-

Electronics - cheap sensors

04/10/2016 at 18:15 • 0 commentsIf you want to get into electronics, one great thing to have is some modules/sensors lying around for fast prototyping. You can buy cheap 'kits' of sensors (Search '37 sensors arduino' on banggood or aliexpress) with tilt, touch, laser, joystick and so on. A good write-up of the common ones can be found here: https://tkkrlab.nl/wiki/Arduino_37_sensors

My loving brother bought me a kit - here's my first useful hack with it as an example of how easy this sort of thing is. I was reminded why so many people choose arduino for prototyping - this whole project took about half an hour. Sure, it's not energy efficient or as cheap as it would otherwise be, but I'll re-use all the components and I didn't even have to solder a single wire.

The goal was to make a box that would play a melody and blink some lights whenever someone recycled a plastic bottle. I thought of having the bottle break a beam, or activate a vibration sensor when it landed, but I decided to go with one of the little mercury tilt switches.

Without further ado, here's the code:

/* * Sketch modified by Jonathan Whitaker * Based on example code by by Tom Igoe http://www.arduino.cc/en/Tutorial/Tone * All code public domain. */ #include "pitches.h" // Copy from arduino tone example for this to work // notes in the melody: int melody[] = { NOTE_C4, NOTE_G3, NOTE_G3, NOTE_A3, NOTE_G3, 0, NOTE_B3, NOTE_C4 }; // note durations: 4 = quarter note, 8 = eighth note, etc.: int noteDurations[] = { 4, 8, 8, 4, 4, 4, 4, 4 }; int tiltPin = 2; // Signal pin of tinlt sensor int led = 13; void setup() { pinMode(tiltPin, INPUT); pinMode(led, OUTPUT); digitalWrite(led, LOW); } void loop() { if (digitalRead(tiltPin) == HIGH) { //read tiltPin digitalWrite(led, HIGH); //turn LED on play(); //Play a tune digitalWrite(led, LOW); } } void play(){ // iterate over the notes of the melody: for (int thisNote = 0; thisNote < 8; thisNote++) { int noteDuration = 1000 / noteDurations[thisNote]; tone(8, melody[thisNote], noteDuration); int pauseBetweenNotes = noteDuration * 1.30; delay(pauseBetweenNotes); noTone(8); } }Simple and easy, especially since I just modified the example tone sketch. SO one wire of the sensor goes to pin 8, the others to power and ground. I also have the option of RGB LED blink patterns, but I'll leave that out of the code for simplicity. Here's a photo of the box (from inside):As a bottle is pushed through the hole it bumps the sensor (which has since been hot-glued in place) and the barbers knock song plays while lights blink. Simple, easy and fun - the perfect beginner project.

-

Making a mini PCB vice

01/19/2016 at 07:44 • 0 commentsInspired by #MobileVise and the scrapvice in #Misc. spur-of-the-moment projects, I decided to make a simple version of the wonderful #Stickvise - low profile soldering vise by @Alex Rich.

![]()

Parts:

One 4x70mm machine screw with nut, One small spring from a printer (any spring that fits around the screw) and a scrap piece of wood.

I drilled a 4.2mm hole through both pieces of wood at the same time to keep things aligned. I used a saw to make a groove just above the hole on both sides to give the PCB somewhere to click in. The picture pretty much says it all.

This is a pretty useful kind of vice. You can play with different ideas (eg having two threaded rods or screws, one at either end, to clamp something in the middle with a bit more force). Or you could make a more conventional C clamp with a few extra pieces of wood. The spring means you can easily clip something in and out, but you can remove it if you want more brute force clamping power.

-

Getting parts/materials - tearing down a printer

01/01/2016 at 16:24 • 2 commentsTo build stuff, you need stuff! While you could just go and buy what you need, not all of us have the $$$ and besides, you learn more by using what you can get sometimes.

