-

It Lives!!!

07/29/2016 at 00:15 • 0 commentsIt is working! The eagle spotted viewer would realize that circle is more of an oval, so I have some belts to tighten and fine tuning to do, but otherwise major forward progress, and next....Printing!

-

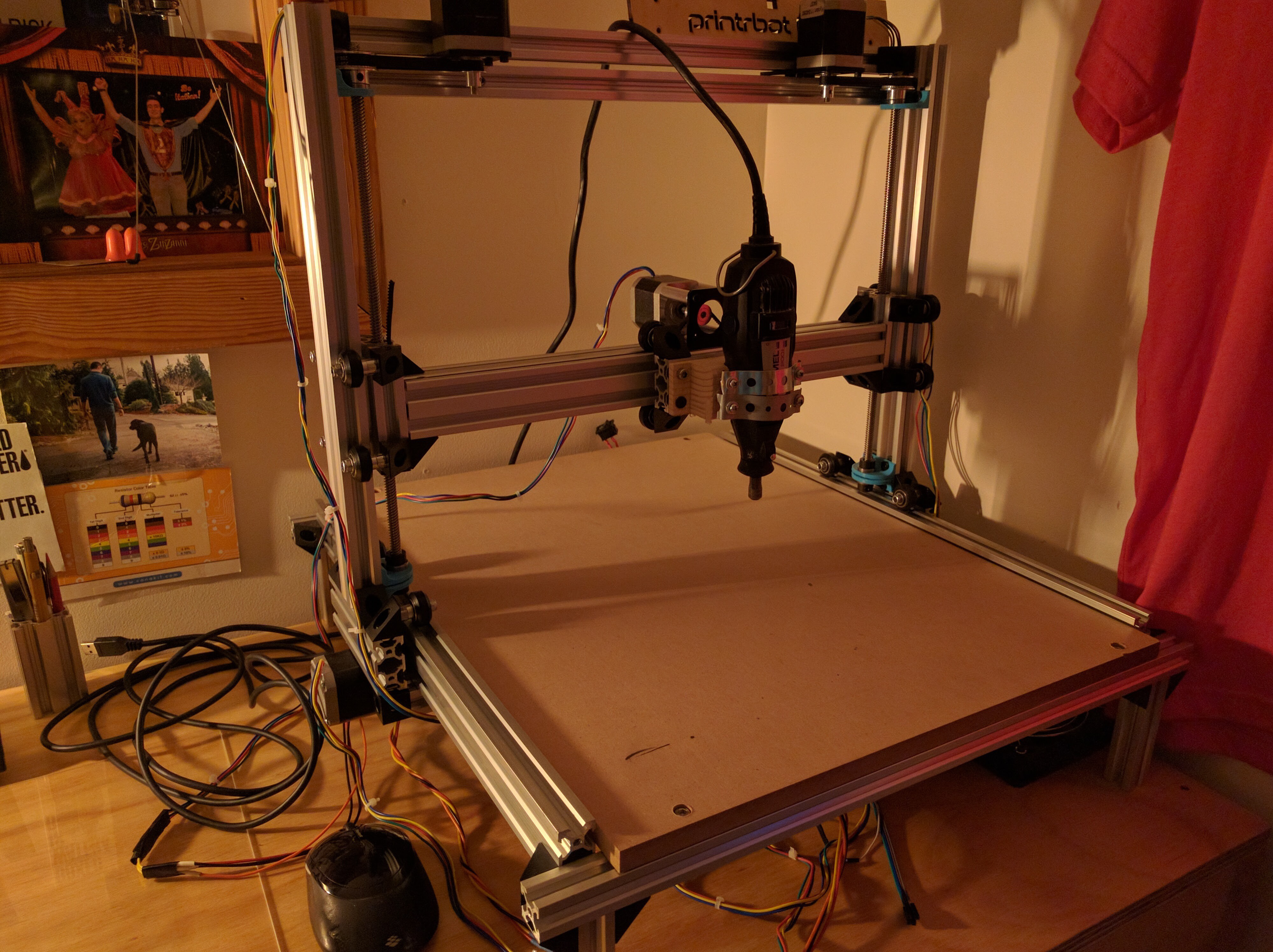

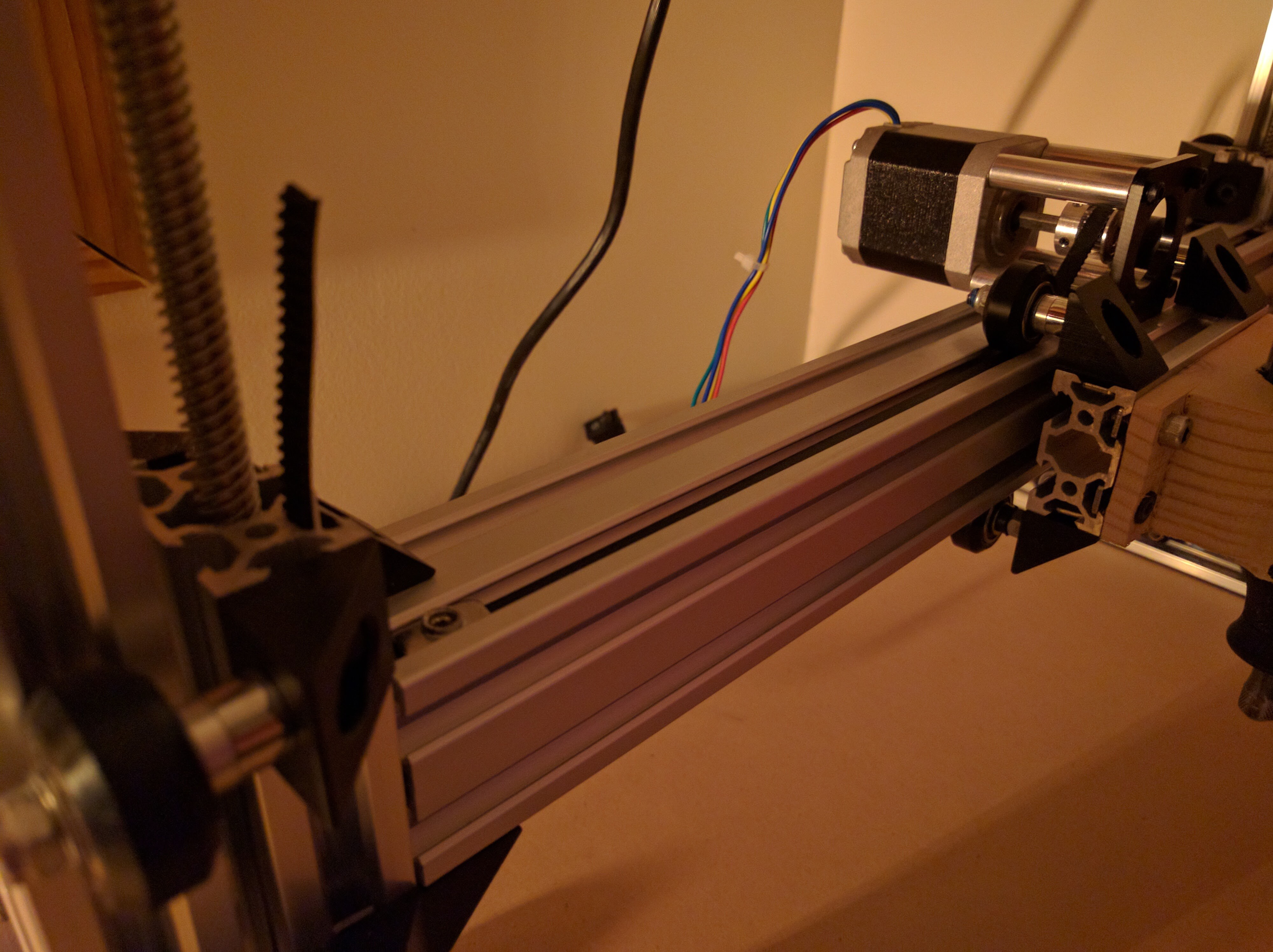

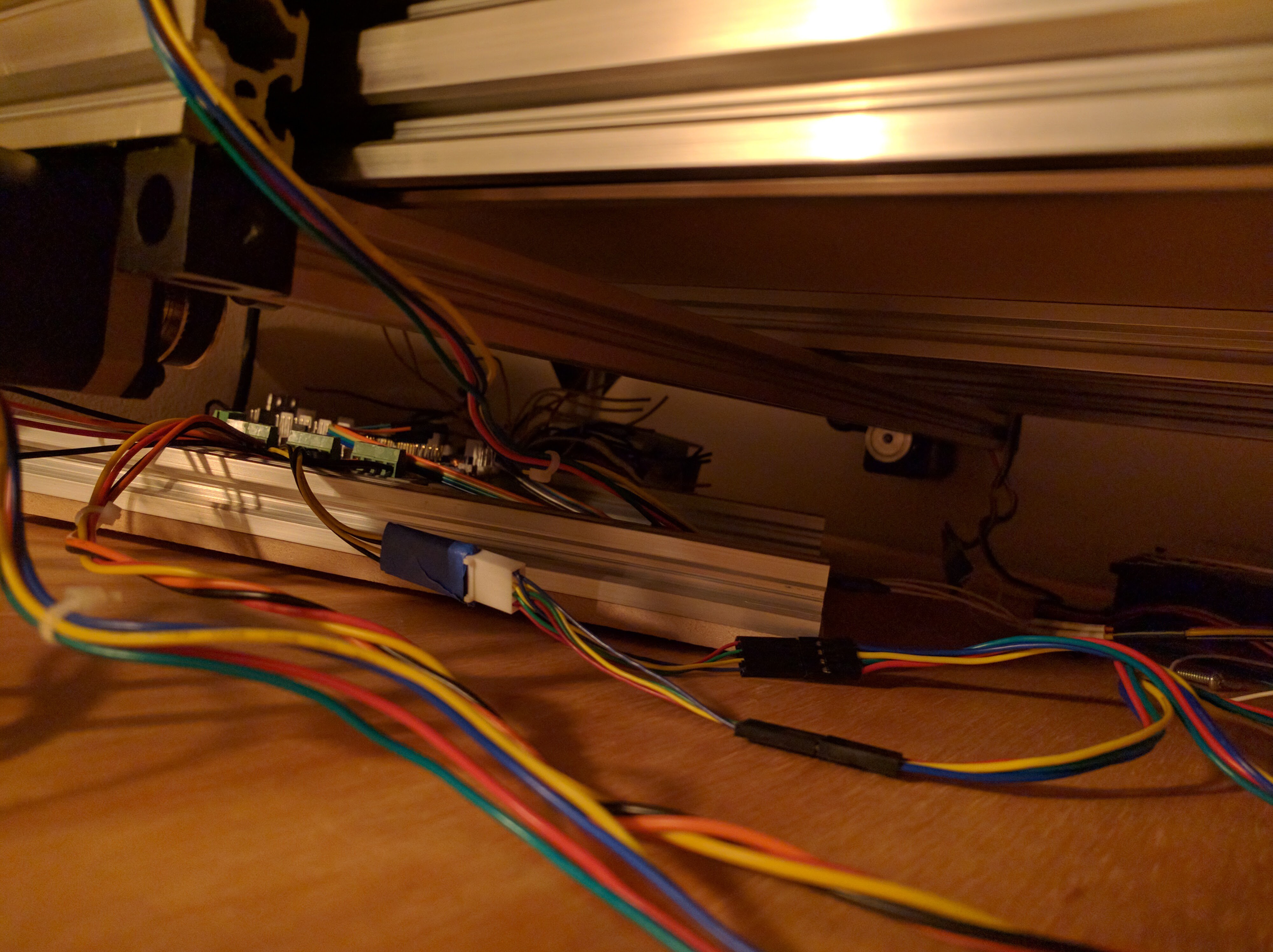

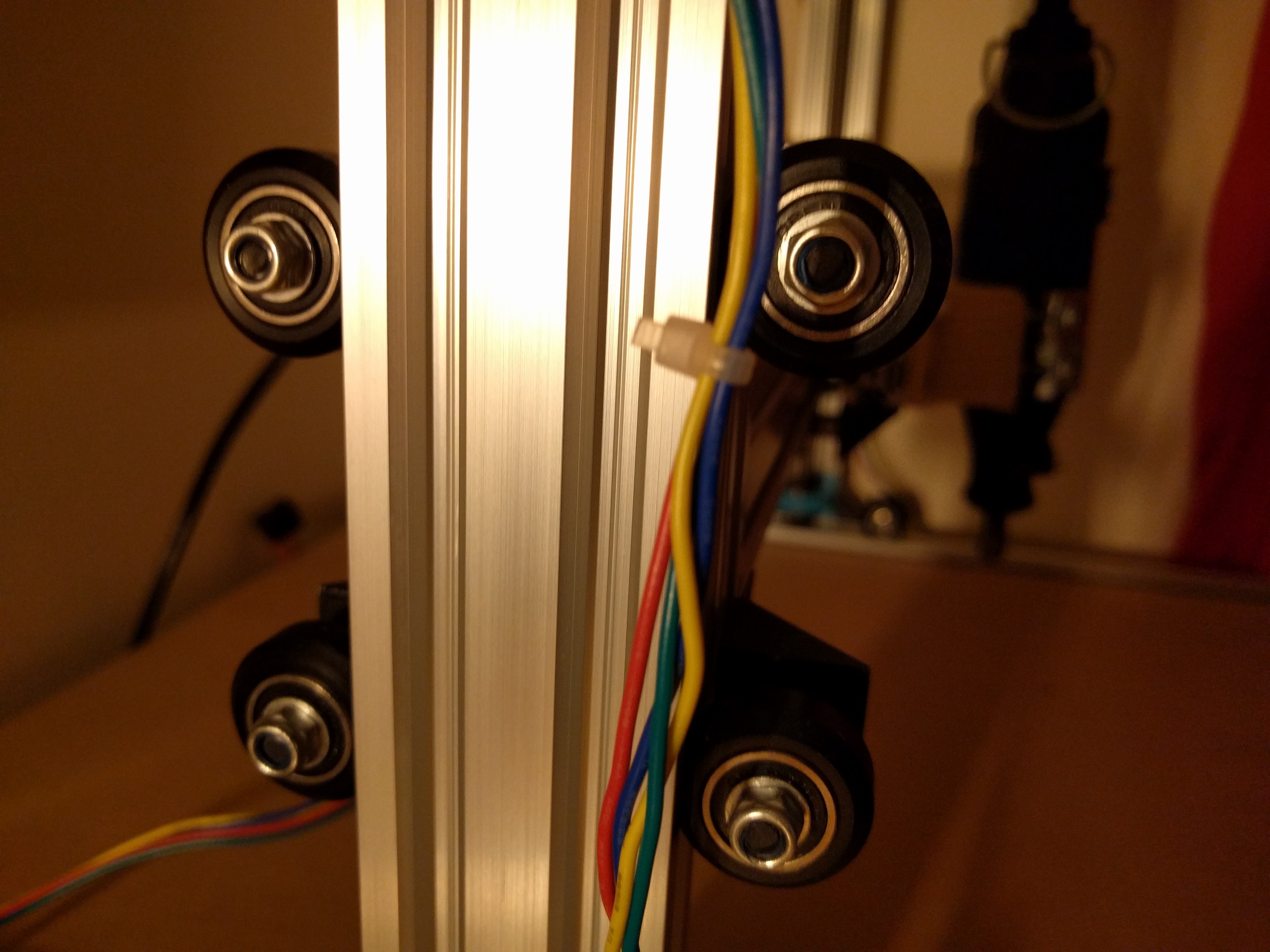

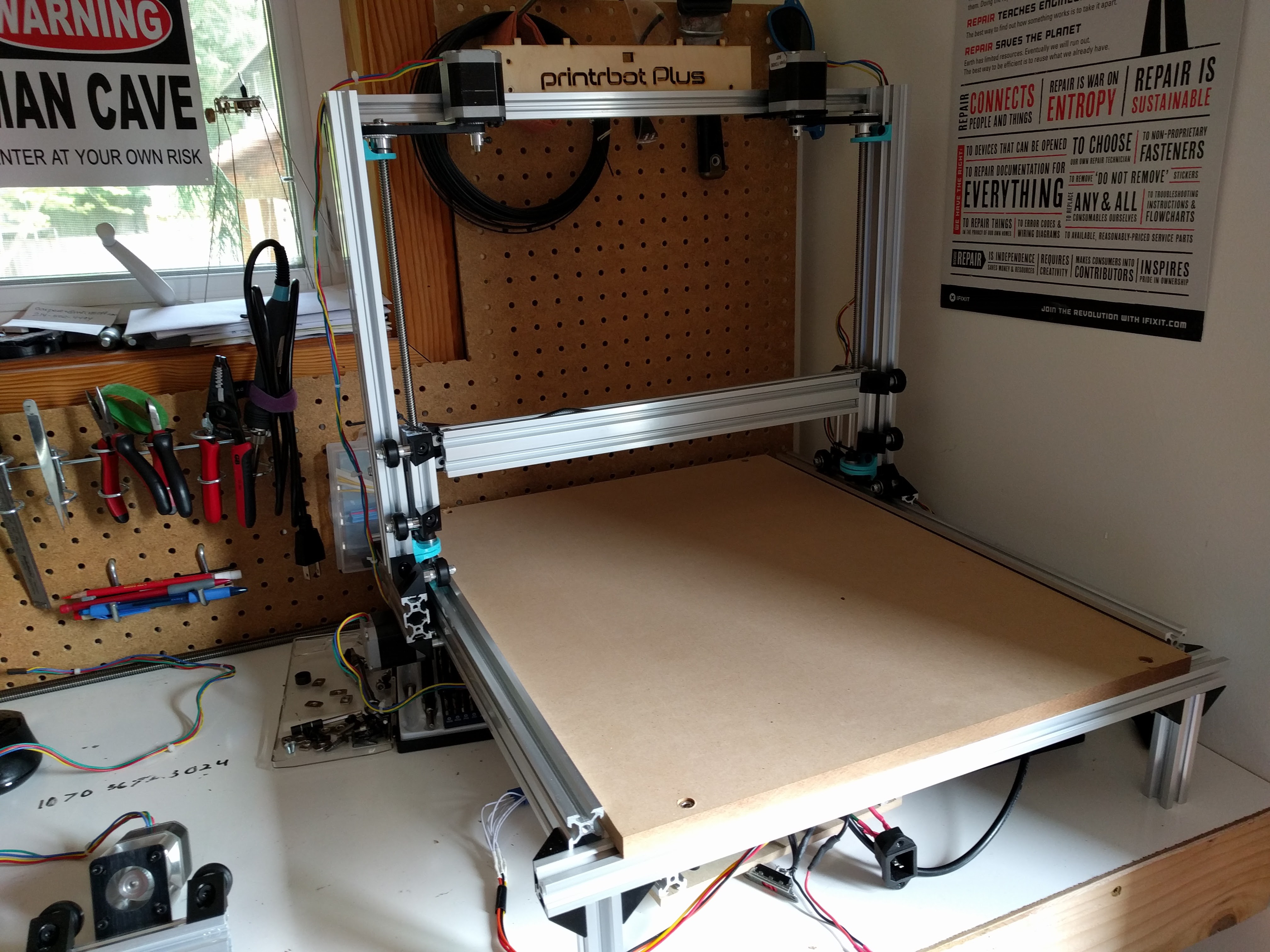

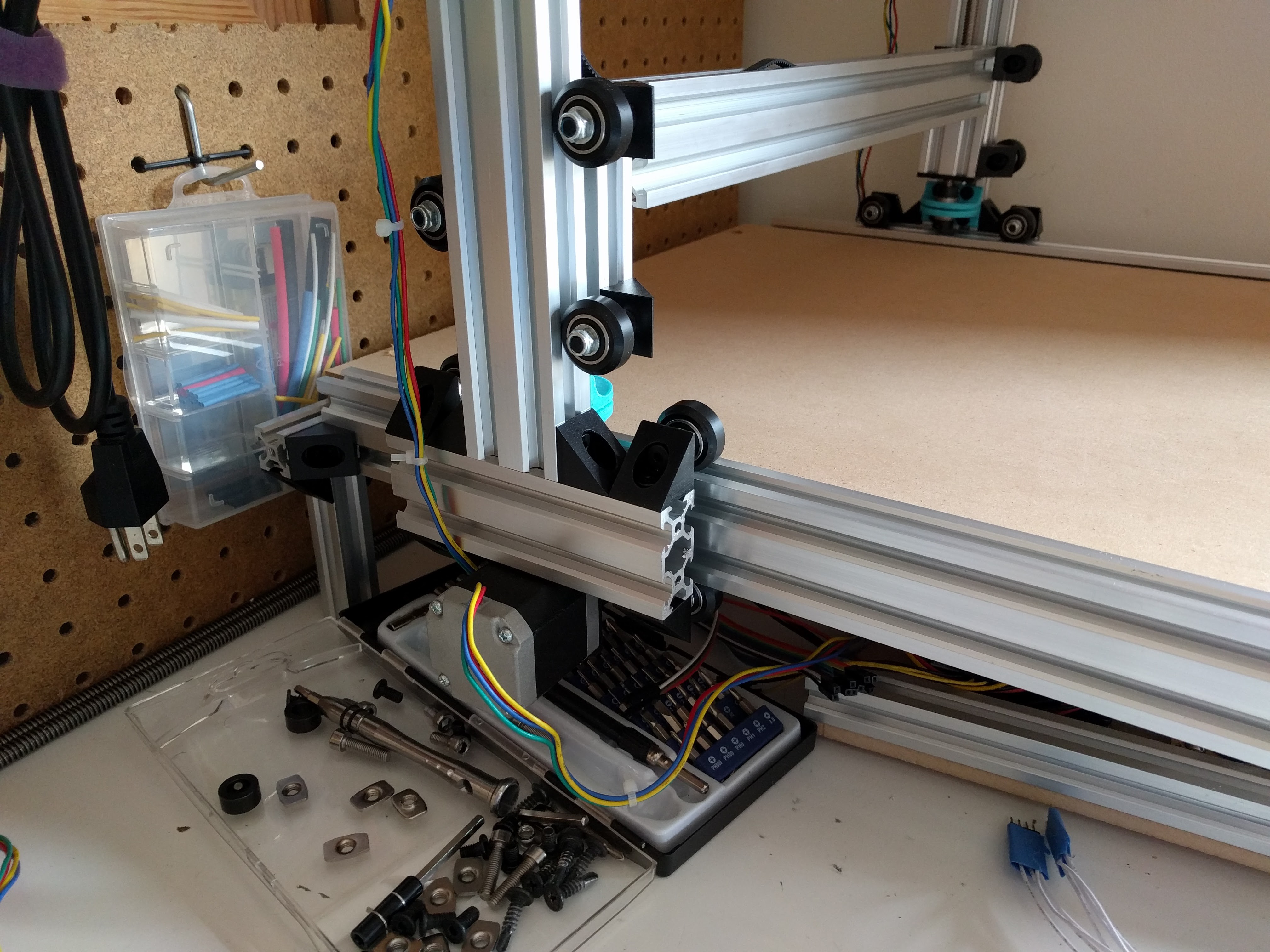

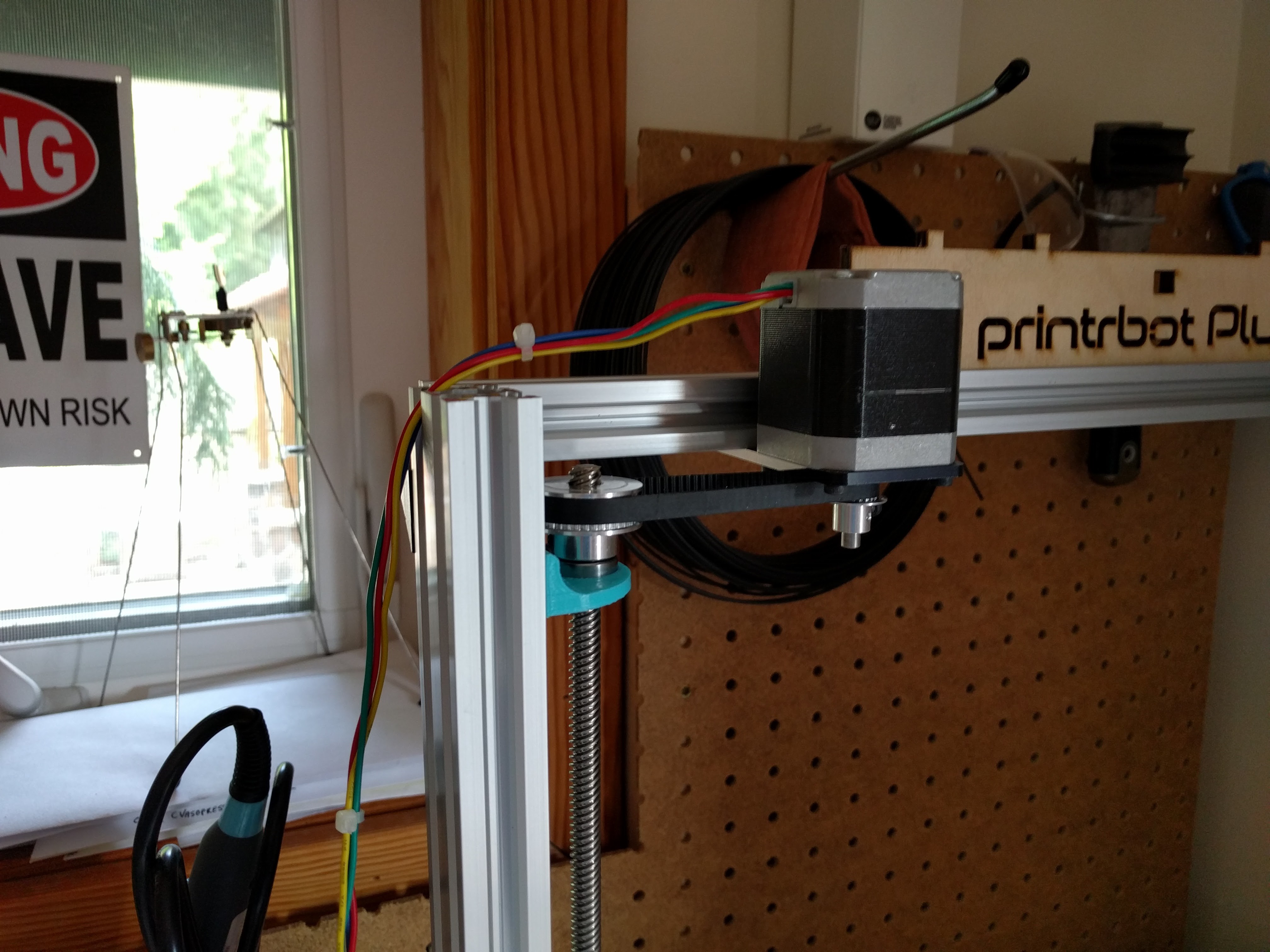

Wiring and Other Tid-Bits

07/25/2016 at 21:45 • 0 commentsProgress on the assembly front! The frame is back together and the wiring is almost complete. I have had to rewire a large portion to allow for the Gshield and Printrboard to used the same motor inputs. They are both tied into the same terminal block now and all I have to do is turn on either one so they will have motor access! The machine is back together and moving, I will most some of the first cut videos soon.

![]()

![]()

![]()

![]()

-

Update Coming!

06/16/2016 at 17:53 • 0 commentsA more detailed update with pictures is coming, but new parts came in for a more robust frame, wiring is being done well so repair and upgrades are far more feasible, and limit switches are going in so printing can begin! Stay tuned!

