PCB stepper motor is certified as open source hardware by the Open Source Hardware Association.

Thanks to OSH for park support !!!

| Check my 2D X-Y linear micro actuator https://hackaday.io/project/154496-2d-actuator-move-micro-robot-in-xy-2d-space |

I am inspired with great project https://hackaday.io/project/39494-pcb-motor

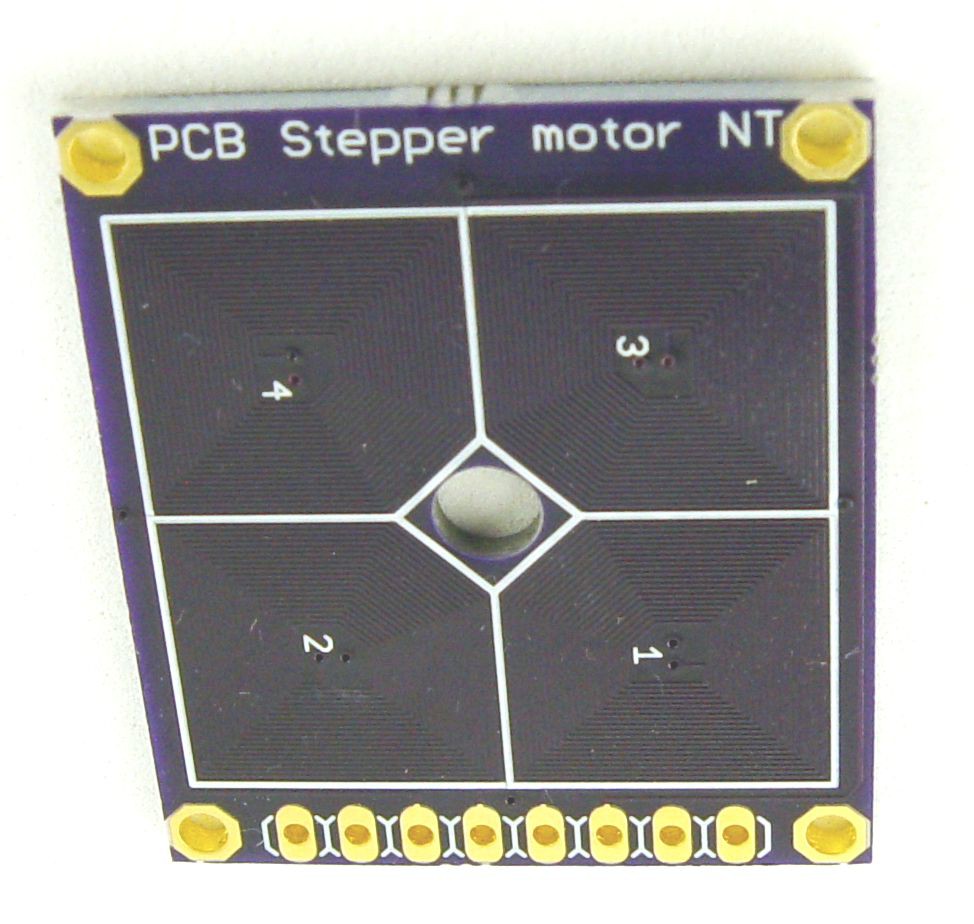

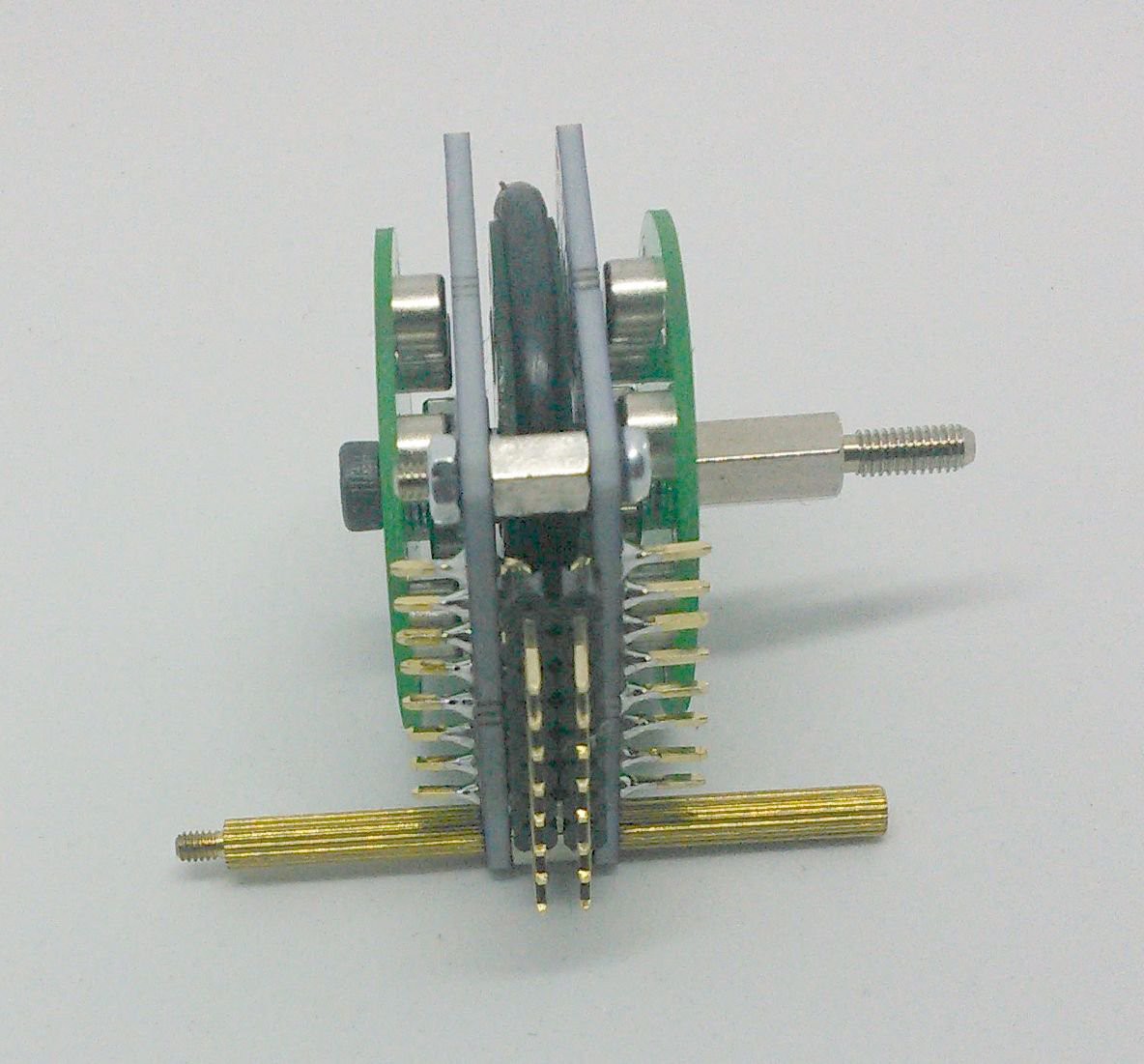