One of my favourite sources for parts is old printers and scanners. The newer they are, the less interesting stuff can be easily had since there has been a shift from printers with several dedicated boards (eg one motor controller board, power supply, processing, interface etc) and a few stepper motors to just one integrated board and a DC motor or two. But even new printers have some useful stuff in them. Here are some of the useful things you can look out for, as well as just pictures from the latest laser printer I took apart:

![]()

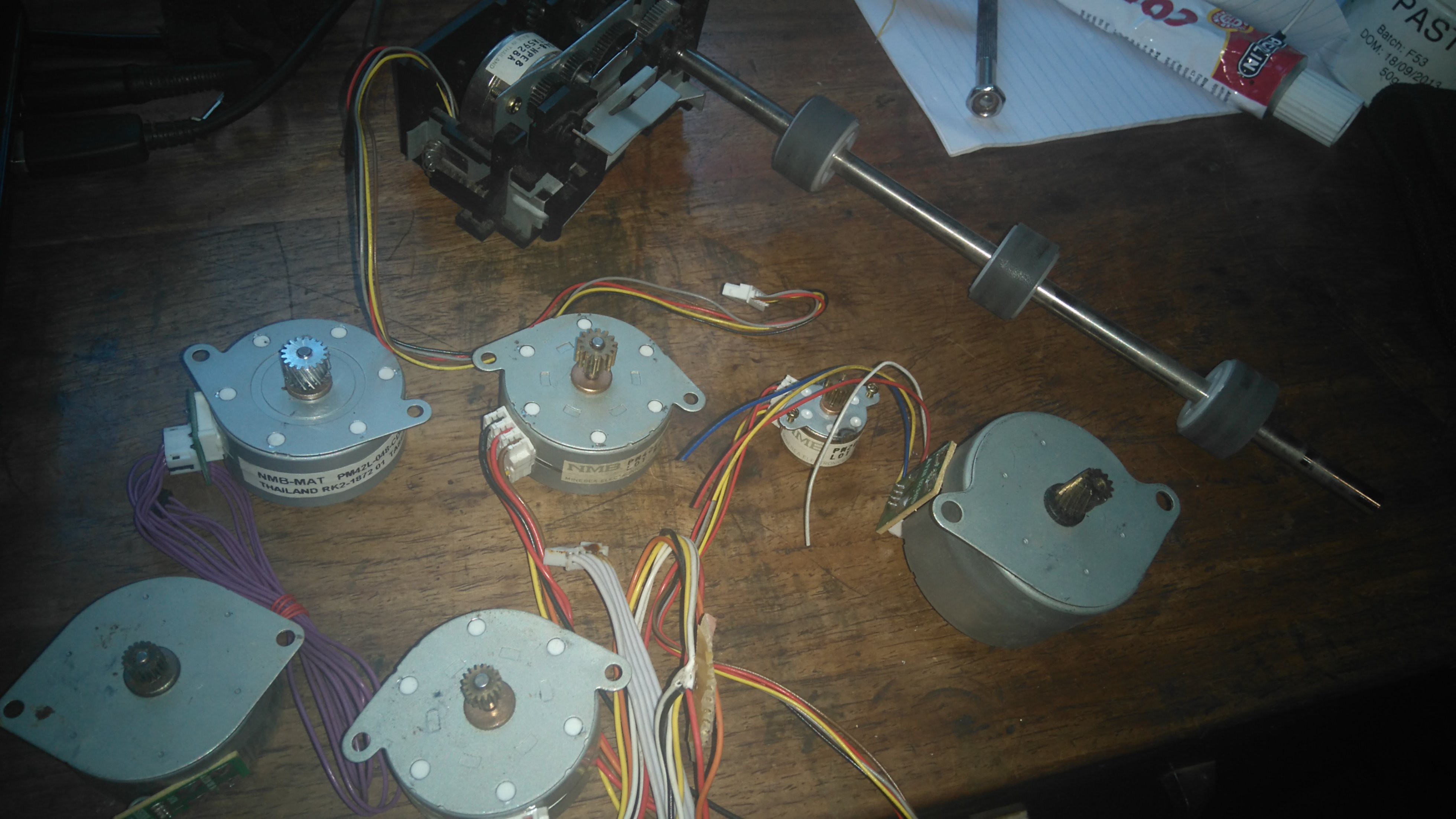

Stepper motors - by far the most useful parts for me at least, these can be controlled by your computer or arduino or whatever to rotate in small increments. You can find various sizes and strengths, so google around to find the pinouts and stats:

![]()

Power supplies. If you're lucky, the printer will have a separate board outputting something like +24V, GND, +5V and possible +12V or something. These are nice for running any motors you scavenge.

DC motors. Some printers use a DC motor and an optical encoder for positional feedback. You can try your hand at working with these for precise control, but personally I just rip the motors out and use them for other things. They are generally quite high torque and decently fast...

