-

Guide to Porting and Configuring Nginx on OKMX6ULx Embedded Linux (Kernel 4.1.15)

5 days ago • 0 commentsNginx (engine x) is an open-source, high-performance Web server, reverse proxy server, load balancer, and HTTP cache server. It is characterized by low memory usage and strong concurrency ability. In fact, Nginx performs well in terms of concurrency among web servers of the same type. It is developed using the C programming language.

Nginx is specifically developed for performance optimization. Performance is an important consideration in its design. It focuses highly on efficiency in implementation and can withstand high-load tests, supporting up to 50,000 concurrent connections.

1. Compilation and Porting

1.1 Compile nginx-1.8 in Yocto

Execute the following commands for compilation:

$ DISTRO=fsl-imx-x11 MACHINE=imx6ull14x14evk source fsl-setup-release.sh -b build_x11 $ bitbake nginx

During the compilation process, the following errors appeared:

Solution:

Modify the build_x11/conf/bblayers.conf file and add the source code path of Nginx to the file. build_x11 is the installation and compilation path defined by yourself.

Modify the content as follows:

After adding, execute bitbake nginx again for compilation.

1.2 Package the Image

After compilation, go to the

build_x11/tmp/work/cortexa7hf-neon-poky-linux-gnueabi/nginx/1.8.1-r0/image

path to package the image.

$ cd tmp/work/cortexa7hf-neon-poky-linux-gnueabi/nginx/1.8.1-r0/image $ tar -cjvf nginx-1.8.1.tar.bz2 *

1.3 Transplant

Extract the image packaged in the previous step to the root path of the system.

tar -xvf nginx-1.8.1.tar.bz2 -C /

2. Test

2.1 Reverse Proxy

2.1.1 Tomcat Installation

① Install the JDK environment

Download address: Oracle JDK 8 Downloads

Download the following two files:

jdk-8u151-linux-arm32-vfp-hflt.tar.gz

and

jdk-8u151-linux-arm32-vfp-hflt-demos.tar.gz

Extract them to the development board:

Extract the above two compressed packages to /home/root/jdk1.8.0_151.

Modify the environment variables:

Add the following content at the end of the /etc/profile file:

JAVA_HOME=/home/root/jdk1.8.0_151 CLASSPATH=.:$JAVA_HOME/jre/lib/rt.jar:$JAVA_HOME/lib/dt.jar:$JAVA_HOME/lib/tools.jar PATH=$JAVA_HOME/bin:$PATH export JAVA_HOME CLASSPATH PATH

Execute the following command to make the environment variables take effect immediately:

$ source /etc/profile

Verify whether the installation is successful:

Enter the following command to check the Java version:

$ java -version

② Install Tomcat

Download the source code: Tomcat 9.0 Downloads. Here, download version 9.0.108.

Extract the downloaded

apache-tomcat-9.0.108.tar.gz

to the

/home/root

path on the development board.

tar -xvf apache-tomcat-9.0.108.tar.gz -C /home/root

Start the Tomcat service:

cd /home/root/apache-tomcat-9.0.108/bin ./startup.sh

After starting, enter 192.168.1.13:8080 in the browser, and the Tomcat interface will be displayed.

2.1.2 Modify Nginx Configuration

Modify the /etc/nginx/nginx.conf file:

server { listen 80; server_name www.123.com; location / { proxy_pass http://192.168.1.13:8080/; index index.html index.htm; } }- listen: It indicates that the port 80 is monitored.

- server_name: The access domain name is defined here.

- proxy_pass: It is a proxy forwarding module. Its main function is to forward www.123.com requests to http://192.168.1.13:8080/.

Start the Nginx service:

mkdir /run/nginx nginx -c /etc/nginx/nginx.conf

Modify the hosts file in Windows:

Press Win + S, run Notepad as an administrator, open the hosts file under C:\Windows\System32\drivers\etc, and add the mapping.

Test:

Enter www.123.com in the browser, and you can access the Tomcat interface via Nginx.

2.2 Load Balancing

1. Setup Service 8080:

Rename the above-mentioned apache-tomcat to apache-tomcat8080, and create a test file:

mv apache-tomcat-9.0.108/ apache-tomcat8080/ cd apache-tomcat8080/webapps mkdir test vi test.html

<!--apache8080--> <html> <body>welcome to service 8080</body> </html>

2. Setup...

Read more -

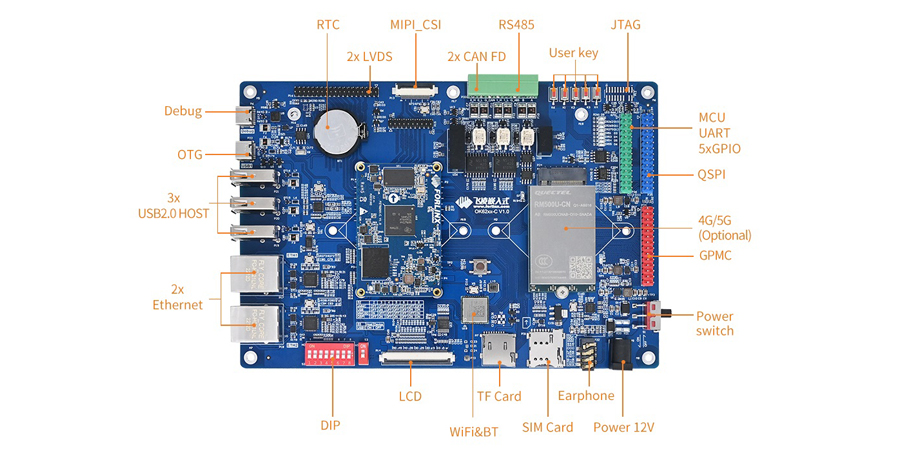

Guide to TFTP Flashing the File System on Forlinx Embedded RK3568 Development Board

5 days ago • 0 commentsThe test is conducted using the standard development environment of Linux 4.19.206 on the OK3568-C development board, which is equipped with the Rockchip RK3568 processor. It has a stable network foundation and can meet the transmission requirements of the TFTP protocol. During the testing, the TFTP server was deployed on the Ubuntu system. Ubuntu and the RK3568 development board were configured in the bridge mode (by leveraging the hardware advantage of the dual network interfaces on the development board, the network transmission latency can be reduced). The server address was set to 172.16.0.177.

Make sure to place the system images (boot.img and rootfs.img) in the TFTP server directory beforehand. Additionally, verify that there is a proper network connection between the development board and the server, as this is essential for the process to run smoothly.

Forlinx RK3568 SoM

1. Configuring U-Boot Environment Variables for Network Access

The Uboot environment configuration of the RK3568 development board is simple and intuitive. Coupled with the on-board Type - C Debug interface (which integrates a USB - to - serial chip, eliminating the need for an additional adapter), developers can quickly enter the Uboot command line through terminal tools (such as SecureCRT and Xshell) to complete the network parameter configuration.

Operation tips: The default baud rate of the Type - C Debug interface is 115200bps, with 8 data bits, 1 stop bit, and no parity check. After connecting, restart the development board to enter the Uboot command line.

=> setenv ethaddr 22:51:a2:cc:47:2d # Set the Ethernet MAC address of the development board to ensure a unique network identity => setenv ipaddr 172.16.0.176 # Configure the static IP of the development board, which should be in the same network segment as the server => setenv gatewayip 172.16.0.218 # Set the gateway address to ensure cross - network segment communication (if needed) => setenv netmask 255.255.0.0 # Configure the subnet mask to match the LAN network segment planning => saveenv # Save the environment variables to the eMMC to prevent data loss after restart Saving Environment to ENV_BLK… Saving Environment to ENV_BLK... Writing to mmc(0)... done # Verify network connectivity: first ping the real machine, then ping the Ubuntu server => ping 172.16.0.77 # Test the network connectivity between the development board and the real machine ethernet@fe2a0000 Waiting for PHY auto negotiation to complete. done Using ethernet@fe2a0000 device host 172.16.0.77 is alive => ping 172.16.0.177 # Crucial step: verify the connectivity with the TFTP server (if it fails, check the VMware bridge mode or the network cable connection of the development board) Using ethernet@fe2a0000 device host 172.16.0.177 is alive => setenv serverip 172.16.0.177 # Specify the IP of the TFTP server, and subsequent transmissions will default to this address => saveenv Saving Environment to ENV_BLK... Writing to mmc(0)... done

Note: If pinging the server fails, you need to prioritize the following checks:

- Whether the VMware network is set to ''Bridge mode'';

- Whether the network cable connection of the development board is normal (it is recommended to use Category 5e or better network cables);

- Whether the TFTP port (default port 69) is blocked by the server firewall.

2. Querying the eMMC Partition Table

The Forlinx Embedded RK3568 development board offers multiple eMMC storage options of 8/16/32/64GB. In this test, the standard Linux partition plan is adopted. The complete partition structure can be viewed through the mmc part command to clarify the target partitions for the boot.img (boot image) and rootfs.img (file system image).

= > MMC part # List the partition table for eMMC device 0 (Partition Type: EFI) Partition Map for MMC device 0 -- Partition Type: EFI Part Start LBA End LBA Name Attributes Type GUID Partition GUID 1 0x00004000 0x00005fff "uboot" 0x00000000 0a100000-... b7030000-......

Read more -

One-click to Achieve Local TTS! Full Process of Deploying Piper Text-to-Speech Tool on OKMX8MP Development Board

12/10/2025 at 05:28 • 0 commentsIn IoT and edge computing projects, the demand for offline and localized text-to-speech (TTS) functionality is increasing. Piper, a fast and open-source neural network TTS engine, perfectly meets this demand.

Today, step by step instructions will be provided to deploy Piper on the Forlinx Embedded OKMX8MP development board and achieve high-quality local voice synthesis. This tutorial includes complete steps, code examples, and troubleshooting for common issues to help you get started easily!

