This post shows the construction process for my nozzles.

The first step is to create the nozzle coupler insert. This is created with 1" Schedule 40 PVC drilled with two rows of evenly spaced sheer points (16 total).

These are then glued into couplers.

15° cones are created out of paper and the couplers are placed on top. The cones are covered in shipping tape and then hydraulic cement is poured in. A 3/8" washer is then placed in to limit choke erosion. An additional layer of cement is then poured on top to protect against heat.

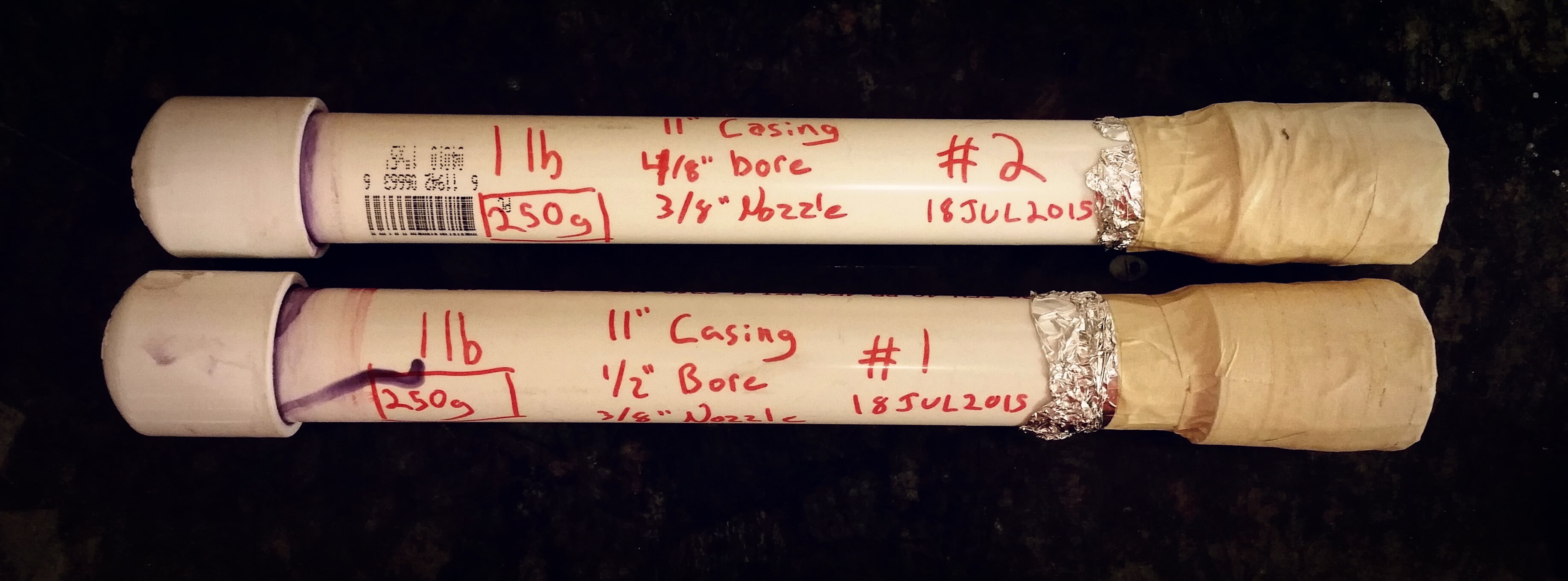

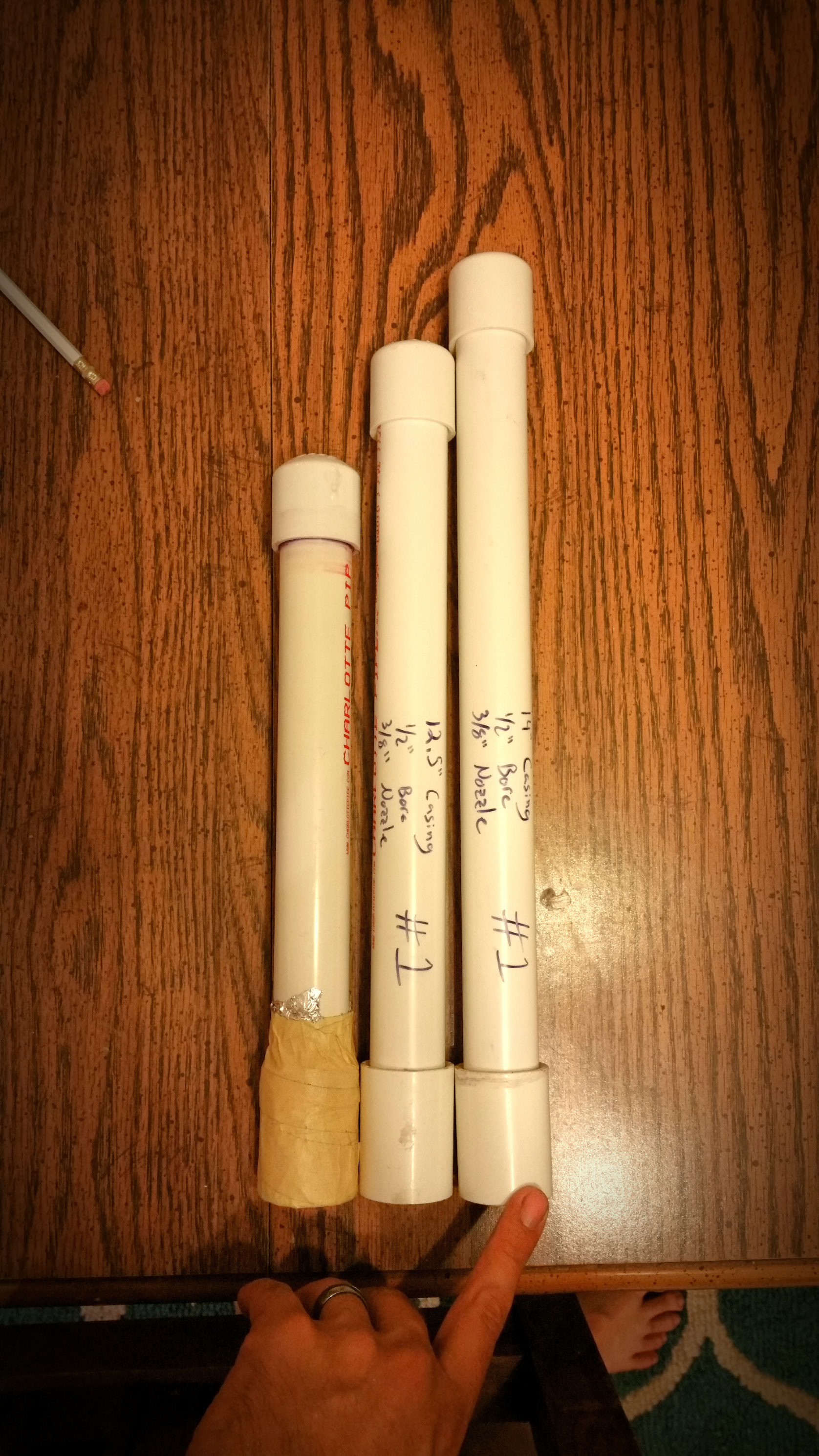

After some curing time the cones are removed and the throat is cleaned out and the convergent cone is created. These are then attached to the appropriate length casing to be cast with fuel.

J. M. Hopkins

J. M. Hopkins

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

How does the pouring of the cement work in the step after putting the cones in? I'm having trouble visualising what the process is after that :)

Are you sure? yes | no

Insure the cones are level and centered in the coupler, slowly poor concrete until the level of the concrete is the same as where the 3/8" washer sits. Place the washer onto the concrete, and then pour some more on top (about 3/16"). After initial curing, remove cone and clear the choke and chamfer the convergent cone.

Hope that makes more sense

Are you sure? yes | no