-

A three-axis system for measuring the magnetic field inside the bore

08/09/2016 at 21:20 • 2 commentsA quick update, with some progress on the magnetic-field-measuring-jig!

![]()

Figuring out a way to measure the magnetic fields inside of the magnet bore has been something I've been thinking and prototyping for a while now. In this case, the task is complicated by:

- The need for anything magnetic (and, metal in general) to be some distance away from the magnet coil, sensor coil, and magnetometer. The working distance I've been using when sketching the prototype is somewhere between a 15-20cm minimum.

- The potential need for the entire system to need to be tilted on an angle to maximize the difference in direction between Earth's field and the prepolarizing field.

These unusual requirements have led me through a bunch of unusual design choices and prototypes, from 64-magnetometer imaging arrays to a polar cylindrical cnc system for measuring magnetic fields that I put together last year, that included (among other things) dental floss and elastic bands as the main source of non-metalic, non-magnetic drive components for one of the axes. I think part of the reason why I've made these choices, aside from it being a strange problem, is that I really like to explore how to design and make inexpensive, easily-sourced mechanical systems with rapid prototyping systems like laser cutters. But -- forest for the trees -- as enjoyable as it is to design these, at some point you have to pick a design, and work the rest of the problem.

![]()

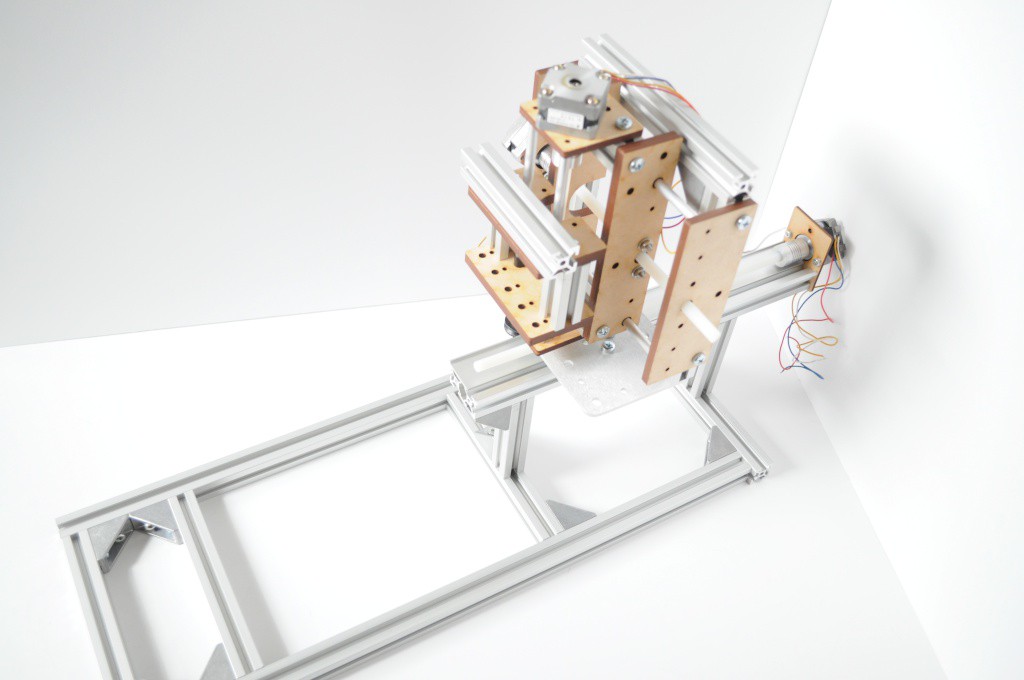

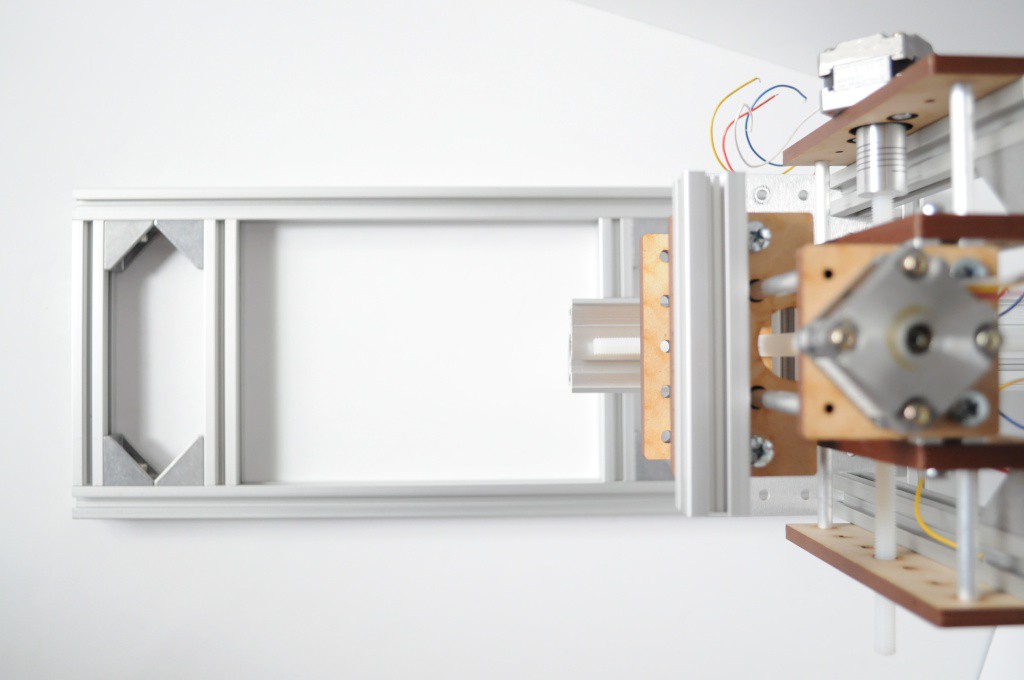

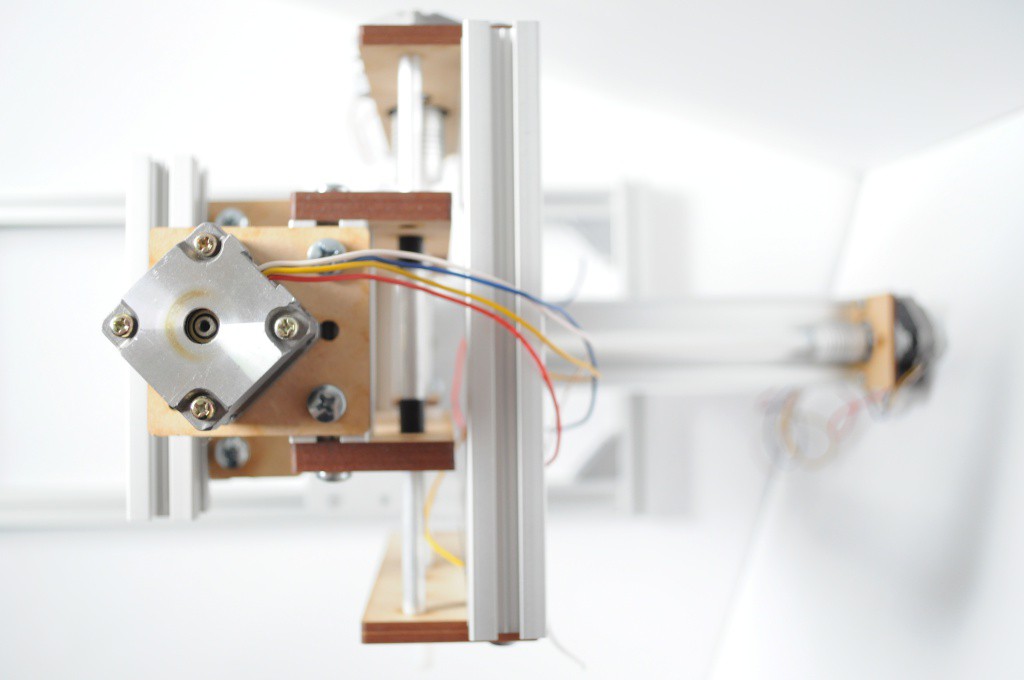

