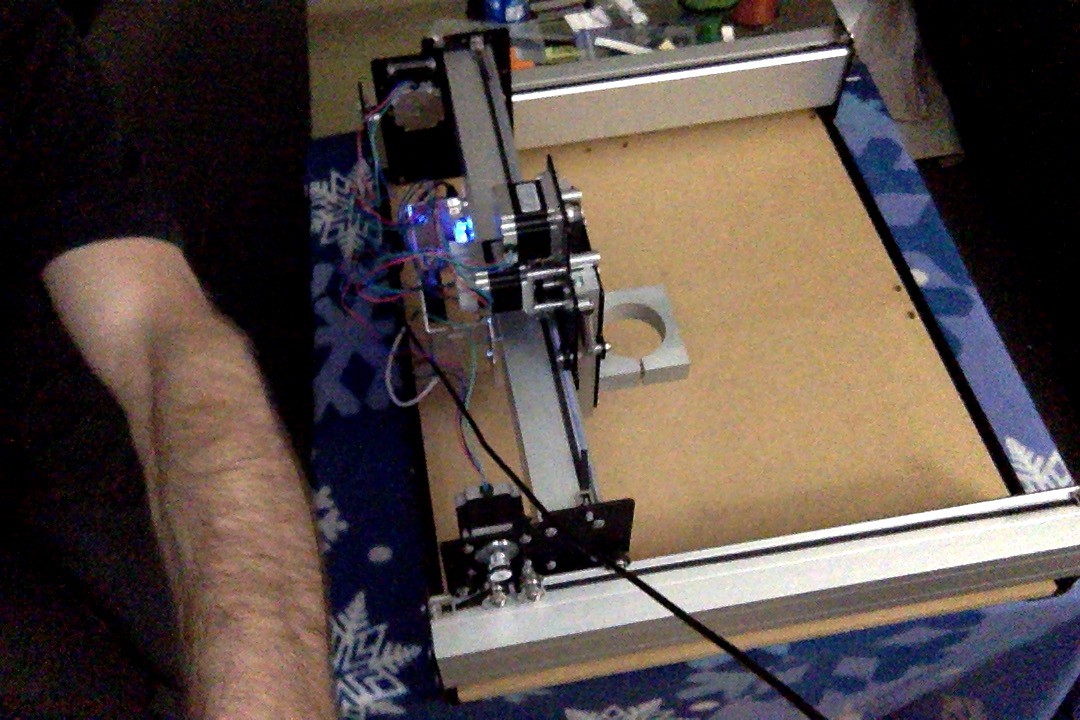

After a long preorder wait I was finally able to get my machine running and drawing the example.

I had some troubles with sizing. Which required configuration of the microswitches on the carbide motion PCB and some GRBL settings.

This information is documented in the Shapeoko setup.

What should the DIP switches be set to on my Shapeoko3 controller board?

The DIP switches on the board should be set to:

- N23 rather than N17 (this is the motor selection)

- 1/4 rather than 1/8 (this is the micro-stepping selection)

$100=40.000 (x, step/mm $101=40.000 (y, step/m) $102=40.000 (z, step/mm

Now it's time to test something a little closer to home. Something I hope to laser cut in the future. Gaskets for engines. Mostly moped engines. In this case Tomos A5x Gaskets. It's something I had tried to do on my vinyl plotter, but had problems with thick materials. (Compared to vinyl)

Looking good.

http://pxn.ca/moped/Tomos/cnc.zip

Updated as I make changes, probably move these to github soon.

Another project I'd like to tackle is guitars.

so time to draw a flying V for fun

Emerica

Emerica

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.