I have a Keurig berwer to hack. Any ideas?

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

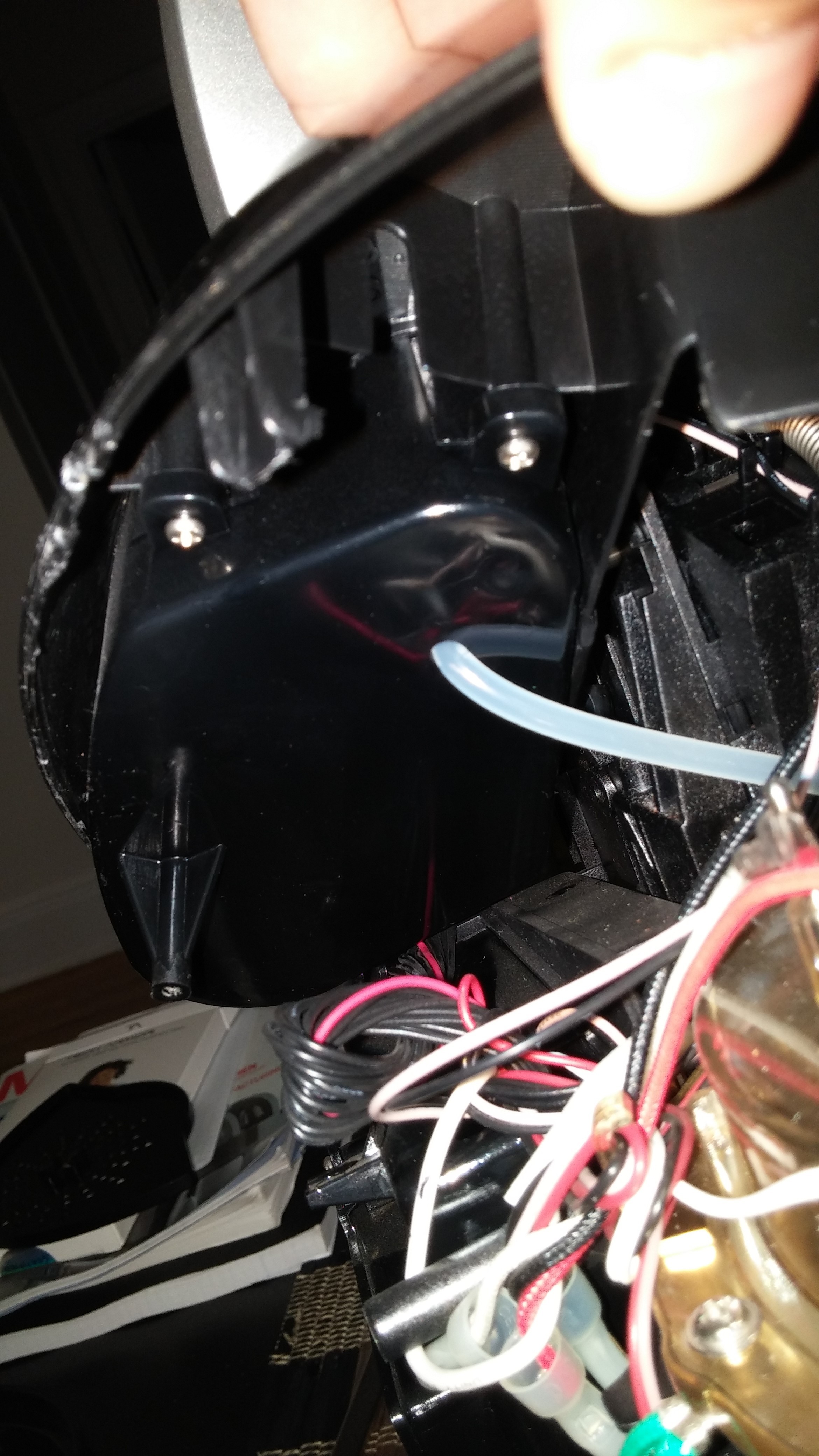

First I want to remove as much unnecessary plastic as possible to see what components I have to work with. The water handling is a lot more complex than I anticipated.