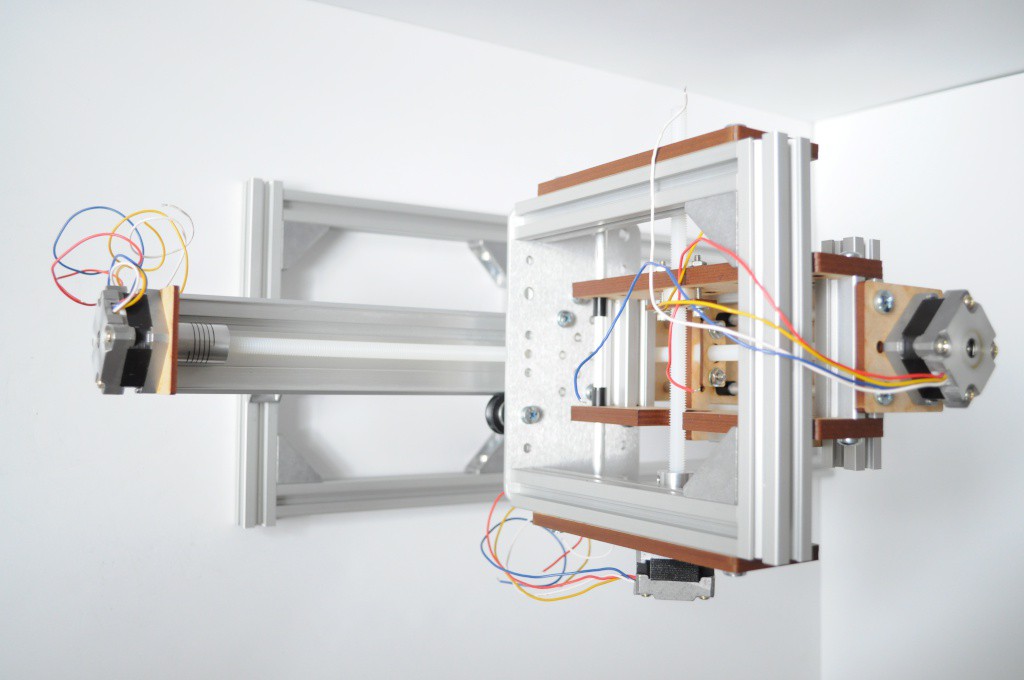

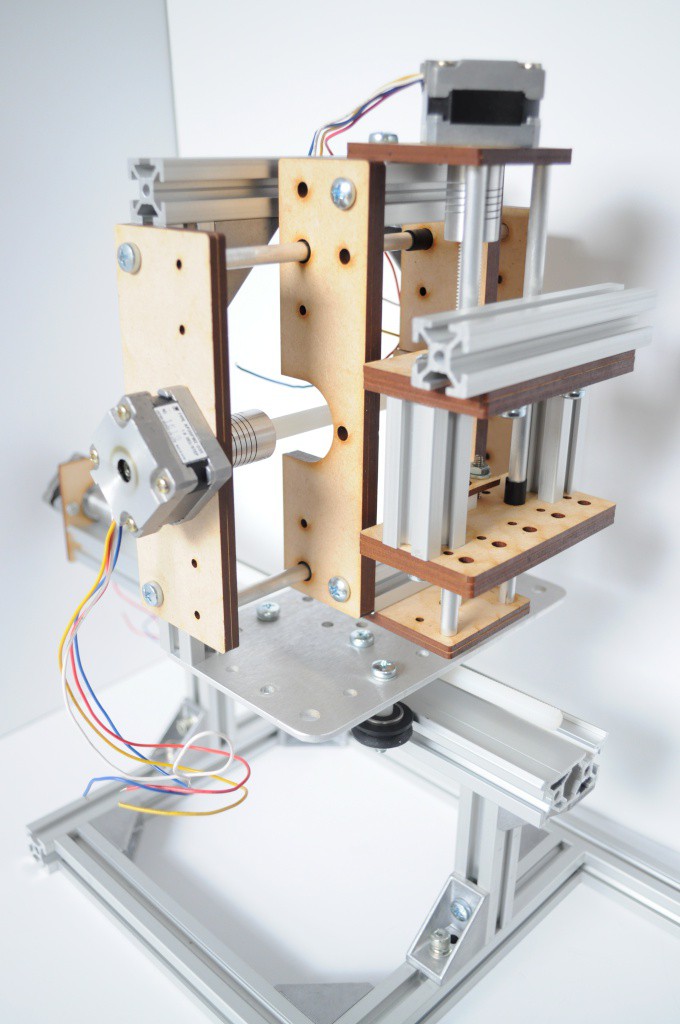

With the design I've settled on, I've tried to keep things as simple as possible given the unusual design requirements. The system is essentially an X/Y table turned on its side, then mounted to a long Z stage. The whole thing is then layed down, and bolted to a supporting frame, that will also include the control electronics for the entire system, as well as the magnet. The magnetometer will mount, so the idea goes, to the outermost axis on the table, on a long stick about a foot or two in length -- as long as possible, while still having the full travel of the bore, plus an inch or two outside to "park" the magnetometer when it's not being used.

Rigidity, repeatability, simplicity and the ability to mount the entire system on one frame drove most of these requirements. All those attempts at an elegant solution -- imaging arrays, polar systems, and in the end it's a magnetometer... mounted on a long stick. Definitely have to laugh at that...

![]()

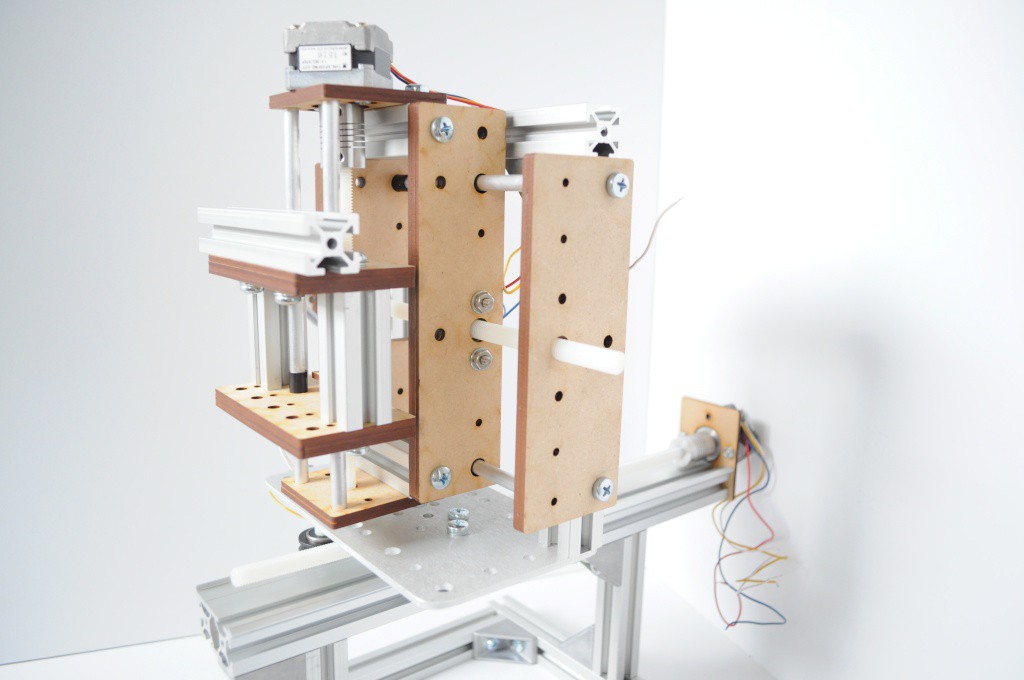

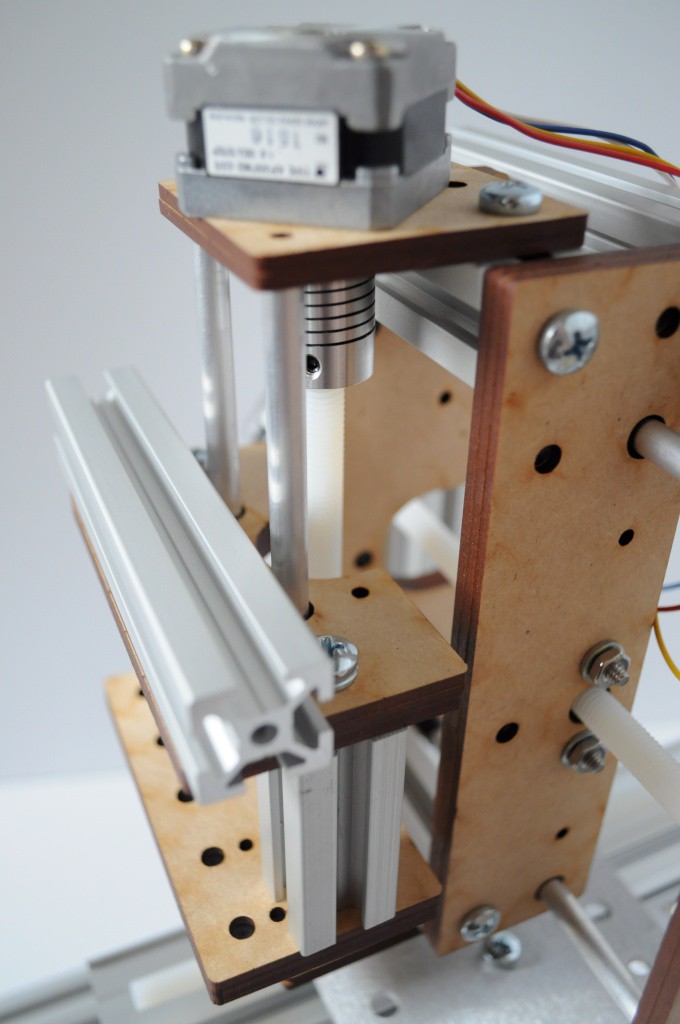

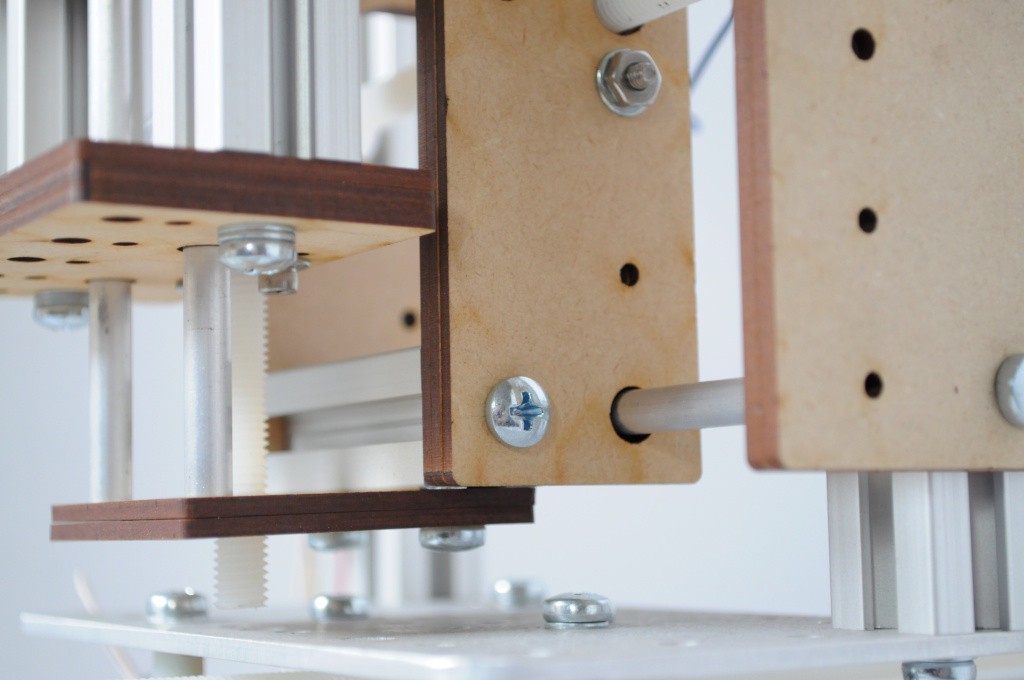

I'm very happy with how these linear axes turned out. The carriages are three pieces of laser-cut MDF, with a cuts that sandwhich 1/4 inch diameter nylon flange bushings firmly in place. The aluminum shafts are 1/4 inch, with what looks to be about a 1-2mm wall. Normally when laser cutting linear axes, I make the entire system out of MDF, but here I decided to add in some pieces of Misumi t-slot aluminum extrusion to increase the rigidity, and make mounting the steppers (and whatever else may need to be mounted) a little easier.