Preparation

Required Files

piper_bin.tar (about 22.6 MB)

Piper executable files and core dependent libraries (e.g., libonnxruntime, libespeak-ng).

piper-voices_cut.tar (about 114.4 MB)

Trimmed Chinese and English voiceprint model libraries.

Development Environment

Forlinx OKMX8MP development board (with Linux system flashed).

Terminal access to the development board via SSH or serial port.

Tools for file transfer (e.g., USB drive, SCP).

Detailed Deployment Steps

Step 1: Deploy Piper Executable Files

1. Copy files to the development board

Copy piper_ok.tar to any directory on the development board (take /root as an example): # Assume the file has been copied to /run/media/sda1 via USB drive root@OK8MP:~# cp /run/media/sda1/piper_ok.tar ./ root@OK8MP:~# sync

2. Extract the files

Enter the working directory and extract the files. The -m parameterpreserves the file modification time.

root@OK8MP:~# tar -xvf piper_ok.tar -m

After extraction, the directory structure of piper is as follows:

piper/ ├── piper # Core executable file ├── lib*.so* # All dynamic link libraries required for running ├── espeak-ng-data/ # Voice data └── *.ort # ONNX-related model files

3. Perform a preliminary test

Try to run the piper program directly:

root@OK8MP:~/piper# ./piper # Expected error output: "Model file doesn't exist"

Note: It's normal to get an error at this point because no voiceprint models have been specified yet. This verifies that the program itself can run.

Step 2: Deploy the Voiceprint Model Library

1. Extract the voiceprint library

Extract piper-voices_cut.tar to the /opt directory, a common locationfor optional software.

root@OK8MP:/opt# tar -xvf /path/to/piper-voices_cut.tar -m

After extraction, you'll get Chinese voiceprint model files, forexample:

/opt/piper-voices_cut/medium_zh/zh_CN-huayan-medium.onnx.

2. Create a Chinese test text

Create a text file named zh_test.txt and write the content to beconverted.

# Use the cat command to quickly create a file root@OK8MP:~/piper# cat > zh_test.txt << EOF Welcome to use Forlinx Embedded OKMX8MP development board: This is a text-to-speech local test. EOF

Note: Ensure that the text file uses UTF-8 encoding to avoid Chinesecharacter garbling.

Step 3: Run Text-to-Speech and Play

1. Execute the conversion command

In the piper directory, execute the following command to convert thetext to an audio file zh_audio.mp3.

root@OK8MP:~/piper# ./piper \ -m /opt/piper-voices_cut/medium_zh/zh_CN-huayan-medium.onnx \ --output_file zh_audio.mp3 < zh_test.txt

Parameter description:

Successful output example:

[piper] [info] Loaded voice in 1.99 second(s) [piper] [info] Real-time factor: 0.61 (infer=1.72 sec, audio=2.82 sec) [piper] [info] Terminated piper

-m: Specify the voiceprint model file to be used.

--output_file: Specify the name of the output audio file.

< zh_test.txt: Redirect the input text from the file.

2. Play the audio file

Use the gst - play - 1.0 tool to play the generated audio.

root@OK8MP:~/piper# gst-play-1.0 ./zh_audio.mp3

Common Questions and Solutions (Q&A)

Question 1:

Error message: ''Model file doesn't exist''

Solution: Check if the path of the voiceprint model after the -m parameter is correct. Ensure that piper - voices_cut.tar has been successfully extracted to the /opt directory and the file permissions are normal.

Question 2:

Unable to directly input Chinese on the command - line or garbled characters...

Read more -

Rockchip RV1126B: The ''Performance Benchmark'' for Edge AI Vision Processing

12/08/2025 at 00:51 • 0 commentsThe emergence of the edge computing era has increased the demands on the AI processing capabilities of terminal devices. This is particularly true in AIoT sectors like intelligent security, industrial vision, and robotics. These applications require not only high-quality image processing capabilities but also efficient AI inference at the edge.

The RV1126B, a mid- to high-end AI vision processing SoC launched by Rockchip in May of this year, is specifically designed to meet this demand. The RV1126B is a significant upgrade to the RV1126 series, featuring 3TOPS of NPU computing power, a dedicated AI-ISP architecture, and comprehensive hardware-level security features. This makes it an ideal choice for intelligent upgrades across various industries.

Additionally, Forlinx Embedded is set to launch a new series of products that are designed and developed based on the RV1126B. Welcome to stay tuned for more updates!

AI Vision Processor with Comprehensive Upgrade in Chip Architecture Performance

As an upgraded version of the RV1126, the RV1126B has achieved significant breakthroughs in multiple key performance indicators.

This chip uses a quad-core Cortex-A53 CPU architecture, with performance more than twice that of chips in the same category, providing strong support for high-performance computing and multi - task processing. Working in tandem with the CPU is Rockchip's self-developed NPU. Its AI computing power has been increased from 2 TOPS to 3 TOPS, supporting weight sparsification, W4A16/W8A16 mixed-precision quantization, and Transformer optimization technology.

This means it can process AI tasks more efficiently and run large language models and multi-modal models with a parameter scale of less than 2B smoothly. The memory bandwidth has been increased from 2166MT/s to 3200MT/s, accelerating data access speed.

Four Core Technologies Build Differentiated Competitive Advantages

The core competitiveness of the RV1126B lies in four technological innovations, which make it stand out in the field of edge AI vision processing.

1. NPU Computing Power Strengths

The built-in 3TOPS NPU of the RV1126B supports INT4/INT8/INT16/FP16 mixed operations and can perform intelligent data processing, voice recognition, and image analysis. It supports deep-learning frameworks such as TensorFlow, TensorFlow Lite, Pytorch, Caffe, and Onnx, meeting the edge-computing AI application needs of most terminal devices.

2. AI-ISP and AOV 3.0

The RV1126B integrates a dedicated AI-ISP hardware, which breaks through the computing power bottleneck of traditional solutions.

Its core advantage is that the AI-ISP can run independently without occupying the resources of the general 3T computing power NPU. Combined with the AI Remosaic technology, it can achieve ''day-night dual-mode adaptation'', outputting ultra-high-definition images during the day and maintaining clear imaging under ultra-low illumination at night.

The AOV 3.0 technology features a low-power audio event wake-up function, enabling 24/7 all-weather audio-video monitoring and real-time detection of abnormal sound sources, including dog barks, broken glass, and gunshots. The device's power consumption is as low as about 1mW in standby mode, ensuring vigilance while being highly energy-efficient.

3. Video Processing Capability

The RV1126B integrates an intelligent encoding engine, supporting 8-megapixel 45FPS ultra-high-definition encoding.

Through the dynamic bit-rate optimization technology, it can save 50% of the bit-stream compared with the traditional CBR mode, doubling the recording time in the same storage space.

The chip also has hardware-level 6-DOF digital anti-shake, which can accurately identify and eliminate high-frequency jitter.

Its binocular/quad-camera panoramic dynamic stitching technology enables multi-camera stitching products to avoid image tearing and provides a super-wide-angle view.

4. Security Performance

The RV1126B chip has a built-in national-level...

Read more -

Master the Complete Process of Reading and Writing Files on Storage Devices at the U-Boot Stage of the RK3588 Development Board in 10 Minutes

11/27/2025 at 08:10 • 0 commentsThe Forlinx OK3588-C development board is built based on a flagship processor that utilizes an advanced 8nm manufacturing process and adopts a big.LITTLE architecture, featuring four Cortex-A76 cores and four Cortex-A55 cores. It not only features a triple-core NPU with 6 TOPS computing power and 8K ultra-high-definition processing capabilities, but also provides a stable and reliable hardware foundation for storage device debugging through rich hardware designs such as dual independent MMC controllers and multi-specification USB interfaces.

This article outlines standardized methods for accessing the contents of various storage devices (eMMC, TF cards, USB flash drives) during the U-Boot console stage of the RK3588 development board. While the initialization subsystems of various storage devices differ, unified read and write operations can be performed through the U-Boot console, making it ideal for development, debugging, and system verification scenarios.

I. Enter the U-Boot Console

The U-Boot for the Forlinx RK3588 development board has been extensively customized and optimized. By default, there is a reasonable boot delay configured. During the U-Boot startup process, you can interrupt this countdown and enter the interactive console by pressing the Spacebar or Ctrl + C before the automatic startup completes.

The operation interface and an example are as follows:

Hit key to stop autoboot('Spacebar'): 0 0:Exit to console 1:Reboot 2:Display type =>Prompt: If you fail to press the key in time, U - Boot will continuethe automatic startup (loading the kernel). You need to restart thedevelopment board and try again.

II. Reading and Writing Files on MMCDevices (EMMC/TF Cards)

The RK3588 development board features dual MMC controllers in its hardware, which correspond to the EMMC and TF card interfaces. It is fully compatible with the EMMC 5.1 specification and the SD 3.0 protocol. The board supports the HS400 high-speed transmission mode and allows for both 8-bit and 4-bit data bus widths. This design provides hardware support for the parallel operation of storage devices. Reading and writing files on MMC devices requires following a four-step process of ''identification → switching → querying → operating''.

The specific steps are as follows:

1. View MMC Controllers

Use the ''mmc list'' command to view the initialized MMC controllers (pre - defined by the device tree, usually 0 corresponds to EMMC and 1 corresponds to the TF card) and confirm whether the devices are recognized:

=> mmc list // View the currently initialized MMC controllers mmc@fe2c0000: 1 mmc@fe2e0000: 0 (eMMC)Device 'mmc@fe2c0000': seq 1 is in use by 'mmc@fe2c0000' mmc@fe2c0000: 1Device 'mmc@fe2e0000': seq 0 is in use by 'mmc@fe2e0000' mmc@fe2e0000: 0 =》

2. Switch MMC Devices

Use the''mmc dev <device number>''command to switch to the target device. The device number corresponds to the controller serial number queried in the previous step:

=> mmc dev 0 // Switch to EMMC switch to partitions #0, OK mmc0(part 0) is current device => mmc dev 1 // Switch to TF card switch to partitions #0, OK mmc0(part 0) is current device

3. View MMC Device Information

After switching the device, use the mmc info command to view the detailed device parameters (capacity, bus width, interface version, etc.).