![]()

Brushless motors. These are super hard to drive, BUT there is usually a motor controller chip right next to them. Google the part number and you can figure out a +V, GND, and GO_AS_FAST_AS_YOU_CAN pin :D These are quite often used to spin the mirror in the laser assemblies of laser printers, but beefier ones are also used to push the paper through in some printers. Here's one with a square mirror Note the piece of paper I keep with it so I don't have to keep looking up the pinout:

Strait rods and slides. If you're planning any sort of mill/3d orinter/laser cutter/xy thingee, these are super useful.

Screws, springs and gears. A lot of printers only use two or three different screws, so they are a good source of parts if you need a lot of the same thing. Chuck the springs and smaller pieces into a jar - they will come in handy when you least expect (see if you can spot one in #Scanning EIT Imaging System (SEITIS)).

Little solenoid/clutch things. Apply a current and the little lever moves and potentially stops a gear from spinning.

Photo-interrupters. Most printers have at least four, with some larger ones having closer to 20! These little things are easy to interface with, and can be set up to triger an event when the beam is broken.

Photo-interrupters, an electric clutch thing and some assorted screws:

![]()

A fusor module from laser printers is basically a heating element. Some a quartz crystals, others are basically a long thin ceramic resistor. Don't burn yourself...

Metal and plastic stock. Especially if you're just starting to build a collection of materials, some nice flat pieces of metal with lots of threaded holes and attachment points are useful building platforms. Don't bother keeping everything, but grab some of the nicer looking pieces of metal and plastic to leave in a box until you need them.

Small PCBs with a few buttons and LEDs. Need to add an interface to something but can't be bothered to breadboard some buttons? These are easy to plug in and go, although not many newer printers have one. :

Some other gems can also occasionally be found, but these are the most likely things. Amazingly, all you need to disassemble most printers is a big phillips screwdriver and perhaps some wire cutters - everything snaps apart quite satisfyingly. Since so many get thrown away this is a nice low cost way to get parts :)![]()

![]()

-

So what do you actually need?

12/29/2015 at 06:15 • 0 commentsOn to the controversial topic of which tools are a *must* for someone starting out. Obviously, everyone has different ideas and the necessities will change depending on what type of projects you're working on, but here are my recommendations and thoughts.

1. The Essentials

Here we come to the meaty question of what exactly I mean by ‘Almost Nothing’. While you could start from a lump of iron ore and a loincloth, the reality is that beginning with a few simple tools will make life easier. Here are some good ones to start with:

- Hacksaw blades. These cost next to nothing, and can cut through all sorts. Getting a hacksaw body will make things vastly easier, but theoretically if you can cut it with a hacksaw then you could cut it with just the blade – it would just be slow and painful.

- Screwdrivers. You can get by with a phillips and a flat-head, but a kit of smaller ones and a few larger ones will be needed of you’re going to be taking much apart.

- Some side cutters/wire cutters. Cut wire and stuff

- Some pliers. Needle-nose pliers will come in very handy, for gripping, bending and shaping things.

- Vice grips/adjustable pliers. The tool of all tools if you listen to some. Grip things, clamp things, hold on to things to your hearts content.

- Tape. A good selection is useful, but some masking tape and some electrical tape will see you through most things. Also duct tape is incredibly useful.

- Glue. Stick things to other things. There are many types, but a 2-part epoxy, some contact adhesive and maybe some super-glue should do for most things. Add some silicone rubber and possibly wood glue if the urge takes you.

- WD40 is a spray lubricant that some people swear by. It will be used in a lot of these projects, but you might get away without it. Get some of you can, or when you first really need it.

- Craft knives/xacto knives. One of those things you don’t realise you’re missing out on. And since they’re so cheap and soooo useful, get a few!

- Sandpaper – get several different grits (200, 400, 800…)

- A few files - one flat and one round for metal and same for wood, add more as needed

I'm also going to be assuming access to e-waste, some basic timber, string, wire etc. You can scavenge most of this stuff by keeping an eye out. I’ll try to use a few different components as possible, and have standard ways of doing things. For example, I have decided to use 3mm machine screws for as many things as possible, simply because I have a 3.2mm drill bit or three for my dremel and it's easy to adjust tension etc by adding a spring washer and a nut to the bolt. For larger stuff i also have 4 and 6mm ones, and I have lots of 3mm screws of assorted lengths from some printers I took apart.

If you're mainly going to be doing electronics, you could ditch some of the above and last quite some time. But you will definitely also need:

- A soldering iron, with some solder and flux (don't buy one for <$10)

- A multimeter (DMM). Again, avoid the cheapest of the cheap, but nothing too fancy is needed to start with.

