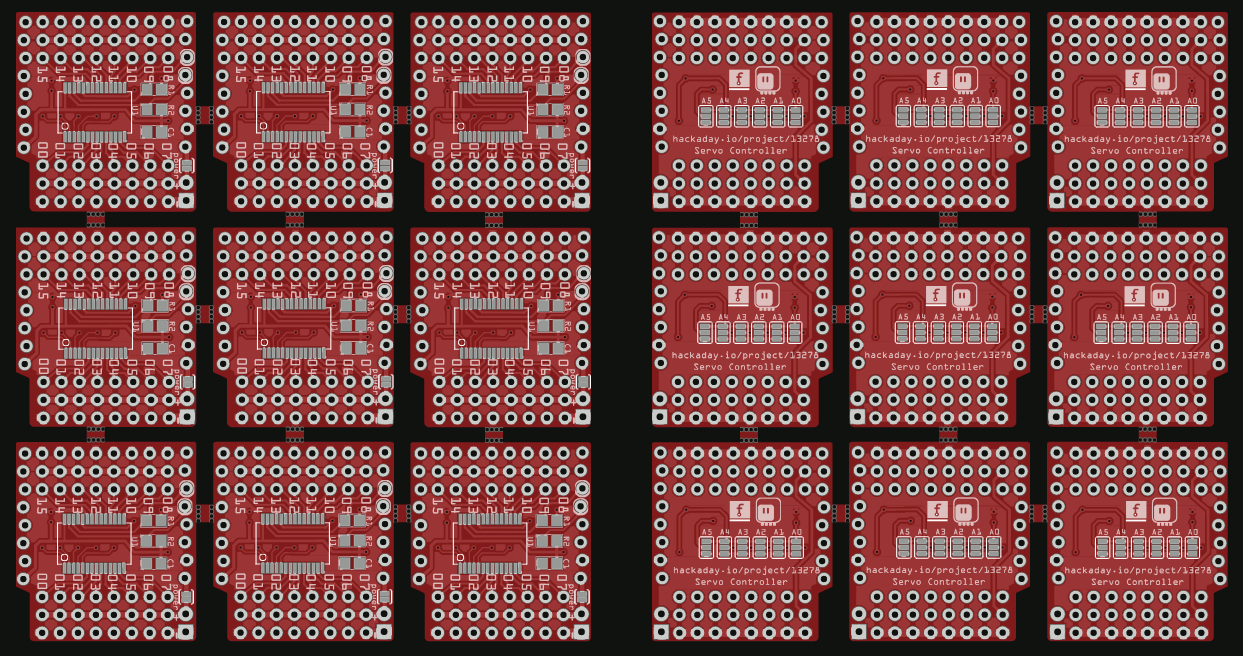

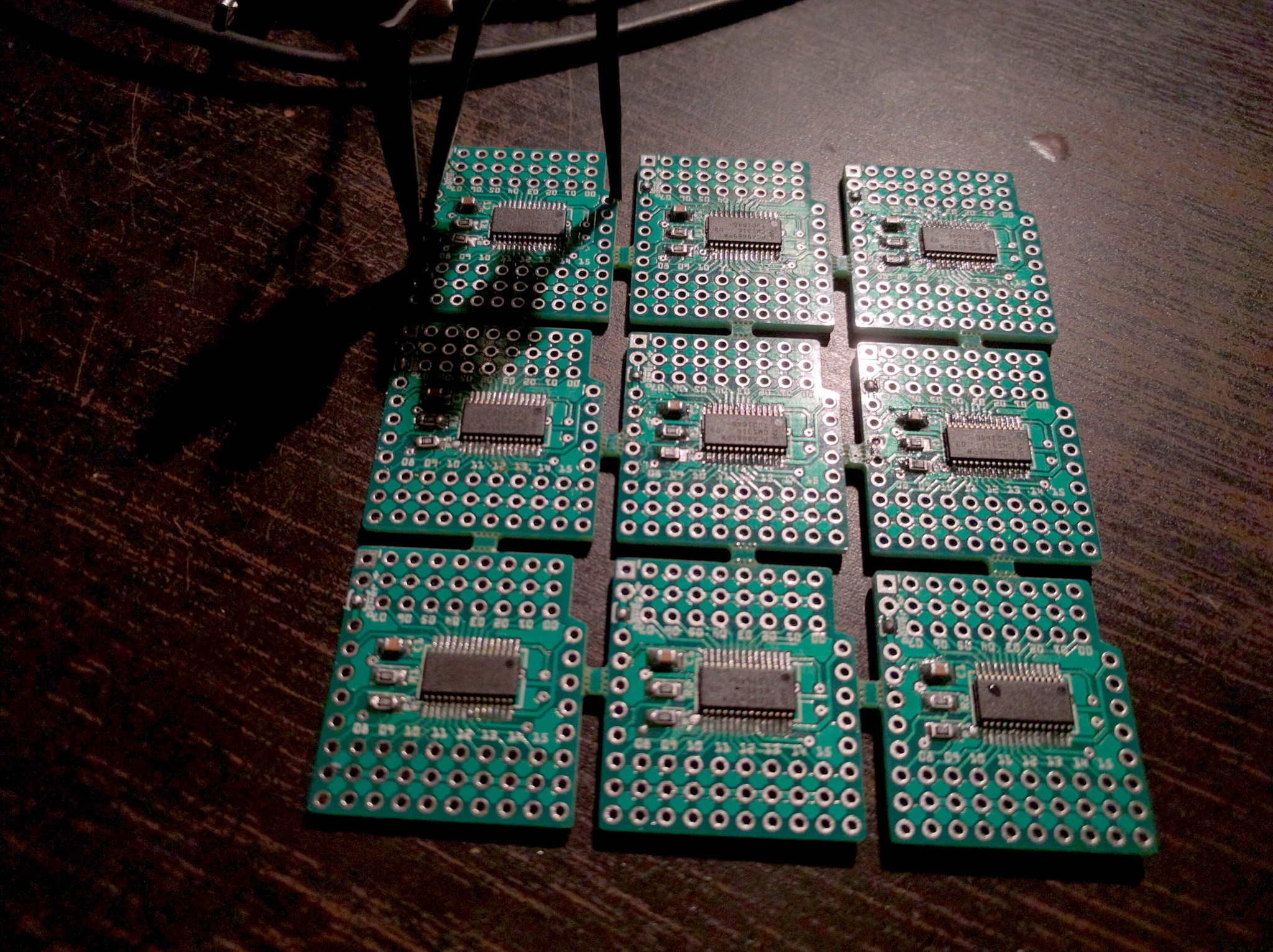

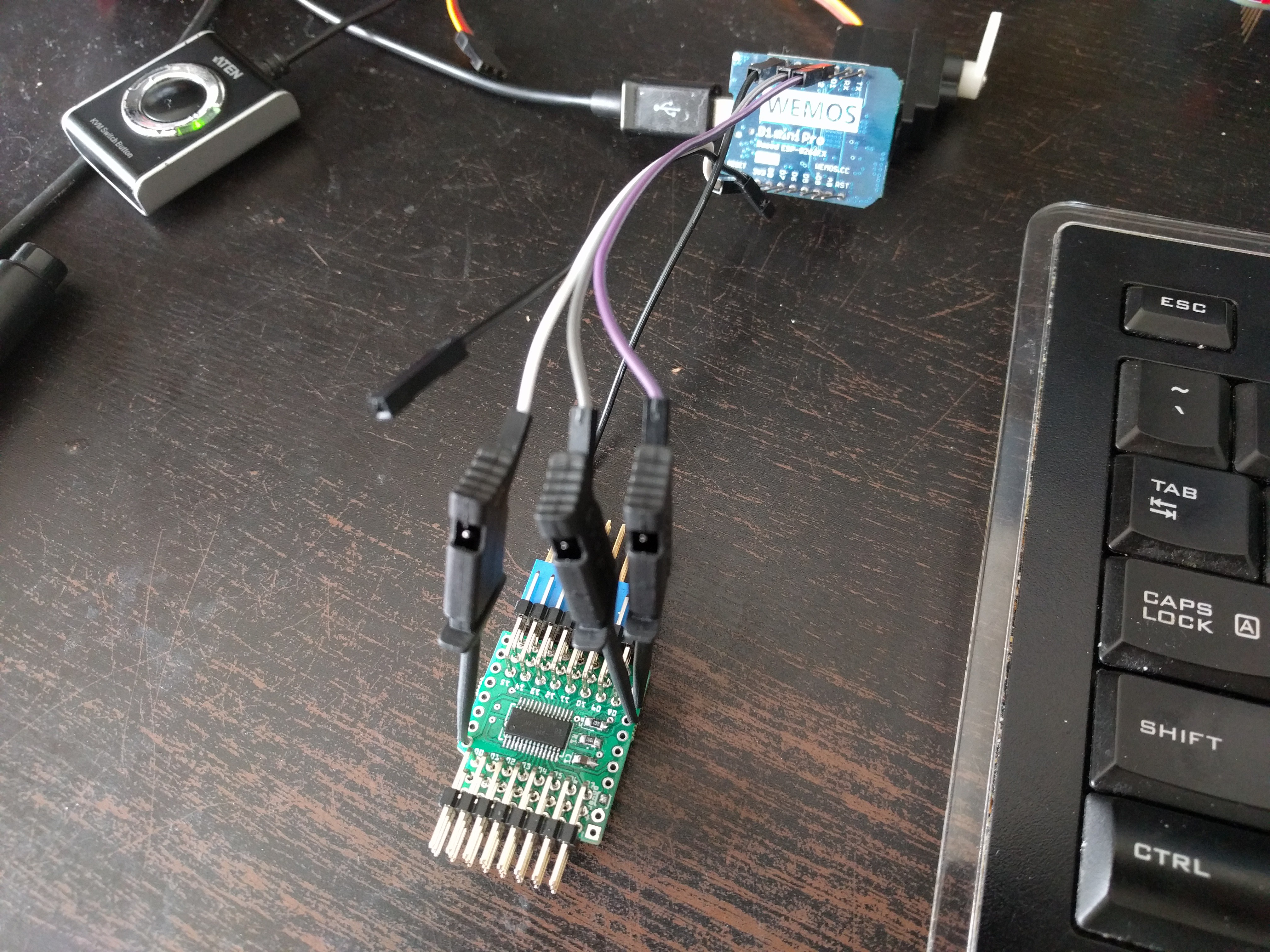

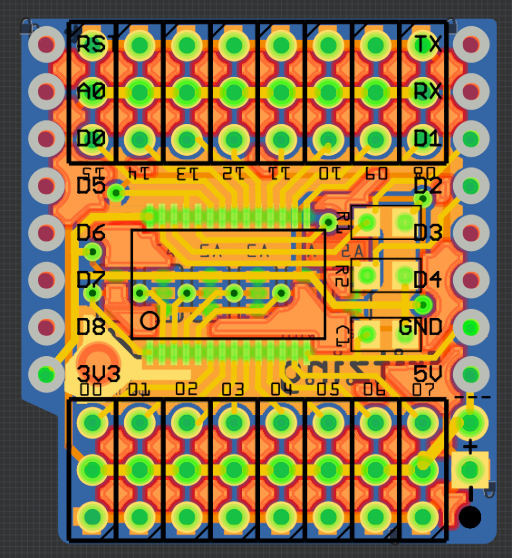

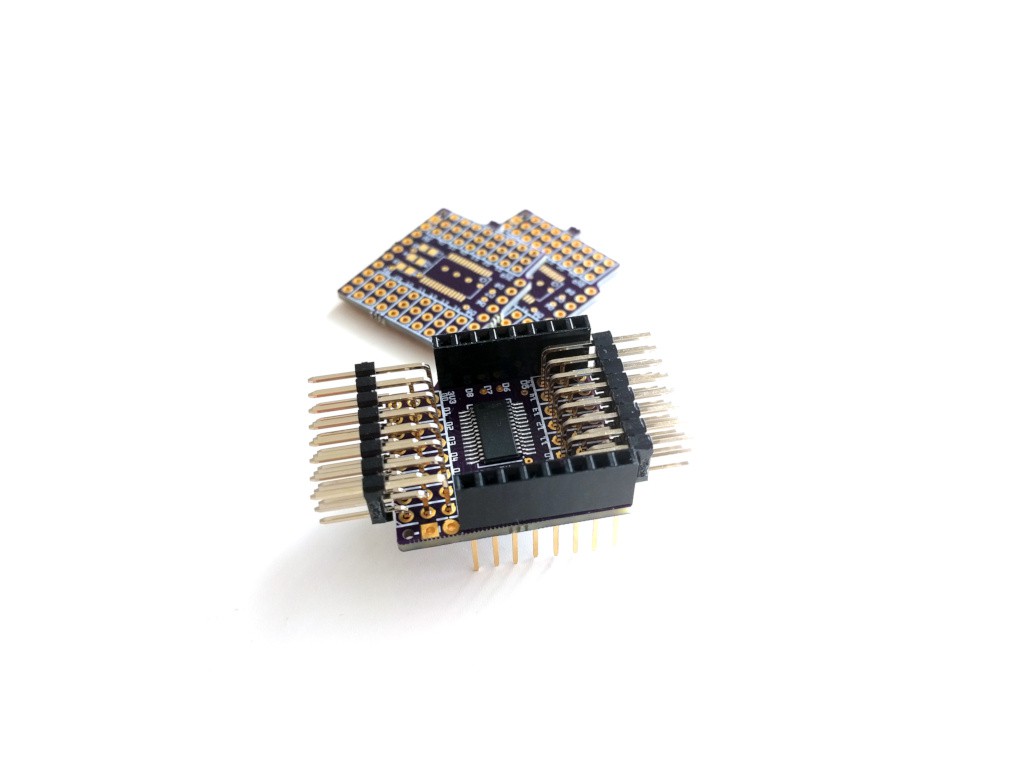

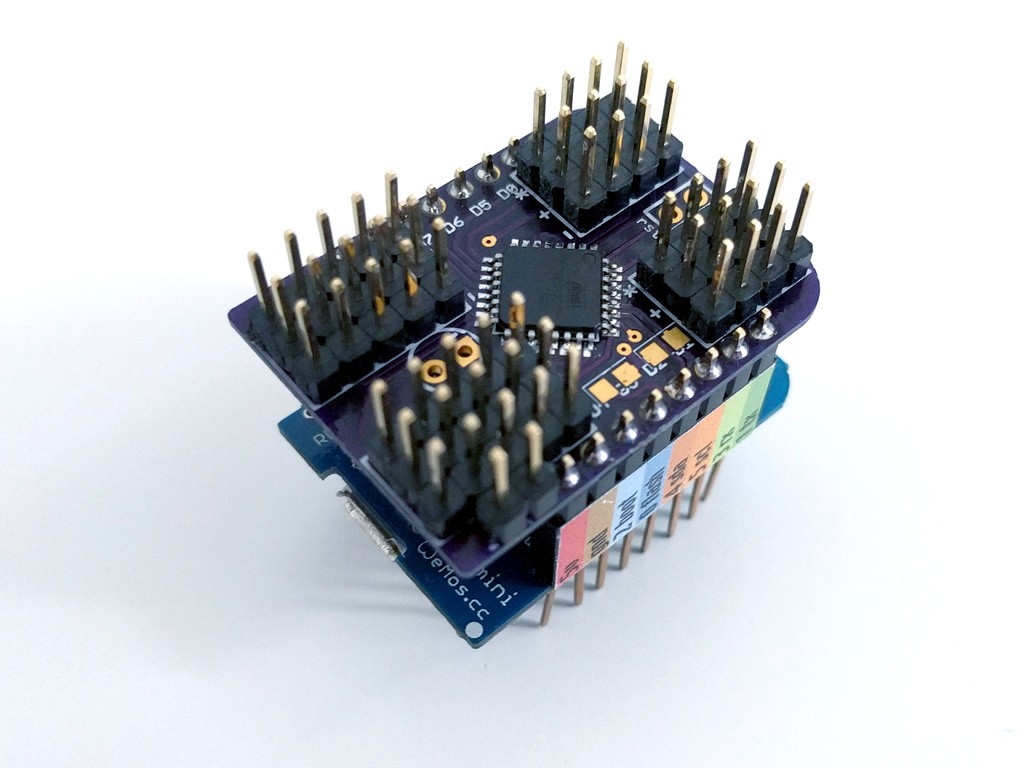

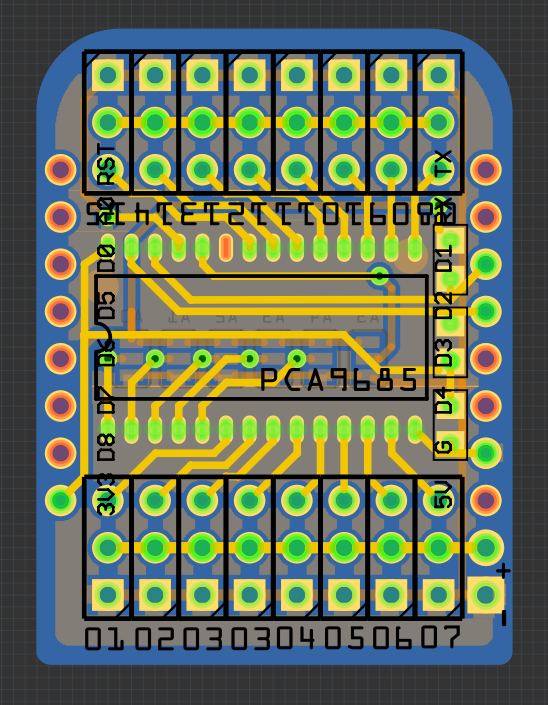