Examples of EMMC and TF card information are as follows:

Example of EMMC device information:

=> mmc info //EMMC device information Device: mmc@fe2e0000 Manufacturer ID: 15 OEM: 100 Name: CJTD4 Timing Interface: HS400 Enhanced Strobe Tran Speed: 200000000 Rd Block Len: 512 MMC version 5.1 High Capacity: Yes Capacity: 58.2 GiB Bus Width: 8-bit DDR Erase Group Size: 512 KiB HC WP Group Size: 8 MiB User Capacity: 58.2 GiB WRREL Boot Capacity: 4 MiB ENH RPMB Capacity: 4 MiB ENH

Examples of TF card device information:

=> mmc info //TF device information Device: mmc@fe2c0000 Manufacturer ID: 3 OEM: 5344 Name: SL16G Timing...

Read more -

Implementation Scheme for I²C Operation during Linux 4.9 System Startup on T507 Platform

11/19/2025 at 02:54 • 0 comments1. Product Configuration

Product: T507

Hardware Configuration: v1.1

Software Configuration: Linux 4.9

2. Requirement Description

- The SoM needs to send an initialization sequence viaI²C.

- The registers of the temperature sensor need to be configured viaI²C.

3. Specific Implementation

- U-Boot Phase

In the U - Boot phase, it can be added to the board - levelinitialization file.

In the ft_board_setup function, there is some content for audio chipinitialization.

Specific Steps:

- Bus Initialization

① First, the pin functions need to be set.

Enable the bus.

② Switch the bus.

After switching the bus, all subsequent read and write operationswill be performed on this bus.

Suppose there are three I²C buses, numbered 3, 4, and 5, and theirnumbers in the U - Boot phase are 0, 1, and 2 respectively.

③ Perform i2c read/write operation according to chip timing.

④ The encapsulated functions of the system can also be used.

Specific Operations:

- Kernel Phase:

If it is just simple read and write operations, it does not need torely on the device tree.

Directly obtain the i2c adapter information in the entry function.The implementation of the write function is as follows.

Implementation of Writing a Function

static s32 aim955_i2c_write(struct i2c_adapter *client, unsigned short devID, unsigned char regadr, unsigned char regVal) { struct i2c_msg msg; s32 ret = -1; s32 retries = 0; static unsigned char cmdBuf[4]; memset(cmdBuf, 0x00, 4); cmdBuf[0x00] = regadr; cmdBuf[0x01] = regVal; msg.flags = !I2C_M_RD; msg.addr = devID; msg.len = 0x02; msg.buf = cmdBuf; while(retries < 5) { ret = i2c_transfer(client, &&msg, 1); if (ret == 1) { break; } else { retries++; } } if((retries >= 5)) { pr_err("write AIM error device ID %d regaddr = %d value = %d\n", devID, regadr, regVal); } return ret; }Examples:

aim955_i2c_write(client, 0x0C, 0x14, 0x10);

The parameter contains the bus information device address registeraddress register value.

11-14: Initialize the msg structure, fill in flag bits, deviceaddress, and register information

17-22: Send msg information through i2c_transfer function

Driver Examples:

#include <linux/module.h> #include <linux/i2c.h> #include <linux/init.h> #include <linux/kernel.h> #include <linux/delay.h> #define DEVICE_ADDRESS 0x5d static struct i2c_board_info __initdata my_i2c_device = { I2C_BOARD_INFO("my_i2c_device", DEVICE_ADDRESS), }; static s32 aim955_i2c_write(struct i2c_adapter *client, unsigned short devID, unsigned char regadr, unsigned char regVal) { struct i2c_msg msg; s32 ret = -1; s32 retries = 0; static unsigned char cmdBuf[4]; memset(cmdBuf, 0x00, 4); cmdBuf[0x00] = regadr; cmdBuf[0x01] = regVal; msg.flags = !I2C_M_RD; msg.addr = devID; msg.len = 0x02; msg.buf = cmdBuf; while(retries < 5) { ret = i2c_transfer(client, &msg, 1); if (ret == 1) { break; } else { retries++; } } if((retries >= 5)) { pr_err("write AIM error device ID %d regaddr = %d value = %d\n", devID, regadr, regVal); } return ret; } static s32 aim955_i2c_read(struct i2c_adapter *client, unsigned short devID, unsigned char regadr, unsigned char *regVal) { struct i2c_msg msgs[2]; s32 ret=-1; s32 retries = 0; static unsigned char readAddr[4]; memset(readAddr, 0x00, 4); readAddr[0] = regadr; msgs[0].flags = !I2C_M_RD; msgs[0].addr = devID; msgs[0].len = 1; msgs[0].buf = readAddr; msgs[1].flags = I2C_M_RD; msgs[1].addr = devID; msgs[1].len = 1; msgs[1].buf = regVal; while(retries < 5) { ret = i2c_transfer(client, msgs, 2); if(ret == 2) { break; } else { retries++; } } if((retries >= 5)) { pr_err("read AIM error device ID %d regaddr = %d error!\n", devID, regadr); } return ret; } static void aim955_devInit(struct i2c_adapter *client) { unsigned char data_rec=0; int iloop = 0x00; //Each step of cgc, 955 configuration aim955_i2c_write(client, 0x0C, 0x01, 0x02); mdelay(4); aim955_i2c_write(client, 0x0C, 0x14, 0x10); mdelay(4); aim955_i2c_write(client, 0x0C, 0x87, 0x02); mdelay(4); aim955_i2c_write(client,...Read more -

Practical Guide: Connect and Configure an SPI Screen on the OK3568 Embedded Platform

11/14/2025 at 02:52 • 0 commentsThis article provides a detailed introduction on connecting and configuring an SPI screen in the Linux system, covering hardware wiring methods, steps for modifying the device tree, and driver adaptation techniques.

With the adaptation solution provided in this tutorial, the ST7735S screen can be quickly integrated with the Forlinx OK3568 development board, creating a cost - effective display solution for applications such as industrial control and portable devices.

If further expansion of functions is needed (such as touch control and backlight adjustment), additional development can be conducted based on this.

1. RK3568-spi Adaptation to 1.8-inch TFT Color Screen

Driver chip: : ST7735S

Resolution: 128×160, supporting 260,000 colors and 65K colors (16 - bit RGB565 format)

Interface Type: 4 - wire SPI (including CS/DC/RES/SCL/SDA pins), with independent backlight BL control

Operating Voltage: 3.3V (VCC pin, do not connect to 5V)

Communication Rate: Supports a maximum SPI clock of 50MHz

2. Hardware Connection

The connection relationship between the screen pins and the OK3568 must be strictly corresponding to ensure normal SPI communication and GPIO control.

The connection table is as follows:

Screen Pin Connected to OK3568 Function Description Notes VCC 3.3V power supply Core operating voltage of the screen Must be connected to 3.3V! Connecting to 5V will burn the chip. GND GND Power supply common ground Must be reliably grounded; otherwise, the display will be abnormal. BL 3.3V power supply Screen backlight control When not controlled by software, connect to 3.3V for constant lighting. CS spi0_cs0 SPI chip-select pin Selects the SPI slave device when at low level. DC GPIO3_A2 Data/command control pin Transmits data at high level and commands at low level. RES GPIO3_B3 Screen reset pin Pull low for reset during power-on and then pull high after completion. SCL spi0_clk SPI clock pin Provides a synchronous clock, up to 50MHz. SDA spi0_mosi SPI master-out slave-in pin Transmits screen commands and display data. 3. Device Tree Modification

diff --git a/arch/arm64/boot/dts/rockchip/OK3568-C-common.dtsi b/arch/arm64/boot/dts/rockchip/OK3568-C-common.dtsi index 31ffd6024..2274b26ec 100644 --- a/arch/arm64/boot/dts/rockchip/OK3568-C-common.dtsi +++ b/arch/arm64/boot/dts/rockchip/OK3568-C-common.dtsi @@ -673,7 +673,7 @@ rx_delay = <0x00>; phy-handle = <&rgmii_phy1>; - status = "okay"; + status = "disabled"; // Turn off the network port function, and the reset pin of &gmac1 conflicts with the pin of spi0 DC }; &mdio0 { @@ -1813,12 +1813,15 @@ pinctrl-names = "default", "high_speed"; pinctrl-0 = <&spi0m1_cs0 &spi0m1_pins>; pinctrl-1 = <&spi0m1_cs0 &spi0m1_pins_hs>; - status = "disabled"; + status = "okay"; spi@0 { - compatible = "rockchip,spidev"; + compatible = "sitronix,st7735r"; reg = <0>; + dc-gpios = <&gpio3 RK_PA2 GPIO_ACTIVE_HIGH>; + reset-gpios = <&gpio3 RK_PB3 GPIO_ACTIVE_HIGH>; spi-max-frequency = <50000000>; + rotation = <0>; }; };4. Kernel Driver Enable

CONFIG_FB_TFT=y CONFIG_FB_TFT_ST7735R=y

5. driver fb_st7735r.c Modification

diff --git a/drivers/staging/fbtft/fb_st7735r.c b/drivers/staging/fbtft/fb_st7735r.c index 9670a8989..e13625cc7 100644 --- a/drivers/staging/fbtft/fb_st7735r.c +++ b/drivers/staging/fbtft/fb_st7735r.c @@ -18,73 +18,49 @@ static const s16 default_init_sequence[] = { -1, MIPI_DCS_SOFT_RESET, - -2, 150, /* delay */ + -2, 10, -1, MIPI_DCS_EXIT_SLEEP_MODE, - -2, 500, /* delay */ + -2, 120, - /* FRMCTR1 - frame rate control: normal mode - * frame rate = fosc / (1 x 2 + 40) * (LINE + 2C + 2D) - */ - -1, 0xB1, 0x01, 0x2C, 0x2D, + -1, 0x11, + -2, 120, - /* FRMCTR2 - frame rate control: idle mode - * frame rate = fosc / (1 x 2 + 40) * (LINE + 2C + 2D) - */ + -1, 0xB1, 0x01, 0x2C, 0x2D, -1, 0xB2, 0x01, 0x2C, 0x2D, - - /* FRMCTR3 - frame rate control - partial mode - * dot inversion mode, line inversion mode - */ -1, 0xB3, 0x01, 0x2C, 0x2D, 0x01, 0x2C, 0x2D, - /*...Read more -

Common Interface Problems and Troubleshooting Ideas for AM62x Development Boards (2)

11/11/2025 at 02:24 • 0 commentsThe AM62x processor from Texas Instruments (TI) is a new-generation, high-performance, and low-power processor widely utilized in industrial control, human-machine interaction, and edge computing. Common issues encountered in the development of the OK62xx-C development board have been summarized, drawing significant interest from many friends.

