I wanted to make an RGB 7-segment clock, the only modules are out there are the adafruit 1" tall units, which are good but have quite a lot of pins on the back and no option for colons (displaying time seperator), they are also $15 which works out £10 before shipping EACH....

£40+ on just the display, one which did not have all the features I wanted made me rethink the problem.

After experimenting with the optical and thermal properties of a couple of different types of hot melt glue, I tried poly-morph.

For those that don't know, poly-morph is a kind of nylon I believe, or at least handles like it, but has a fusing temperature of around 60 degrees C. this means you can plonk the pellets into boiling water, they tun clear and are mould-able. It's also possible to use a blowtorch lighter or heat gun to make it malleable, and even roll it out into sheets with a rolling pin.

I cut out the segments as needed, backed it in aluminium tape as a heat shield and light shield and stuffed poly-morph into the holes.

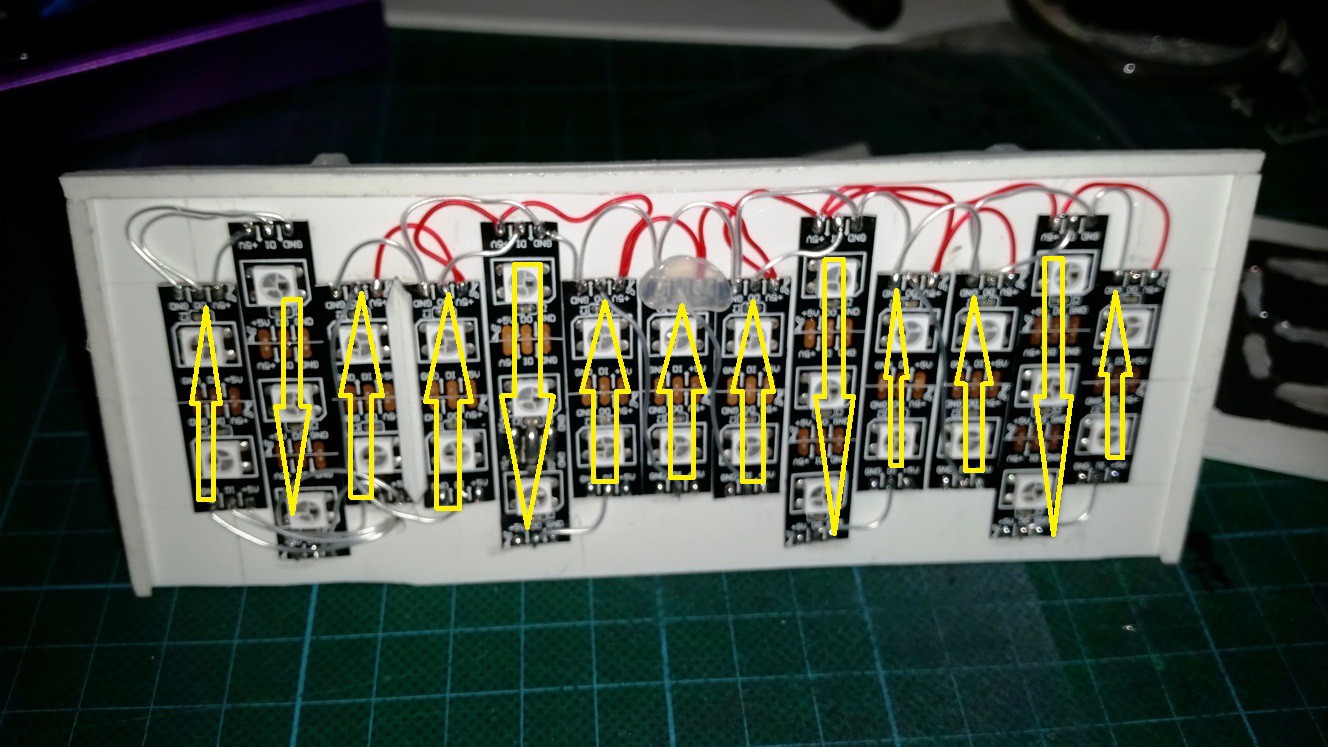

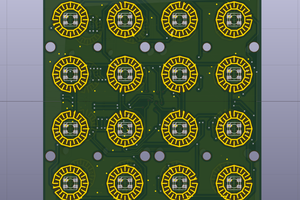

Make up the led board, add some extra poly-morph where the LED's will sit and melt it with a blowtorch, the press the LED board and diffuser board together. this ensures that the LED's don't simply shine on the back of the diffuser, but are connected to a rudimentary light pipe getting more light where its needed and therefore less leakage.