The major partslist for each axis is very minimal:

- NEMA 14 stepper -- I purchased these from a local electronics shop for about $4

- 5mm to 8mm aluminum shaft coupler -- eBay, about $2 each

- 8mm nylon threaded rod -- $10/meter from McMaster. Each axis uses about $2 worth.

- 1/4 inch aluminum rods -- a few dollars from a local hardware store

- Nylon flange bushing -- four of these are about $1 from the same hardware store

- Misumi extrusion -- cut down from larger pieces, likely a few dollars worth

- Laser cut MDF -- about $1 (assuming access to a laser cutter)

- A handful of M5 screws

This places the mechanical bits in about the ~$10-$15 range, which is very reasonable for a short-travel axis that doesn't require a huge amount of precision.

![]()

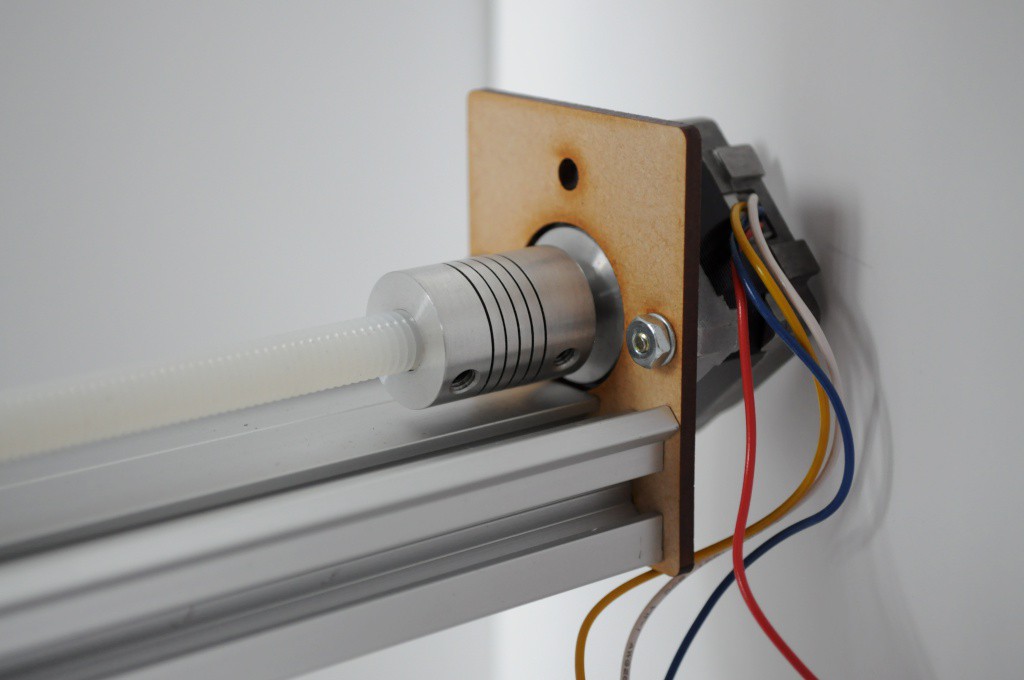

The "Z" axis is simply a single piece that mounts to the end of a piece of Makerslide, and was reused from the coil winder I cobbled together earlier.

![]()

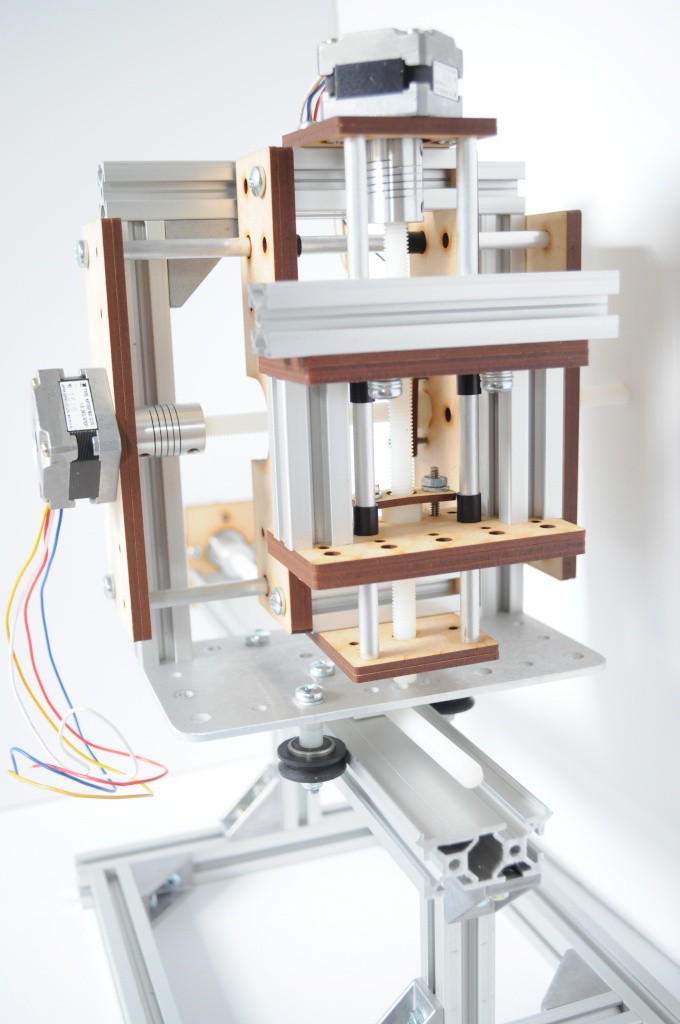

Another vie of the X/Y table. The larger frame is also made of aluminium extrusion, and mounts edge-on to a standard Makerslide carriage plate on the Z axis.

Each of the table axes has about 3-4 inches of linear travel, which is more than the 2 inch diameter of the sensor coil. If this works, I'd like to wind another coil with a larger diameter, to fit larger objects inside.

![]()

The front end of the system. On the left, a large fork will mount that holds the magnet bore and sensor coil about 20cm high -- both away from the aluminum frame, and high enough that a magnetometer mounted to the outermost table axis on a long stick will be able to travel around the bore without issue.

![]()

And the back end of the system -- the Z axis. The control electronics will likely mount against the bottom frame toward this end, away from the sensor coil.

![]()

The back/bottom of the table axis is visible here, showing several of the black nylon flange bushings extending along the axis. A cutout is also visible in each axes carriage that lets it slide overtop of the aluminum coupler off each stepper, adding nearly an inch to the travel. This wouldn't normally be a big deal, but with such small axes, this adds an appreciable amount to give them their total of 3-4 inches of travel.

![]()

Another view from the "front" of the table, with the notch for the shaft coupler clearly visible.

![]()

![]()

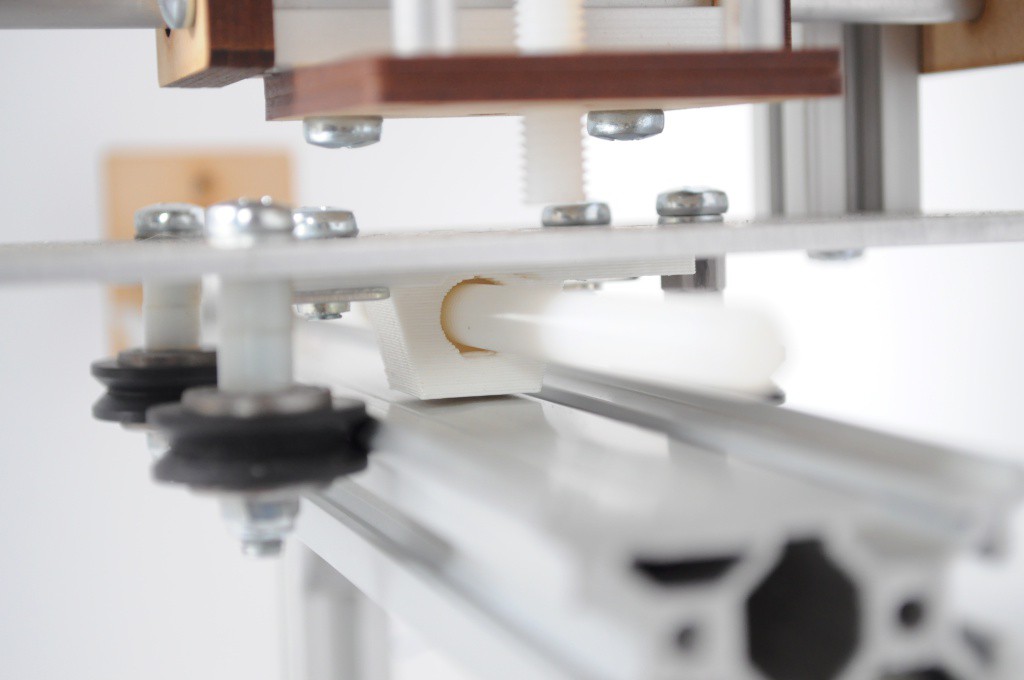

The Z axis transfers motion to the Makerslide carriage through a 3D printed nut holder that mounts to the back of the Makerslide carriage. I designed these for the OpenCT2 project, and they've become very handy for making quick linear axes with Makerslide -- an hour of printing, a quick laser-cut mount plate on the end of the makerslide, and you're often set. This same style of linear axis was also used for the coil winder, though the nut holder was mounted to the top of the Makerslide carriage -- here that wasn't possible, given that the table has lots of things in the way on the top.

![]()

A good amount of progress, but plenty left to do. I keep telling myself that I'll get the mount plates for the electronics complete, but the linear axes took a little longer than I had expected to put together. I'm a little slow on a milling machine, so it took me a while to cut down all that aluminum extrusion for this jig and the axes -- but I think it's coming along really well, and I'm excited to see how it works out.

Thanks for reading!

-

The start of a probe to measure the magnetic field

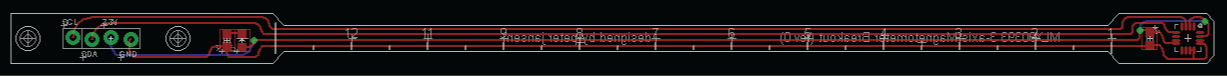

07/12/2016 at 05:38 • 0 commentsA quick update, with designs for the magnetometer breakout board.