This article lists systematic troubleshooting ideas and solutions for various interface problems that may arise during the development process.

![AM62x Development Boards]()

1. LVDS Problem

(1) Check whether the output mode of the LVDS display is consistent with the screen (VESA and JEIDA);

(2) Confirm whether the 100Ω resistors of each differential signal of the LVDS screen are soldered;

(3) Please incorporate a soft-start circuit for the LVDS power supply. Verify that the resistor at R247 is present to ensure Q3 turns on gradually, preventing the screen from pulling down VDD_5V;

(4) Measure whether the clock and data output are normal.

2. ENET Problem

(1) Confirm that the communication interface between the PHY chip and the MAC is consistent and that equal-length processing has been performed;

(2) Verify if the MDIO bus is properly pulled up and that the waveform appears normal; also, avoid splitting the MDIO wiring;

(3) Confirm whether the precision resistors meet the requirements;

(4) If the speed does not meet the requirements, check if each power supply and the reference ground are functioning properly;

(5) Detect whether the center tap of the network transformer is correct;

(6) Verify that the addresses of different PHY chips on the same bus do not conflict and are consistent with the software settings;

(7) Verify if the MDI data lines have been processed to equal lengths and if the impedance meets the specified requirements.

3. CAN Problem

(1) When there are multiple devices on the CAN bus, confirm whether there are 120Ω matching resistors at both ends of the devices;

(2) If the CAN devices cannot communicate, you can try to connect the reference grounds of the CAN devices to reduce common - mode interference.

4. UART Problem

(1) The serial port transceiver signals need to be cross - connected;

(2) Confirm whether the serial port tool configuration is correct, such as the baud rate.

(3) Measure whether the data output is normal.

5. RS485 Problem

(1) When there are multiple devices on the 485 bus, confirm whether there are 120Ω matching resistors at both ends of the devices;

(2) If the 485 devices cannot communicate, try to connect the reference grounds of the 485 devices to reduce common - mode interference;

(3) Since RS485 is a half - duplex transmission, some 485 chips require transceiver control signals. Confirm whether the chip driver has been added.

6. Audio Problem

(1) If the system cannot detect the audio chip, check whether the I2C bus communication is normal;

(2) If the chip can be mounted normally but there is no sound output, first check whether the I2S data waveform is output normally, and then check whether the audio output is normal.

7. PCIe Problem

(1) Confirm whether the PCIe device and the CPU use the same source clock and whether the frequency is correct;

(2) Detect whether there is an AC coupling capacitor for the PCIe transmission signal;

(3) Generally, an AC coupling capacitor has been added to the transmission signal at the PCIe device end, so there is no need to add another coupling capacitor at the receiving end.

8. GPIO Problem

When selecting a GPIO, confirm whether the signal is a Boot startup item pin. If so, do not use a pull-up or pull-down circuit when powering on, or a buffer chip needs to be added.

-

FET153-S SoM: Empowering PLC Intelligent Control Upgrade with Multi-core Performance and High Reliability

11/08/2025 at 06:56 • 0 commentsIn the era of Industry 4.0 and intelligent manufacturing, Programmable Logic Controllers (PLCs) serve as the core equipment for industrial automation and are encountering various challenges in enhancing performance and fulfilling high-reliability standards. The FET153-S SoM, launched by Forlinx Embedded, offers a new solution for PLC equipment due to the inherent advantages of the T153 industrial processor, including multi-core heterogeneous computing, comprehensive interface coverage, and industrial reliability design.

Multi-core Heterogeneous Architecture

Solving the Contradiction Between Real-time Control and Efficient Computing in PLC

Traditional PLC main control primarily relies on single-core architecture, which can lead to computing power bottlenecks when handling complex logic controls, such as motor speed regulation and real-time sensor acquisition, as well as high-throughput data tasks like multi-port communication and equipment status monitoring.

The Allwinner T153 processor, used in Forlinx Embedded's FET153-S SoM, features a multi-core heterogeneous architecture consisting of a 4-core Cortex-A7 and an independent RISC-V E907. This design effectively addresses the dual requirements of programmable logic controllers (PLC).

The 4 x Cortex-A7 cores are responsible for the communication management, data storage, and complex algorithm operations of the PLC. For example, on the welding production line in automobile manufacturing, they can process the status data from multiple welding robots and the instructions from the upper-level computer, realizing real-time data analysis and response.

The RISC-V E907 core focuses on real-time control tasks, such as millisecond/microsecond-level logic operations, high-speed I/O point scanning, and interrupt handling in PLCs. In automated assembly line scenarios, strict synchronization between multiple sensors and actuators can be ensured, preventing declines in production rhythm or errors in product processing caused by delays in the scanning cycle.

Full-Scenario Interface Coverage

Meets the Complex Industrial Interconnection Needs of PLC

As the ''nerve center'' of the industrial field, PLCs need to connect various types of devices such as sensors, actuators, and Human-Machine Interfaces (HMIs). Forlinx FET153-S SoM exposes all CPU pins through a stamp hole and LGA connector, allowing high-bandwidth communication and flexible expansion interfaces.

Industrial Network Integration: It includes 3 x Gigabit Ethernet ports (supporting RMII/RGMII) and 2 x CAN-FD interfaces, compatible with CAN 2.0A/B. This allows for "industrial switch-level" networking without the need for additional expansion chips. For instance, a power monitoring terminal can simultaneously connect smart meters, circuit breakers, and an upper-level computer.

Sensor and Actuator Connection: It features 24 x 12-bit GPADC, 30 x PWM channels, and 10 x UART channels, which can accurately collect analog signals such as temperature and pressure, as well as drive equipment like servo motors and frequency converters. In the photovoltaic inverter scenario, the GPADC can monitor the DC-side voltage in real-time, with a PWM output frequency ranging from 0 to 24MHz or 0 to 100MHz, ensuring efficient execution of the MPPT algorithm.

Display and Interaction Support: It integrates MIPI-DSI, LVDS, and RGB interfaces, supporting a maximum display resolution of 1920×1200@60fps, and can be adapted to industrial touch screens and HMI devices. Meanwhile, the 4-lane MIPI-CSI interface supports the access of dual cameras, providing a hardware foundation for machine vision inspection.

Industrial-grade Reliability

Stable Operation in Harsh and Complex Environments

In the harsh industrial environment, PLC needs to withstand multiple tests such as high and low temperature, vibration, electromagnetic interference and so on. The FET153-S SoM ensures long-term stable operation through the following...

Read more -

Porting of MobileNetV3 Model and Implementation of Handwritten Digit Recognition Based on OKMX8MP-C (Linux 5.4.70)

10/31/2025 at 01:19 • 0 commentsThis article details how to port and run the MobileNetV3 model on the Forlinx OKMX8MP-C embedded platform to achieve the function of handwritten digit recognition. From dataset import, model training and validation to TensorFlow Lite quantization and deployment, it fully demonstrates the usage process of the eIQ Portal tool. Through this case, readers can quickly learn how to implement edge inference of lightweight deep-learning models on an industrial-grade ARM platform.

1. Importing the Dataset

Before training the model, you need to prepare the dataset first. If you don't have a dataset, you can directly click ''Import dataset'' and select the dataset provided in the tool. (If you have your own dataset, you can click ''Create a blank project'' to directly import it.) As shown in the figure below.

This paper uses the dataset provided by the tool. Use the tool to load the dataset from TensorFlow, as shown below.

You can select the provided datasets from the drop - down menu in the upper - left corner. These are all datasets commonly used in TensorFlow. This paper uses the mnist dataset.

The mnist dataset has 60,000 handwritten digits as the training set and 10,000 handwritten digits as the validation set. In addition, there are three other datasets:

- cifar10: It contains color images of 10 classes, with 50,000 images as the training set and 10,000 images as the validation set.

- horses_or_humans: horses_or_humans: It has 2 classes, humans and horses. There are 1,027 images of humans and 1,027 images of horses respectively.

- tf_flowers: It has 5 classes, with a total of 3,670 images of all kinds of flowers.

Also, there is a ''Problem type'' drop - down menu in the upper - left corner, which represents the type of task. As shown below, this version of the tool only provides two types, one is image classification and the other is object detection. In the object detection task, there is only one dataset, coco/2017. This dataset can detect 80 types of object recognition, with 118,287 images as the training set, 5,000 images as the validation set, and 20,288 images as the test set.

After selecting the dataset, click the ''IMPORT'' button, select the save directory, and wait for the import. As shown in the figure below:

Select the save directory.

Wait for the dataset to be imported.

