-

layouting mockup / makefu lamp build

04/17/2016 at 19:27 • 0 commentssuch a nice mockup

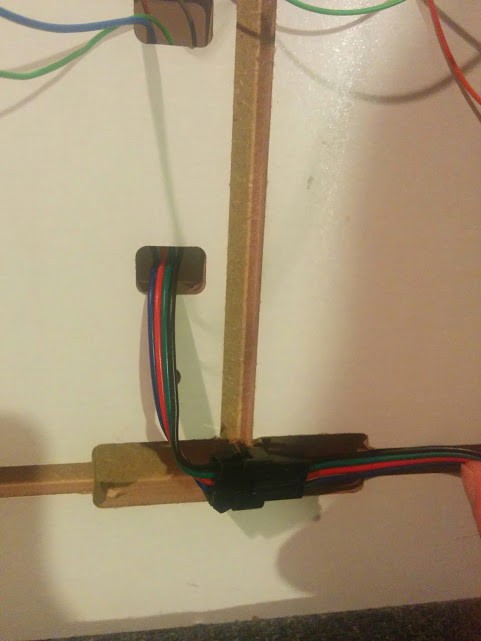

![]()

behind the scenes - routed cabling slots

![]()

manual rework (not getting it right on the cnc mill is a good opportunity to use the manual router)

![]()

so much win:

![]()

mounted on white painted wooden plates gives a completely different look from the first installation.

![]()

-

light tests and first installation

04/13/2016 at 21:51 • 0 commentssome tests before our first wifi controllable led lamp installation.

![]()

Better drilling with Festool ... and Nadka.

![]()

looking good - notice the breadboard glued to the ceiling ... with the esp and ams1117 (5.5 -> 3.3V) regulator.

![]()

-

cube electronics

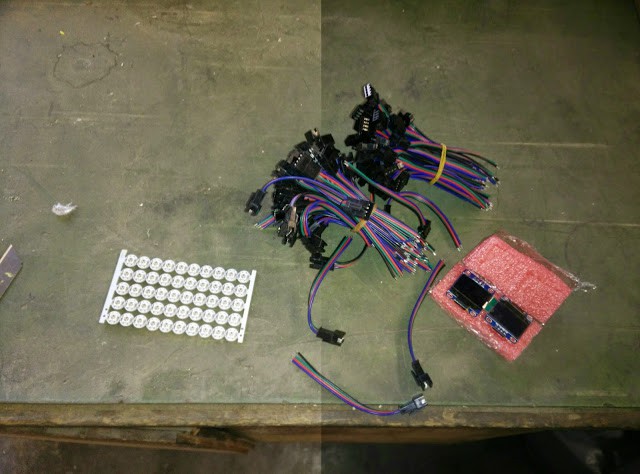

04/12/2016 at 23:45 • 0 commentsws2812b on pcb for hassle free soldering.

4 pin connectors for +- 5V, signal and signal loop through if necessary for some setup.

Connectors should be protected against polarity reversal- otherwise I will always short sth.![]()

helper (soldering) fairy

![]()

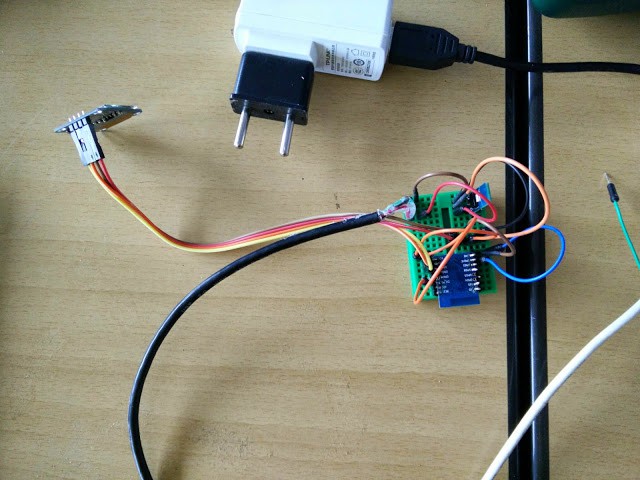

esp8266 breadboard test

![]()