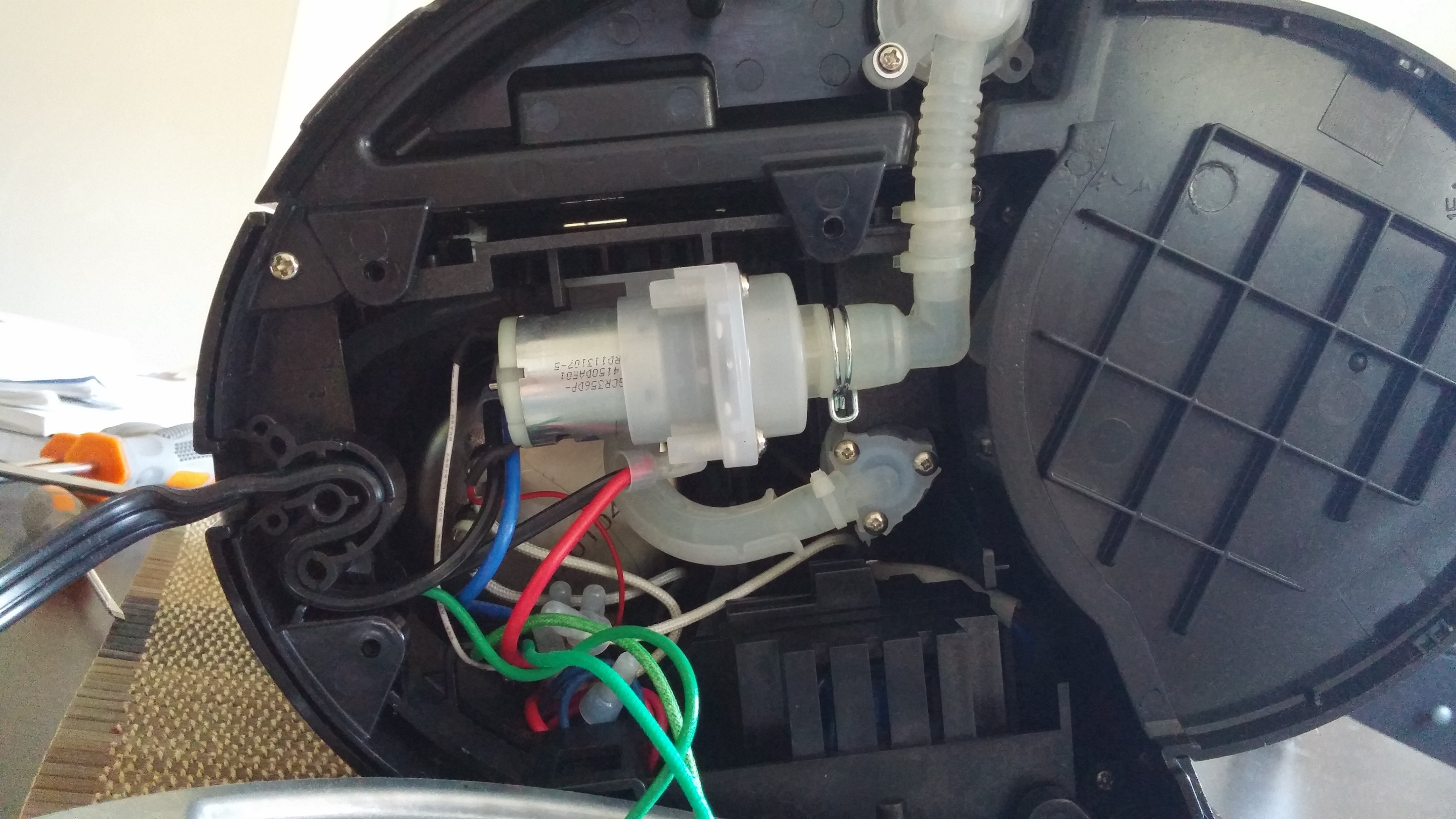

Any easily removed pieces, like the k-cup holder, drip tray, and water reservoir were removed. The easy screws are beneath the unit on the metalbase. This exposes the transfer pump that moves water out of the reservoir.

The k-cup holder pulls right out. Two screws hold the bottom of the holder mount, two hold the "collar" around this, and 2 screws hold the top cover. Without these components you can see the proof of closure switch and what looks like a check valve.