-

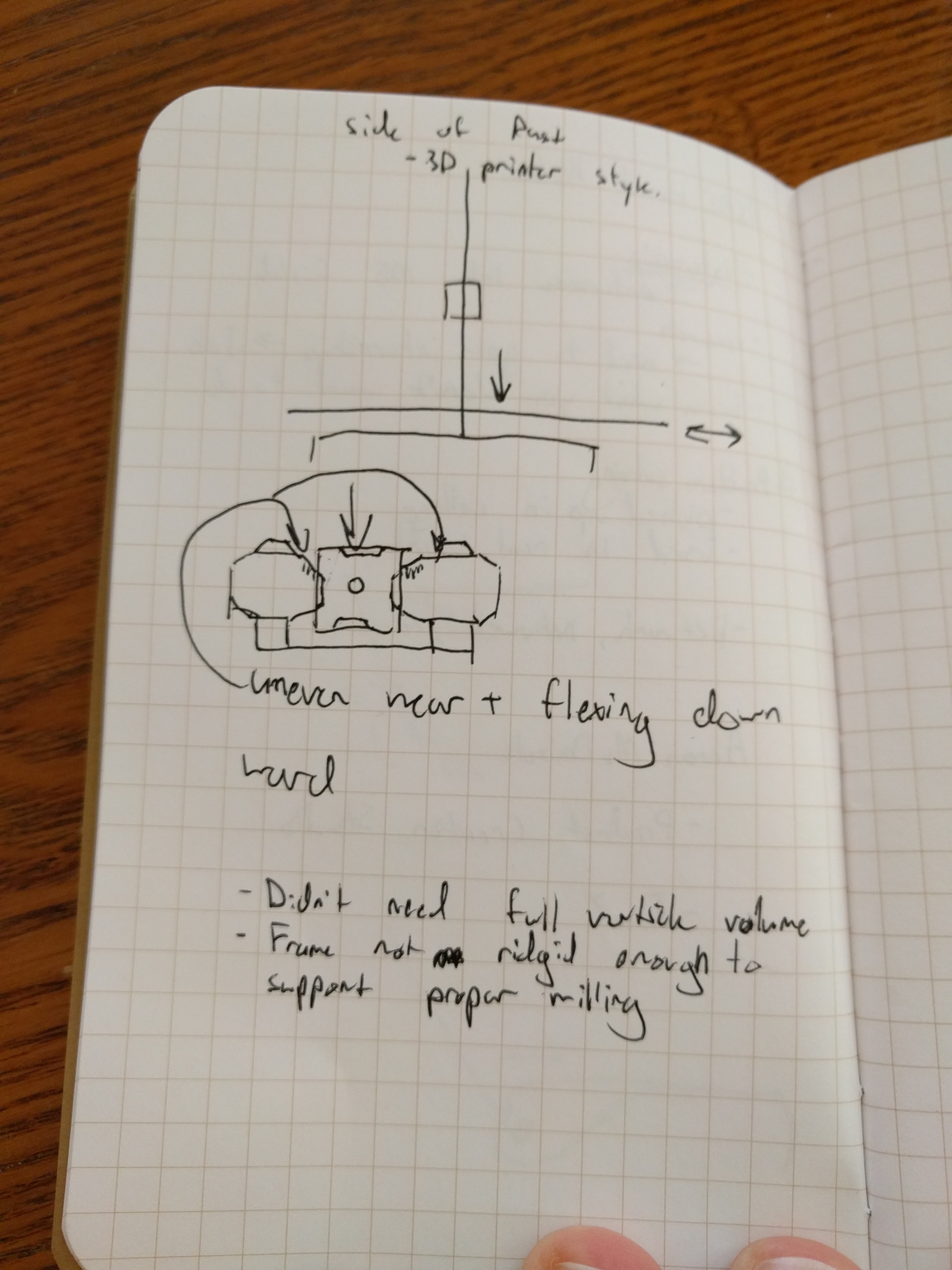

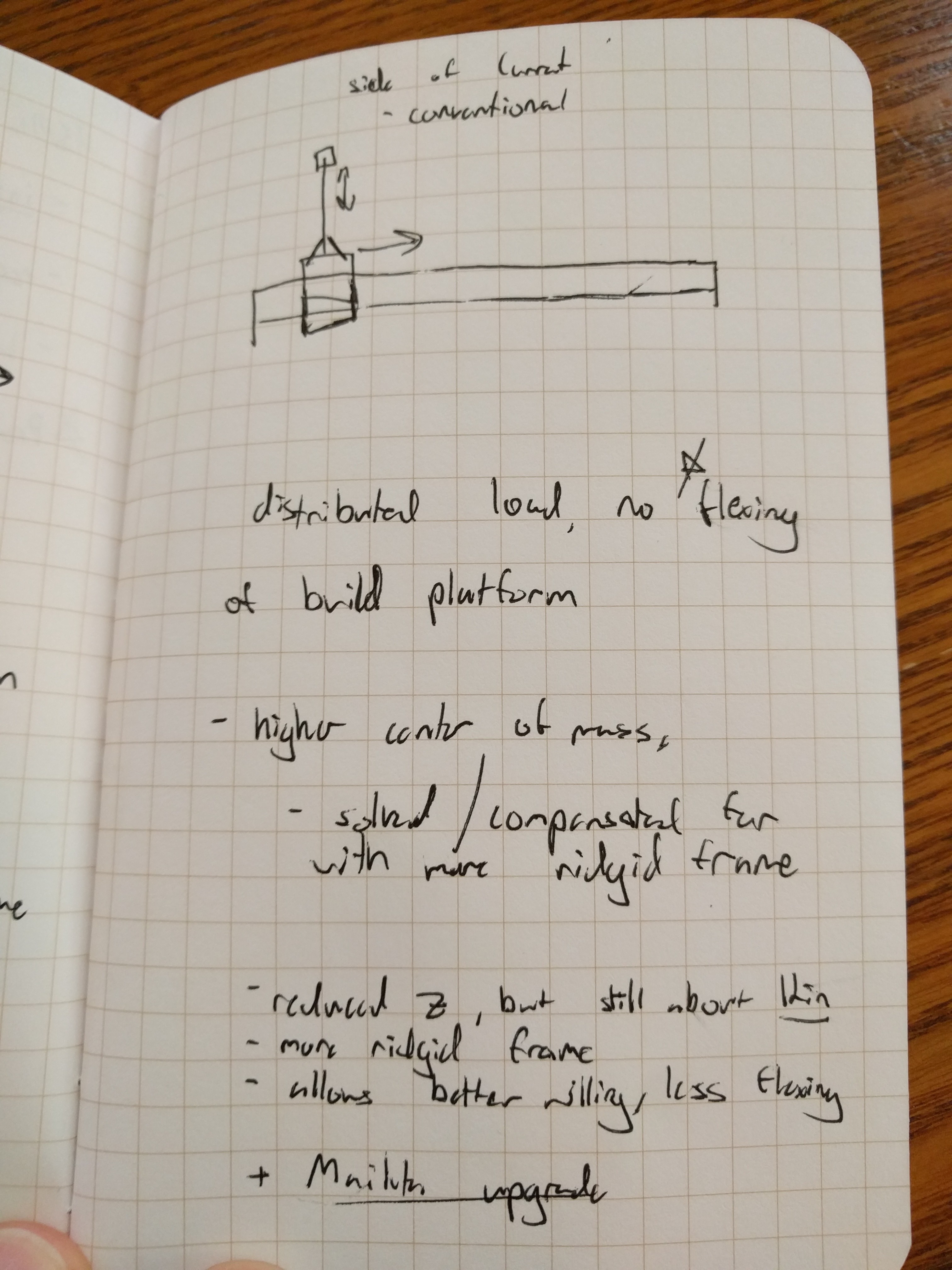

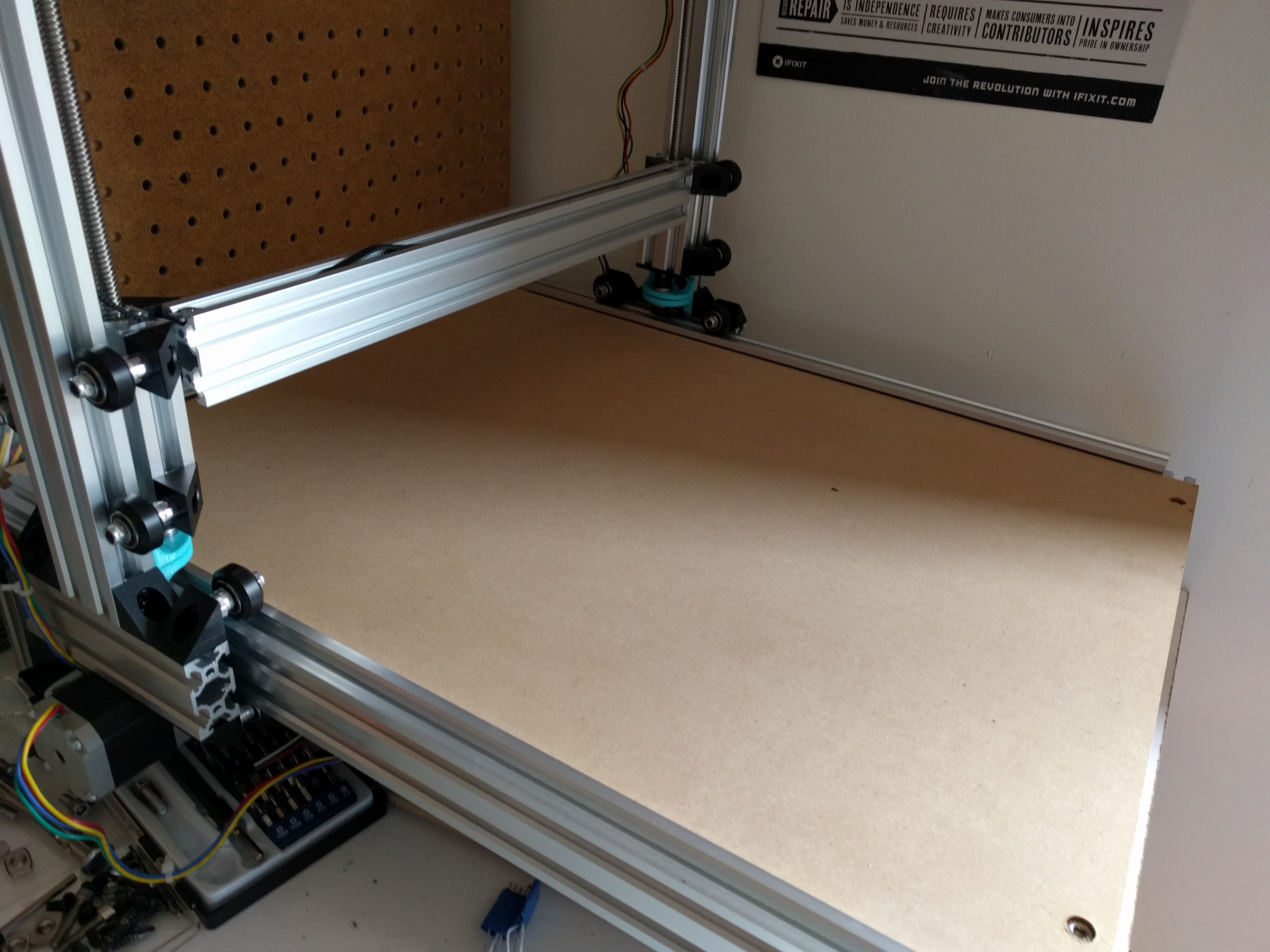

Reworking the Frame

04/10/2016 at 20:54 • 0 commentsThe time is ripe for another frame change! After making some test cuts, I made some observations, notably:

- I was a serious amount of walkout due to the dremel I am using. This will be solved my using a legit metal mount and a more powerful tool (the Makita I mentioned in the previous build log).

- The bed would flex due to only three points, very close together. His caused cuts to be at an angle which is now resolved with the fixed bed design.

- Also, even with 3D printing in mind, The z was higher than I needed. Shortening it would allow me to change to a moving gantry and fixed bed system.

- Here are a few notes in my notebook:

![]()

![]()

The solution is to change the design from a more 3D printer inspired design to a more conventional milling setup. This keeps the bed in place and lets the gantry move in both the x and y direction. This new setup allows for a more ridged frame to allow for less walkout/better milling as well as supporting a heavier, more powerful spindle.

![]()

![]()

![]()

![]()

-

Upgrade for spindle

03/28/2016 at 21:25 • 0 commentsI am looking at upgrading my spindle from my punny dremel tool I am currently using. This would allow me to really cut some materials and not have to baby the mill making sure the spindle doesn't choke. I am looking at a Makita rt0701c palm router as I have heard that the Makita is far less noisy than the comparable Dewalt, and a few bucks cheaper. It will also give me more power than a Chinese DC spindle, and cost less.

![]()

This upgrade will force me to rethink my gantry slightly to bear a larger load and to design a better mount for the spindle which will be the next update.