After the import is completed, you can view the mnist dataset. The left side shows the number of each image and the image labels. The right side shows each image in the dataset. You can view the detailed information by selecting an image.

2. Model Training

After importing the dataset, the next step is to select a model. As shown below, click the ''SELECT MODEL'' button in the figure.

The interface for selecting a model is as shown below. In this interface, three different options are shown on the left, and their functions are as follows:

- RESTORE MODEL: Load the model used last time.

- BASE MODELS: Select the provided base models.

- USER MODELS: Select the models you created.

On the right, models with different functions are shown, such as classification models, image segmentation models, and object detection models.

This paper uses the base model provided by eIQ Portal, so select ''BASE MODEL'' as shown in the figure below.

The figure below shows several base models provided by the tool. This paper uses the mobilenet_v3 model. The structures of different models can be viewed through the ''MODEL TOOL'' on the initial page.

After selecting the model, enter the model training stage. Its interface is as shown below. The left side shows the parameters to be adjusted during the training process, including the learning rate, Batchsize, and epochs, etc. It can be adjusted as needed. The right side can show relevant information such as the accuracy and loss value during the training process.

The parameters for this training are as shown below. After selection, click ''Start training''.

The training process is as shown below....

Read more -

How to Configure and Port Library Files via Buildroot on the RK3568 Platform

10/17/2025 at 02:53 • 0 commentsAs a high-performance industrial-grade chip, Rockchip RK3568 adopts a quad-core Cortex-A55 architecture and integrates a GPU and an NPU. It is widely used in edge computing and Internet of Things (IoT) devices. Buildroot is a lightweight build tool designed specifically for embedded systems. It can quickly generate a customized Linux root file system through modular configuration. It is particularly suitable for the hardware features of RK3568, significantly improving development efficiency.

Operation method:

1. Switch to the path OK3568-linux-source/buildroot/output/OK3568/ and execute the command ''make menuconfig'';

2. Press the ''/'' key to open the search box and search for relevant library files by keywords. Take adding PYTHON3 as an example;

3. Select options from 1 to 3 according to the search results to jump to the corresponding configuration options. Please use the ''↑'' and ''↓'' keys to turn pages;

Select an option by pressing the ''Y'' key or toggle the selection state by pressing the ''Space'' key.

Choose whether to perform a complete installation according to the needs.

4. Keep selecting ''Exit'' until exit the graphical interface. When prompted to save the configuration, select ''yes'';

5. Recompile Buildroot. Execute the following command in the OK3568-linux-source directory:./build.sh buildroot

6. When prompted whether to overwrite the old.config configuration file, enter ''n''.

7. Rewrite the rootfs.ext2 image generated in OK3568-linux-source/buildroot/output/OK3568/images to the development board. In fact, the rootfs.img generated by a full compilation is created by directly renaming the rootfs.ext2 file. Therefore, using rootfs.ext2 for flashing has the same effect;

8. First, click on the device partition table, then select rootfs.ext2, and click to start the flashing process.

-

Implementation Scheme of Linux 4.14 OTA Upgrade Based on RAUC for OKMX8MM

10/16/2025 at 02:04 • 0 commentsThis document aims to provide an Over-The-Air (OTA) upgrade solution based on RAUC (Robust Auto-Update Controller), which is suitable for embedded Linux systems. RAUC is an open-source OTA framework developed by Pengutronix. It is specifically designed for industrial-grade devices and provides secure, reliable, and atomic firmware update capabilities. It can run on multiple platforms, including Linux, FreeRTOS, and bare-metal environments. OTA is a technology for remotely updating the firmware of embedded devices via wireless networks (such as Wi-Fi, 4G, 5G, etc.). It enables functions such as firmware updates, configuration pushes, and security patches without physically accessing the devices.

In this paper, the RAUC-V0.1 version (the official initial version) is taken as an example for deployment and verification on 8mm-linux4.14.78. Currently, RAUC has been updated to version V1.14. Other platforms can select appropriate versions for transplantation according to the kernel version, glib version, and openssl version. This transplantation only supports manual upgrades and manual partition switching. If necessary, automatic upgrades can be achieved by adding environment variables in U-Boot.

Other OTA upgrade tools: SWupdate

Configuration requirements

Note: Only the basic RAUC upgrade functions are described here. For example, streaming online updates are only supported in RAUC-v1.7 and above.

1. Kernel Version:

It has been verified that it can run on kernel versions above Linux 4.14. Lower versions have not been verified yet, but theoretically they can also be used. For kernel versions without systemd service, --disable-service needs to be specified when compiling the RAUC source code.

2. File System:

RAUC has no restrictions on the content of the file system. However, since an A/B system is implemented, the flash should have at least twice the capacity of the file system.

Deployment scheme

1. Install RAUC in the development environment.

~/work/project/rauc$ git clone https://github.com/rauc/rauc ~/work/project/rauc$ cd rauc ~/work/project/rauc$ git checkout v0.1 ~/work/project/rauc$ ./autogen.sh ~/work/project/rauc$ ./configure ~/work/project/rauc$ make

2. Install RAUC on the development board.

Note: Copy the json-glib and json-glib-native libraries to the cross-compiler for cross-compilation purposes

~/work/project/rauc$ git clone https://github.com/rauc/rauc ~/work/project/rauc$ cd rauc ~/work/project/rauc$ git checkout v0.1 ~/work/project/rauc$ ./autogen.sh ~/work/project/rauc$ ./configure --host=aarch64-poky-linux-gcc ~/work/project/rauc$ make

3. Key File

Manually generate a key in the development environment and put it in the source code of the file system. RAUC will verify whether the key of the image is consistent with that of the system when upgrading;

OK8MM-linux-sdk$ openssl genrsa -out autobuilder.key.pem 4096 OK8MM-linux-sdk$ openssl req -new -x509 -key autobuilder.key.pem -out \ autobuilder.cert.pem -days 365 -subj "/CN=AutoBuilder OTA \ Signing Authority/O=YourCompany/C=CN"

Place the generated autobuilder. cert. pem and autobuilder. key. pem key files under the filesystem/etc/rauc/.

4. bundle

Compile the configuration file of the upgrade package

Generate image check code: OK8MM-linux-sdk/images$ sha256sum ./rootfs.ext4de2f256064a0af797747c2b97505dc0b9f3df0de4f489eac731c23ae9ca9cc31

To create a manifest profile:

OK8MM-linux-sdk/bundle$ vim manifest [update] compatible=Forlinx_rauc_8m version=20250801 build=20250808 [image.rootfs] sha256=de2f256064a0af797747c2b97505dc0b9f3df0de4f489eac731c23ae9ca9cc31 size=24117248 filename=rootfs.ext4 Copy the upgrade image to the bundle directory: OK8MM-linux-sdk/bundle$ cp ../images/rootfs.ext4 ./

5. system.conf

The system. conf is the system configuration file of RAUC, which is responsible for configuring the storage, partition, and boot mode; it is the configuration file used in the upgrade process.

The path can be:/etc/rauc/system....

Read more -

Guide to Applying Real-Time Patches and Solving Problems on the T507 Platform Based on Linux 4.9

10/14/2025 at 03:40 • 0 commentsApplying Real-Time Patches

Each version of the kernel has a corresponding real-time patch.

The kernel version of T507 is 4.9.170, and here is the corresponding real-time patch version.

Download address: https://mirrors.edge.kernel.org/pub/linux/kernel/projects/rt/4.9/older/

After obtaining the patch compressed package, extract it in the virtual machine:

tar -xzvf linux-4.4.206.tar.gz gunzip patch-4.4.206-rt190.patch.gz

Apply the patch under the kernel path.

Enter the kernel configuration menu.

Select the full preemption mode.

After the application is completed, compilation usually fails because the source code has been modified later, and there will be some parts that conflict with the official patch files. .rej files will be automatically generated at these locations.

Please manually add the modifications in these files to the source code. When adding, do not directly copy and paste.

For example, if the content in the patch file contains a variable a, but the context in the source code uses sunxi_a. Please unify these modifications with the existing source code and pay attention to these differences.

Solving Compilation Errors

1. The kernel source code of T507 is quite special. The zram part refers to the kernel of 5.10, so this part should be modified with reference to the real-time patch of 5.10;

2. During the compilation process, an error occurred regarding the driver of the 6256 wifi and Bluetooth chip. The error information at that time was not saved. The general meaning is that the actual parameters passed to one of the functions do not match the parameter types defined in the function;

The modifications are as follows:

diff --git a/linux-4.9/drivers/net/wireless/bcmdhd/dhd_pno.c b/linux-4.9/drivers/net/wireless/bcmdhd/dhd_pno.c old mode 100644 new mode 100755 index 8d2957fd8..52d491f21 --- a/linux-4.9/drivers/net/wireless/bcmdhd/dhd_pno.c +++ b/linux-4.9/drivers/net/wireless/bcmdhd/dhd_pno.c @@ -35,7 +35,7 @@ #ifdef PNO_SUPPORT #include #include - +#include #include #include @@ -3169,7 +3169,7 @@ exit: } mutex_unlock(&_pno_state->pno_mutex); exit_no_unlock: - if (waitqueue_active(&_pno_state->get_batch_done.wait)) + if (swait_active(&_pno_state->get_batch_done.wait)) complete(&_pno_state->get_batch_done); return err; } @@ -3948,7 +3948,7 @@ dhd_pno_event_handler(dhd_pub_t *dhd, wl_event_msg_t *event, void *event_data) { struct dhd_pno_batch_params *params_batch; params_batch = &_pno_state->pno_params_arr[INDEX_OF_BATCH_PARAMS].params_batch; - if (!waitqueue_active(&_pno_state->get_batch_done.wait)) { + if (!swait_active(&_pno_state->get_batch_done.wait)) { DHD_PNO(("%s : WLC_E_PFN_BEST_BATCHING\n", __FUNCTION__)); params_batch->get_batch.buf = NULL; params_batch->get_batch.bufsize = 0;The reason is that after applying the real-time patch, the interface used has been changed from waitqueue_active to swait_active, so an error regarding function parameter passing occurred.

3. The compilation script added to the kernel also needs to be modified.

The path in the above figure is the output path of the kernel driver module, which will be automatically created when compiling the kernel. If no modification is made, the compilation output will follow the path 4.9.170-rt129, but the path created by the compilation script is 4.9.170, so the compilation cannot pass.

4. After packaging into an image and running it on the board, the kernel keeps crashing, and the printed information is consistent with the content in the document provided by Allwinner.

(1)

(2)

5. When running the packaged image, the screen does not display.

The GPU driver module fails to load normally because the path of the startup script in init.d is incorrect.

The modifications are as follows:

By analogy, when loading other modules, please pay attention to the path changes.

Real-time performance after applying the patch.

-

Guide to OTA System Upgrade for Forlinx OKMX8MP-C Development Board on Linux 5.4.70

09/24/2025 at 02:53 • 0 commentsOTA is a method that enables lossless system upgrades for devices, allowing new features to be remotely deployed on products. The OTA upgrade package can not only be downloaded via the network but also used to upgrade the device after being downloaded to an SD card or a USB flash drive.

This article will introduce the specific implementation method of using OTA to upgrade the system on the Linux 5.4.70 system through the Forlinx Embedded OKMX8MP-C development board.

1. Environment Setup

1.1 Download the 22.04 Image of the Compilation Environment

Since RAUC version 1.6 is required, the 22.04 ISO image needs to be downloaded.

Download URL: https://mirrors.tuna.tsinghua.edu.cn/ubuntu-releases/22.04/

1.2 Modify the GCC Version of the Development Environment

1.2.1 Modify the apt Source

sudo gedit /etc/apt/sources.list

1.2.2 Add the Source at the End of the File

deb [arch=amd64] http://archive.ubuntu.com/ubuntu focal main universe

1.2.3 Update the source

sudo apt update

1.2.4 Install GCC

sudo apt install gcc-7 g++-7

1.2.5 Back up the original GCC and G + +

sudo mv /usr/bin/gcc /usr/bin/gcc.bak sudo mv /usr/bin/g++ /usr/bin/g++.bak

1.2.6 Link to gcc-7

sudo ln -s /usr/bin/gcc-7 /usr/bin/gcc sudo ln -s /usr/bin/g++-7 /usr/bin/g++

1.2.7 Install and test

gcc --version g++ --version

GCC test run results:

G + + test run results:

1.3 Install the rauc tool

sudo apt install rauc

2. Source code configuration

2.1 EMMC partition

Need to modify the source code OK8MP-linux-fs/rootfs/etc/init.d/Init.sh

#! /bin/sh ## add forlinx user useradd -k /etc/skel -m -U forlinx -s /bin/bash passwd forlinx <<EOM forlinx forlinx EOM DEVICE="/dev/mmcblk2" # Create the partition fdisk $DEVICE <<EOF n p 3 13818240 13988608 t 3 c n p 4 13988609 30589000 w EOF # Refresh the partition table partprobe # Output partition information lsblk $DEVICE resize2fs /dev/mmcblk2p2 /usr/bin/fltest_runRefreshMatrix.sh ## delete Init.sh sed -i "s/\/etc\/init.d\/Init.sh//g" /etc/rc.local rm -f /etc/init.d/Init.sh sync

2.2 Decompression of rauc and dependent tools

(1)Decompress under liblz4.tar.bz2在/OK8MP-linux-sdk/OK8MP-linux-fs/rootfs/usr/lib

tar -xvf liblz4.tar.bz2

(2)Decompress fw_setenv.tar.b z2 under /OK8MP-linux-sdk/OK8MP-linux-fs/rootfs

tar -xvf fw_setenv.tar.bz2

(3)Decompress unsquashfs.tar.bz2 under /OK8MP-linux-sdk/OK8MP-linux-fs/rootfs

tar -xvf unsquashfs.tar.bz2

(4)Decompress yocto-rauc-1.5.1.tar.bz2 under /OK8MP-linux-sdk/OK8MP-linux-fs/rootfs

tar -xvf yocto-rauc-1.5.1.tar.bz2

2.3 Modifying the tool configuration

2.3.1 Modify the fw_env.config to specify the env base addr

/OK8MP-linux-sdk/OK8MP-linux-fs/rootfs/etc/fw_env.config

gedit fw_env.config

Delete the original content and only add:

/dev/mmcblk2 0x400000 0x2000

2.3.2 Modify the rauc configuration file

/OK8MP-linux-sdk/OK8MP-linux-fs/rootfs/etc/rauc/system.conf

gedit system.conf

Note: It is necessary to ensure that the compatibility is consistent with that in the upgrade package and that the partition contents are correct.

2.3.3 Modify the compilation script

forlinx@ubuntu:~/OK8MP-linux-sdk$ gedit tools/fakeroot.fs

This part of the script needs to be commented out:

2.3.4 Modify the mount configuration file

forlinx@ubuntu:~/OK8MP-linux-sdk/OK8MP-linux-fs/rootfs/etc$ gedit fstab

Modify OK8MP-linux-fs/rootfs/etc/fstab as follows:

/dev/mmcblk2p3 /run/media/mmcblk2p3 auto defaults,sync,noauto 0 0 /dev/mmcblk2p4 /run/media/mmcblk2p4 auto defaults,sync,noauto 0 0

Note: The main purpose here is to prevent the service from automatically mounting the partition and causing the upgrade time partition to be already mounted.

3. Generate an upgrade package

3.1 Full compilation to obtain the required image

forlinx@ubuntu:~/OK8MP-linux-sdk$ . /opt/fsl-imx-xwayland/5.4-zeus/environment-set\up-aarch64-poky-linux forlinx@ubuntu:~/OK8MP-linux-sdk$...

Read more -

Tutorial on Creating and Configuring the psplash Boot Animation for the OK3588-C Embedded Linux System

09/13/2025 at 01:18 • 0 commentsIn the embedded Linux system of the RK3588 platform, the boot screen can not only enhance the user experience but also display brand logos or system status information. psplash is a lightweight boot screen program that can display static pictures or simple animations during system startup, providing intuitive feedback to users. This article will take the RK3588 as an example to introduce in detail how to create a boot animation from videos or pictures and configure psplash on the embedded device to achieve the display of a customized boot screen.

This method uses the psplash tool, which is a lightweight startup screen program commonly used in embedded Linux systems. Its main function is to display a graphical boot screen during system startup to provide user feedback, usually in the form of a brand logo or a progress bar.

Features:

- Lightweight: psplash is designed to be as small as possible to fit resource - constrained embedded devices.

- Graphical interface: It can display static images or simple animations, offering users a better visual experience during startup.

- Progress bar support: It can display a progress bar during the startup process to indicate the system loading status.

- Flexible configuration: Users can customize the boot image, progress bar color, display time, etc. through the configuration file.

The following is the operation method:

Picture Creation

Place the adapted files in the folder into the virtual machine for conversion.

Create a folder to save the project:

forlinx@ubuntu20:~$ mkdir -p psplash_logo/mp4_logo/

Then, put the video into the mp4_logo folder.

Download ffmpeg, which will be used later when processing the MP4 video:

forlinx@ubuntu20:~/psplash_logo/mp4_logo$ sudo apt-get update forlinx@ubuntu20:~/psplash_logo/mp4_logo$ sudo apt-get install ffmpeg

Create a new part0 folder to store the pictures that will be generated later:

forlinx@ubuntu20:~/psplash_logo/mp4_logo$ mkdir part0

Enter the following command for conversion:

forlinx@ubuntu20:~/psplash_logo/mp4_logo$ ffmpeg -i logo.mp4 -f image2 -r 7 part0/%04d.png

Now, take a look at the pictures in the part0 folder.

forlinx@ubuntu20:~/psplash_logo/mp4_logo$ ls part0/ 0001.png 0004.png 0007.png 0010.png 0013.png 0016.png 0019.png 0022.png 0025.png 0028.png 0031.png 0034.png 0037.png 0040.png 0043.png 0046.png 0049.png 0052.png 0002.png 0005.png 0008.png 0011.png 0014.png 0017.png 0020.png 0023.png 0026.png 0029.png 0032.png 0035.png 0038.png 0041.png 0044.png 0047.png 0050.png 0053.png 0003.png 0006.png 0009.png 0012.png 0015.png 0018.png 0021.png 0024.png 0027.png 0030.png 0033.png 0036.png 0039.png 0042.png 0045.png 0048.png 0051.png 0054.png

Convert Images to .h Files

Before converting to .h files, please check if the images match the screen resolution. When using psplash, the image resolution must be consistent with the screen resolution.

Use the following command:

forlinx@ubuntu20:~/psplash_logo/mp4_logo/part0$ file 0001.png 0001.png: PNG image data, 640 x 360, 8-bit/color RGB, non-interlaced

The current resolution is 640x360. Next, the conversion will be carried out.

Create a logo_h folder and inside it, create h, logo_1024x800, and master folders respectively:

forlinx@ubuntu20:~/psplash_logo$ mkdir logo_h forlinx@ubuntu20:~/psplash_logo/logo_h$ mkdir h logo_1280x800 master

Then, copy the previously generated PNG files into the master folder. The copying process is not demonstrated here.

Start resolution conversion after copy is complete:

Create the fix _ 1280x800.sh script in the master folder:

forlinx@ubuntu20:~/psplash_logo/logo_h/master$ vi fix_1280x800.sh /*File content*/ #!/bin/bash for img in *.png; do convert "$img" -resize 1280x800! "../logo_1280x800/$img" Done

Give executable permissions:

forlinx@ubuntu20:~/psplash_logo/logo_h/master$ chmod +x fix_1280x800.sh

After execution, the modified file is created at logo _ 1280x800.

forlinx@ubuntu20:~/psplash_logo/logo_h/logo_1280x800$...

Read more -

Configuration and Debugging of PCIe Endpoint (EP Mode) on OK3588-C Linux 5.10.66 Buildroot

09/09/2025 at 03:26 • 0 commentsWith the rapid development of high-performance embedded applications, the RK3588 processor has become the preferred platform for development boards and industrial applications due to its powerful multi-core computing power and rich peripheral interfaces. In the Linux 5.10.66 Buildroot system based on the Forlinx OK3588-C, the configuration and debugging of the PCIe Endpoint (EP) mode are crucial for achieving high-speed data transmission and device interconnection. This article will provide a detailed introduction on how to complete the kernel configuration, U-Boot settings, and performance testing of the EP device on the RK3588 development board, helping developers quickly set up an efficient and stable PCIe Endpoint environment.

The document testing is based on the RK3588 development board.

- During the testing, both the RC (Root Complex, host device) and the EP (Endpoint, peripheral device) are Linux devices (RK3588 development boards).

- This article focuses on describing the configuration and testing process of the EP device. For detailed configuration information, please refer to the document: Rockchip_Developer_Guide_PCIe_EP_Stardard_Card_CN.pdf.

- Software:Linux 5.10.66 4G+32G

Kernel version: OK3588 linux 5.10.66 version kernel (Android12 Linux ForlinxDesktop20.04 R5 release)

Uboot version: OK3588 protection encryption uboot (Android12 Linux ForlinxDesktop20.04 R4 release)

Hardware connection:

For the hardware connection, only one PCIe 3x4 lane male-to-male extension cable is required.

Software settings

Applying patches

To set the PCIe-EP mode on the 3588, Rockchip officially provides the configuration reference document and source code patches for the PCIe EP mode. The document is located in the docs directory.

Note:

1. The patch file is the basic configuration for the EP card. There is also an update package in the data package. The update package contains update patches based on the base patch, mainly for optimizing the base patch and fixing issues. First, apply the base patch, and then replace the corresponding files in the SDK with the files in the update package directory.

2. Both the patch directory and the source code directory contain necessary modifications. Users can choose to directly apply the patch file or replace the corresponding source code files, either method is acceptable.

(1) kernel

The kernel patch file is located at:

Rockchip_PCIe_EP_Stardard_Card_20231215\patch-kernel5.10\linux_base\Patch directory\kernel

Modify the kernel according to the patch file.

Modify the kernel according to the patch file.

Then replace the files under the kernel in the update package.

(2)uboot

The U-Boot patch file is located at:

\u-boot

After applying the patch, replace the files in the u-boot in the update package.

(3) rkbin

It is a bit cumbersome to use the patch method to modify the files under rkbin. Directly replace the source code files:

Rockchip_PCIe_EP_Stardard_Card_20231215\patch-kernel5.10\linux_base\Source code directory\rkbin

After replacing the files in the folder, replace the files in the update package to the corresponding positions.

The above configurations are required for both the EP card and the RC card.

General kernel configuration

The following configuration items need to be completed during the actual testing process to enable the functions of the EP card. It is recommended to make modifications according to the following configurations. If there are any objections, please refer to the Rockchip official document:

Rockchip_Developer_Guide_PCIe_EP_Stardard_Card_CN.pdf1. SRNS

In the SRNS mode, the Refclock uses its own internal clock. Set this option so that the RC card and the EP card each use their own 100M clock generators.

uboot

diff --git a/arch/arm/mach-rockchip/spl_PCIe_ep_boot.c b/arch/arm/mach-rockchip/spl_PCIe_ep_boot.c index 7a24a1d..f1ce41a 100755 --- a/arch/arm/mach-rockchip/spl_PCIe_ep_boot.c +++ b/arch/arm/mach-rockchip/spl_PCIe_ep_boot.c ...

Read more -

Edge Computing-Driven Intelligent Access Control Upgrade Solution: Application Analysis of FET3568-C SoM

09/03/2025 at 03:07 • 0 commentsEdge computing, as a new-type architecture that decentralizes computing power to the terminal, is widely empowering Internet of Things (IoT) applications in various industries, significantly enhancing the real-time performance and reliability of systems. In the typical scenario of access control systems, traditional solutions struggle to meet the requirements of high concurrency, high real-time performance, and high security in modern access scenarios due to limited local computing power, high network latency, and excessive reliance on the cloud. An intelligent access control system integrated with edge computing technology can greatly improve the response speed and system stability by completing identity verification and data processing on-site. It has become an important direction for industry upgrading.

1. Demand Upgrade Spurs Technological Innovation

As users' requirements for access management experience continue to increase, access control systems are no longer limited to traditional card-swiping and password verification. They are gradually evolving towards a more intelligent, flexible, and efficient direction. Here, list three main upgrade directions:

- (1) Intelligent identity recognition: If users expect seamless access, the system needs to support AI capabilities such as face recognition and voice interaction to enhance convenience while ensuring security;

- (2) System expansion and customization capabilities: Diverse requirements for the functions of access control systems are put forward in multiple business scenarios. Therefore, access control systems should have good scalability and be able to flexibly connect to various functional modules;

- (3) Fast-response experience: During peak hours in public places, the access control system must complete identity verification in a very short time to avoid delays and recognition errors.

2. RK3568 SoM Empowers Intelligent Access Control

To address the new challenges brought by new requirements, Forlinx Embedded recommends using the FET3568-C SoM as the main control solution for the edge-computing-based intelligent access control system. This platform has many advantages that can specifically improve the overall performance of the access control system:

(1) Powerful computing power for smooth AI inference:

The Forlinx Embedded FET3568-C SoM is equipped with the Rockchip RK3568 high-performance processor, which adopts a quad-core Cortex-A55 architecture with a maximum main frequency of 2.0GHz and has a built-in independent NPU with a computing power of 1TOPS; It can smoothly support edge AI applications such as lightweight face recognition and voice recognition, meeting the dual needs of real-time performance and accuracy of intelligent access control.

(2) Rich interfaces for flexible expansion:

The Forlinx Embedded FET3568-C SoM provides rich interfaces such as USB 3.0, GPIO, UART, I2C, and SPI, which can be widely connected to various recognition modules (such as face, fingerprint, iris, etc.) and sensor devices, facilitating system customization and secondary development by customers to meet the functional integration requirements of different scenarios;

(3) Large-memory configuration to ensure multi-task response:

The FET3568-C SoM has an on-board LPDDR4x running memory with a maximum option of 8GB and a storage option of 64GB eMMC, ensuring that the system can efficiently process multiple video streams and concurrent recognition tasks, greatly improving the recognition speed and system fluency and avoiding response delays caused by insufficient memory;

(4) Diverse system support:

In addition to the above-mentioned hardware advantages, Forlinx Embedded has also adapted multiple operating systems such as Linux, Android 11, Ubuntu, Debian 11, Linux-RT, and OpenHarmony for the FET3568-C SoM and ensured their stable operation through multiple tests to meet the needs of different users in different fields and scenarios;

3. Conclusion...

Read more -

Forlinx Embedded's FET-MX9596-C SoM: Achieving Performance, Real-time and Security Balance in Edge Computing

08/29/2025 at 06:24 • 0 commentsIn the current era of the deep integration of Industry 4.0 and AIoT, traditional single-core or even multi-core processors struggle to meet the complex requirements of high performance, real-time and security in the field of edge computing. To address this pain point, major chip companies have successively launched multi-core heterogeneous processors with both A-cores and M-cores. The NXP i.MX95xx series processor equipped on the newly released FET-MX9596-C SoM by Forlinx Embedded is a flagship multi-core heterogeneous chip. It integrates six Cortex-A55 cores, one Cortex-M7 core, and one Cortex-M33 core.

The advantages of this multi-core heterogeneous architecture are obvious. It enables hierarchical task processing via hardware isolation: the A55 core cluster handles Linux system-level computing, the M7 core focuses on real-time tasks like motion control, and the M33 core independently manages security encryption. In short, it combines “high performance, high real-time and high security”.

Analysis of Multi-core Heterogeneous Architecture

Achieving Hierarchical Task Processing through Hardware Isolation

Traditional embedded processors are often limited by the resource competition of homogeneous cores when facing complex application scenarios. The core advancement of the Forlinx Embedded FET-MX9596-C is its three-core heterogeneous architecture for physical quarantine, with each core fulfilling its designated role.

- Cortex-A55 Cluster: 6 high-performance cores @ 1.8GHz, responsible for running the Linux system, AI inference and processing complex algorithms;

- Cortex-M7 Core: An 800MHz real-time core dedicated to deterministic tasks such as motion control and sensor data collection;

- Cortex-M33 Core: A 333MHz security core that independently runs the encryption engine and security monitoring program.

This design is essentially a hardware-level functional decoupling. Through NXP's Energy Flex power management architecture, the three domains can be started and stopped independently. The real-time domain continuously monitors sensors, the security domain maintains the encryption state, and the application domain is only awakened when needed, reducing the system-level power consumption by at least 30%.

Breakthroughs in High-Performance Edge AI and Multimedia Processing

The high-performance of the FET-MX9596-C SoM comes from the A55 core cluster. Six Cortex-A55 cores share a 2MB L2 cache. Coupled with 8GB LPDDR4x memory, it can provide a bandwidth of up to 51.2GB/s, paving the way for edge AI computing.

Moreover, the inference speed of the integrated 2TOPS NPU in the processor is significantly improved, reaching 800MHz in normal mode and up to 1GHz in overclocking mode. The integrated image signal processor (ISP) and video processing unit (VPU) work together to provide excellent edge machine vision capabilities. Users can run advanced AI models on the NPU to achieve scene segmentation, real-time video enhancement and denoising, ensuring high-quality video images.

In addition, the new-generation ARM Mali-G310 GPU supports OpenGL ES3.2, Vulkan1.2 and OpenCL3.0, providing users with rich graphic experience and computing acceleration capabilities. The display controller can achieve two independent display output streams.

High Real-time

Hard Real-time Core Ensures Critical Tasks

High real-time is crucial in industrial scenarios. A timing deviation of more than 1ms in motion control may lead to product scrapping. In a vehicle system, a 1ms delay in brake signal processing may cause an accident. The Cortex-M7 core of the i.MX95xx series processor is designed for such scenarios. It is physically isolated from the A55 cluster. Even if the Linux system crashes, it can still ensure the stable operation of key communication interfaces, such as continuous communication on the CAN-FD bus, accurate output of PWM signals and uninterrupted ADC data collection.

On Forlinx Embedded's OK-MX9596-C development board,...

Read more -

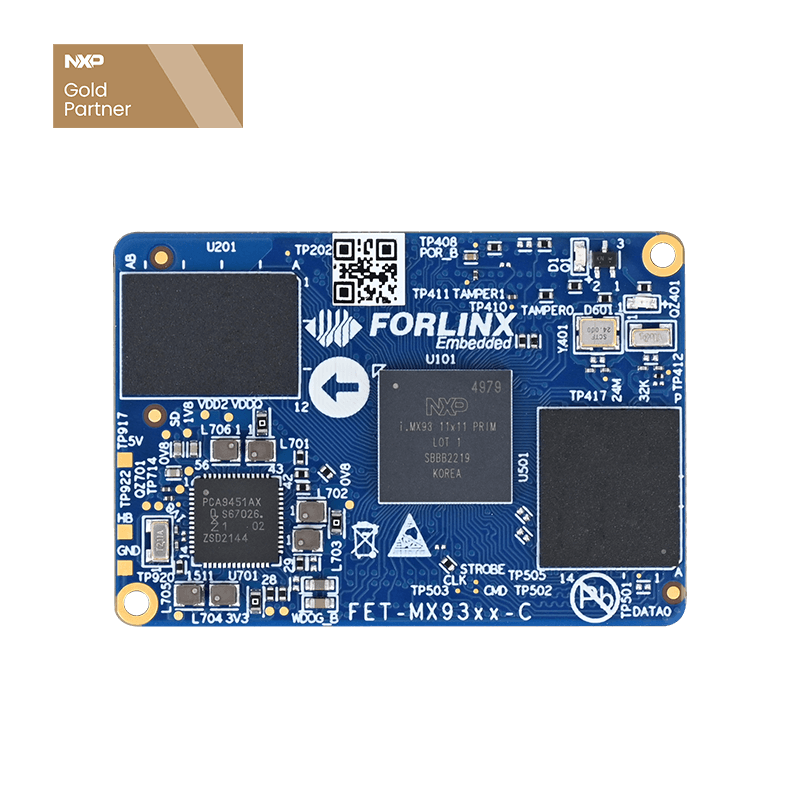

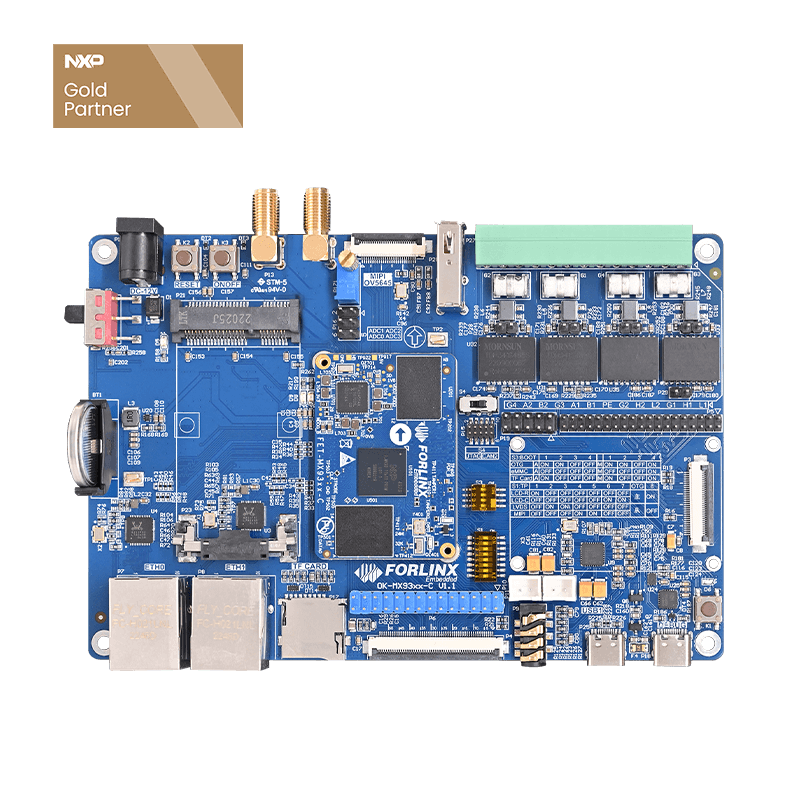

Common Issues and Troubleshooting Ideas in the Development Process of the i.MX9352 SoM

08/29/2025 at 05:56 • 0 commentsAs a gold partner of NXP, Forlinx Embedded has launched several embedded main control products based on the i.MX series of application processors. In addition to the newly released i.MX95xx series of System on Modules (SoMs), the i.MX93xx series of SoMs—also part of the i.MX9 family—has been available on the market for many years and has gained recognition and preference from numerous customers.

Throughout the long-term technical support service process, Forlinx Embedded has compiled common issues and troubleshooting methods encountered by users developing the i.MX93xx series of products. This article aims to outline these experiences to help developers quickly identify problems and enhance the development efficiency.

General Troubleshooting Ideas

For troubleshooting the i.MX93xx series master control, follow these general steps for any abnormal functions:

1. Hardware Consistency Verification

- Ensure that the carrier board design is consistent with the schematic diagram. If the functional chip is replaced, the corresponding driver shall be transplanted;

- Check whether the power supply, reset, and clock of the functional chip are normal.

2. Cross-Test Positioning

- Determine the source of the problem by replacing the SoM or the carrier board.

3. Signal and Soldering Inspection

- Confirm that the pin levels are matched and the data signal output is normal.

- Check whether there are process problems such as cold soldering or bridging in the resistor and capacitor components.

4. Pin Multiplexing Configuration

- Verify whether the pin multiplexing settings are consistent with the functional requirements.

Common Issues and Solutions for Specific Modules

1. Non-startup Issue

- In addition to the power supply and reset, you need to confirm whether the PWR_EN signal is normal.

- Check whether the pull-up and pull-down resistors of the BOOT start pins on the carrier board are configured as required.

2. I2C Bus Issue

- Confirm whether a pull-up resistor is added to the I2C bus (open-drain output characteristic);

- Check whether there is an address conflict among devices in the same group;

- Measure the waveform: it should be at a high level in the idle state, and the waveform should meet the standard during data transmission;

- Adjust the resistance value of the pull-up resistor: if the rising edge is slow, reduce the resistance value; if the low level is too high, increase the resistance value;

- Use tools for detection:

i2cdetect -l # Detect the I2C bus groups i2cdetect -r -y 2 # Detect the devices on the second group of buses

3. SPI Communication Issue

- The MISO and MOSI of the SPI interface need to be connected correspondingly;

- Confirm that the chip-select signal (CS) is correctly connected;

- Verify whether the modes (such as CPOL and CPHA) of both communication parties are consistent;

- Measure whether the clock and data output are normal.

4. USB Interface Issue

- The USB_VBUS_3V3 signal must be 3.3V;

- Cross-connecting USB differential signal lines is strictly prohibited.

5. SDIO Interface Issue

- The pin level of the SD2 interface is related to the transmission speed. It is 3.3V by default and 1.8V in high-speed mode;

- The SDIO signal cannot have its pin level converted through a level-conversion chip;

- Check whether the SDIO bus has been treated for equal-length;

- Prioritize checking whether the clock output is normal.

6. LVDS Display Issue

- Confirm that the screen output mode (VESA/JEIDA) is consistent with the driver configuration.

7. Ethernet Network Issue

- Verify whether the PHY chip and the MAC interface mode (such as RGMII) are consistent and whether equal-length processing has been done;

- Check whether the pull-up resistor and the waveform of the MDIO bus are normal. Avoid bifurcated wiring;

- If the speed does not meet the requirements, you can check whether all power supplies and the reference ground are intact;

- Confirm that the...

-

29×40mm Ultra-Small SoM: 2-Second Quick Assembly & Rockchip RK3506J Processor

08/22/2025 at 03:55 • 0 commentsIn the field of embedded development, engineers are always pursuing a balance among performance, size, and reliability. FET3506J-C SoM, newly launched by Forlinx Embedded based on Rockchip RK3506J processor, has become the preferred solution for developers in fields such as industrial automation, new energy, consumer electronics, and smart medical care, thanks to its ultra-small size of 29mm×40mm, the design of board-to-board connectors for quick disassembly and assembly, and industrial-grade features.

Ultra-small Size of 29mm×40mm, An Ideal Choice for Compact Scenarios

The FET3506J-C SoM uses a compact design, with a size of only 29mm×40mm, which is significantly smaller than conventional SoMs. This breakthrough design comes from Forlinx Embedded's efficient use of the processor pins. Through the matrix IO design, 98 functional signals can be flexibly mapped on 32 physical pins. Any functional signal, such as UART, CAN-FD, JTAG, FSPI, etc., can be assigned to any pin through software configuration.

In space-constrained scenarios such as industrial handheld terminals and portable medical devices, the ultra-small SoM can be directly embedded in the device motherboard without the need for additional expansion board design. It can significantly improve the portability and market competitiveness of the products.