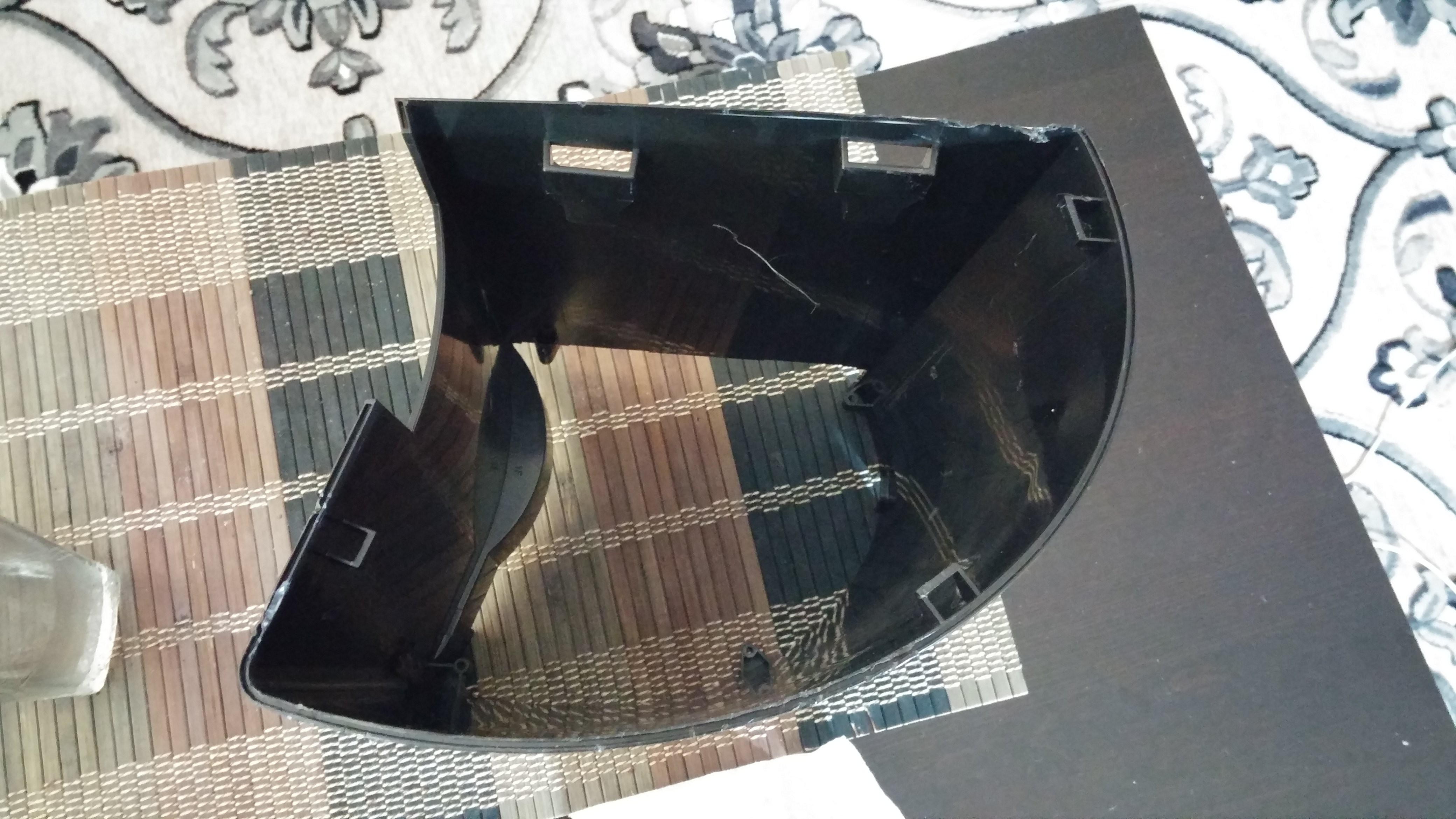

Now the teardown gets a little tougher. If you are doing a similar teardown expect to do some cosmetic damage. I cut the grounding wires holding the metal base on. These were only used to ground the bottom plate and can easily be re-attached later if necessary. There is 1 Phillips head screw and 3 plastic tabs holding the top on the Keurig. These require very long screwdrivers, and none of the tabs are easy to see. I ended up prying the top up until I snapped the tabs. Now the full plastic enclosure can be removed.