![]()

It's been a very busy week in the lab (conference season), so I unfortunately haven't had a great deal of time to devote to much other than data analysis, eating, and sleeping. I've tried to load up my queue so that I can do quick tasks (like create a magnetometer breakout board suitable for measuring the field inside the bore) that have long turn times, like the two weeks that it takes for boards to arrive from the fab. That way, when the dust clears, there will be plenty to get busy with.

I've been itching to connect everything together, place a bottle of water inside the bore, start pulsing the field, and see if I can collect the first proton precession signals. But I've restrained myself, in that everything is currently a jumble on the bench, and the last time that I rushed a delicate system (nearly one year ago), I ended up accidentally blowing up two of the OpenCT2 detectors, and setting the project back a few weeks. Here, I'm extremely anxious about connecting up a nest of wires that has several amps of current pulsing through, so I just have to wait a week or two, until I can laser cut something to properly and safely mount everything.

I did get the chance to test out the polarizing coil field (above), and as near as I can tell until I have a magnetic probe that can fit into the small bore, the field is performing as expected. The HMC5883L magnetometer in the Arducorder Mini saturates 5-10cm away from the coil itself, which is a good sign that the field intensity inside is high enough to detect the proton precession signal.

![]()

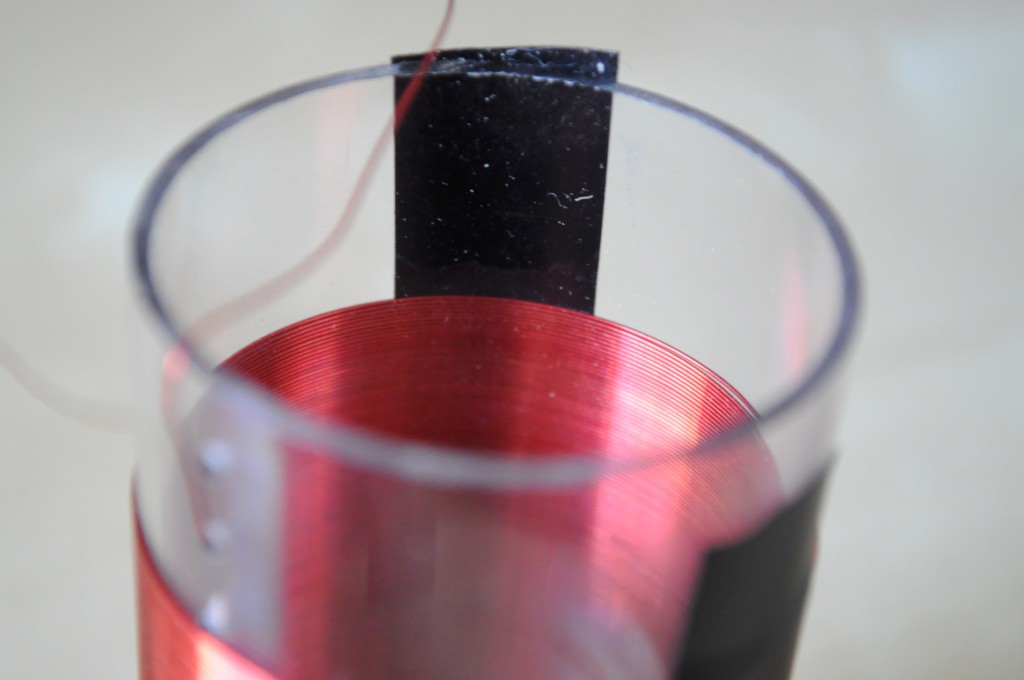

The coil form itself gets reasonably warm after a minute of being on, it essentially being a giant resistor, as if to implicitly warn me that I'm treading somewhat outside my expertise in low-voltage, low-current digital electronics to something that requires serious juice -- and to make my mistakes cheaply. One of the worries that I've had, given that some other folks (like the PyPPM) tend to use the sensor coil both as a polarizing electromagnet and as a sensor coil, is how much of a voltage spike will be carried through the system from having to pulse the coil. I included some clamping diodes on the inputs to the amplifier board, but those are more for accidental overvoltage, and I'd rather not pulse the board with large spikes several orders of magnitude over its sensing range every few seconds, if possible.

I haven't yet completed the circuit to quickly quench the polarizing field, but viewing the voltage induced on the sensor coil simply from powering on the polarizing coil from a bench supply couldn't be more clear -- even with a relatively small number of turns and the air gap between the polarizing coil and sensor coil, a very large voltage spike is induced, and the sensor coil needs to be connected through a relay that disconnects the coil while the polarizing field is powering up or quenching.

![]()

One of the main pieces of the instrument that's left to complete is the volumetric magnetic field measurement apparatus. Last year, I spent a great deal of time on this aspect -- at one extreme creating a board with an 8x8 grid of magnetometers, while at the other extreme I put together a large polar CNC system that contained nearly no metal, used a single magnetometer (and some tensioned dental floss) to scan it through space, and smelled very minty while in operation. In retrospect I think I was enjoying the nonstandard design constraints a little too much, and ended up sketching (in hardware) a variety of prototypes that were a little overkill.

This year, I'm benefited by the happy coincidence that other open source folks have also become interested in magnetic field measurement. Ted Yapo has been doing a beautiful job putting together a magnetic field scanner by simply strapping a magnetometer to an old 3D printer, sparsely moving the 3-axis system around the object, then interpolating the fields to produce some beautiful visualizations. One of the great contributions of Ted's project is his detailed approach, which began with characterizing a bunch of off-the-shelf magnetometers, and discovering that the HMC5883L (which the Arducorder Mini uses!) has unexpected behavior when the field saturates. Through Ted's project I also became introduced to the new MLX90393 3-axis magnetometer. Unlike many traditional off-the-shelf magnetometers that are largely designed for measuring the Earth's field for compass applications, the MLX90393 appears to have a huge dynamic range (50,000uT @ 0.5nT resolution), all while behaving very well, even under large fields. This is clearly a great magnetometer to use to characterize the fields in the bore in this low-field system, while also being able to comfortably handle the 10,000uT polarizing field without saturating.

This time around, I've decided to keep things as simple and tractable as possible, and use a single magnetometer mounted to a very long stick (above, just FR4) that can be moved in and out of the bore on a linear axis. We also have to figure out a low-effort way to make it scan about an inch off axis in any direction to capture the field within the entire bore, rather than getting bogged down in designing the perfect bore scanning apparatus -- and both David and I have been plugging away at thinking about this in time for putting thoughts-to-laser-cutter sometime shortly. In anticipation of not really knowing what the mount will look like, I designed three separate and extremely low profile MLX90393 breakout boards [github link], all 6mm in length on the smallest edge, and slightly larger on the long edge. The exception to this is the long megetometer probe board (seen above), that's essentially the magnetometer mounted to the end of 16cm of 6mm wide FR4, with a connector and mounting holes on the other end, and a handy silk-screened ruler to measure depth. It'll be good to try out this low-cost magnetometer wand, and mount it to a linear axis to begin (finally) characterizing the field.

Thanks for reading!

-

A prepolarizing coil, and second sensor coil

07/01/2016 at 07:09 • 0 commentsA quick update, with two freshly-wound coils.

![]()

One of the tasks that I'd completely underestimated the difficulty of when I first began this project is coil winding. On the surface it looks very easy -- just winding a wire around a cylinder, many many times -- but keeping track of the number of turns, making multilayered coils, and keeping enough tension that the whole thing doesn't fly apart and uncoil in a fury of wire and tears (which has happened more than once) is all more challenging than it first appears. That's why it's comforting to feel like I'm finally getting the hang of this whole coil winding thing.

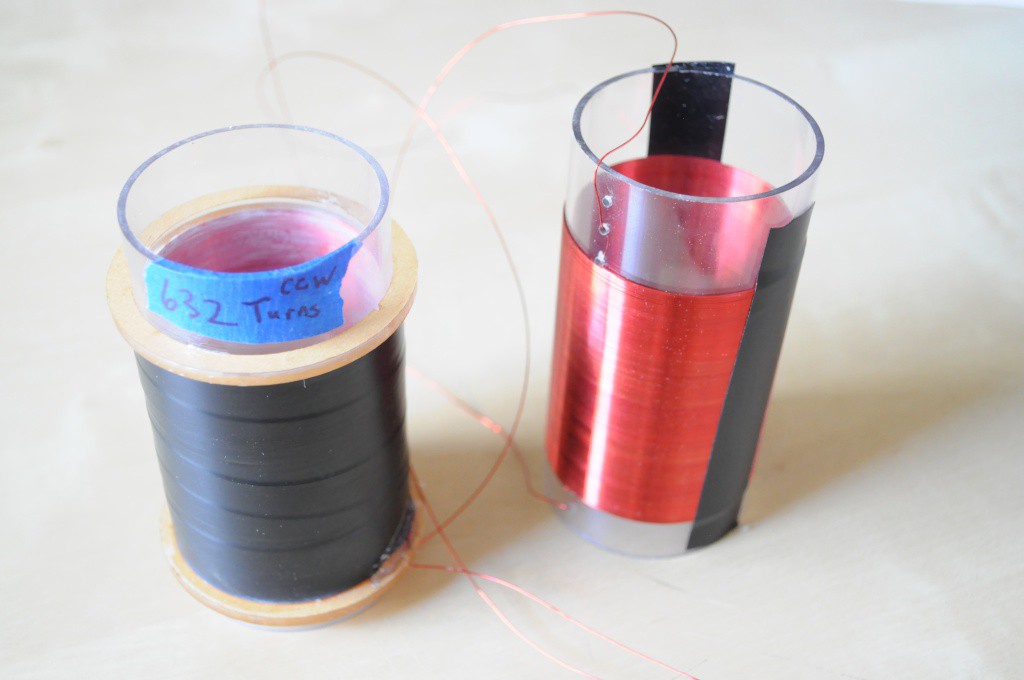

While I'd previously wound my first sensor coil, this was more of a practice coil, and the first multilayer coil that I'd attempted to wind. A proton precession magnetometer (and, presumably, a spatially resolved PPM) generally needs at least two coils: the sensor coil, which receives the very low-intensity signals, and a polarizing coil, which pulses a large 100+ Gauss field around the sample immediately before recording from the sensor coil. Some PPM designs use the same coil for the polarizing field and sensor coil, but here we've decided to break them out into two separate coils. This is largely because if the design works, it'd be wonderful to be able to experiment with different coil geometries, to see how open (as in spatially) the system could be while still working.