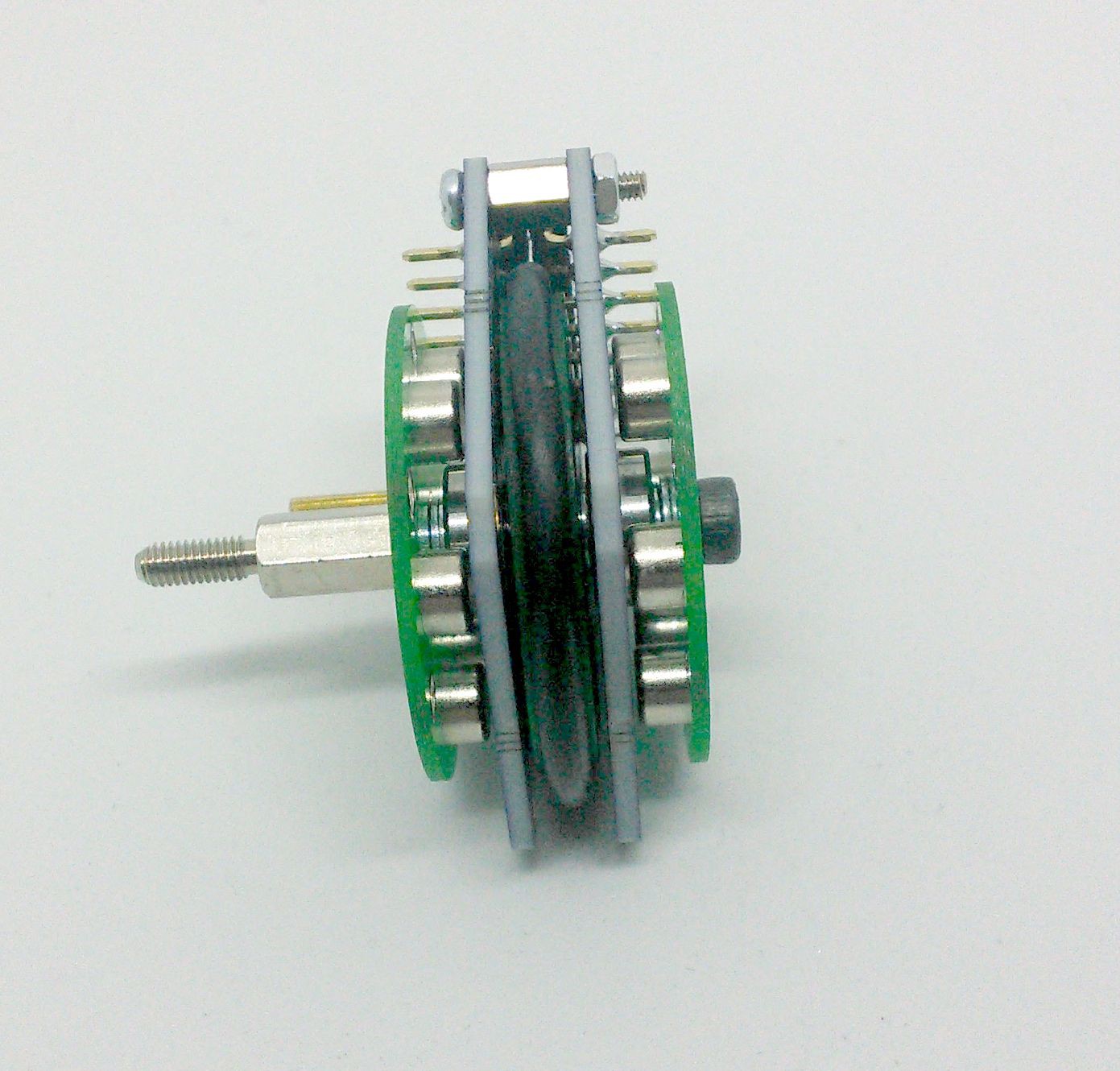

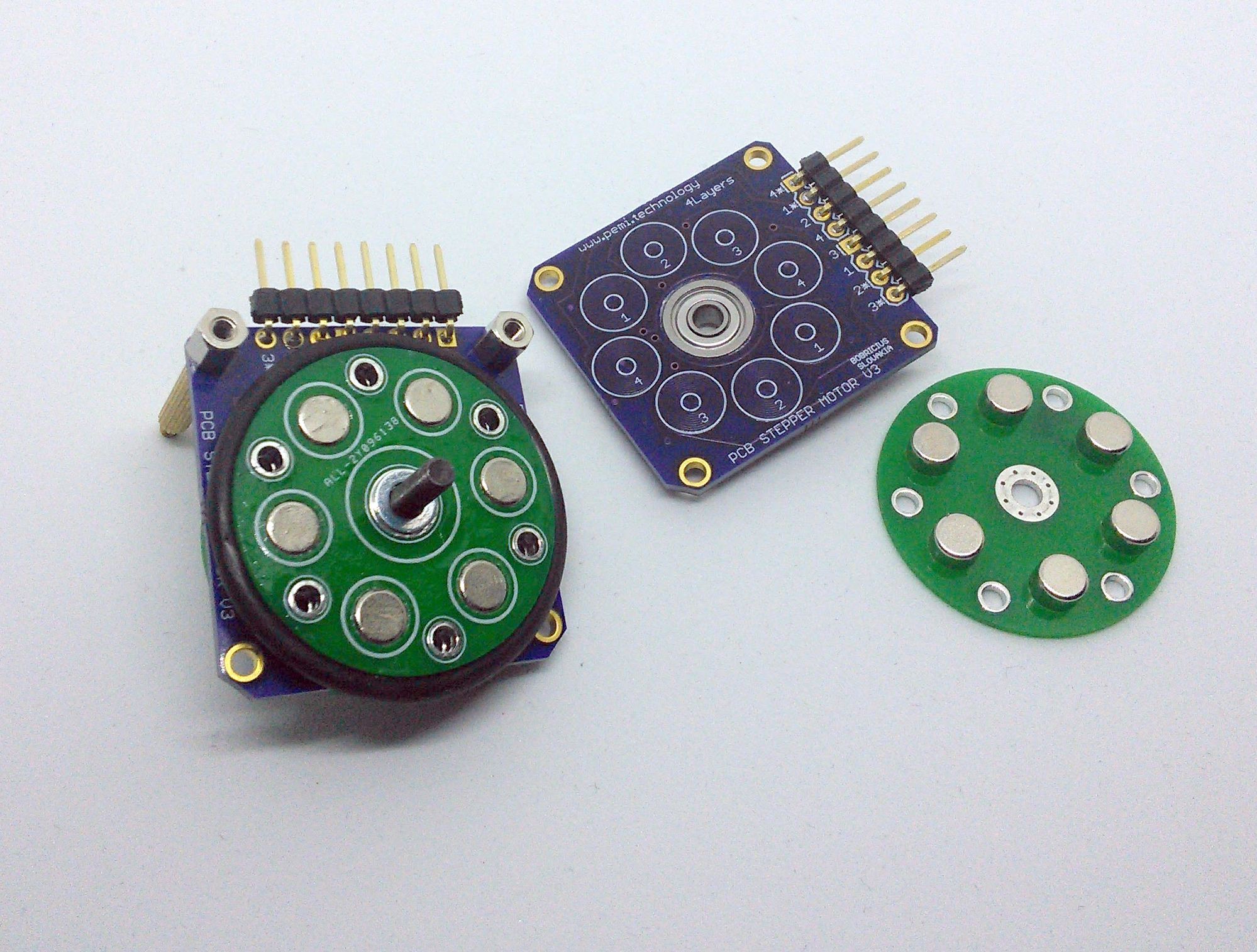

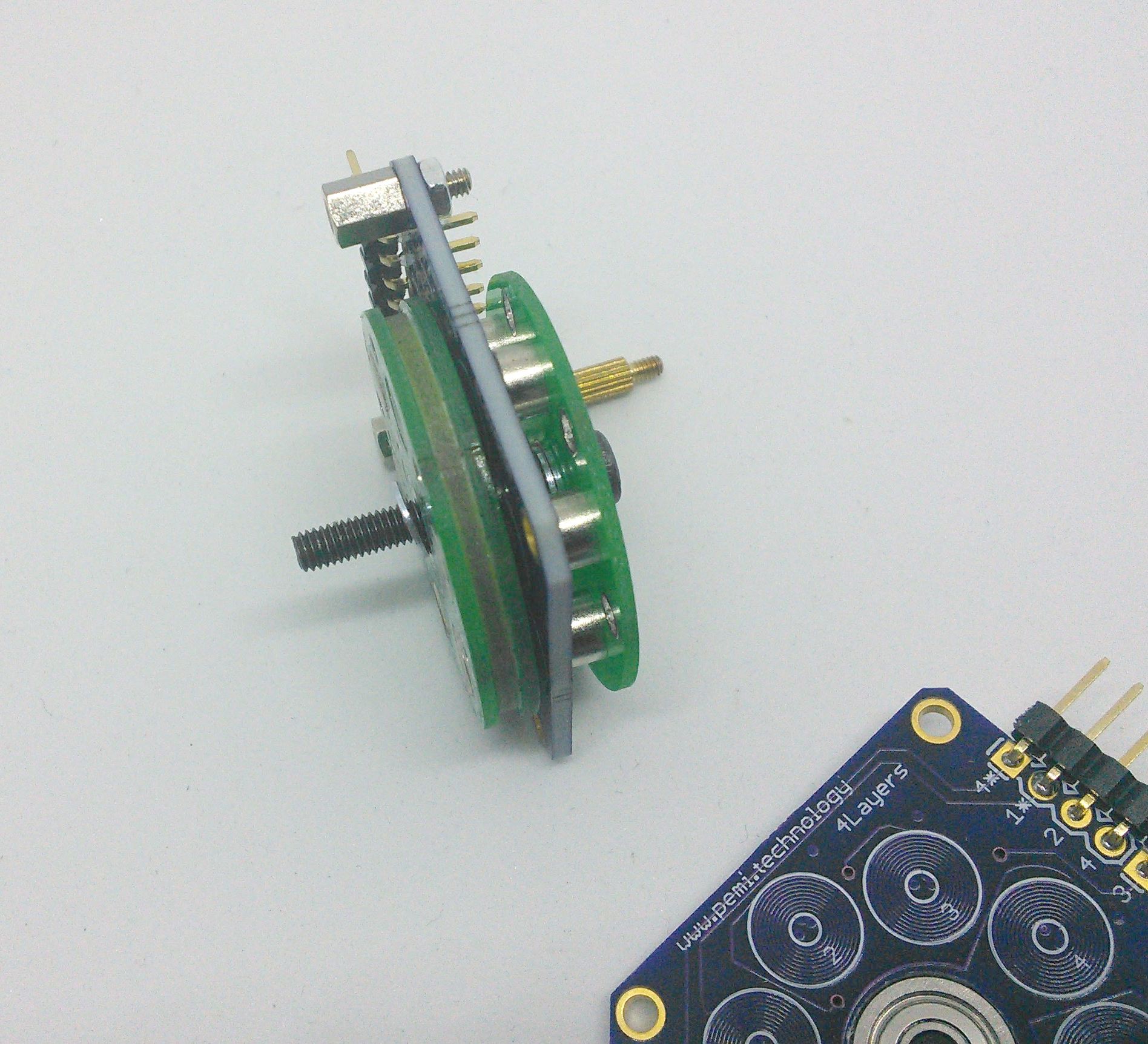

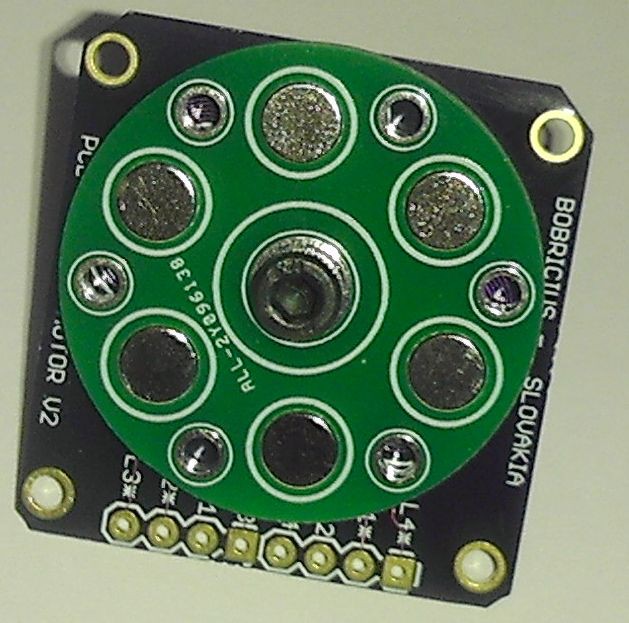

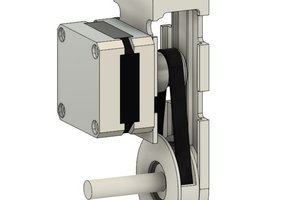

Instead of printed rotor I am using PCB rotor (3 layers of 1mm PCB and 5x3mm magnets)

middle layer rotor PCB have 1mm smaller diameter and making rim for simple rubber