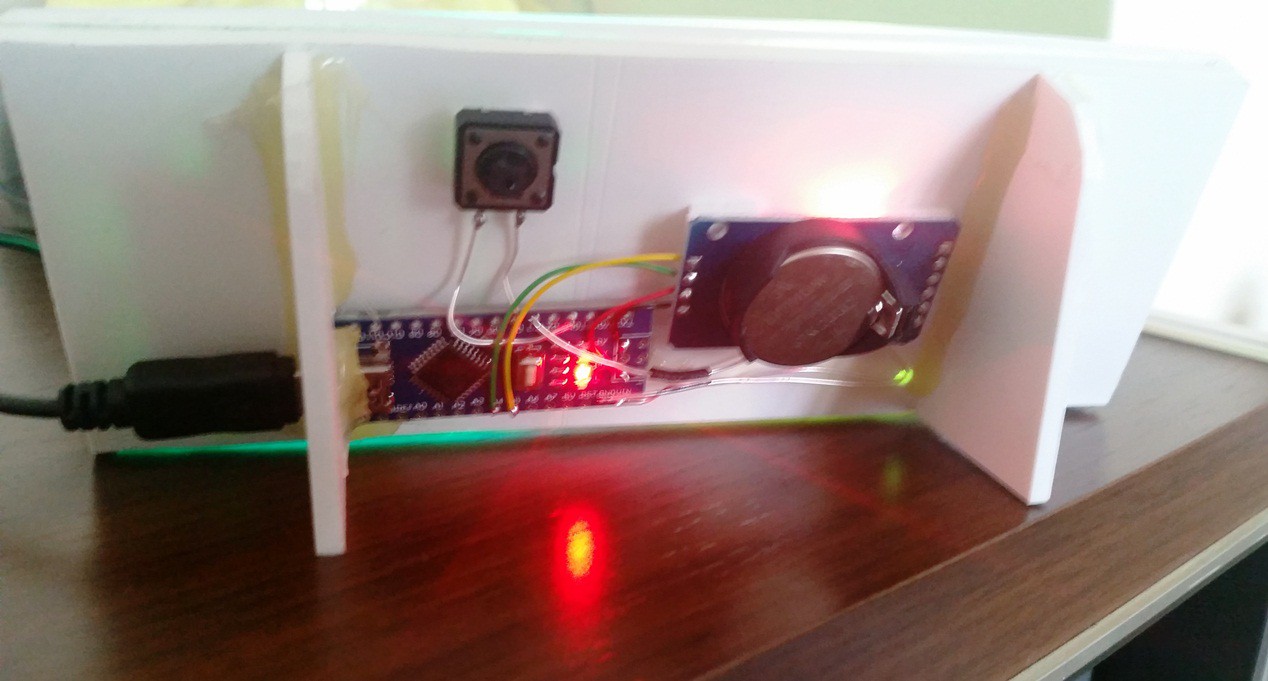

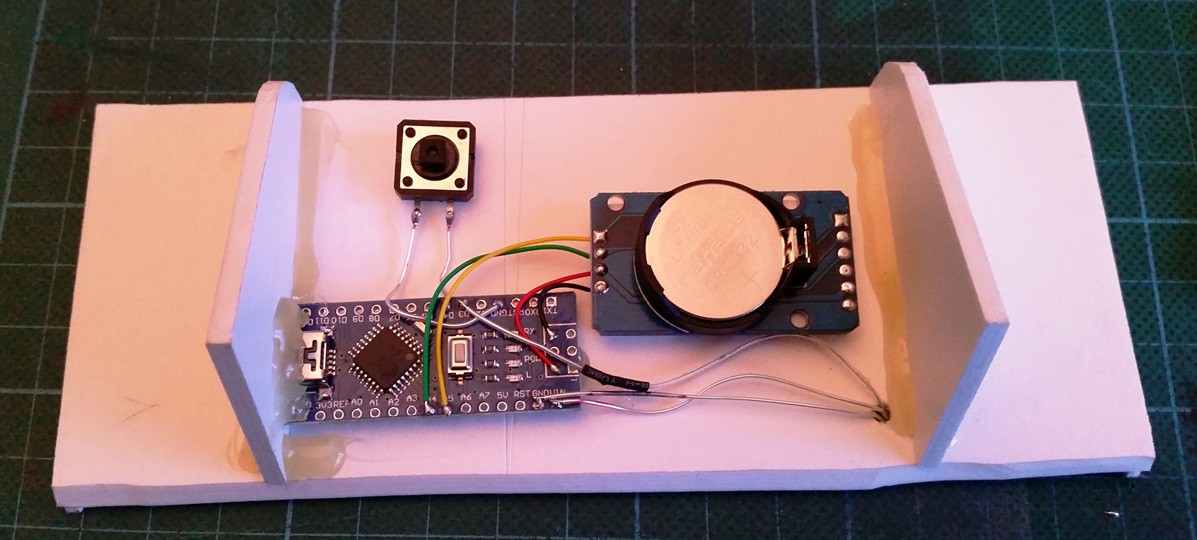

The rest is wiring and playing with code... end result:

Front diffusion is finished with a piece of paper attached with spray mount to help hide the segments that are not illuminated.

David Hopkins

David Hopkins

Pierre-Loup M.

Pierre-Loup M.

Grant Giesbrecht

Grant Giesbrecht

Tom Dowad

Tom Dowad

Michael Wessel

Michael Wessel

How thick is the plasticard and any tips on cutting out the segments?