-

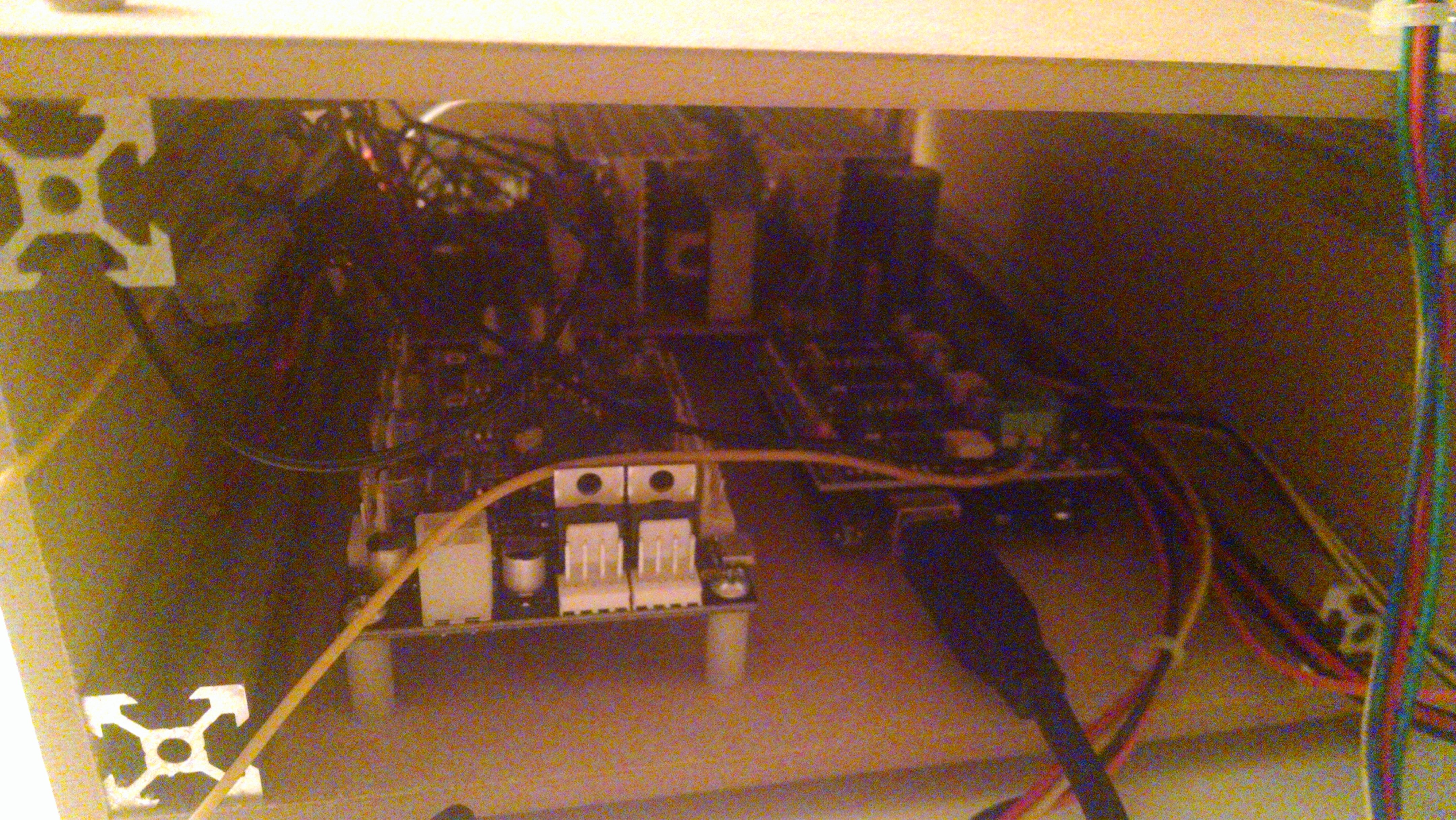

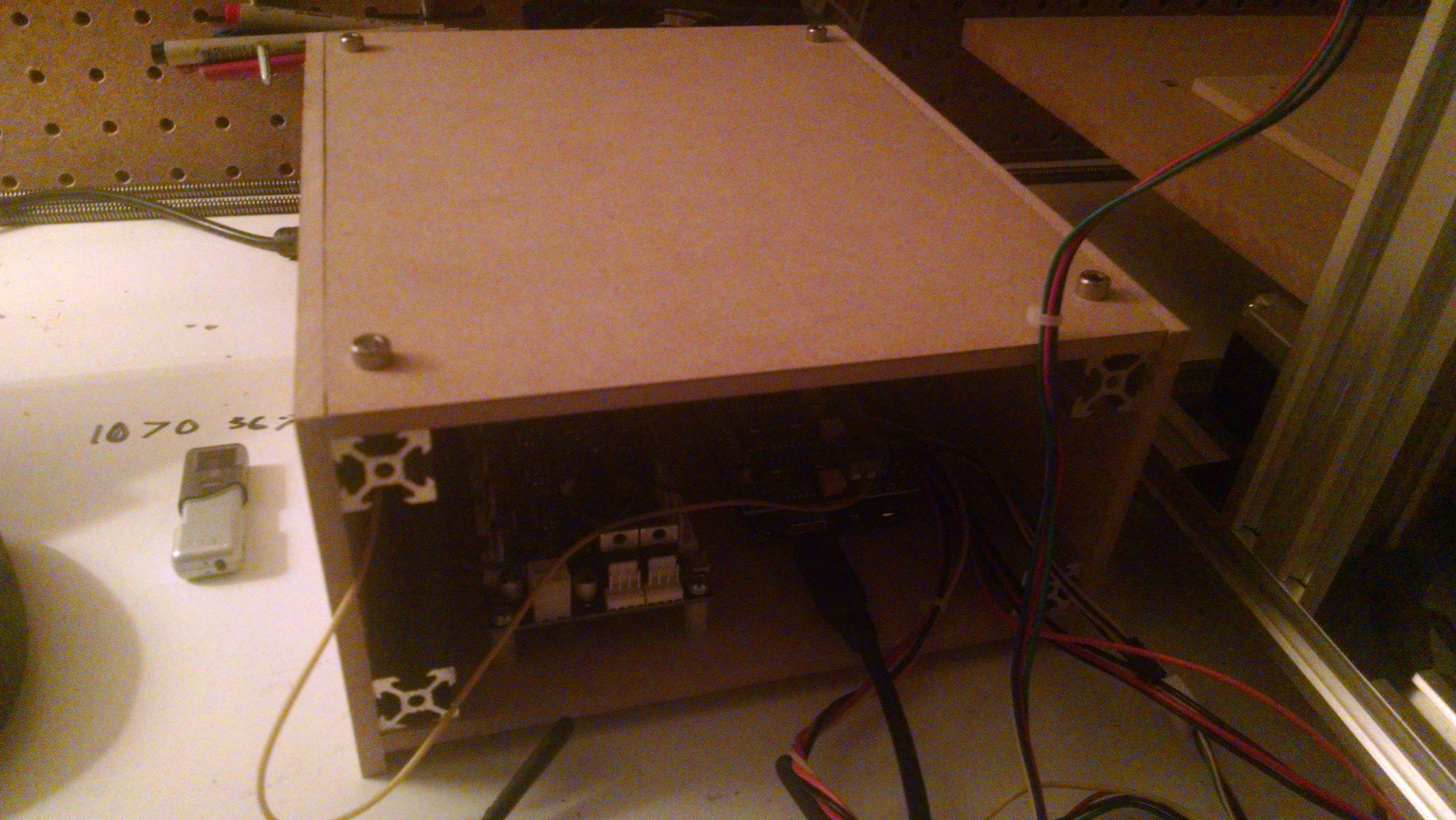

Doing Some Tidying up

03/22/2016 at 05:44 • 0 commentsI have added an enclosure to the electronics (printrboard, gshield, and PSU) cut out of MDF with a frame of aluminum extrusions. The front panel will be added soon to include quick connectors for the motors and limit switches as well as a power/kill switch.

![]()

![]()

Also, a dust collection tube has been added. This is not an ideal design, since it is hot glued and zip-tied, but when I upgrade the spindle I will design in a full dust collection system. This just makes clean up much faster.

![]()

Combo CNC/3D Printer Build

Rebuild of 3D printer to be bigger and better than before

Alex Anderson

Alex Anderson