- A helping hand or PCB vice for holding stuff while you solder. You can also make your own.

- A collection of components (This will be a separate post).

This is not a definitive list by any stretch of the imagination. But everything listed above other than the soldering stuff should come in around $30 depending on how you get things. To be honest, you can start making things with hacksaw blades, box cutters, some nails and a screwdriver for <$5, and most of us should have hammers and things lying around or be able to steal hem from dads/uncles/grandparents who were handy around the house.

2. Nice to have

These tools are nice, and generally speed things up a lot, so are often worth it in terms of time they save

- A chisel or two for woodwork

- A grindstone. So useful for removing material, and probably the power tool I use the most.

- A drill, or ideally a drill press. One of the first power tools you will need, you can also get sanding and cutting bits, plus you can use a drill as a lathe in a pinch.

- A rotary tool - can drill, sand, cut and buff like a smaller version of four power tools. I just got a dremel and can think of so many uses. Again, you could do all this by hand but where's the fun in that? :P

- A multi-tool. Having a leather-man at your belt means quick access to a knife, a saw, screwdrivers, pliers, wire cutters and so on. My current one (yaay for Christmas) is the sidekick - $40 and has a nice selection of tools. I also love my gerber dime - a miniature multi-tool that lives in my pocket and has come in useful so many times. Definitely a worthwhile investment, as it almost negates the need for a full sized tool and is small enough for civilised society yet capable enough for everything that I need it for.

- A hot melt glue gun. For quickly sticking A to B, securing and insulating wires, knocking together prototypes or just burning your fingers, this is a very useful addition.

3. Other thoughts

This is such a dynamic thing, and your tool collection will grow with you and expand as you need things. You'll notice that I have left off things like laser cutters and 3D printers. That's because I haven't used them, and I have found that you can make most things as well with a grindstone and some patience. Nevertheless, if you have the cash to invest in a full machine shop with milling machines, lathes, cutters etc etc then go for it! But if you don't have the cash, don't worry - the one time you need a 3D printer go borrow time on someone else's and pay $5 for the part rather than $1500 for a printer you'll use a few times.

On that note, tool sharing is a thing. You can rent power tools (so why buy one that you'll use twice?) or find a friendly person who's been making things longer than you and borrow! If you're lucky enough to live near some sort of hacker-space then take advantage - they will probably have more than you can dream of!

4. Links and inspiration

- Adam Savage's ideas http://www.tested.com/art/makers/454389-still-untitled-supplemental-adams-inexpensive-beginners-toolkit/

- http://makezine.com/tag/tools/

EDIT 1: Things I forgot and have just remembered:

Measuring tape, ruler, calipers, hand saw, clamps, flashlight, hammer, vice, pens/markers, power supply, breadboard, storage

This is still a work in progress. PLEASE post your own recommendations and thoughts so I can update and improve this list :)

-

Nail tools

12/28/2015 at 19:08 • 1 commentA bag of 10mm (or 6 inch) nails, a hammer and a file or two (or a grindstone, or some rough concrete, or a rock) can be used to make some pretty useful things in a pinch. Without further ado, here are some ideas:

1) Leave the nail exactly as it is - useful for banging quick holes in things). Can also round the end with a file to make nice round holes.

2) Flatten the end, sharpen it to make a chisel. Useful for cutting thin metal (like a tin). Lots of info and diagrams at nzdl - chisel

3) A drill, also described at the nzdl link.

4) Flat and Phillips screwdrivers. Flat is simple - file it to a flat point! But Phillips? Well, ok, 2D phillips... but it still works! Basically make a flat triangle at the end...

5) Various other pokers and pointy things as the need arises - the whole point is that you make what you need. Filing away 5 or 6 sides and adding a right angle bend for example could make a crude allen key, etc.

Notes:

- All these tools can be fire hardened by heating up to red hot then quenching in water a few times.

- Obviously these don't work as well as a 'proper tool' in some situations, but they are cheap, easy, and disposable (so if it might break, rather break a $0.05 nail than a $5 screwdriver).

- Sharp tools are more fun - sharpen on a file or sand paper.

Here are the ones I have made that are lying within reach right now (I made them recently away from home):

![]()

How to build some things from (almost) nothing

A collection of tips and info about making on a budget. Ideas welcome!

johnowhitaker

johnowhitaker