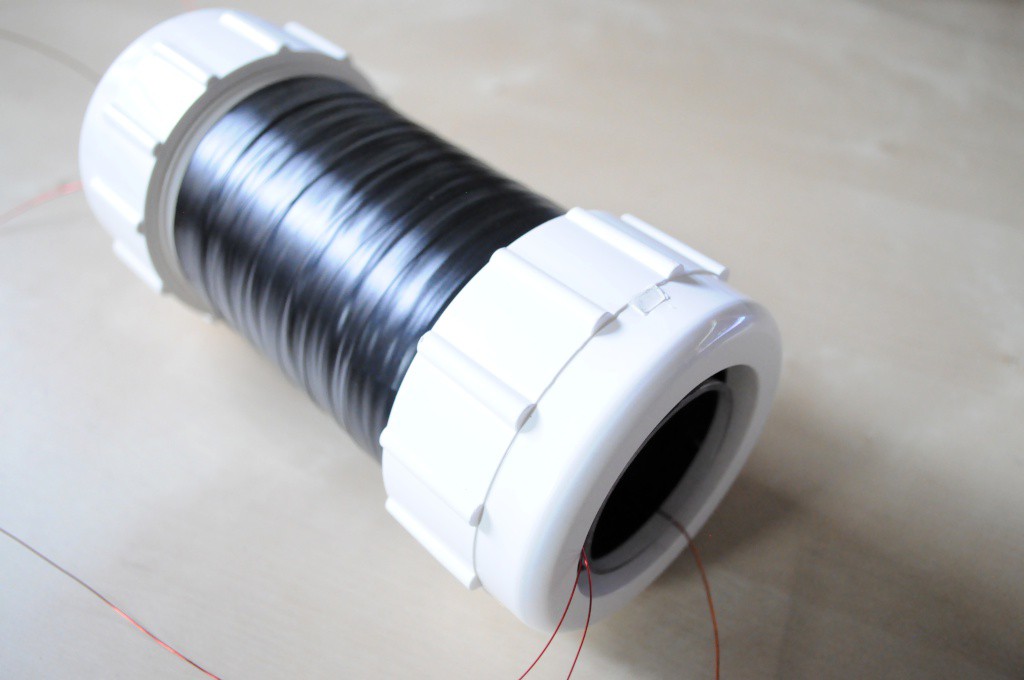

![]()

With a minimum field intensity of 100 Gauss and a desired power supply voltage of 12V and ideally somewhere in the range of 2 amps, the constraints were so specific that the prepolarizing coil nearly designed itself. The coil could only have a diameter slightly larger than the sensor coil, so I set off to find a coil form with a diameter of about 2.5 inches. After roaming the plumbing aisle of Home Depot, I stumbled across a beautiful coupler (above) with a ~2.5 inch inner diameter, about 10cm of length for the prepolarizing coil windings, and some wonderful screwable caps with rubber gaskets that allow the sensor coil to be both firmly held in place, and easily disassembled. Great! David popped this on the lathe to smooth out/remove some nubs and markings on the outter surface, then it was time to head on down to coil winding town.

This coil has three layers of 22 AWG wire, at about 128 winds each. This is about 10% less than the theoretical density per layer for this coil form (about 145), but I've found in practice that small kinks in the wire tend to lower the density yield a small amount. I think professional coil winders likely include a jig to straighten the tiny kinks out of magnet wire coming from the spool, but I don't suspect that it'll be an issue here.

![]()

While we were at it, we put together a coil form for a second sensor coil, that perfectly fits inside the polarizing coil. Using the lessons I learned from the first sensor coil, I used wider 1/4 inch acrylic to make the ends for this coil form, and paid very close attention to the distance (exactly 81mm) between the two ends at all points around the circumference. I hadn't appreciated that this would be an issue with the first coil, and the end plates are unfortunately a tiny bit uneven, which makes the tricky bit of stacking one layer atop another extra tricky. At 81mm, this coil form is also about 25% longer than the original, and uses 740 winds of 26 AWG magnet wire, at with 4 layers at 185 turns each.

With these two coils complete, I think we're starting to get very close to having a proton precession magnetometer, and observing the first PPM signal. I'm hoping to connect a relay to the prepolarizing coil, adding a bit of code to the firmware to pulse this, and see if we can't observe our first signals from the subatomic world!

-

Amplifier appears to be working!

06/30/2016 at 06:52 • 0 commentsA quick update, with background data recorded from the sensor coil!

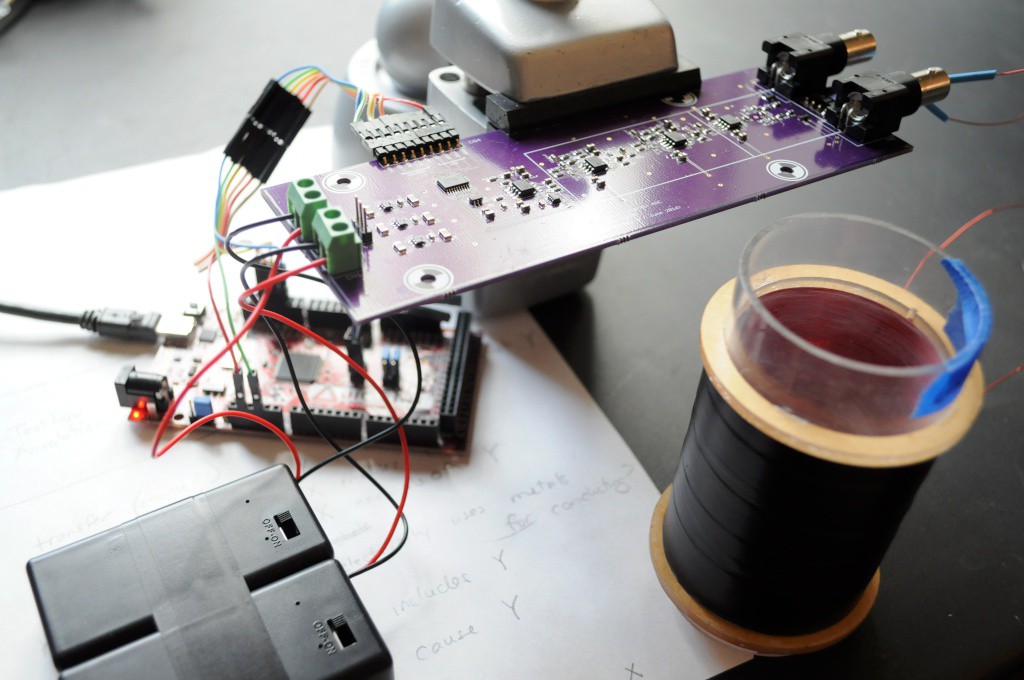

![]()

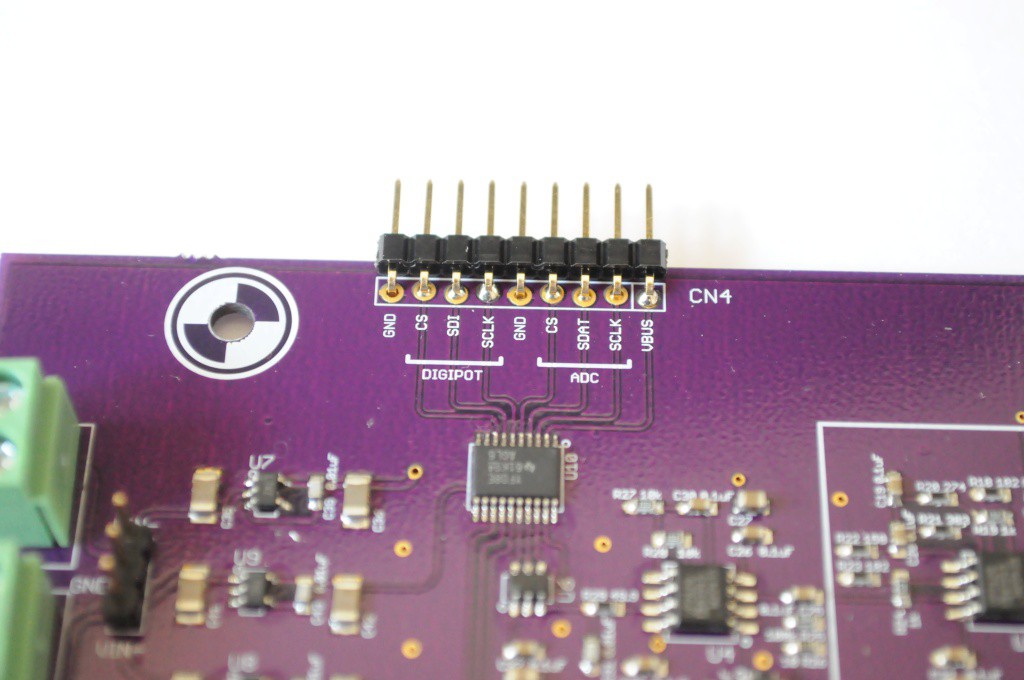

I had the chance to write some firmware to test out the amplifier board this weekend. The amplifier board consists of an AD7680 16-bit 100ksps ADC with an SPI interface, with a 1-10KHz bandpass filter. There's also an AD5160 digital potentiometer to adjust the gain on the final amplifier stage, also using an SPI interface.

I'm still new to the Raspberry Pi, so I put together a quick AD7680 driver for the Chipkit MAX32, which contains a PIC32 processor and about 128K of RAM, or enough to hold about half a second of data at 100ksps. The chipkit reads in this data, then very slowly streams it down the serial port to an Octave script that plots both the time-domain and frequency-domain signals. Because the polarizing electromagnet isn't complete, this first test is just to observe the ambient background radio noise, and verify the amplifier is functioning correctly.

