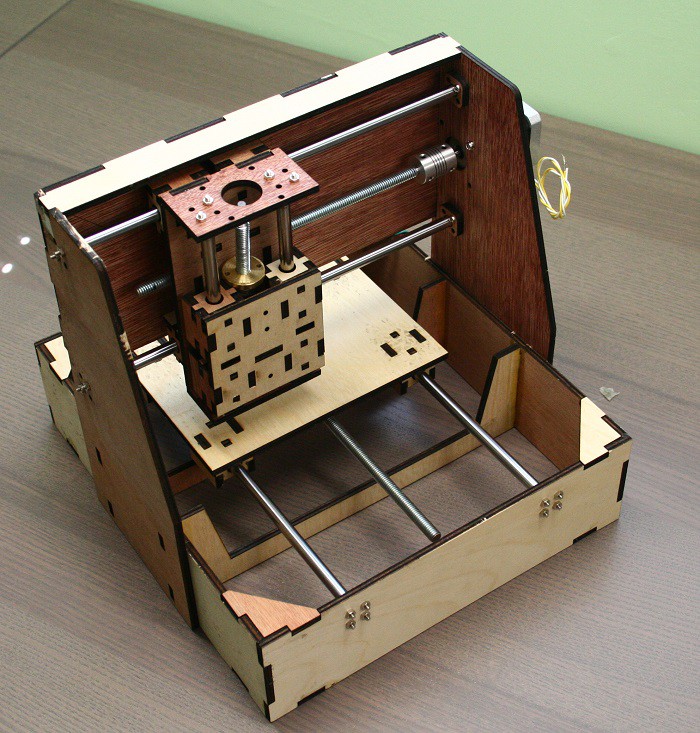

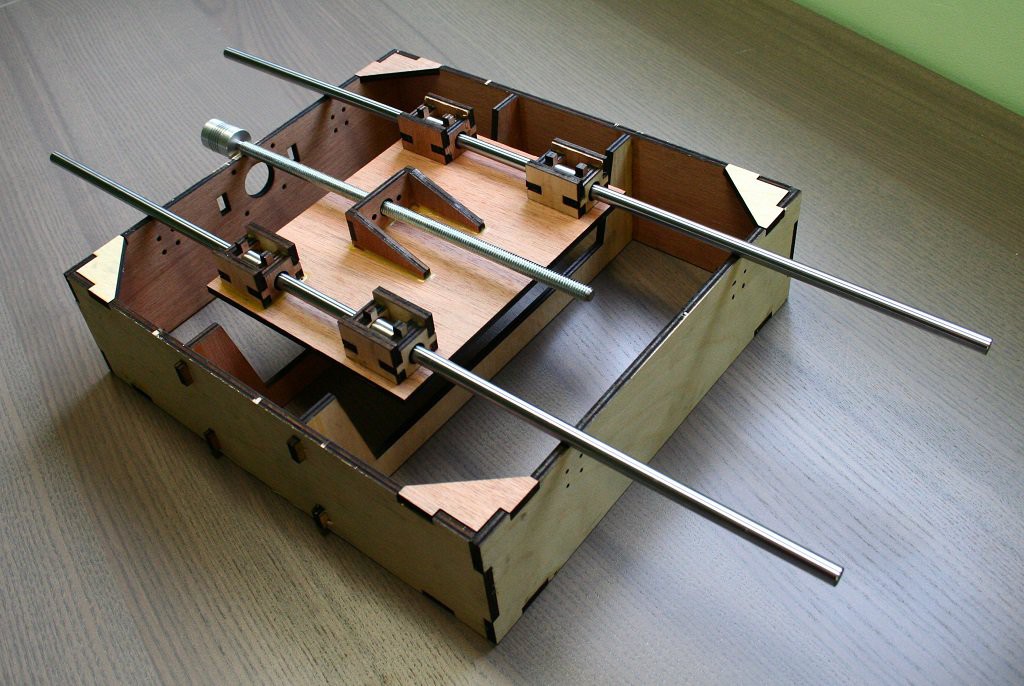

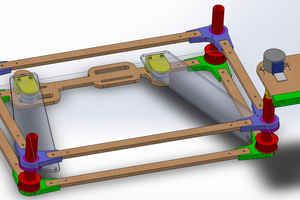

The goal of this project is to produce a small milling machine that can be cut on increasingly common small laser engraver/cutters like the Chinese 3020 laser engraver.