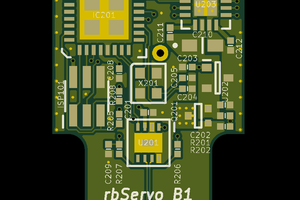

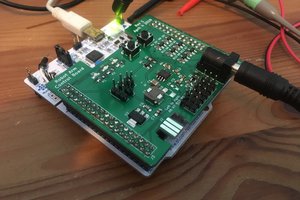

I thought I will try to make some shields for the WeMos D1 Mini, because it's one of my favorite ESP8266 boards. There is already an official motor controller shield (though I can't get it to work reliably), so I decided I will make some servo shields.

deʃhipu

deʃhipu

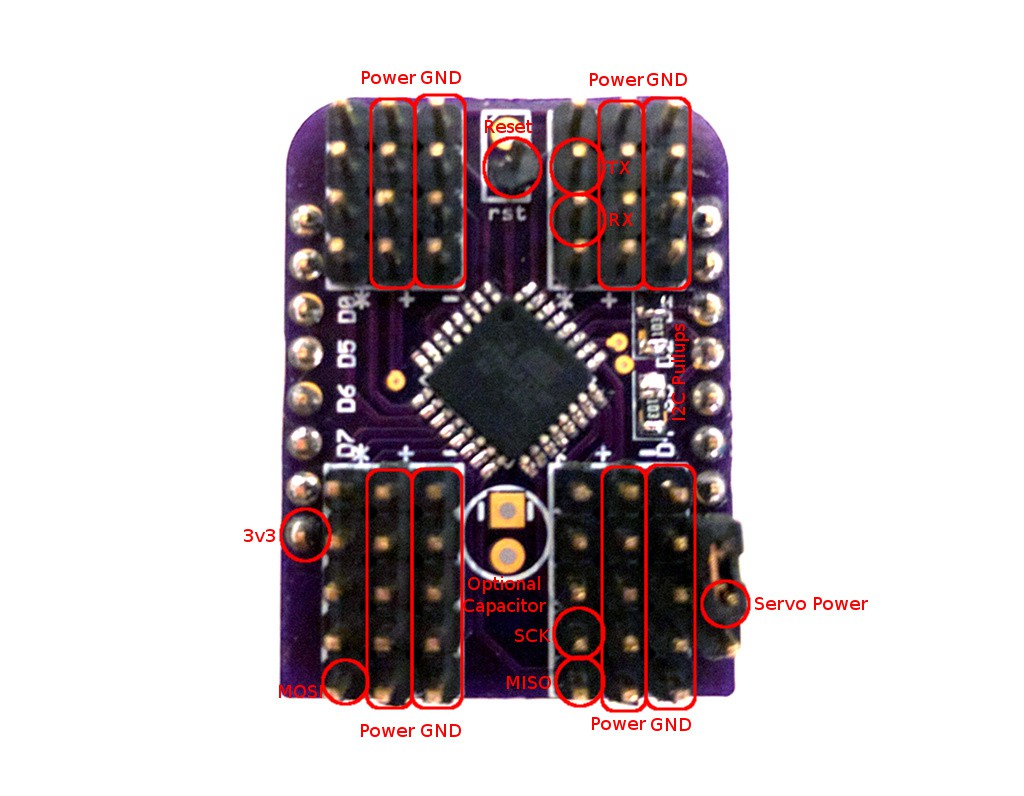

I also wrote proper documentation manual for this board, it's available here:

I also wrote proper documentation manual for this board, it's available here:

RasmusB

RasmusB

Maybe I've worked too long in the field of electrical reliability to put too much trust in the mechanical fitness of a two rows of 8 pin headers to support the mass of an assembly of a rather dense assembly [shield-PCB+48 pin headers+16 3pin connectors+attached cables]. It might be advisable to provide mounting options that take away mechanical strain and stress from the pin headers. Also such an assembly easily draws a lot of current, even if no servo is ever stalled (0.2A x 16). The requirements of an adequate power supply (with sufficiently designed ground) might also be a good thing to be getting aware of.