![]()

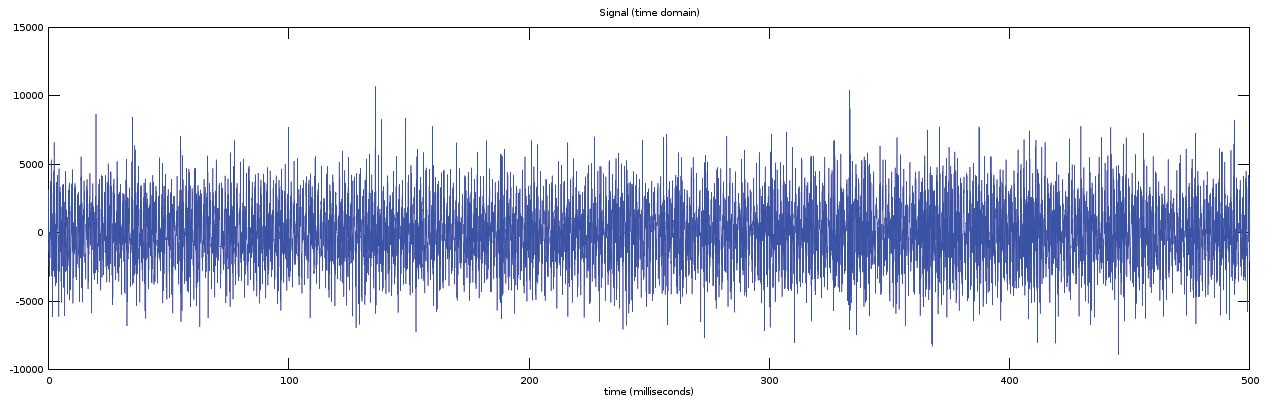

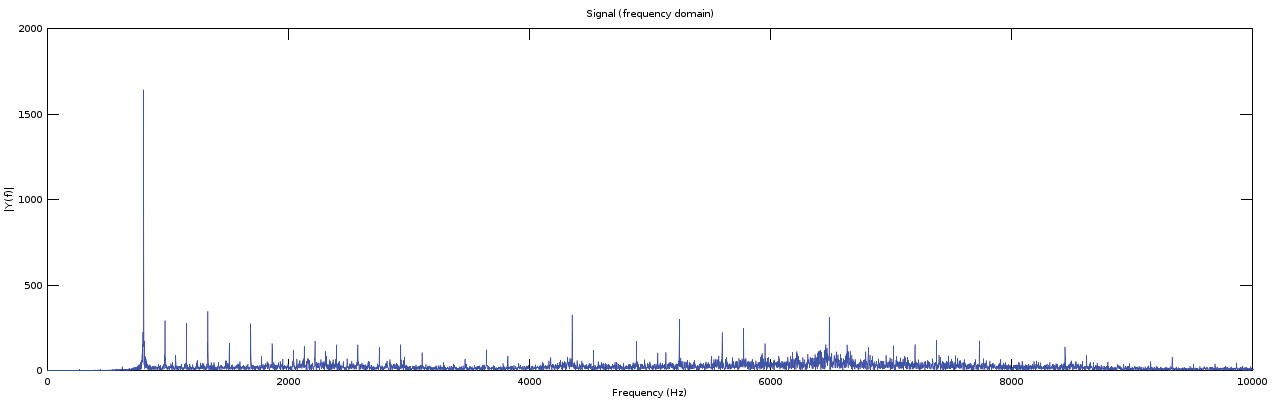

The time-domain plot (above) shows plenty of activity.

![]()

And plotting this to the frequency domain (above) shows peaks very closely matching the characteristics of the background noise that Bradley Worley observed with the PyPPM, which he speculated are largely harmonics of the 60Hz line noise, and other electrical noise emitted by nearby devices. This is a great news, and likely means that the amplifier is working as expected! A sharp rolloff is visible at approximately 1 KHz, and signal amplitude decreases quite a bit approaching 10 KHz, also suggesting that the 1-10 KHz bandpass filter is performing well. One issue did come up -- changing the AD5160 digipot doesn't appear to be changing the gain, which likely means that there may be a small soldering issue, or an issue with the driver. Thankfully the default AD5160 resistance was ideal for this test, and occupies nearly half the full-scale range -- so while it's important to have the variable gain working, this small issue wasn't critical in verifying the functionality of the amplifier.

Onward to constructing the polarizing coil, and attempting to observe the first proton precession signal!

-

Putting together an amplifier to measure proton precession

06/22/2016 at 05:46 • 0 commentsA quick update, with the first pass at a proton precession amplifier!

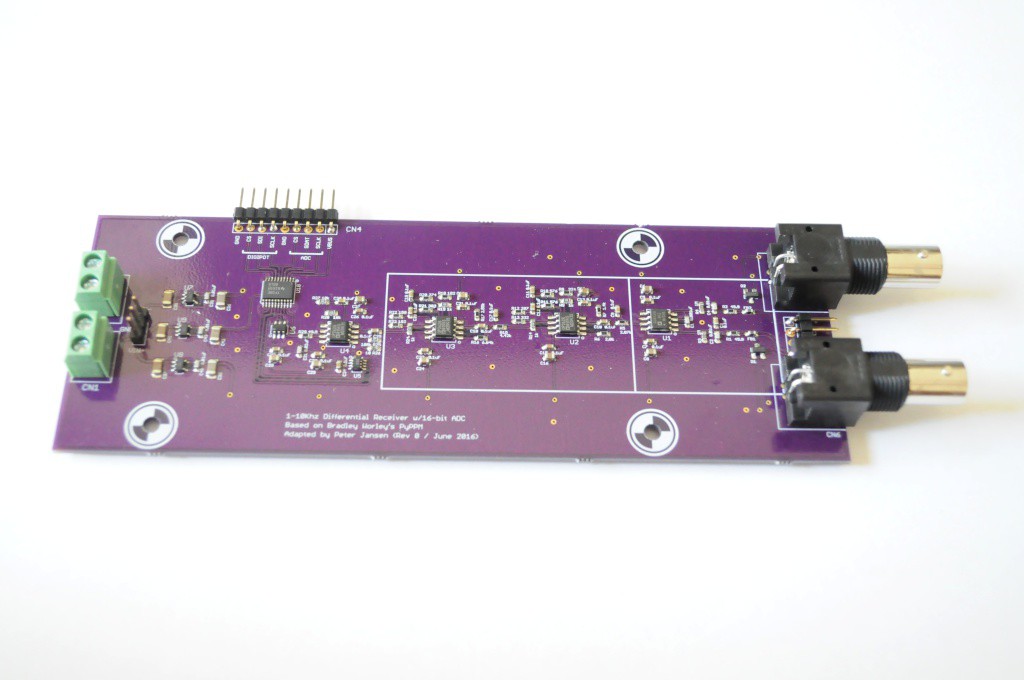

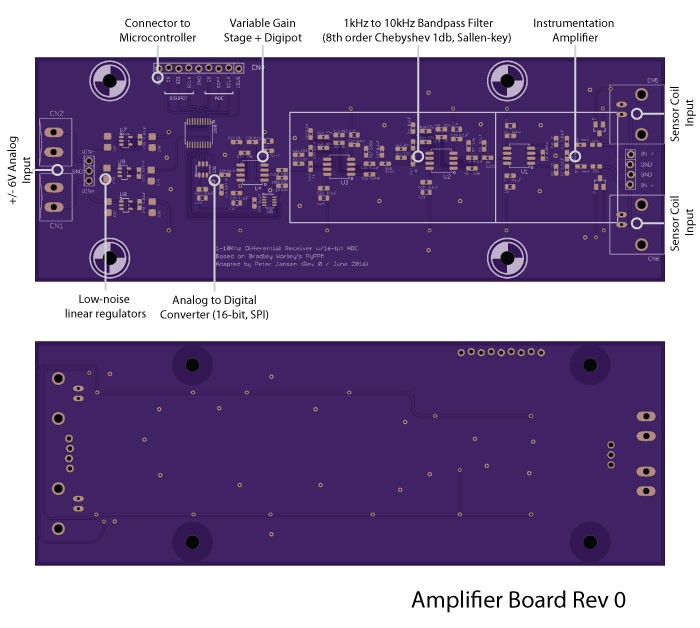

![]()

When I'd placed this project on the backburner last year, it was after hitting two technical challenges that I didn't have good solutions for:

- Assembling quality radio coils (which can now be done largely automatically using the handy coil winder!)

- An inexpensive, tractable way of amplifying, sampling, and digitizing the very low amplitude proton precession signal over a broad range of frequencies.

This second bit is addressed by the amplifier board, described in this post.

![]()

I'd realized that most of my issues in coming up with a design for the amplifier / analog-to-digital converter were over-estimating the specifications for the board -- too high a sample frequency, resolution, and so forth, and that for a first-pass proof of concept, something with more modest specifications would likely meet with success. Thankfully, the requirements of this design are very similar to an Earth's field Proton Precession Magnetometer, which has a small but non-zero community of open-source builders. Bradley Worley, a graduate student in nuclear magnetic resonance, put together a very well documented and iterated proton precession magnetometer about two years ago, after heavily researching what other's had done -- and his work is a great resource, and the most recent build that I've found.

![]()

The design I've put together is heavily based on Bradley's design, and uses the same ultra-low noise instrumentation amplifier, low-noise filter opamps, and 16-bit SPI ADC. I'm still a novice at many things analog, including low-noise design, and took the opportunity to pored over the Analog Devices application notes to understand the design choices that were made, and where they might be improved. I made a few modifications to the original design:

- The signal chain now progresses as: instrumentation amplifier -> bandpass filter -> additional gain -> adc. In the original design, the gain was all completed before the bandpass filter, but this this could allow the noise to clip the signal before it's filtered.

- Instrumentation amplifier: The internal bandpass filter was lowered. I changed the topology of the input protection diodes to the "low noise" topology in an Analog application note.

- Bandpass filter: I couldn't find the original specifications for this, and PPMs are intended for Earth's field, so they can get by with a much narrower frequency range. Here, the bandpass filter has a 1-10kHz bandpass window, and uses the Sallen-key topology, which looks to have better noise characteristics than the original Multiple feedback topology.

- Second gain stage: Since I don't have a good idea of what the signal intensity will be, and it'll likely be variable depending on the sample size, I've modified the second-stage gain to be variable. This is controlled through the AD5160 digipot, which I had success with in the OpenCT2 radiation detectors.

- ADC: The same AD7680 16-bit 100ksps SPI ADC is used. Instead of having an onboard microcontroller, I've broken out the input to the ADC and digipot to a header, so that I can first try interfacing to a Raspberry Pi, which has plenty of buffer memory, and fall back to using another system if that ends up generating too much noise.

