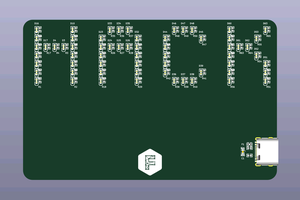

There are a number of international standards for sizes (see: https://en.wikipedia.org/wiki/Business_card), but I

chose the ID Card form factor (ISO/IEC

7810 ID-1) because the shape of

85.60

× 53.98 mm with

rounded

corners of

radius

of 2.88mm looked

pleasing.

At first I drew up all sorts of crazy designs mostly to satisfy curiosity, but of course very little of it was appropriate for the application. I wanted it to have a real world function, or tools to offer, if possible.

In the end, I decided simplicity is best. I included a test pattern of all the “layers” (or colours) that the usual manufacturing process offers, ranging from a route to the silkscreen, a Silkscreen pad that can be written on with vivid markers, and a QR Code linked to a shared Google Drive folder, acting as my Portfolio.

The hardest part of the design was actually... the design. Choosing type faces and sizes to fit nicely in the frame was something I don't quite have the artistic, or perhaps visual judgement for.

One major limitation I had to keep in mind, was that if I wanted some text to be plated (written on the Solder Mask layer), then the resolution of the Solder Mask Printer had to be taken into account. In the price range I was hoping to target, I couldn't reliably print a gap in the Mask less than 0.2mm thick. This had a big impact on the choice of Font and sizes that I could choose from.

0.2mm sounds quite skinny for most other applications, but for an object the size of a business card, and for the text to fit pleasantly, the thickness of the lines drawn become a real concern.

I narrowed the fonts down to Copper Plate, Copperplate Gothic Bold, 914 (as in the Porsche model), and Bank Gothic.

I chose Bank Gothic in the end for Title and Subtitle because it looks modern and clean cut, lending itself to the Engineering field quite nicely.

Future revisions include plating the route in the corner, adding my abbreviated qualifications, and adding design notes to the Fabricator, to place their silkscreen notes in a predefined region.

Chris Tully

Chris Tully

Rohan Fichadia

Rohan Fichadia

Lorenzo Palloni

Lorenzo Palloni

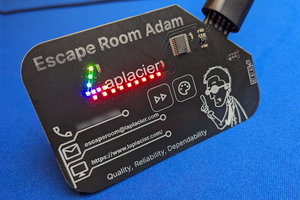

Adam Billingsley

Adam Billingsley

Very nice design and I've considered doing the same. It might cost a bit more but you could have the pcbs manufactured using thin material and have the manufacturing serial number removed. Love it!