHRAGM. (Shown in red)

Made from Beryllium copper, the diaphragm moves back & forth (out of phase with the displacer) depending on the pressure in the outer can.

Flanges. (2 fairly fat yellow bits, one at the top of the drawing, other around the hot cap)

These are bolted tightly together holding everything in place. The entire assembly is put on springs to allow the device & displacer to both move increasing overall efficiency & allowing for a natural rhythm.

NOT SHOWN.

There are many more parts but they are not in the 3D representation. Key part are the upper & lower caps enclosing the diaphragm & planar spring, the bulkhead displacer, casing springs, various Gaskets, clamping rings & then entire magnet array that goes on top of the device. These parts will be added later.

SOME SCIENCE..The total pressure/volume gas is changing as its average temperature is changing (pV=nRT for ideal gas, where p is pressure, V is volume, n is the number of moles of the gas, R is a constant, and T is absolute temperature in kelvins). V is almost constant, it changes a bit because of the membrane deflection; the p is what pushes on it. n is the amount of gas in the can, that's constant. R is also a constant, so we can count nR as a constant specific for the given assembly. T is the average temperature of the gas in the can (the active volume, displacer does not count). As the displacer is itself serving as a re-generator, it stores the heat of the gas along its length. So a material with low thermal conduction is used . In other words, gas flowing from hot to cold end is heating the displacer's left end (assuming hot end is left) and on its way back cools the right end.)

PROJECT LOG CONCLUSION.

If the above does not make sense, do not worry, it is me, not you. The diagram is incomplete & the explanation is poor. The next log will show representations of the missing bits & hopefully an overall explanation. I suspect the only way to demonstrate this effectively is with pics of actual parts & a video of the device being assembled. Both will follow someday....& this log will probably be heavily edited once the thought process is more clear....

-

Rough 3D desing

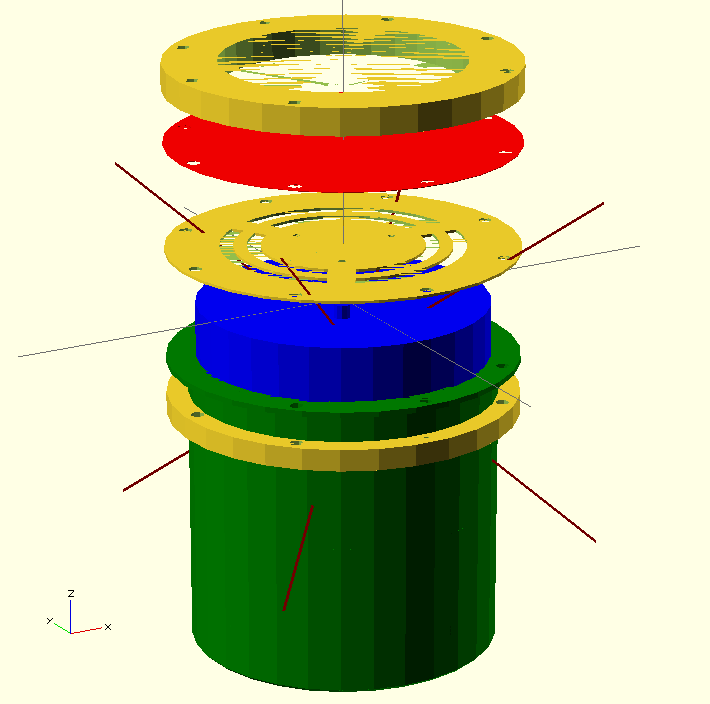

07/08/2015 at 16:47 • 0 commentsBelow is a rough 3D design outlining most of the parts

![]()

On top of this will be a magnetic assembly (to produce electricity). Heat will be added to the the green bit at the bottom (Hot cap)...For test reasons, the heat source can be anything, we will use a candle or any flame for tests. But, longer term, we will use solar power. We have a really small dish we no longer use. We can cover this in tin foil for test purposes...

In the next project log, I will attempt to explain how this thing is supposed to work !.. It is fairly simple with a hot cap, displacer, planer spring, O ring, magnet assy on top...& a few other bits & pieces!. It will not be exciting to watch it because it will have no moving parts that are easily visible to the naked eye. I expect the displacement to be about 1 mm.. So, we will connect it to something like a LED array so results are visible....

For sure, we are not the first people to make one of these. We know of 2 other projects. A guy called Barumman has 7 videos about a very similar device. One at. These videos show us that such a device can work & show exceptional craftsmanship.

Also Igor Beletskiy has a wonderful device at You can even buy the plans for this device (& we did). The rough 3D at the top of the log is ours, not Igors. As a lot of what we are doing will be based on Igors plans, we can not open source this but Igors 3D plans are not expensive so, if we get the thing working, we will give a link to how to buy the base plans...

Advanced Stirling Radioisotope Generator

NASA cancelled this program in 2013 after spending USD260 Million. Lets see what we can do for USD260!.

MW Motors

MW Motors