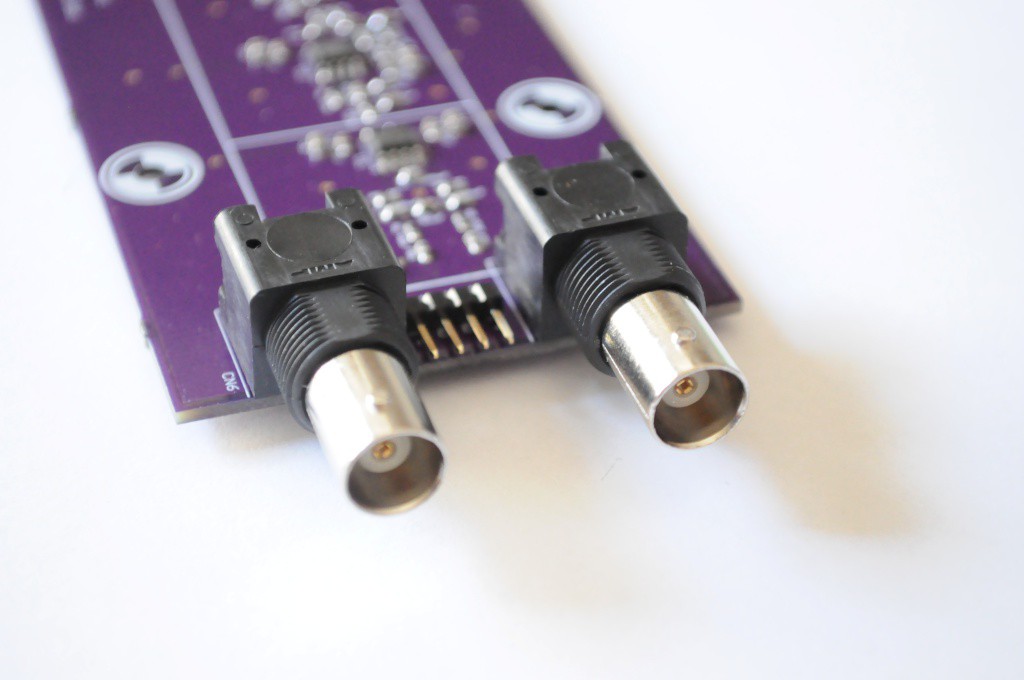

![]()

The input to the instrumentation amplifier is differential, allowing for a humbucker coil to be used, as Bradley spec'd for the PyPPM, and the folks who wrote Signals from the Subatomic World used.

![]()

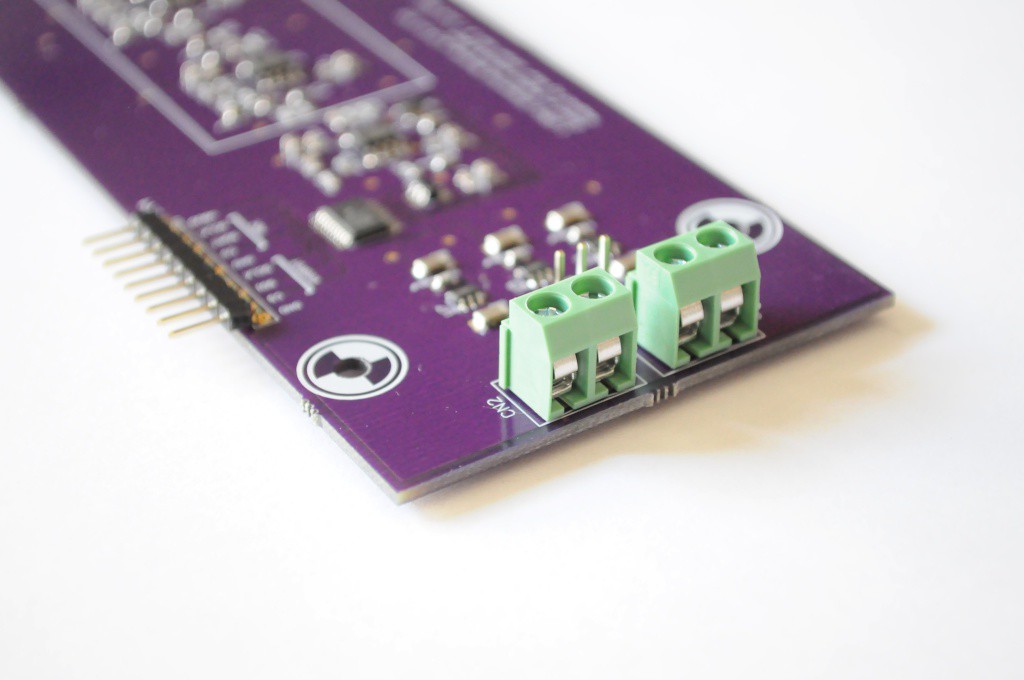

The amplifiers require dual supplies, which are regulated to +/-5V. I think two 9V batteries should work famously -- the draw is very low.

![]()

And the user interface connection, with separate SPI pins for both the digipot and the ADC. Here I've opted to break out each SPI interface individually rather than share the clock and data lines as the digipot will likely rarely be changed, but is part of the final gain stage -- so I wanted to avoid having a trace carrying the ~2MHz SPI clock for the ADC nearby, potentially introducing noise.

Next steps

The board powers and passed the "smoke test" (didn't catch fire when I applied power, always a good sign). The next step is to connect the sensor coil and a microcontroller, and sample data (which will all be noise), to verify the design. This board also doesn't include any aspect of the polarizing magnetic field coil driver, which is largely a relay and a constant-current driver, and that should be the last critical bit to attempting to observe a proton precession signal -- the first step towards imaging.

Thanks for reading!

-

Back at it, with coil winding!

06/22/2016 at 05:14 • 0 commentsWith the recent success of the OpenCT2, I'm back thinking about the coded aperture MRI again. David was also in Antarctica for a while for his radio astronomy graduate work, but he's been back and we've been chatting about MRI things lately.

The two issues: Coil Winding, and a USB ADC

When the project went on the backburner, I'd hit two stumbling blocks that seemed like good solutions would have to present themselves for before things could progress:

- Coil Winding: It's much, much more difficult to wind radio coils than it looks. My attempts to do this by hand ended in tears (and very sore fingers).

- High Speed, High Resolution, Long Capture ADC: It's apparently very challenging to find a high speed (100ksps+, ideally 1 msps+) high resolution (14-16bit) USB analog to digital converter peripheral that can also stream at least several seconds worth of data. Most have very small sample buffers (approximately a few thousand samples)

Coil Winding Machine

Just like a prerequisite for becoming a jedi is building your own lightsaber, it seems like a prerequisite for being interested in radio is building your own coil winding machine. Radio coil winding seems like a somewhat lost art (I'm sure if this was a century ago, I'd know a dozen folks who were expert coil winders), but youtube has no shortage of videos of folks who have put together their own machines. It seems that one can also purchase manual coil winders fairly easily, but they tend to look ancient, and like one could come up with an automated design in a few evenings of work.