ring tyre

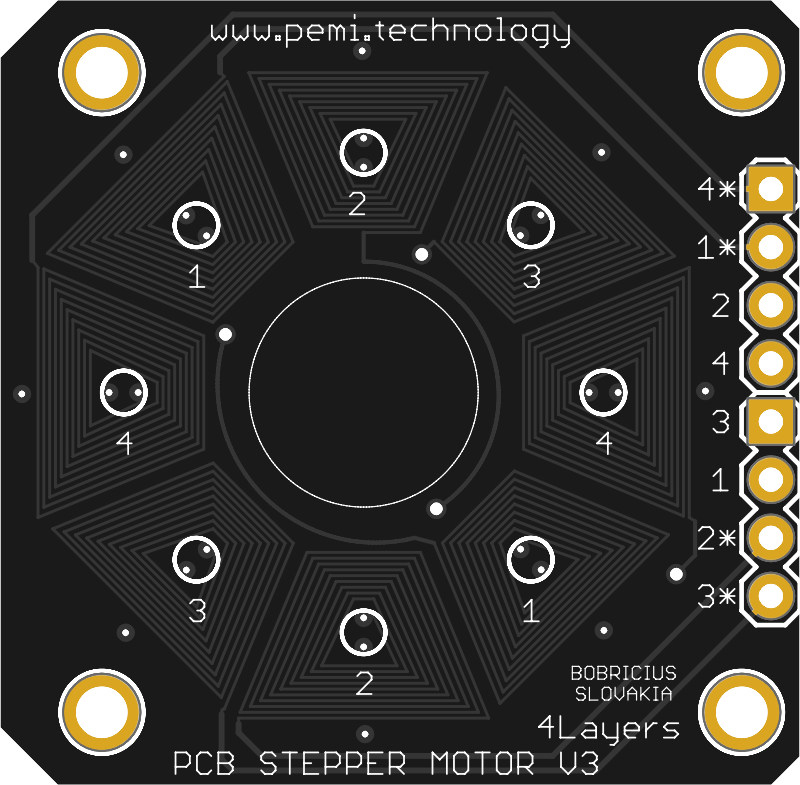

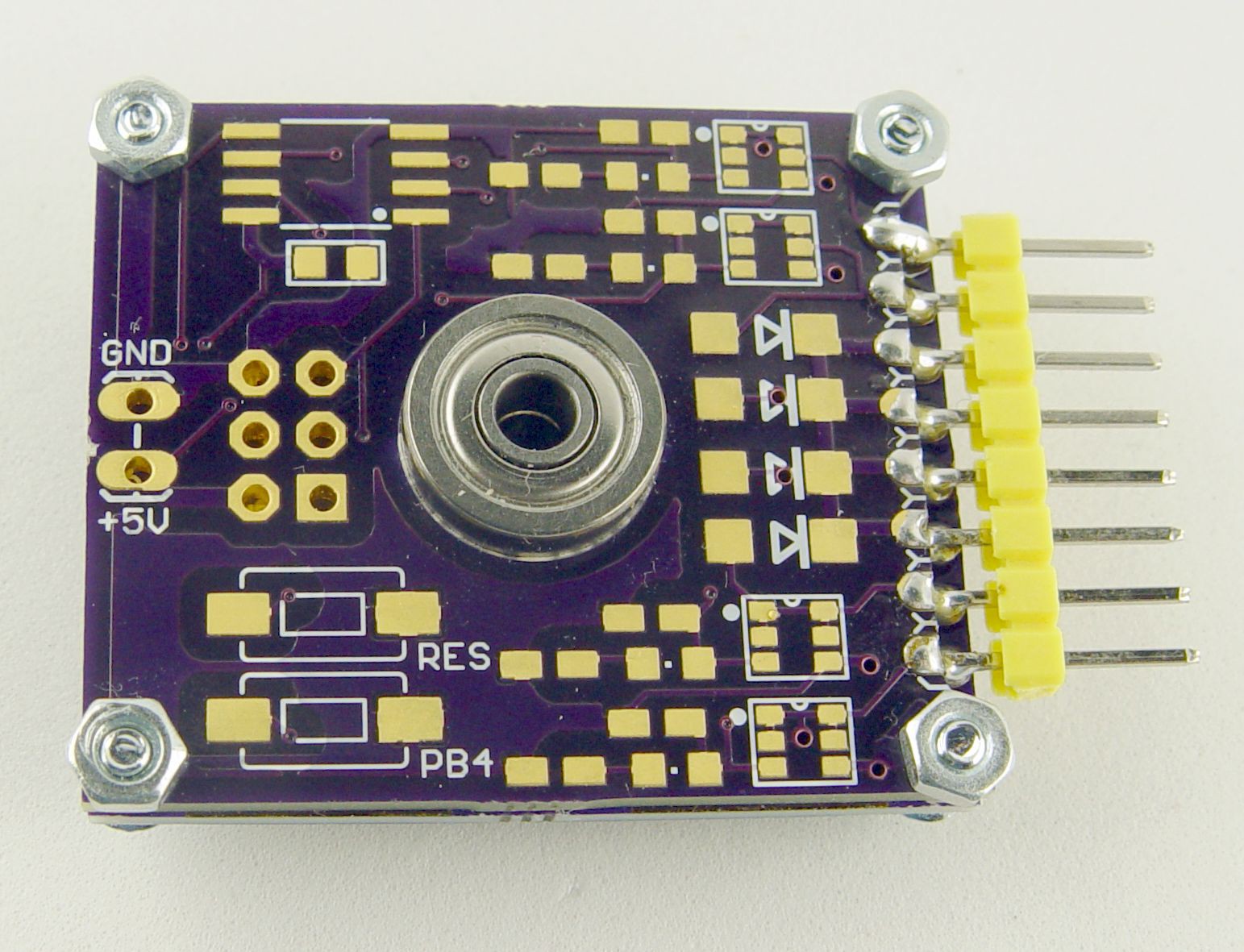

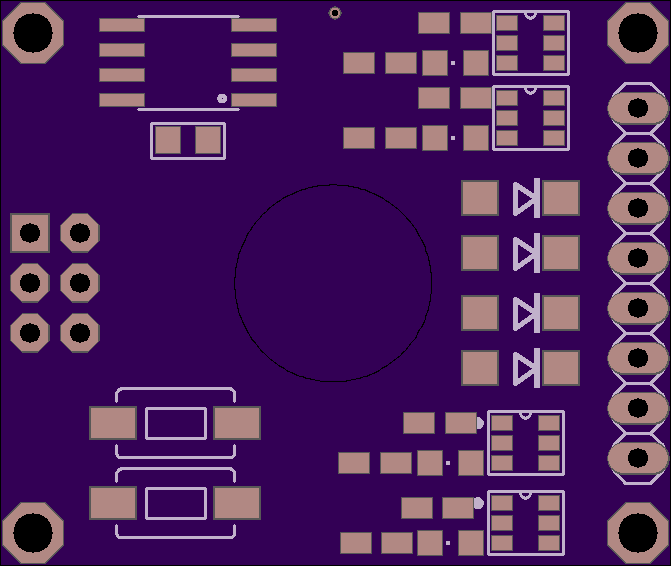

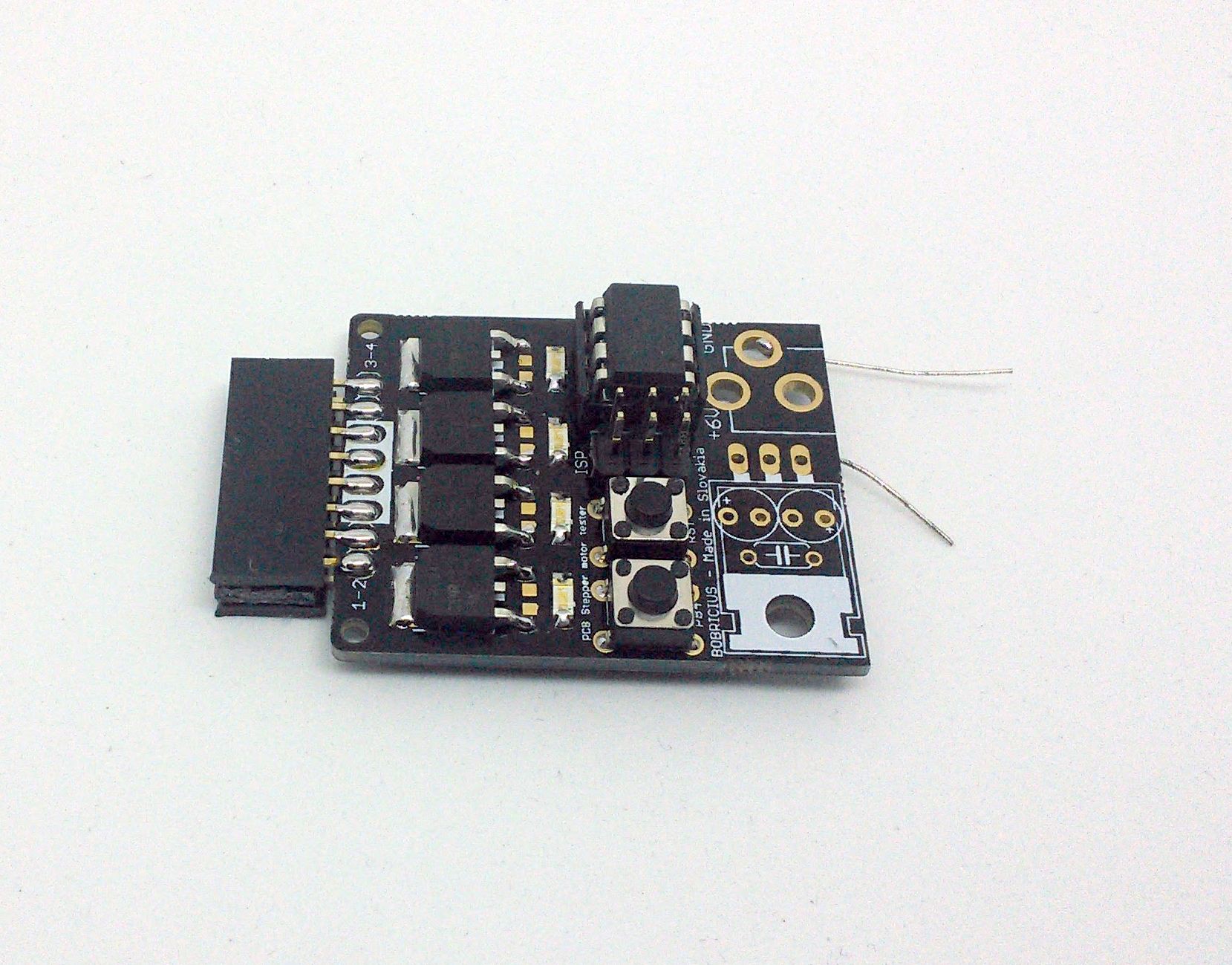

