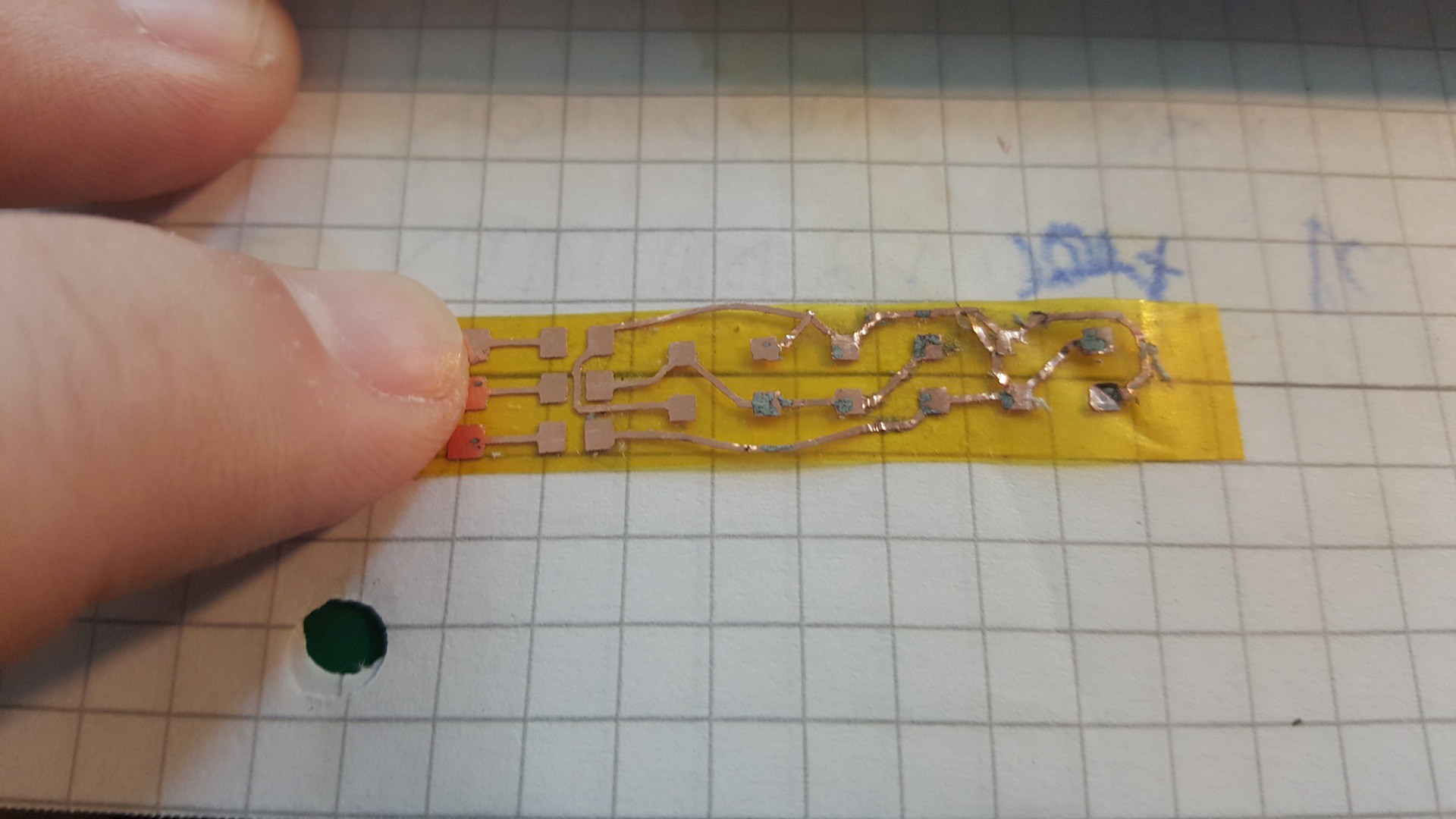

flexible pcbs

Playing around with capton tape and copper

Playing around with capton tape and copper

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

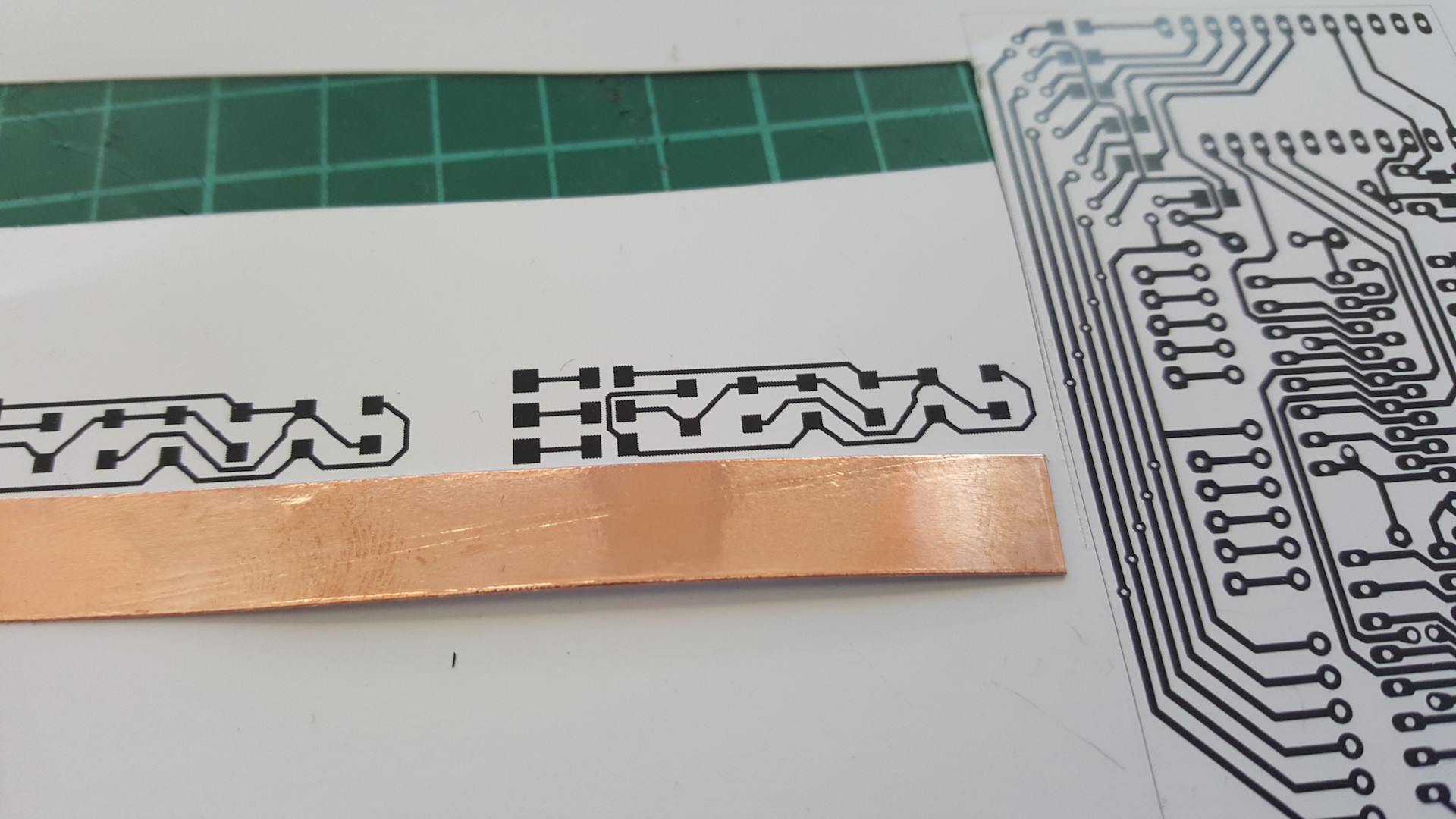

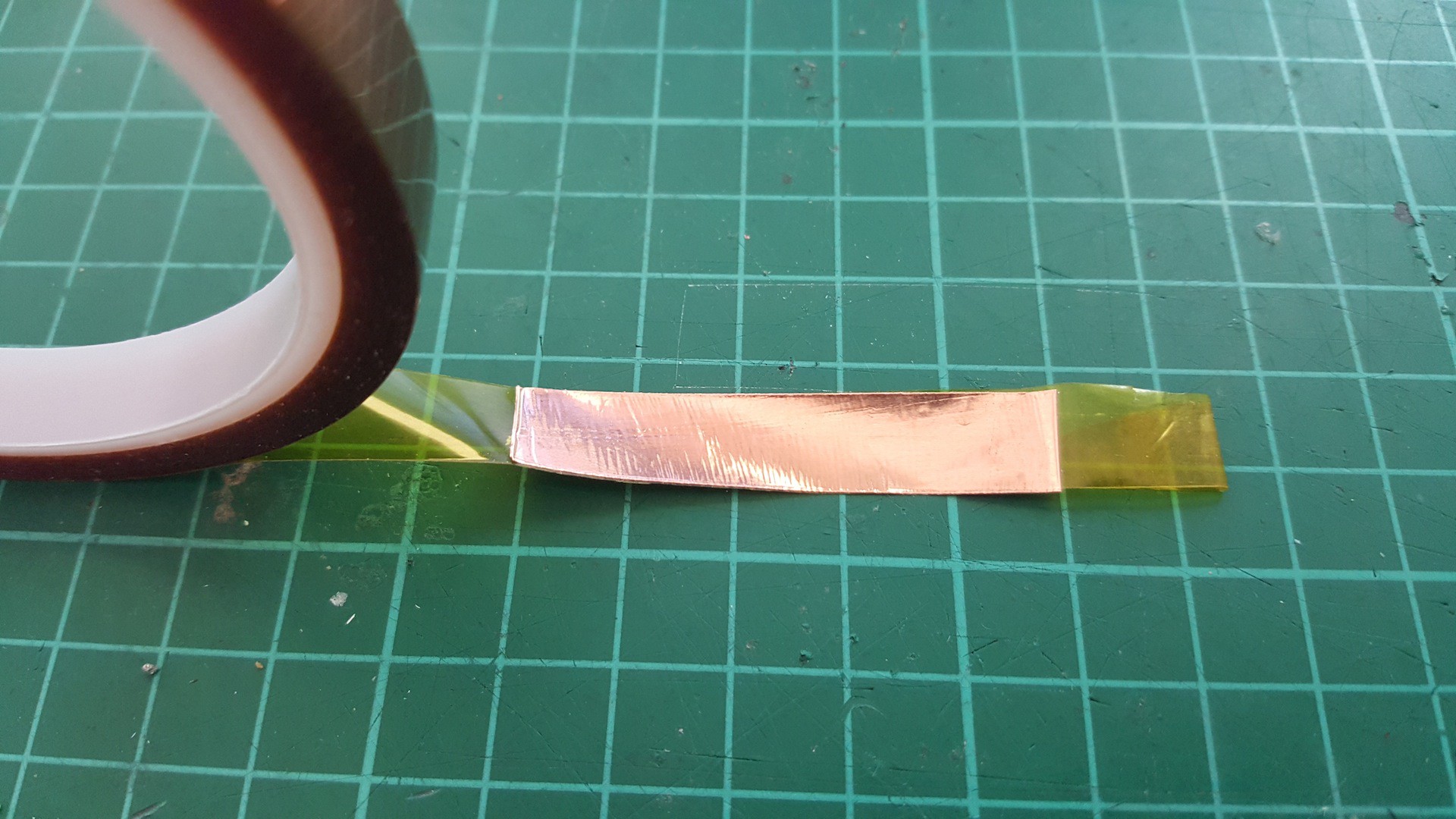

First cut off a very clean and not bended stripe of copper tape

carefully peal it off and glue it to the sticky side of the capton tape

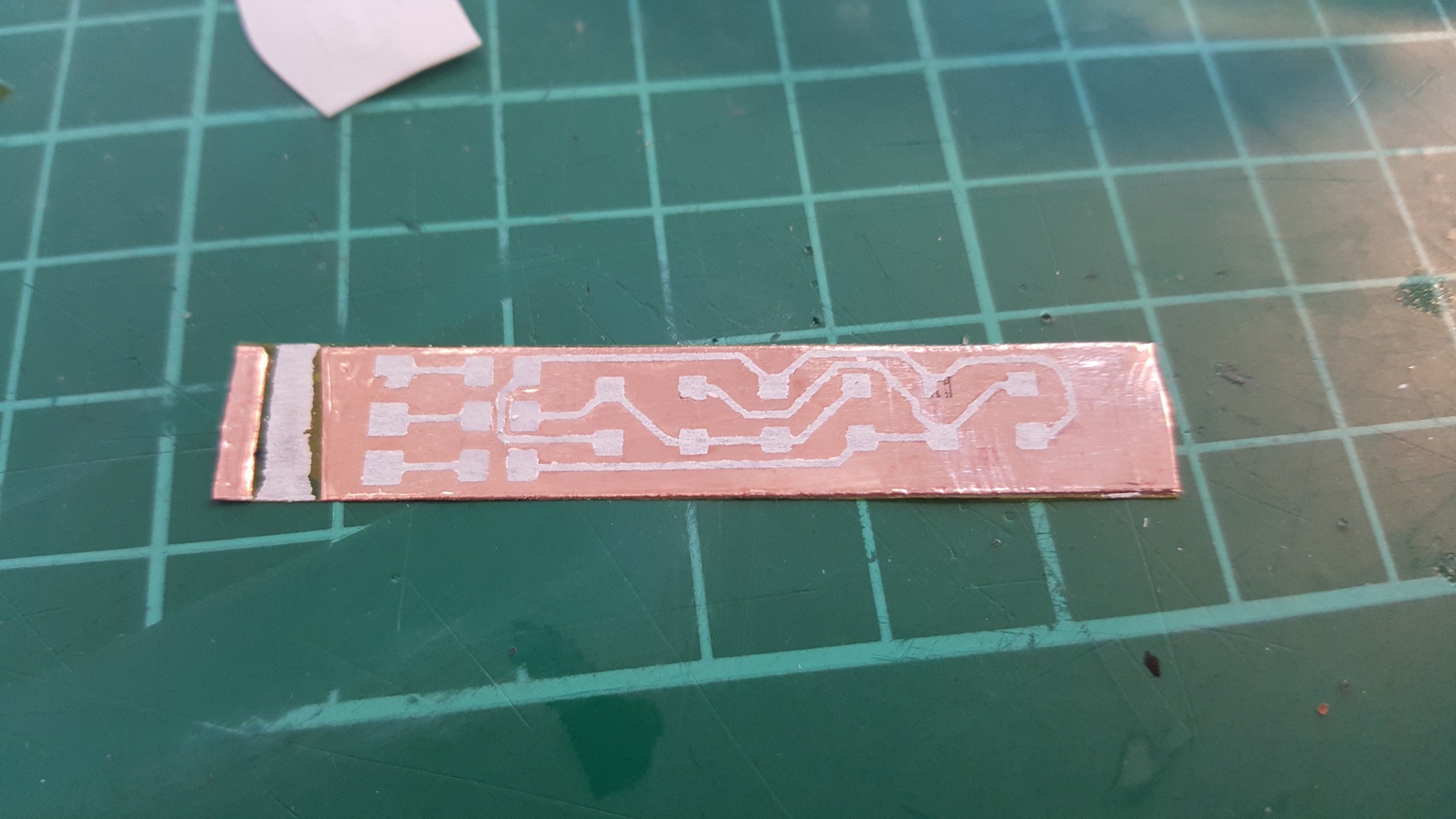

Fixate the toner transfer paper to the sheet

Release the from the tape with water

check traces - WIN

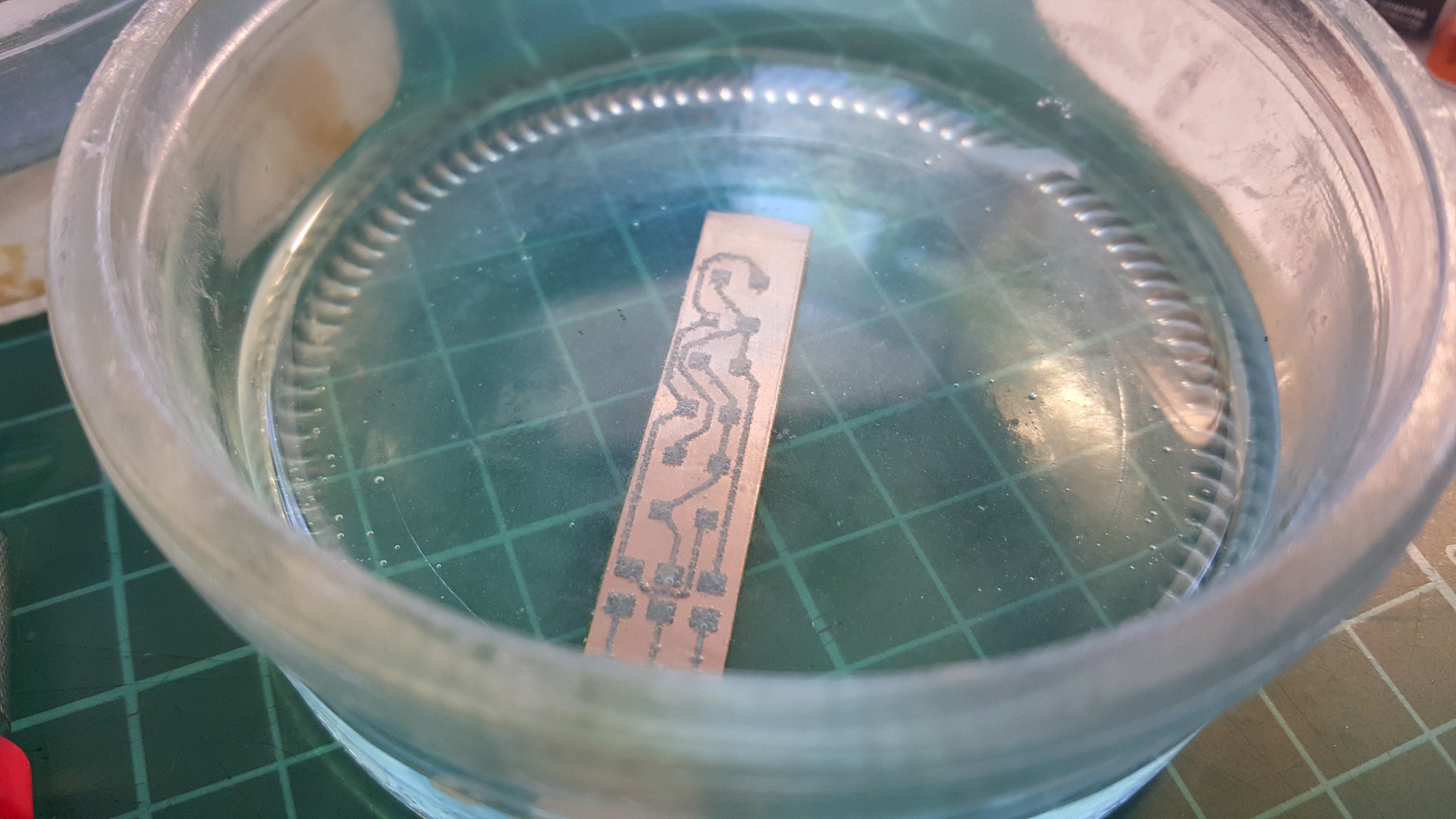

etch it

looking good!

Create an account to leave a comment. Already have an account? Log In.

I was looking for a place to skull you for the project generator but found this one instead.

