-

Cutting aluminium for a tracked rover

01/19/2019 at 07:08 • 0 commentsAs a test run for my CNC v3.2.2 I have cut 3mm aluminium sheets to build a new, tracked robot:

While cutting the parts I found some minor issues with the linear drives and I have ideas how to fix those problems, so my CNC project goes on...

-

Motor upgrade for fairs in Nuremberg and Munich

10/26/2018 at 12:58 • 0 commentsI am preparing my CNC v3.2.2 for two fairs in November 2018:

The first one is the Hack & Make on November 3. + 4. in Nuremberg (Germany). I will be on the stand of my sponsor Siemens, showing my CNC v3.2.2 in live action.

Next schedule is the Electronica in Munich (Germany) on November 13-16. I will be in Halle C5, Stand 147 being part of the presentation of my sponsor RS-Components. Besides CNC v3.2.2 I will have a new machine with me.

If you come for a talk, you can get a sample carved by this CNC.

I am currently implementing an upgrade of more powerful motors:

-

Harvesting sunbeams

07/16/2018 at 07:02 • 0 commentsThe "Power harvesting Challenge" of this year's HackadayPrize is ending today, so here is what my open source CNC router can do to evolve that technology.

To check what precision my latest CNC v3.2.2 can deliver and if the software works fine, I wrote a Perl script that generates Gcode for carving lenses. After (semi) manual finishing work, the result was good enough to concentrate sunbeams to "laser" a piece of paper:

![]()

This was just a first test run. To get better precision and to automatize all steps of lens production, I will add two more axes on my CNC. Being able to carve lenses of any shape will enable me to harvest small portions of light to get closer to the stars or microscopic structures - something that excites my since my childhood days...

-

CNC v3.2.2 made its first run on Maker Faire Berlin

06/03/2018 at 06:44 • 0 commentsThe Maker Faire in Berlin was a great place to be and demonstrate my CNC v3.2.2 for the first time. The mechanics worked fine during the three days and I had talks with many makers, students and teachers so that new ideas came to my mind.

![]()

The software is still in a very early stage, but part of the cooperation with Siemens is to make it process G-Code, thus there is pressure on me to do it in the not so far future ;-)

As a short demonstration the machine was cutting octagons from 2mm acrylic plastics.

I always say that small is beautiful, however this machine is huge (it occupies approximately 1x1x1m) and fits in my estate car with almost no space left:

![]()

I will build a second mechanics with half the size of this one. I am sure that a working area of 20x15cm will still be enough for most projects.

-

CNC v3.2.2 is on the Maker Faire Berlin May 25-27, 2018

05/18/2018 at 04:58 • 0 commentsI am working on a new version of my CNC v3.2 that will be displayed on the stand of Siemens on the Maker Faire in Berlin on May 25. to 27, 2018. Siemens sponsors the development of this machine that is powered by a SIMATIC IOT2020 (Siemens product page). That industrial grade board runs Yocto Linux and has the pin layout of an Arduino Uno, so it's no big deal to implement the IOT2020 in a project like that.

Most of the frame of the new version is now made of chipboard so that the mechanics becomes cheaper and more easy to build. I am using bipolar stepper motors with a4988 driver boards to give people another option to control my CNC v3.2 (a request I got a couple of times). Time will show if the wooden frame is sturdy enough for good results such as with my CNC v3.2.1. If you come to Berlin, you can have a look at this new prototype and see it running.

-

I was lazy, but the community wasn't!