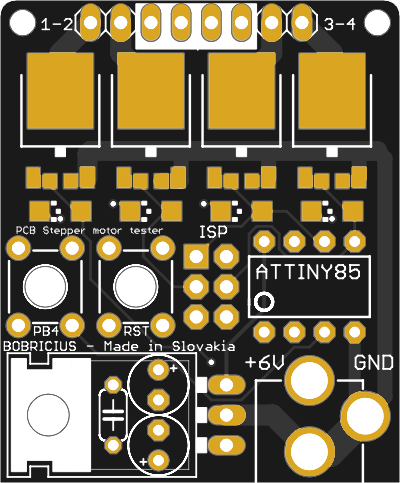

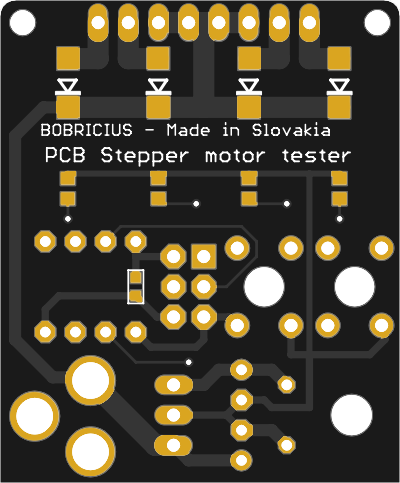

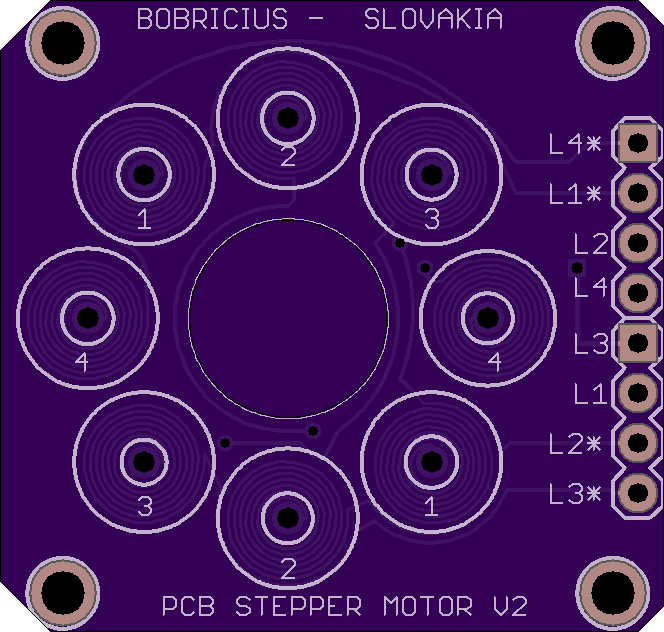

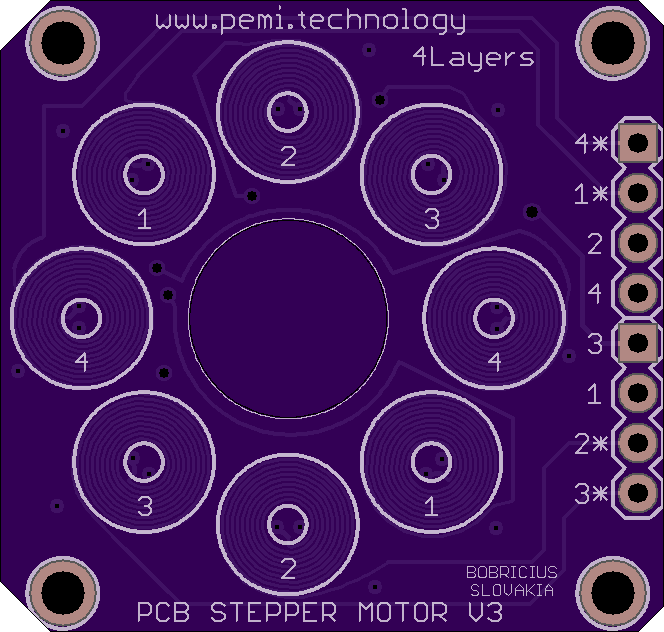

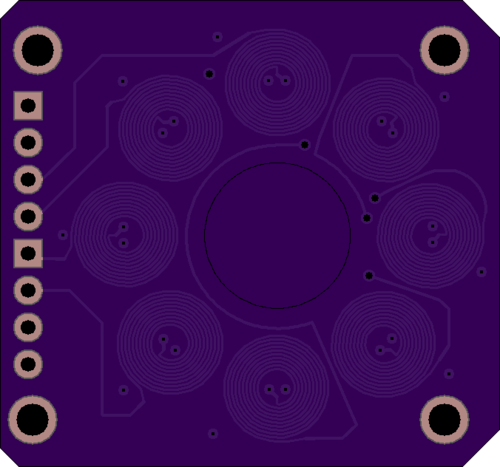

Board can be easy configured to unipolar or bipolar mode

- 4 layer 40 turns per coil !

HACKADAY article https://hackaday.com/2018/03/28/a-brushless-motor-on-a-pcb-made-from-pcb/

bobricius

bobricius

Vitaly

Vitaly

cjh

cjh

Hello.

Is it available to download the scheme and the PCB you use to control your stepper motor?

Regards