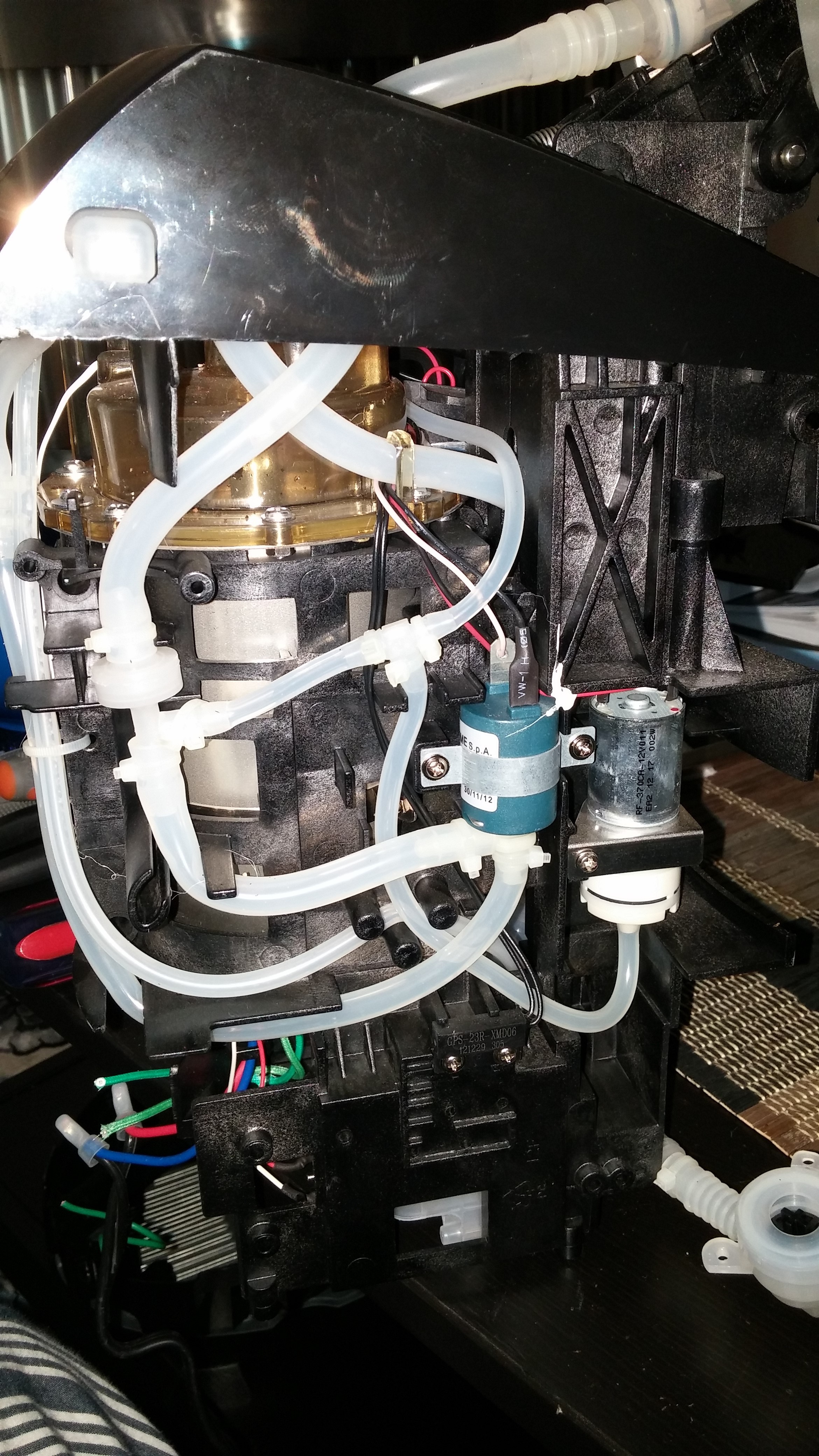

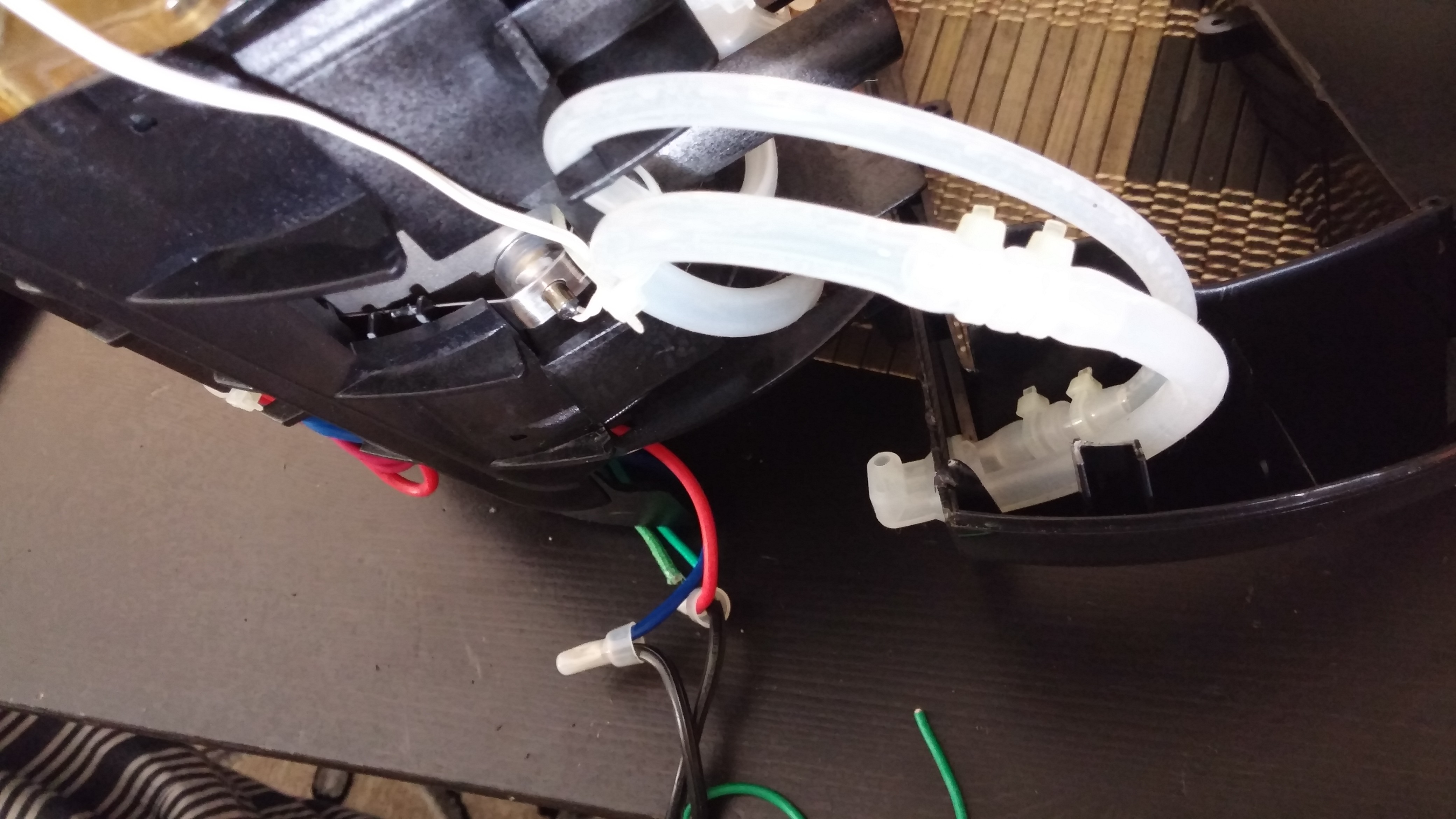

Now the entire inner workings are revealed. There is a lot of extra tubing, what at first appeared to be 3 pumps, and the water heater. I never understood why this machine needed more than 2 pumps maximum, or at the very least 1 pump and 1 switch-over valve.

Now the entire inner workings are revealed. There is a lot of extra tubing, what at first appeared to be 3 pumps, and the water heater. I never understood why this machine needed more than 2 pumps maximum, or at the very least 1 pump and 1 switch-over valve.

One interesting observation is the water tube that goes into the control panel. This connects to a pressure/vacuum sensor on the back of the board.

Another strange set of water tubes are the two that run to an open spout at the top of the water reservoir. I have never seen water come out of here, nor do I think the unit has any sort of automatic cycle feature. In this picture you can also see the temperature switch pressed onto the metal can of the water heater. While this might be a temperature sensor, this style is typically used as an over-temperature safety switch.

Another strange set of water tubes are the two that run to an open spout at the top of the water reservoir. I have never seen water come out of here, nor do I think the unit has any sort of automatic cycle feature. In this picture you can also see the temperature switch pressed onto the metal can of the water heater. While this might be a temperature sensor, this style is typically used as an over-temperature safety switch.

