-

Plans...

06/29/2014 at 13:41 • 0 commentsAfter a little thinking, there is finally a direction for this project. The ideal outcome is to create a generic control board that will allow the use of any sensorless mechanical drive system in a closed loop system. The board will include basic H-bridge and servo PWM drivers so that users can just plug in simple DC motors and have a working CNC. It would be nice to have a full self calibration routine which allows the board to auto identify the axis to make it even easier to use.

The board will most likely have a camera, fpga and a micro. With a bit of luck the BOM should be less than $25. And with cheaper hardware, it should bring cheaper CNCs.

-

Too slow....

04/29/2014 at 11:29 • 0 commentsThe dev. has slowed due to an inconsistent Z axis on the machine. The milling motor was too slow and has lead to damage to the cutting head and then the whole Z axis. And the X and Y is too slow. There are plans to upgrade the axis to a belt driven system from multiple inkjet printers. More to come when the hardware is replaced.

-

Added a milling bit and gcode

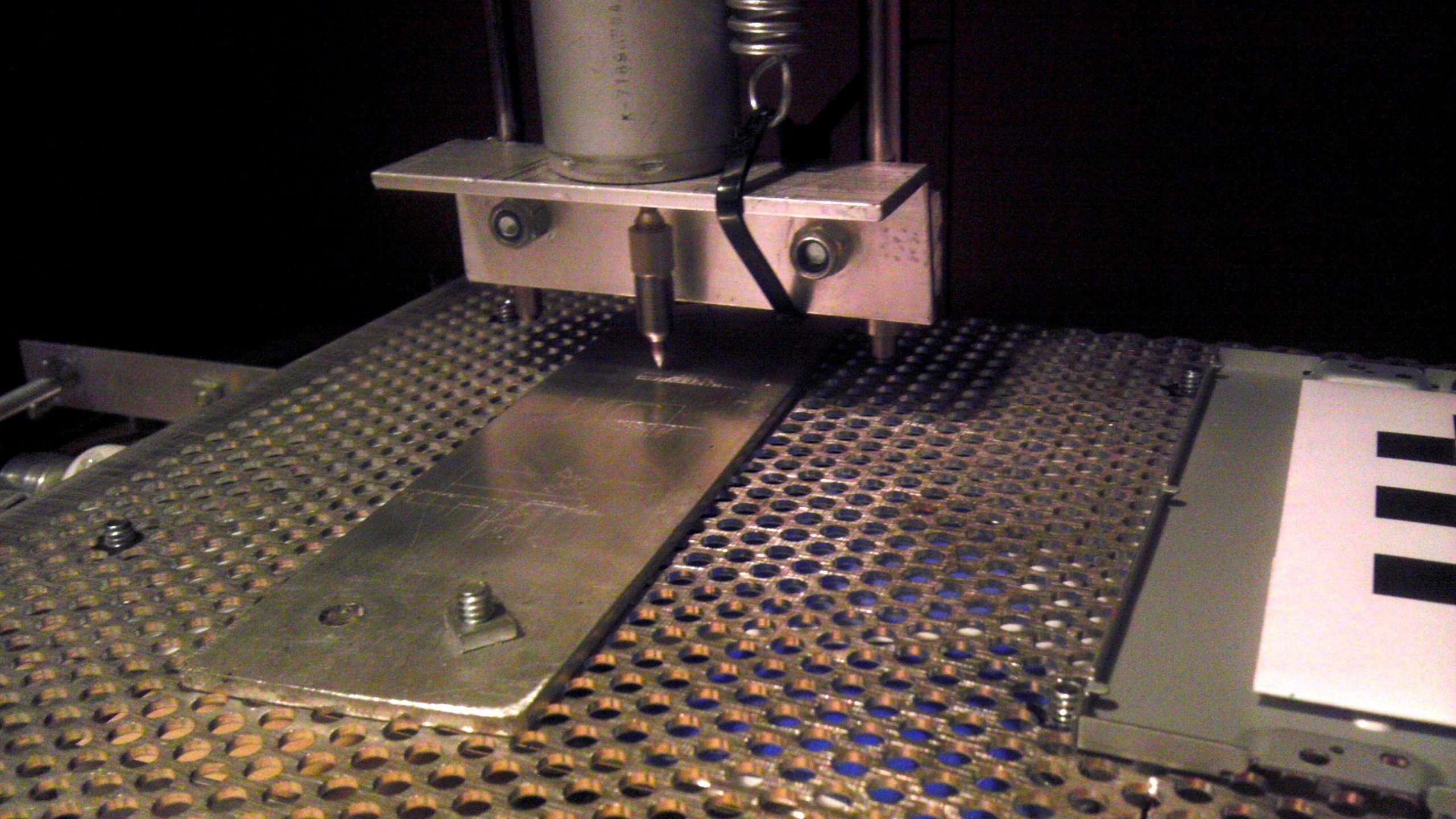

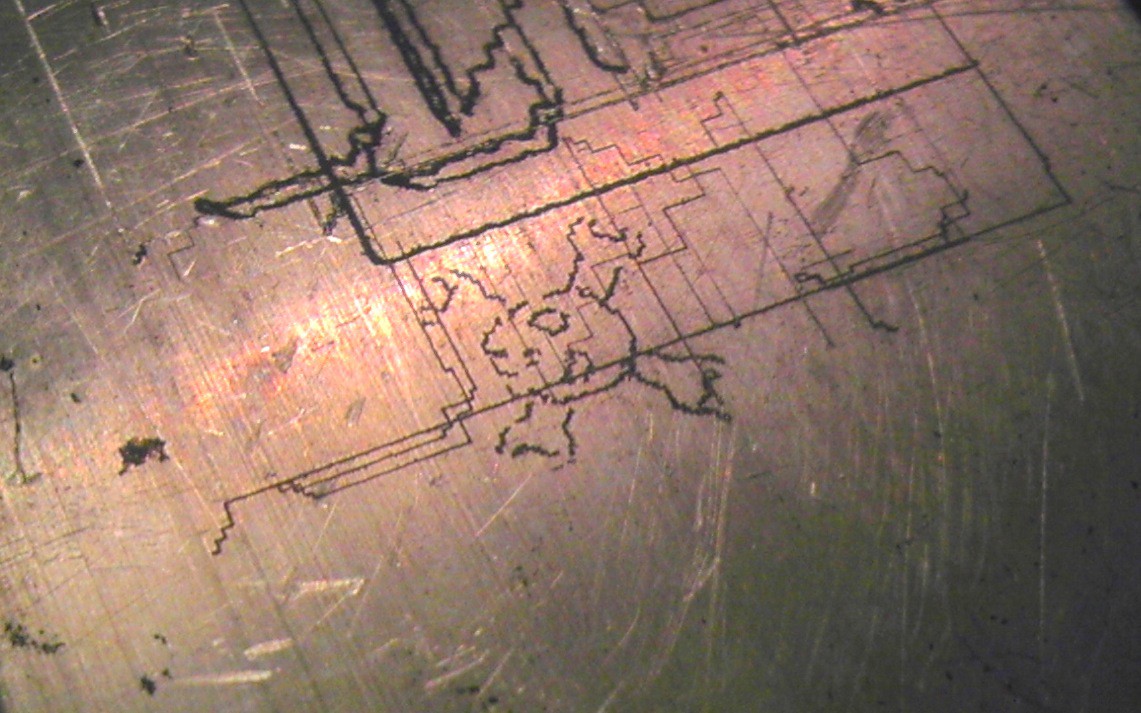

04/07/2014 at 12:48 • 0 commentsThe end goal of this CNC was to be able to mill PCB, make stencils and any other tedious tasks of fine cutting. So adding a V mill bit is getting the machine one step closer. The software has just been moved to a g-code input as oppose to a image input.

The bit is mounted in a head cut off from mini hand-drill, which has been soldered to the motor. The bit itself was a bit of rod with the tip ground to a V. There is very little lateral movement and can put a good scratch on a piece of aluminum.

The new software has issues with commanding the CNC. There are overshoots and Z-axis issues. New controls for cutting diagonal lines should also be considered. The current lines are in little steps.

-

Hardware is stable

04/02/2014 at 21:25 • 0 commentsIt's not all bolted down, nor is it all off-breadboard, but the CNC is stable with ove 10hr operation time under its belt. The control board need to be isolated from the drive side due to power spiking issues, whcih may (or may not) need to be fixed. May also need add a few limit switches in case the CNC runs out of bounds while I'm out of the room. It's done it once resulting in the need to regear the motors...

TIME FOR SOFTWARE DEV!

Quite excited about it as the current software is horrible. Once the software is semi-presentable it will be uploaded.

JLAM

JLAM