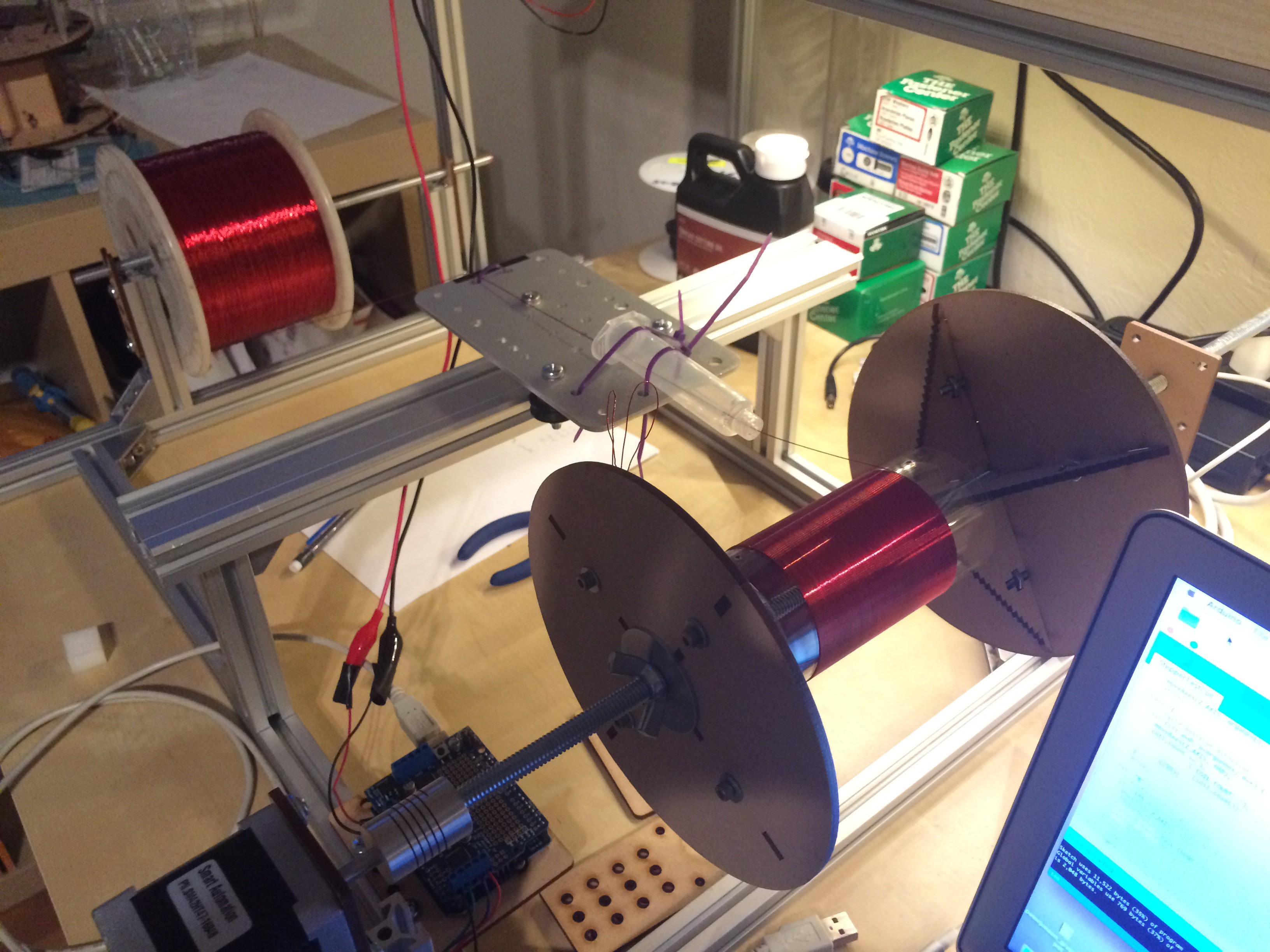

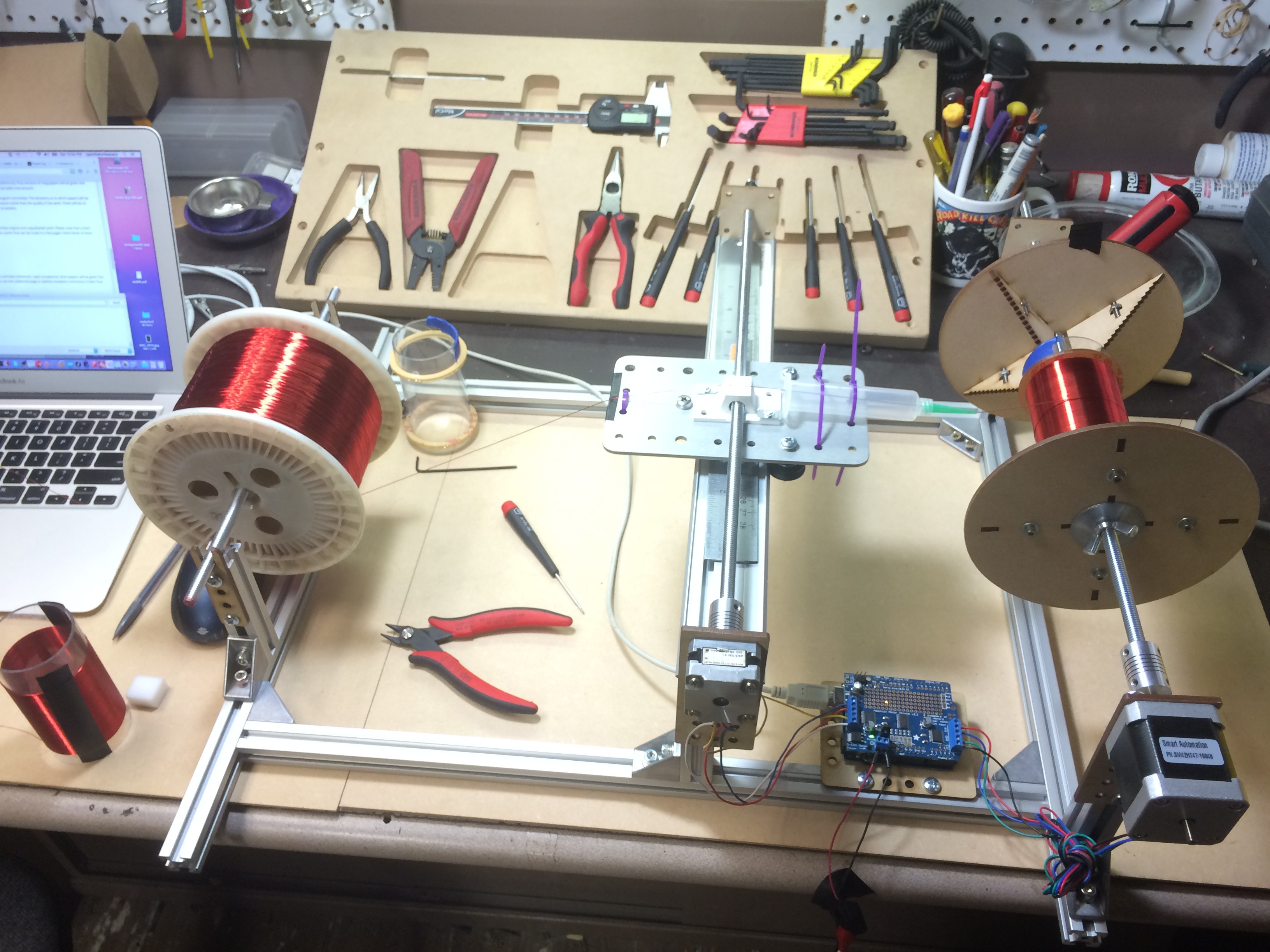

Being somewhat at the mercy of inspiration, a seemingly simple design suddenly came to me, and after a quick trip to the hardware store for some threaded rod, and by the end of the evening I had cobbled together some leftover Makerslide and Misumi aluminum extrusion into this:

The above half-complete winder allowed was just enough to wind a single-layer coil hundreds of times faster than I'd done it by hand (and nearly perfectly), convincing me that I was onto something.

After another evening slaving over a warm laser cutter, the coil winder emerged:

The different components, drawn from leftover pieces of projects, are the following:

Rotational/Winding Stage (right side):

- NEMA17 Stepper with plenty of torque to draw the wire from the spool (from Inventables, I believe)

- Coil Wedges: Two laser-cut wedges that are tightened around the coil form to hold it in place. I cut these to look like step drills, so the coil would be positioned relatively straight, and there'd be at least a millimeter or two of area to bite onto.

- 5/16 threaded rod, M8 coupler, and large washers/wingnuts (hardware store/ebay)

- Laser cut NEMA17/threaded rod holder that mounts to the aluminum extrusion.

Linear Stage (middle):

- Makerslide linear rail and carriage (from Inventables)

- Plastic syringe and tips intended for solder paste (from Zeph Paste), zip-tied onto the carriage

- 5/16 threaded rod, NEMA14 motor, M8 coupler

- 3D printed carriage/nut holder from the OpenCT2 project

- Laser cut NEMA1/threaded rod holde

Spool Holder (left):

- Heavy wire spool (for tension)

- 5/16 rod, two laser cut holders.

Control:

- Arduino Uno with Motor Shield

- Modified OpenCT2 motion control firmware, with added commands on the serial console for coil winding and keeping track of the number of winds!

The dimensions of the long aluminum extrusion pieces are about 50cm, and the short ones holding each component are about 10-12cm high. The aluminum extrusion makes it easy to resize for larger/small coils, and to move in the tip of the liner stage very close to the coil form during setup.

Winding Coils

Following Bradley Worley's great proton procession magnetometer (PyPPM) project, I decided a good place to start would be replicating his (or a similar) proton procession magnetometer, then experimenting with it under different non-uniform field conditions to see how viable the coded field technique may be. About 10 years ago Stefan and Richard Hollos published a book called Signals from the Subatomic World that also describes building a proton procession magnetometer. Both serve as good introductions and have conceptually similar hardware (even if the specifics are different).

Bradley had success with his version 1 coil, which is a single coil containing 4 layers of 158 turns each (632 turns total). I decided this was a good coil to start with (since I've never successfully wound a coil before), and then I'd work towards winding more sophisticated coils. Bradley specifies using a version 2 "humbucker" coil (two identical but counterwound coils) to cancel out much of the 60Hz environmental noise, which is easily visible on his great first raw plots. The Hollas PPM sensor coilalso uses a humbucker arrangement, with similar specifications to Bradley's single coil (4 layers @ 138 turns/layer). The raw data in Chapter 7 of their book looks substantially noisier than Bradley's, but they were doing this a long while ago, and it's not clear whether they were subtracting baseline measurements, which should clean up the data a great deal.

My first multilayer coil (the 4 layer, 158 turn/layer, 638 turns total) turned out much better than I was expecting. The current coil winder doesn't include anything to smooth out the very occasional tiny bump or bend in the wire, so some layers have one or two more winds than others, but the overall packing density was very good, and the coil has a total of 638 counterclockwise winds. Another coil counterwound (to make the humbucker arrangement) will make for a good first set of coils for initial tests, I hope.

To keep the coil windings in place, I used some super glue, then covered the coil in electrical tape -- but next time I'd like to try something better. The superglue didn't bond well to the wire, and the electrical tape obscures observing the beautiful windings!

Analog to Digital Converter

An Earth's field proton procession magnetometer nominally weakly oscillates at 2khz, making an ADC with a sampling frequency above 20Khz adequite. The Hollas PPM uses a 12-bit ADC, where Bradley's uses a 16-bit ADC. Here, because we're interested in trying to spatially resolve the signal using potentially a wide range of frequencies, the requirements are higher. The Nyquist rate for resolving protons in a 1 milliTesla field, which is only about 20 times as large as the Earth's field, is about 84kHz. A 1 megasample/second ADC would give a Nyquist rate equivalent to about a 10 milliTesla field, which seems like it would give some room for experimentation. Intuitively I have no sense of how much frequency range will be required, with it likely relating to a bunch of factors, and so it will likely be best determined empirically through some experimentation.

It's been oddly difficult to find an analog to digital converter that has the following specifications:

- 1 megasample per second or greater (but 100kSps would be okay to start, too)

- 14 to 16-bit resolution

- Ability to record several seconds of data

- Ability to stream the data through an easy-to-use API

I have investigated the specifications for every USB digital storage oscilloscope or DAC that I could find, and while many have substantially higher sample frequencies or sufficient resolution, most attractive solutions (like the Analog Discovery Kit) appear to have not been designed to acquire data for long, and suffer from an extremely low sample memory.

I don't have a great solution for this, but I've thought about starting with a USB soundcard capable of sampling at 16-bit/192Ksps to begin. I've also picked up anArty FPGA board to tinker with, which includes a fast ADC and a large amount of memory that could be used to store samples -- but creating a high-resolution long-memory FPGA oscilloscope would be quite an undertaking, and I'd rather make my mistakes cheaply and find an off-the-shelf solution. Suggestions are welcome!

As always, thanks for reading!

-

Continuation of a previous project

06/22/2016 at 05:13 • 0 commentsThis is a continuation of a previous project that was placed on the back-burner when I encountered a few roadblocks.

The previous build logs cover the concept, a MATLAB simulator, and measuring magnetic fields in a volume: https://hackaday.io/project/5030-low-field-mri

low-field MRI Continued

An attempt at a prepolarized Earth's-field compressive magnetic resonance imager

peter jansen

peter jansen