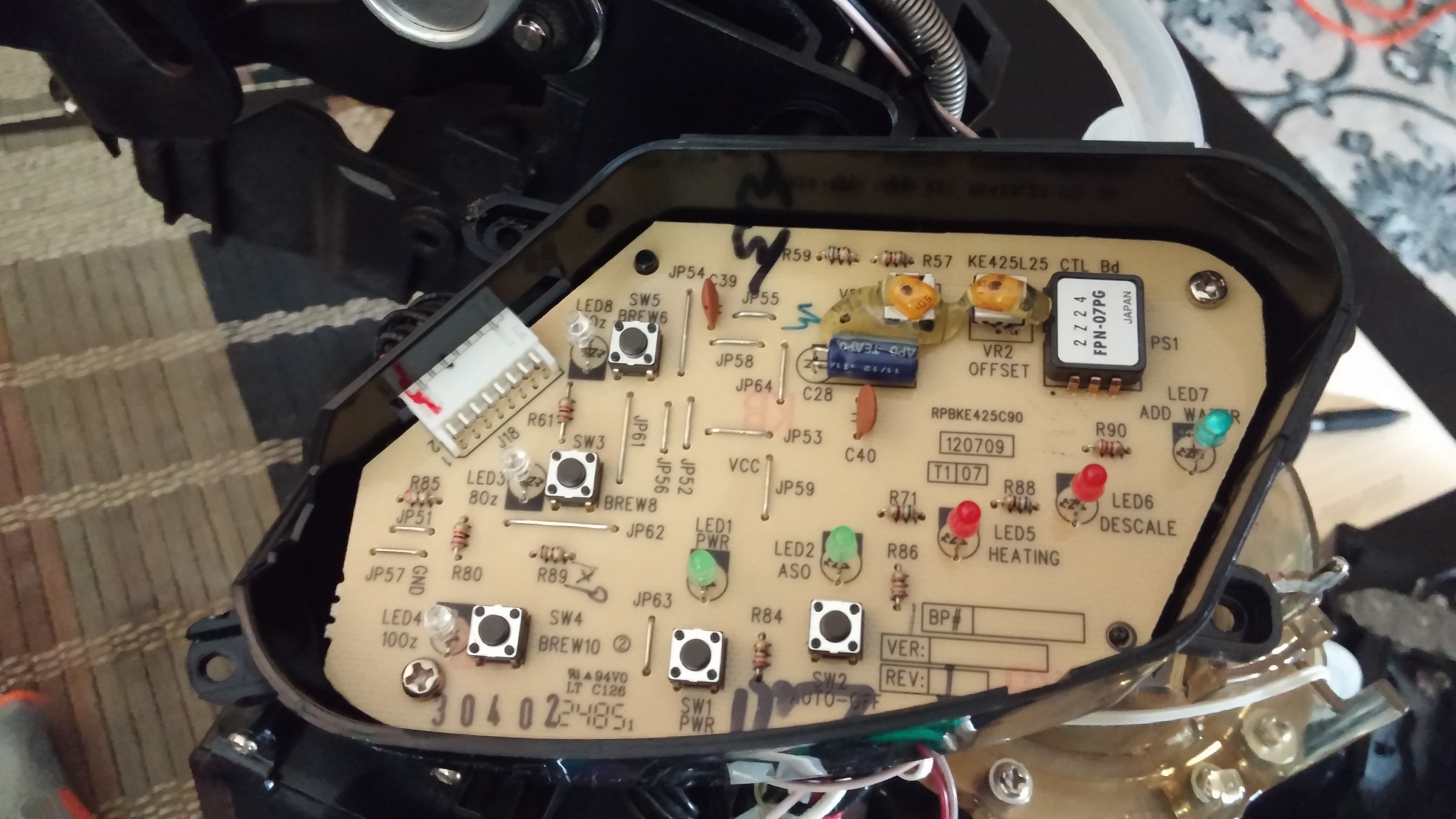

The control panel can now be accessed as well. This contains all of the buttons, LEDs, 2 trim pots that have been epoxied over, and the pressure sensing chip (FPN-07PG).

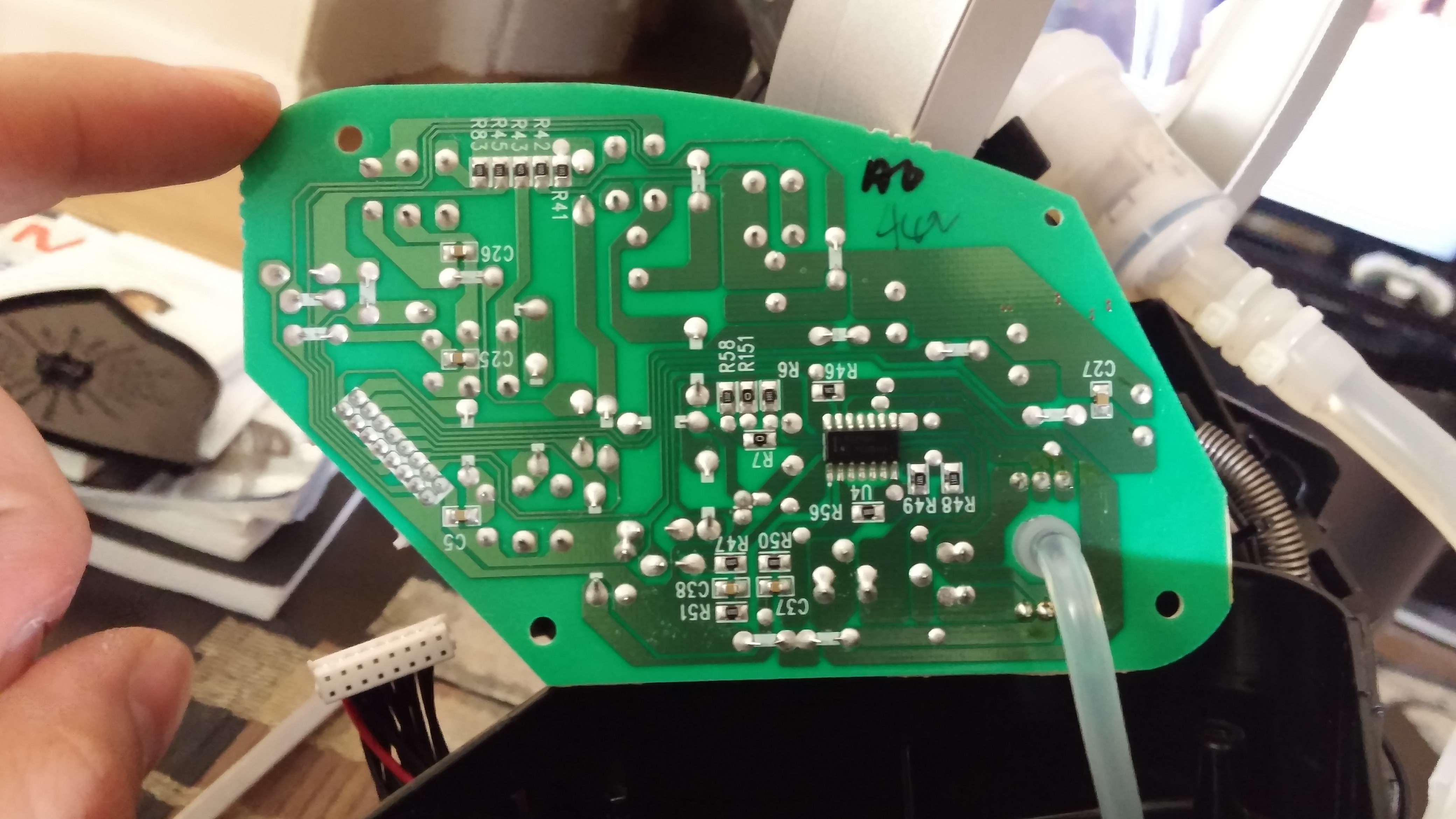

To my surprise, the back of this board has no major components on it, which means there is a logic/master control board elsewhere on the unit.

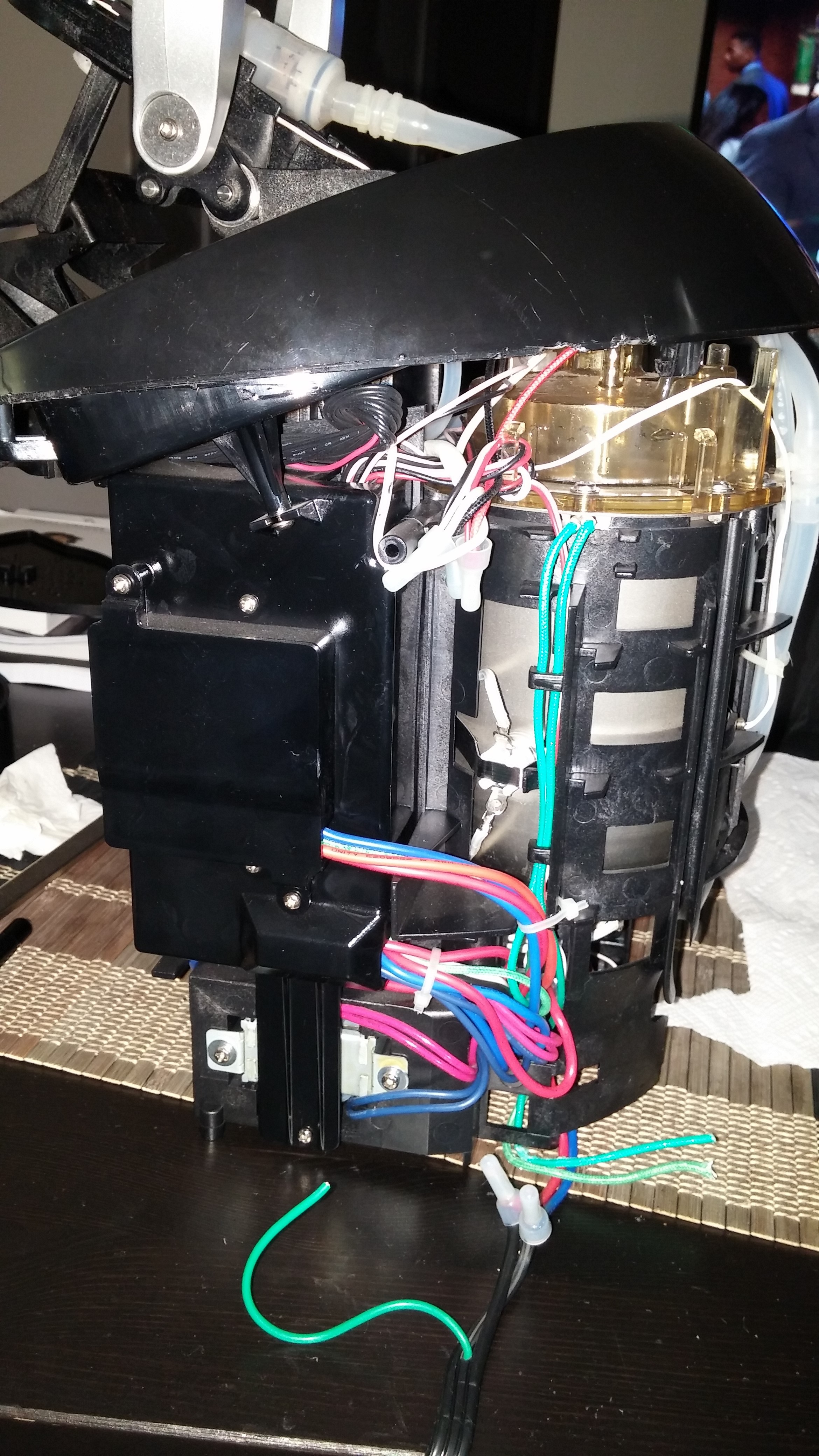

One side of the brewer has a large plastic cover that likely contains this missing board. The first set of screws reveals some sort of power supply board.

Behind this is the control board I've been looking for. The brain of this board is a Microchip PIC16F917.

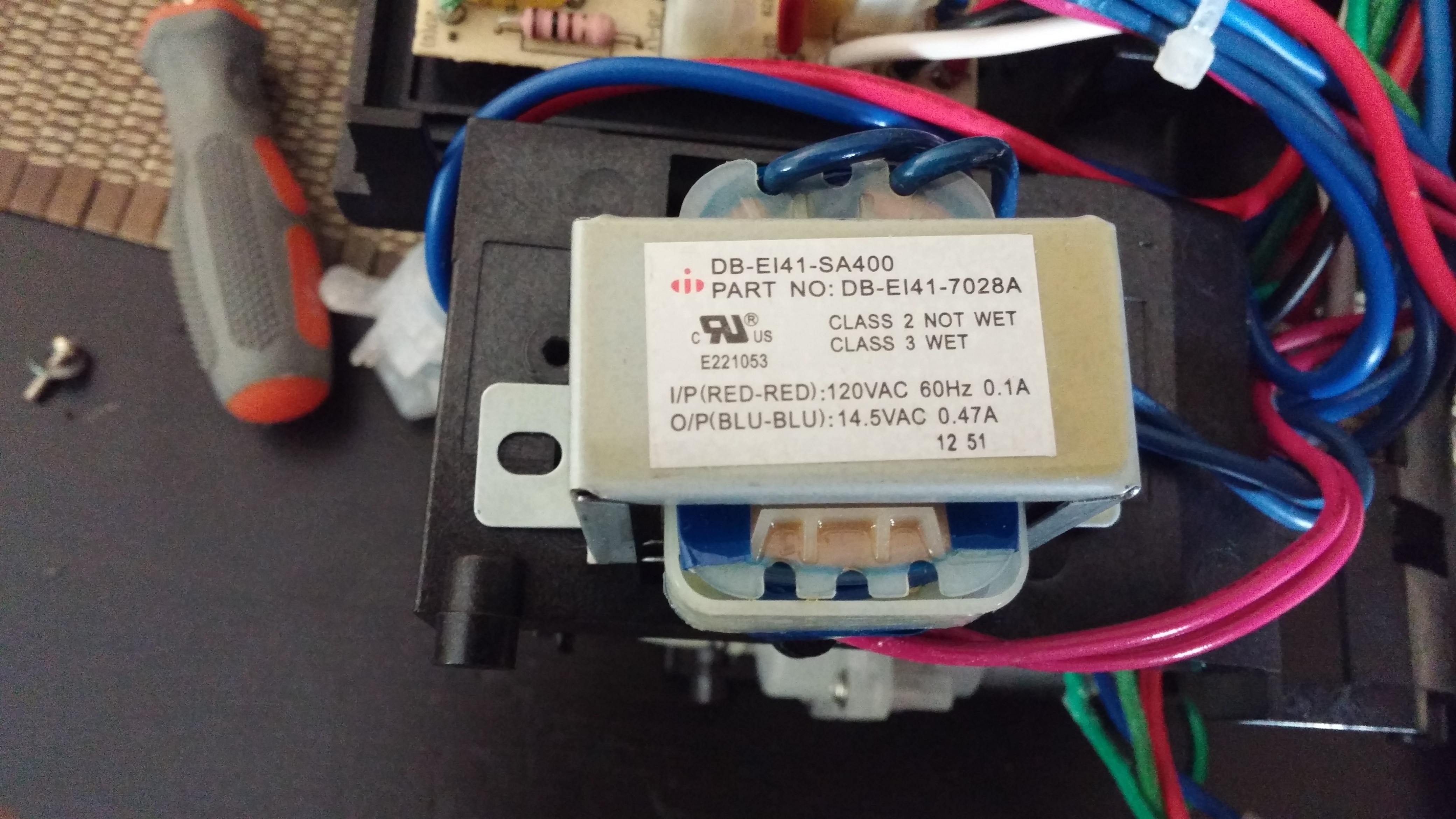

The only other electronic component is a 14.5 VDC transformer on the bottom of the unit.

The side of the brewer holds a few important components. The water reservoir works off of a magnetic proximity sensor float, and the sensor is held on by two screws beneath the pump. The silver component is interesting. I assumed it was a pump, but there is only a single tube connected to it. The sticker claims it is a "mini pump", and careful disassembly reveals a rubber diaphragm with three 'pistons'.

The water heater has several water connections and at least one thermal element. I started to take this apart as well, but the screws were stripping, so I held off for the time being.

The water flow diagram is below. I am not 100% what is going on inside the water boiler.

I have several ideas, but nothing I truly love yet.

Create an account to leave a comment. Already have an account? Log In.

if you attach an touchless automatic paper towel dispenser from a public bathroom ,.. and control the flow of steam evenly across a wide surface --> it could be hacked into (drum roll) ... HOT TOWELS DISPENSER.

Brew yourself a hot towel in seconds. ( also a little hopper /reservoir for essential oil? )

I suggest using the best quality paper towels more like cotton fabric.

Hi, i have a question about this machine. I would like to convert it 110v to 220v, the only thing i will change is tarnsformer, it will be 220 to 14 v transformer ? Do you have any idea ?

All I can tell you about the transformer is what is on the sticker in the picture: the output is 14.5 VAC, 0.47 A, 60 Hz

Become a member to follow this project and never miss any updates

Investigate the machine to find out two things:

1) How to manipulate the temperature control system and get the brewing temp up to 200°F immediately before it delivers the water to the cup.

2) Figure out how to slow down the water delivery so it happens over the course of 2-1/2 minutes instead of 30-90 seconds.

Doing these two things would be a great service to humanity, and a Nobel prize is a reasonable possibility.

Either do that or rearrange the parts, and add a few more to make an electric moonshine still. No Nobel, but perhaps a Medal of Freedom.