-

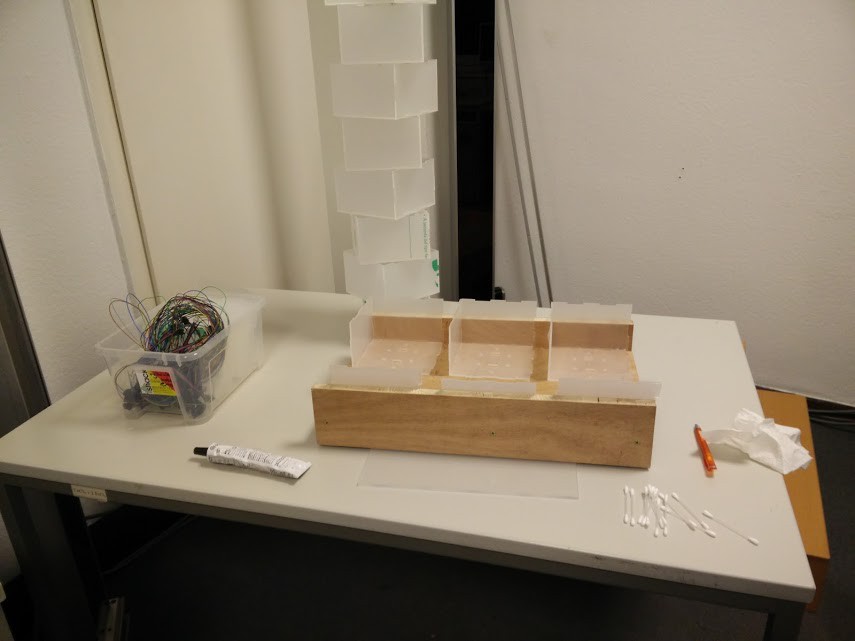

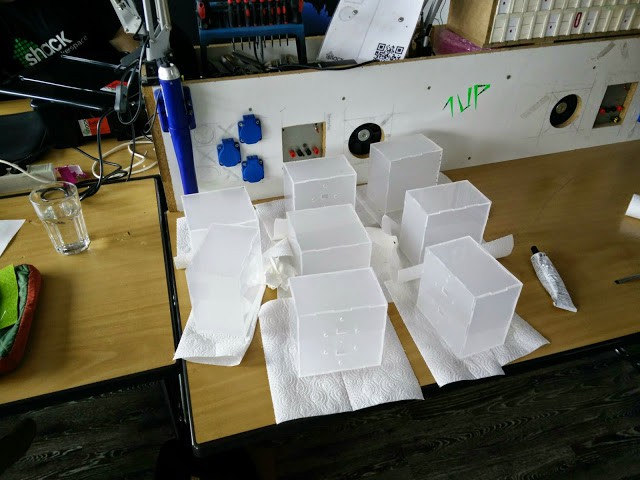

all the glue

04/08/2016 at 11:49 • 0 commentsAcrifix (applied with a q-tip) works really good gluing the notched pieces.

Hot glue if you want to get it open ever again (here: top for access).

Gluing tool (perpendicularity)

![]()

some more gluing

![]()

first harvest:

![]()

-

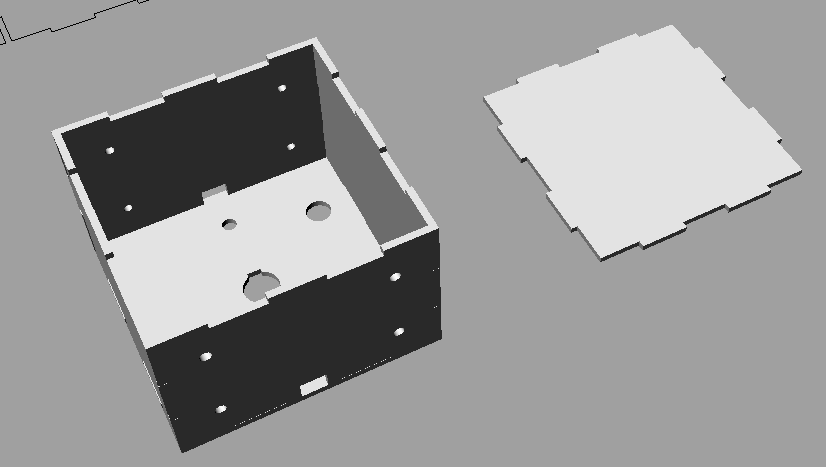

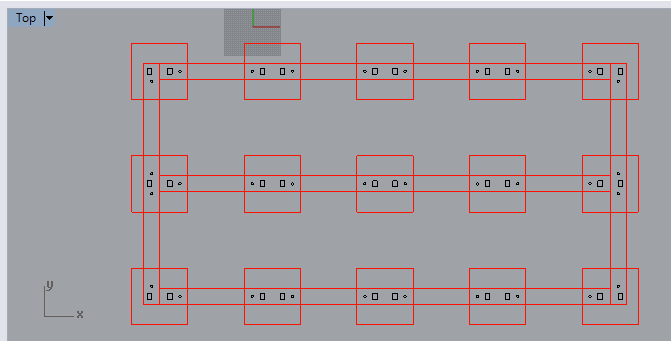

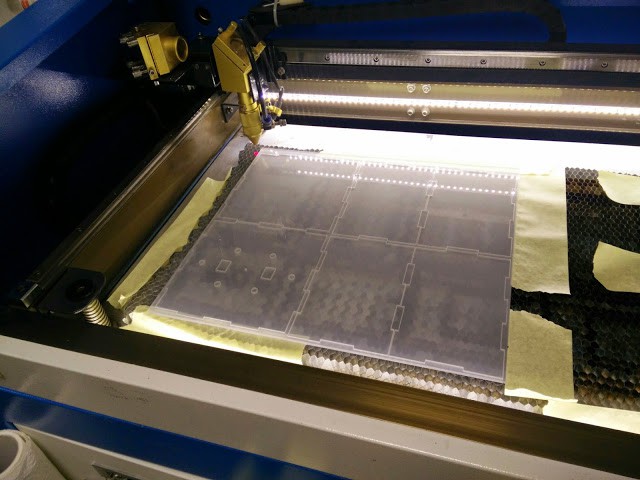

lasercut the acrylic

04/06/2016 at 20:37 • 0 commentsFirst you have to design the lamp - in our case square boxes. Boxmaker to the rescue - or at least to jump start the notched boxes.

![]()

Some draft of one of the final lamps.

![]()

Then off to buy some acrylic...

![]()

... and put it in your hackerspaces' lasercutter (far cheaper than having the acrylic guy do it).

![]()

good material planning:

![]()

-

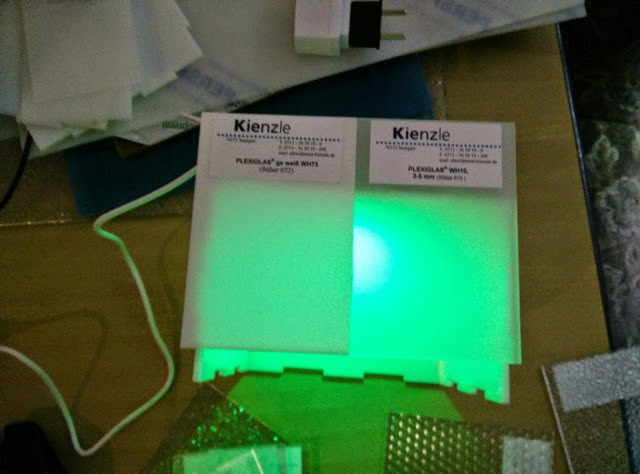

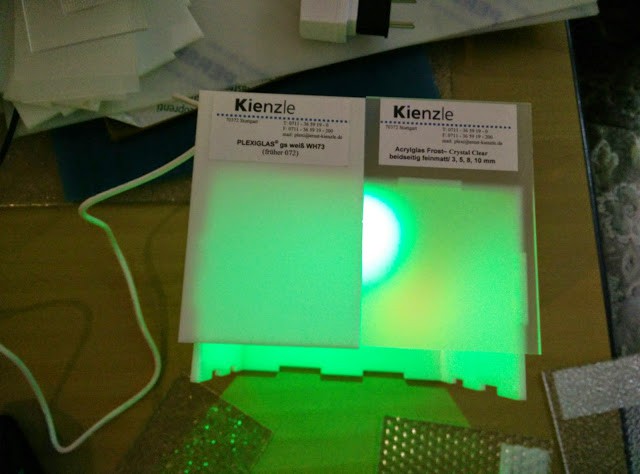

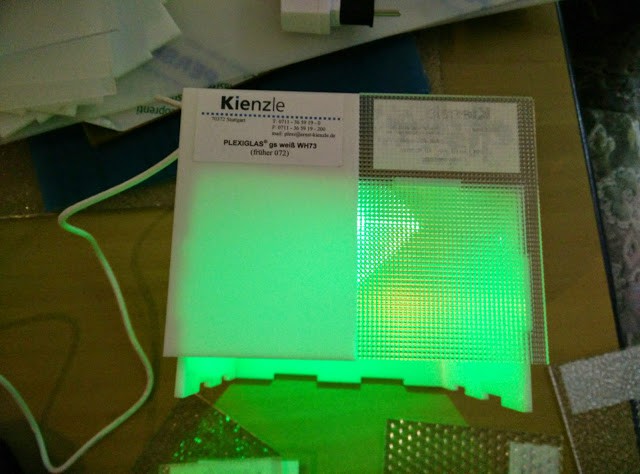

finding the right acrylic

04/05/2016 at 20:49 • 0 commentswe went to a local acrylic shop and asked for samples we liked without illumination.

![]()

then the selection followed

![]()

![]()

![]()

![]()

![]()

![pyramide gives a really nice effect - is a hackers favourite (as 3D cube)]()

-

project start

04/04/2016 at 23:15 • 0 comments

rgbcubes - iot finder

glowy cubes (ws2812b) made from frosted acrylic with web service to easily find it on your network.

Christian Stöveken

Christian Stöveken