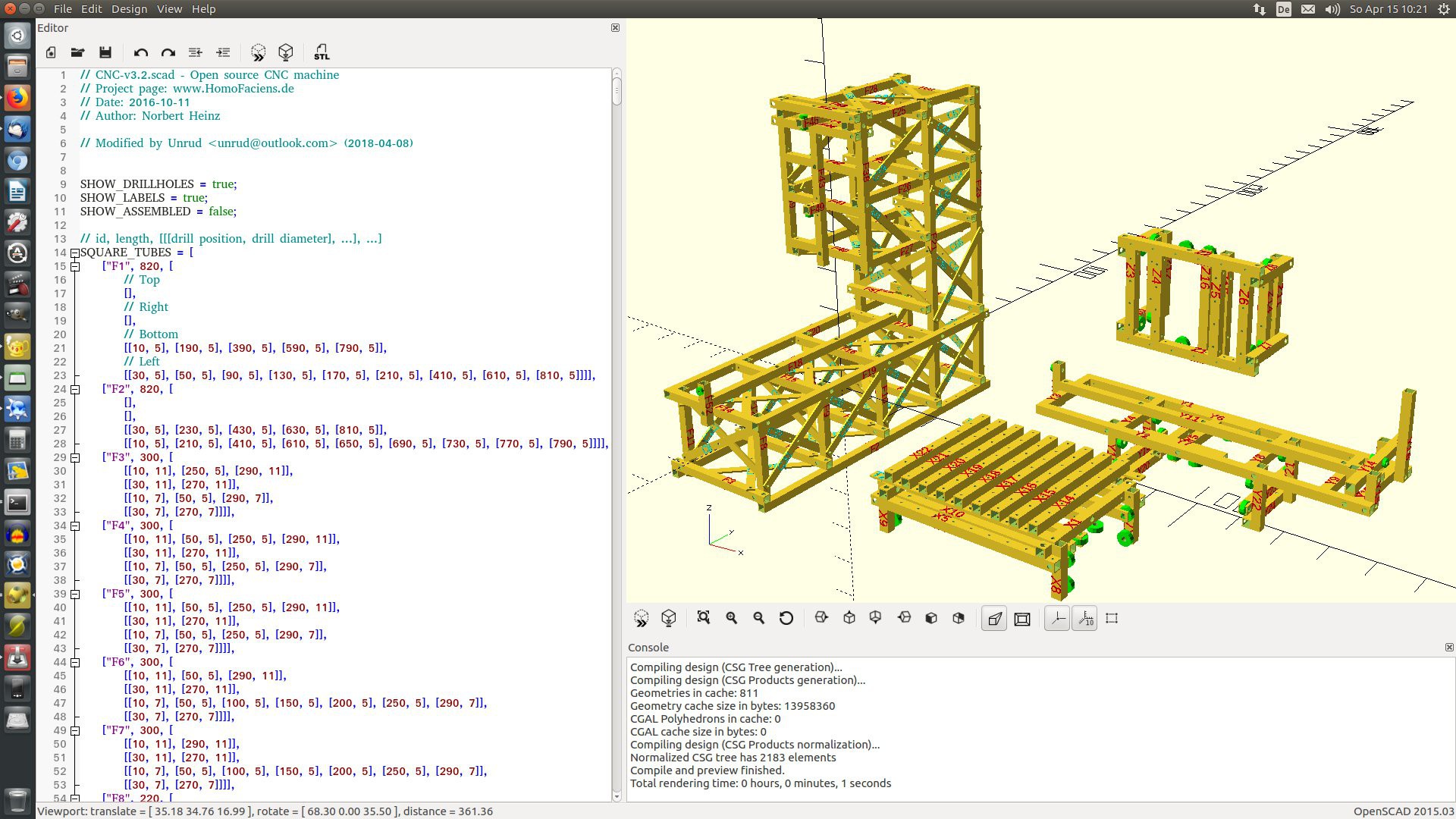

04/15/2018 at 08:29 • 0 commentsWhile I still haven't done all of the coding to make my software process gcode, there is a huge improvement on the construction side of my CNC v3.2 project:

[Unrud] has rewritten the source of my openSCAD model to give it a better readability. Furthermore the drill holes are now included as well. Finally he has written a Python script that extracts the length of the bars and the scheme for all the drill holes from the openSCAD file. Fantastic work, thanks a lot!

https://gist.github.com/Unrud/61cfb145a9026b9bebab6ba41143373f

![]()

With those tool it will be more easy to change the dimensions of the machine to meet your requirements.

Basic DIY CAM 2018

Build computer controlled manufacturing tools from commonly available materials.

Norbert Heinz

Norbert Heinz