The current design goals are:

- All structural parts can be cut on a small laser cutter, largest size cut area is under 300mmx200mm

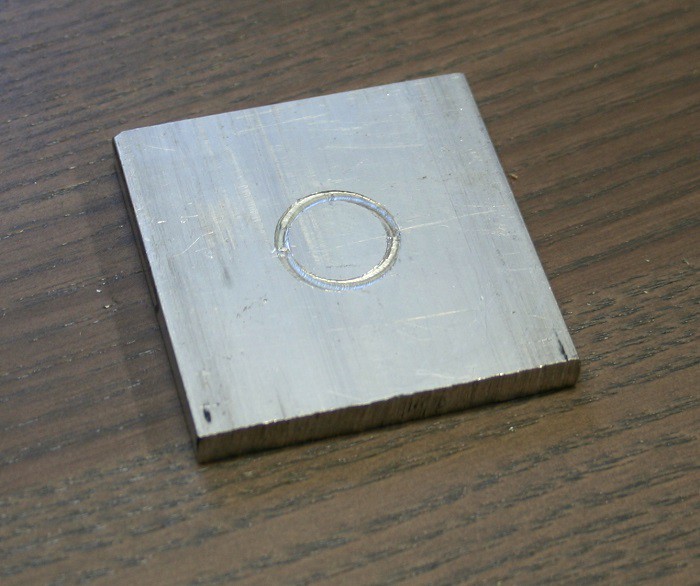

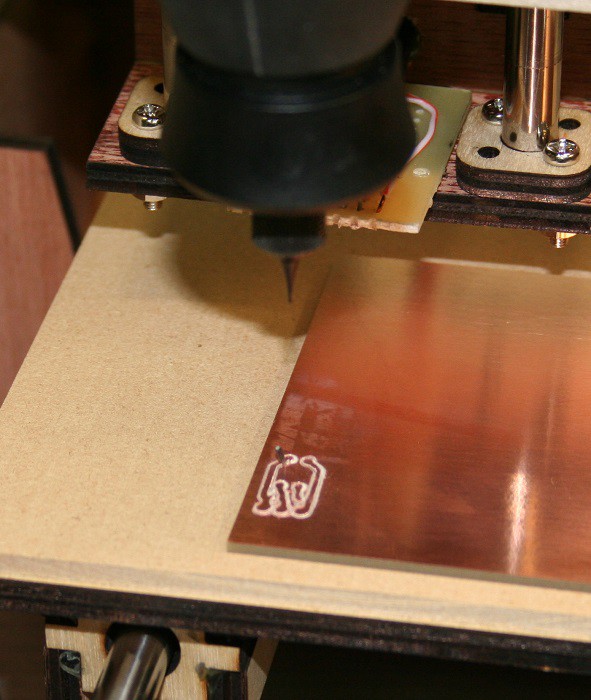

- Produce milled PCBs using SOIC, QFP and 0603 packages reliably

- Interchangeable heads

The current design will be using standard threaded rod attached to Nema 17 steppers, and 8mm linear rods with LM8UU bearings for the linear motion. Basic anti-backlash nuts will be included to help reduce backlash, but software compensation may be required.