This is very nice! I think I missed this one. I've had this on my to do list, just to see if it would work, but you beat me to it.

Did you do more experimenting with this method?

Hmm... interessting topic... did you notice that there are also non PCBs which have a thickness of less than 0,3mm? i think it should be able to bend them rather good ;-)

are you talking about dead bug style soldering? :D cause otherwise I have no idea what you mean :)

hm I only need longer stripes aaround 1cm wide for a little led strip.

On another note, I wonder if you could use something like this: http://www.amazon.com/Modern-Masters-ME149-06-Reactive-Metallic/dp/B000I1THBO/

That's an awesome idea. I wonder if it would be possible to somehow hold the copper in place while etching with something, and *then* transfer it to anything (I want to try a glass PCB at some point). You know, something like keeping it between two layers of a dense net while etching.

An alternative would be to glue copper foil on paper with some weak glue, cut it on a plotter, then glue the other side on the target surface, and wash away the paper.

Thank you :) I have to test a bit more and see if I can get better results.

I've seen @CNLohr making glass pcbs on his youtube channel but not the way you describe it.

If I had a laser powerful enough to burn away capton, I would love to use it as solder mask and second layer for stability.

Yeah, I saw that, but the glass became matte in the etching bath. If you transferred the copper after etching, you could use clear glass, or even acrylic (careful with soldering on that, though). You know, the thing you are transferring to doesn't even have to be flat, you could have your circuit on the surface of a light bulb!

I think that capton is intentionally made to be hard to burn. But if you had a plotter with a mechanical blade instead, one that is used for cutting paper...

(1) You can actually buy Pyralux. It's rather nice and pretty easy

to work with. I have done the kapton-copper thing - though with me, I

used sheets of copper, not copper tape and relied on the sticky on the

kapton to help me out. Pyralux along with Riston can be purchased from

Tech-Place. http://www.tech-place.com/en/5-pyralux

(2) Use Bismuth solder paste! The stuff melts at ~140C.

(3)

Though I often used copper that had an etched back (got it off ebay was

for making PCBs) I now frequently use bright copper, like that from

nimrod-hall. You have to sand it first to get the surface to make a

good interface to things, though. If you use bright copper, even after

sanding it, it is still very shiny. http://imgur.com/a/pUTYg

The next time I'm going to try it by putting the sticky sides together.

Become a member to follow this project and never miss any updates

shenzhen

shenzhen

Hacker404

Hacker404

Ted

Ted

fjkraan

fjkraan

What sets Deepmaterial apart is its commitment to delivering products that cater to a wide array of industries, including electronics, aerospace, automotive, tooling, marine, and construction. https://www.adhesivesmanufacturer.com/