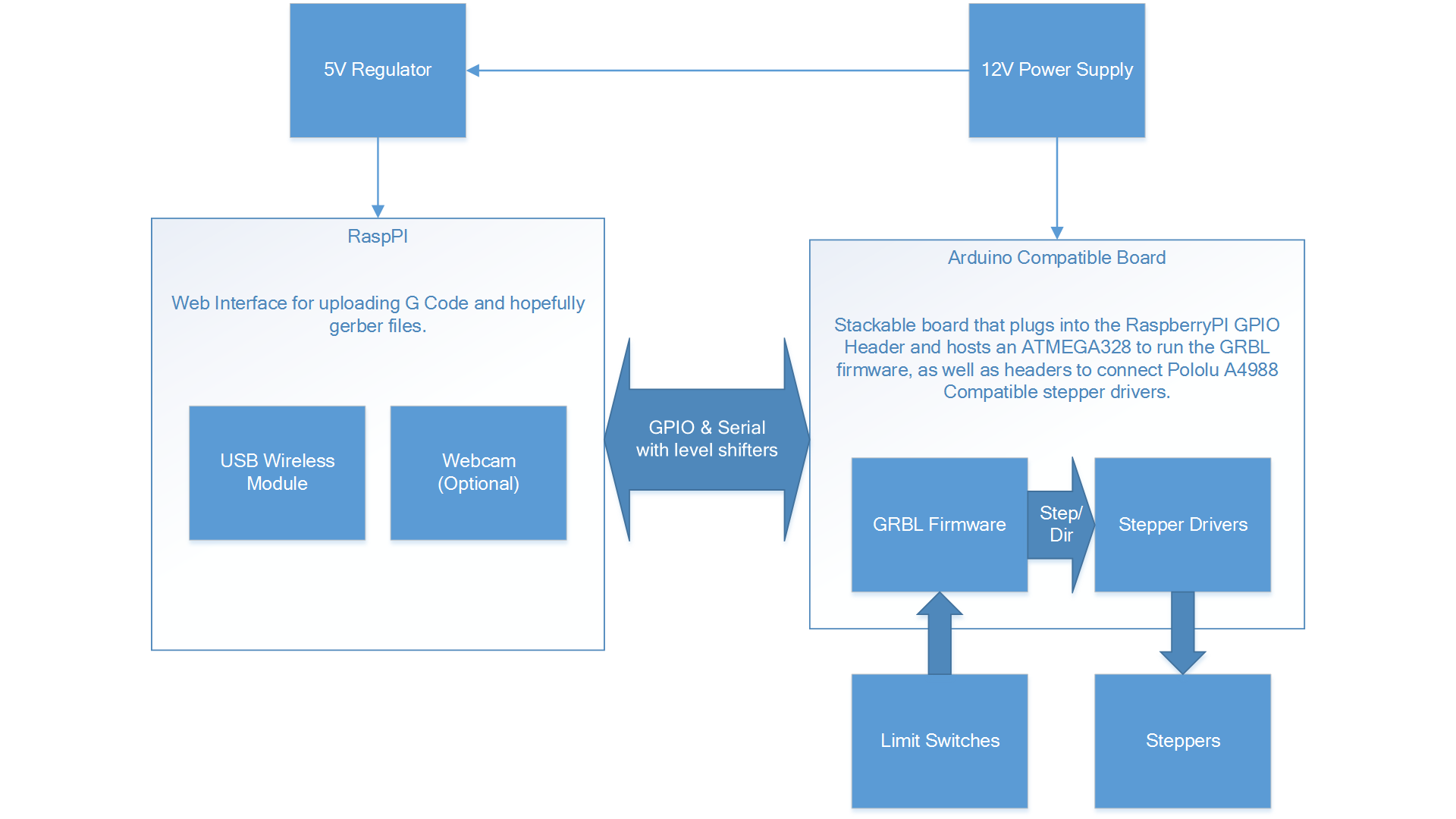

The core electronics will likely be an Arduino compatible board with Pololu stepper drivers running GRBL. The intention is to make a web based interface to the milling machine using either a Raspberry PI or an OpenWRT router which will give the commands to the Arduino over serial.

Systems Design Diagram:

Wudagem

Wudagem

Timo Birnschein

Timo Birnschein

gregstephenson

gregstephenson

Christophe Machet

Christophe Machet

zakqwy

zakqwy

you may also add powerful laser on your device: