-

1PULSE PACK Enclosure Build

The PULSE PACK is a wearable computing platform that orchestrates a collection of body augments, all part of the SHE BON project. These augments are individual systems that sense and indicate when the user's body enters an "excited" state. Each system is designed for a particular region of the human body and uses various types of sensors to detect bio-data as input, and then communicate the user's status with electronic and mechanical devices as output.

You can think of the PULSE PACK as a wearable breakout board. Its primary function is to house the master circuit board, called the "Pulse". This heart-shaped Pulse board sends power and data over a network of cables, much like a heart pumping blood to distant organs through a series of veins.

Why would I have the platform which senses and triggers the indication of my arousal be a BIG. TRANSPARENT. PULSING. HEART-DRUM?......Well... it might be a metaphor. ;)

![]()

I am defining the cyber-punk reality I wish I lived in by creating my own works of technology and art. Also, there is something satisfying about a wearable that routs wires all over my fleshy bits. Bottom line, this is another meditation in the book of Sarah: body data as a means to communicate the intimate and the unseen.

![]()

---------- more ----------

In this build log I will outline how I crafted a transparent *stitch free* backpack, from vinyl and a 3D printed frame which I designed in Fusion360. This log focuses primarily on the enclosure. I will publish more about the circuit board and how the system works in a separate post!

( This post will outline the build of the *yellow* heart... since I was bad and forgot to take pictures while assembling the *red* one... <3 )

![]()

THE VINYL

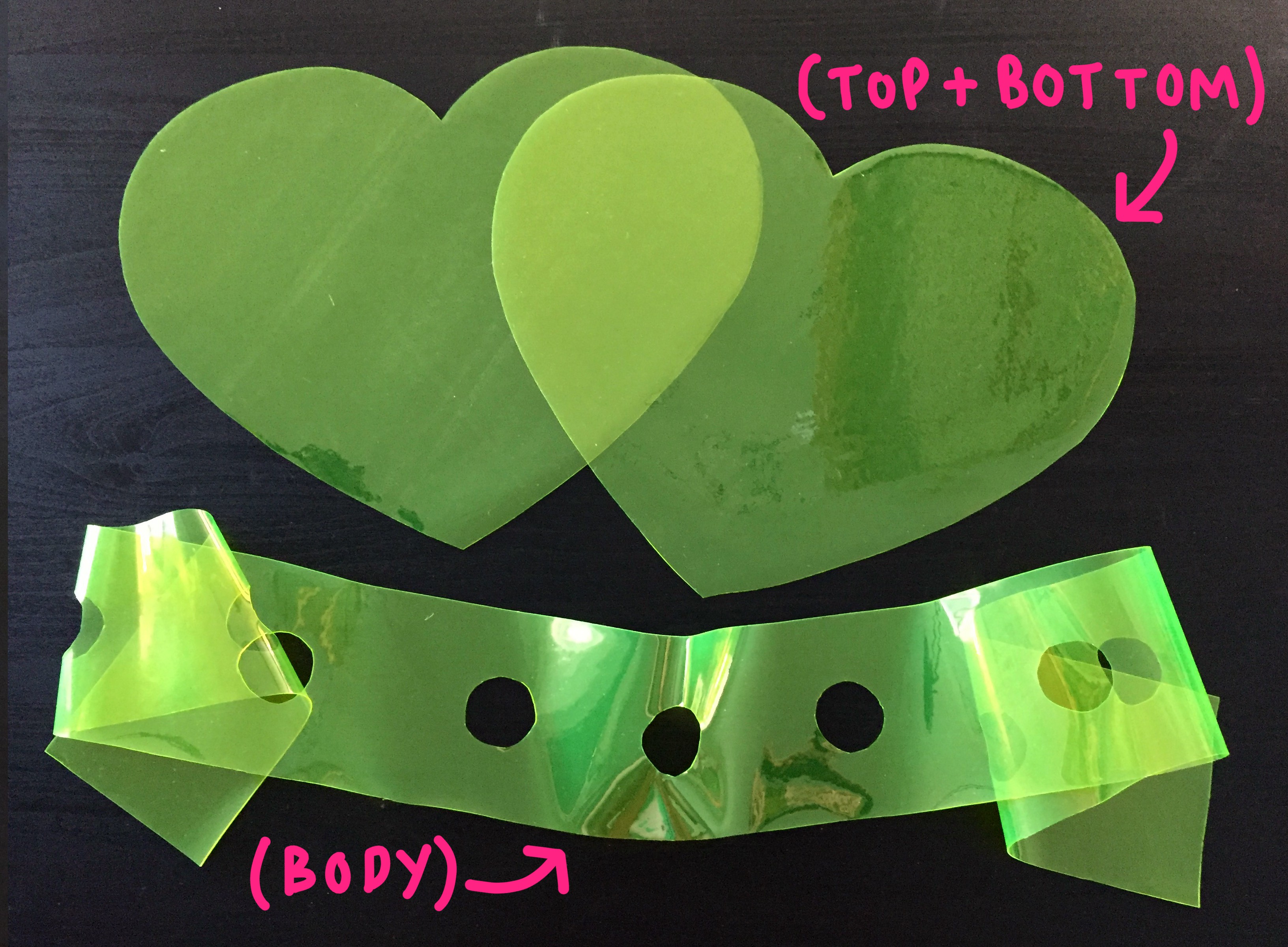

So, all it takes to create a heart backpack is (3) pieces of vinyl. (2) identical heart shapes for the top and bottom vinyl, and (1) longer strip that will act as the outer wall and body vinyl:

![]()

notice: The outer wall piece has some holes in it! These are where the "bulkhead" adaptors mount along the edge of the backpack!

These vinyl pieces mount to the 3D printed frame with plastic rivets which thread through a series of small corresponding holes on the plastic and vinyl. I printed a paper template from a dxf I exported straight from fusion360 to ensure everything was precise:

![]()

I used a punch to poke the tiny 2.4mm "rivet holes" and the 4mm "hardware holes" around the edges of each piece:

![]()

THE MOUNTING PLATE

This is technically still part of the primary backpack body, but its function has more to do with coupling to the PCB mounted in the center and the harness that's worn by the user. So basically the function of these three parts are as follows:

- back plate: couples to the harness

- adaptor plate: couples to the backpack

- front plate: couples to the PCB

![]()

...but Sarah... why does there have to be three separate pieces? Would it be easier if they were design as just one?

-Since all of these pieces bolt onto their respective assemblies with 3mm hardware, layering them this way facilitates in capturing countersunk nuts in between:

![]()

back...

![]()

The extra top and bottom piece help to capture all of this vital hardware in place and prevent it from falling out when I wish to bolt onto the mounting plate later on

![]()

This happily joined (3) piece assembly can be directly mounted onto from the back and the front!

THE PRIMARY ENCLOSURE

As mentioned, the primary enclosure is "stitch free". I designed it this way because I didn't want to attempt hand sewing vinyl fabric at 90 degree angles in less-than-straight lines. To connect the seams of my vinyl pieces, I plastic welded my vinyl to the a 3D printed frame with small rivets made from raw 3D printer filament.

Don't get me wrong, this method likely wasn't any less tedious than hand sewing with a punch and thread... BUT, it felt like I had more control during the assembly process. Once everything was in one piece, the hard frame structure helped define the backpack's overall shape.

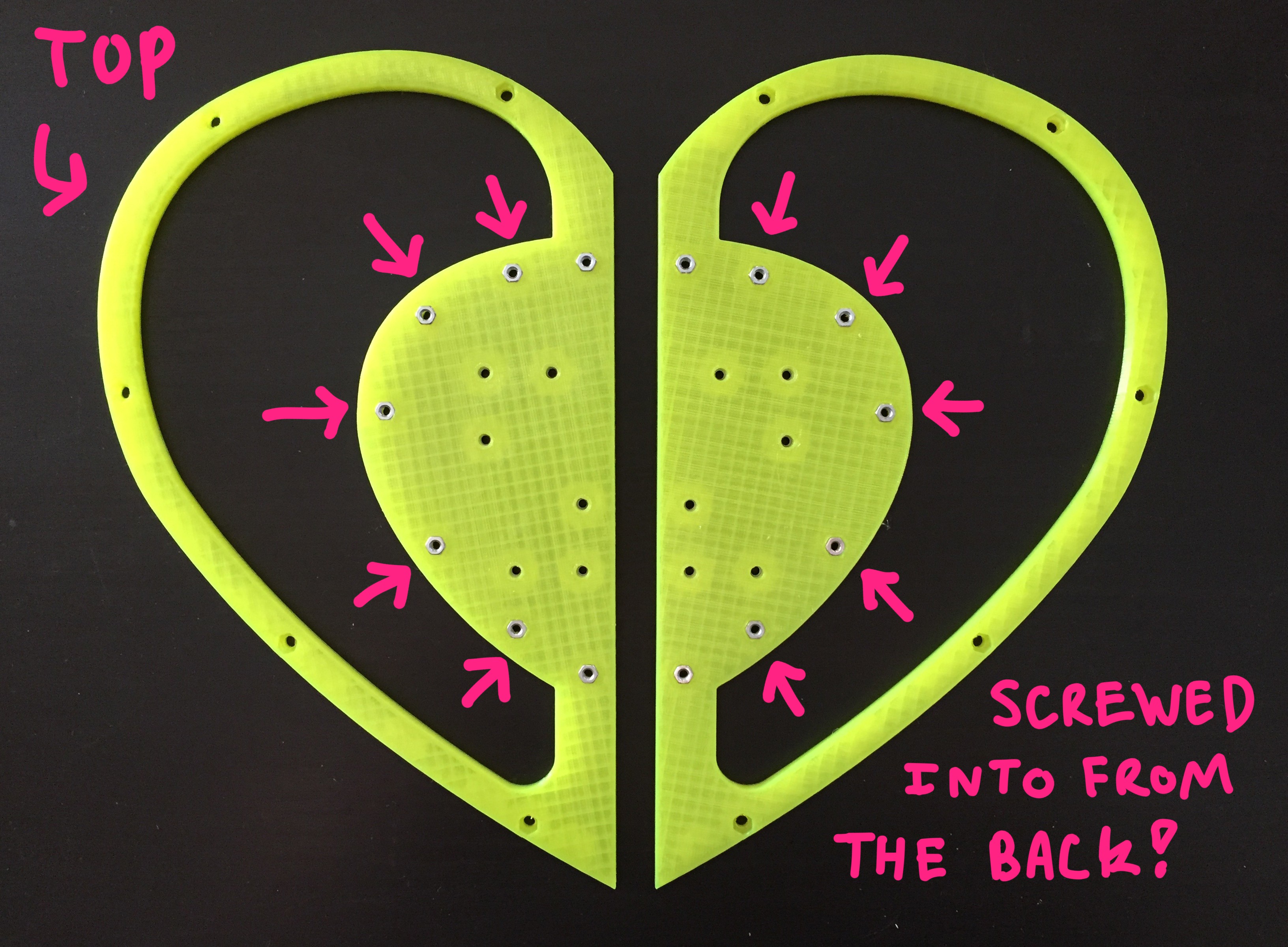

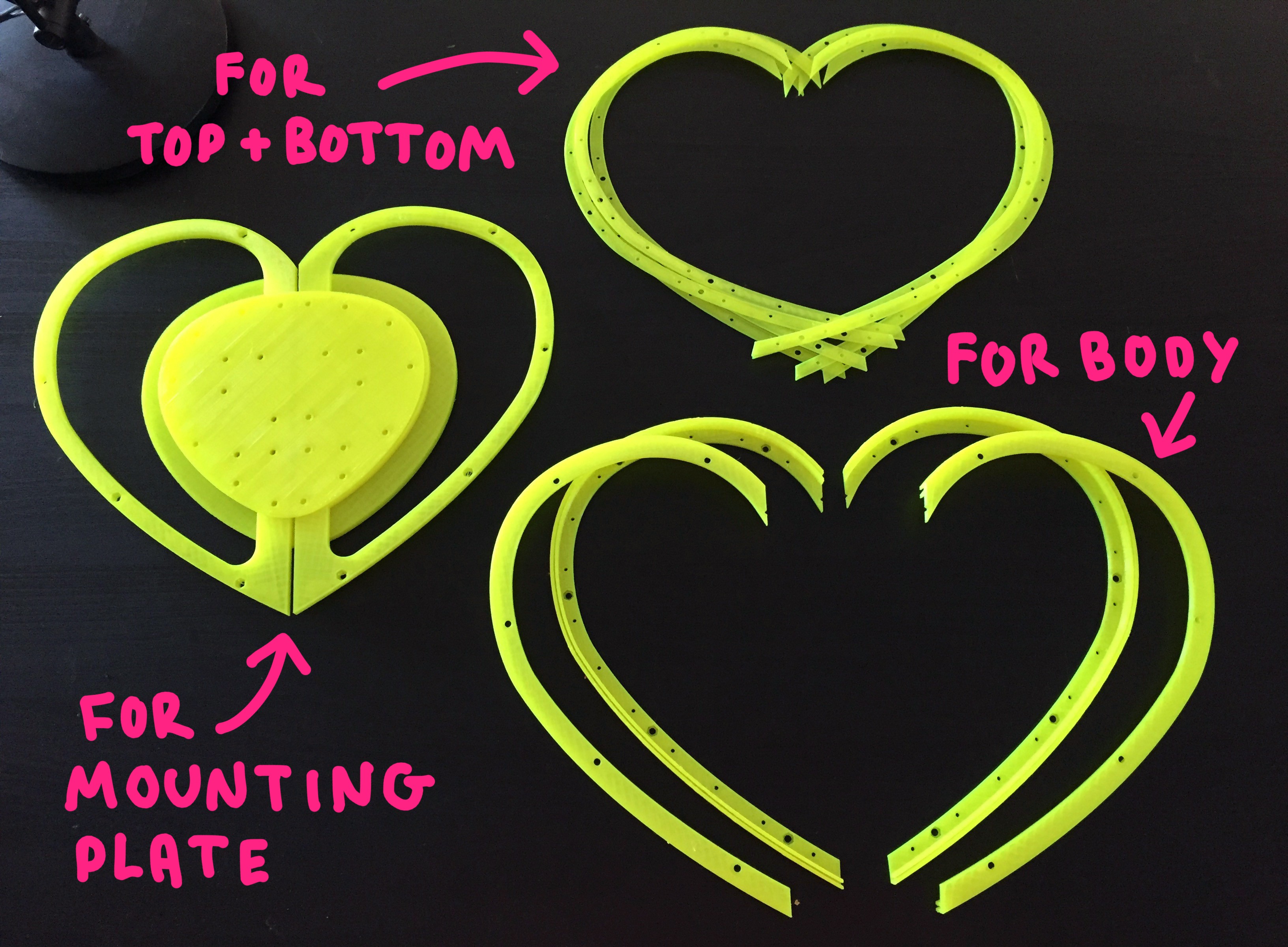

The vinyl attaches to the pieces of the frame with tiny plastic rivets to complete (3) separate parts: the top heart,the bottom heart, and the body.

![]()

Four pieces total make up the body frame:

- (1) body_front_left

- (1) body_front_right

- (1) body_back_left

- (1) body_back_right

![]()

The parts for the body are kinda fancy because they have a channel sticking up at a 90 degree angle which is meant to receive the long strip of vinyl used for the outer wall of the backpack:

![]()

There are similarly (4) smaller pieces for the top and bottom frame, making for (8) pieces total:

- (4) topBottom_left

- (4) topBottom_right

![]()

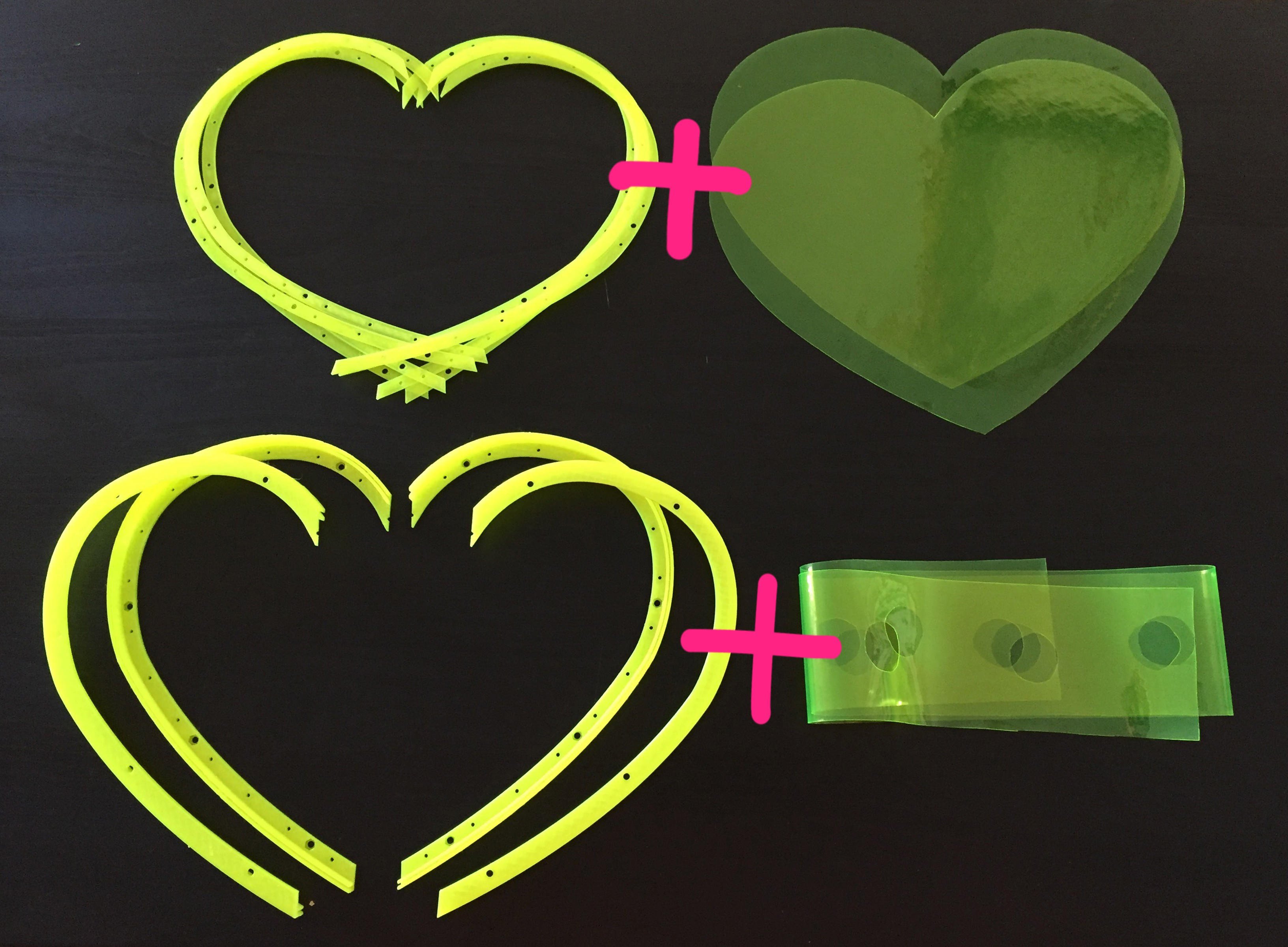

The body vinylgoes with the body framepieces, and the top and bottom vinylpieces mount to the top and bottom framepieces:

![]()

PLASTIC RIVETS + HARDWARE

The plastic riveting technique is simple. I cut many 7-10mm pieces of raw 3D printer filament, and threaded them through the corresponding holes of the vinyl and frame, melting a cap on each end to hold it in place. (this is more or less sewing but with plastic).

To prepare the rivets, I cut pieces until I was numb inside:

![]()

...I then used my soldering iron on low heat (~280 F) to melt a cap on one end:

![]()

I decided to weld the top and bottom pieces of the enclosure together first (since they're a bit easier to do). There are (6) pieces total for each the top and the bottom. They make up two halves of two frames which sandwich the vinyl in between them like two slices of bread. Two smaller joint pieces connect the halves in the middle (because I couldn't fit each frame as a whole on the printer bed!)

I used some 3mm hardware in the larger holes to temporarily hold everything in place while I placed my rivets:

![]()

The holes in the frame lined up with the holes in the vinyl! success!:

![]()

The smaller holes are begging to be skewered by those rivets!:

![]()

I pushed two or three in at a time, and then used my soldering iron to melt and flatten out the opposite end. It's important to keep the cap semi-flush with the frame as to keep everything pressed together tightly.

The steps are the same for both the top and bottom parts of the enclosure.

Lastly, I had to repeat a similar process with the body of the heart enclosure! This involves the meatier frame pieces and the remaining long strip of vinyl with the large holes along the center:

![]()

This is slightly trickier than the alignment of the top and bottom, because the long "side wall" piece of vinyl must seat in a long slot that sticks up off the frame at a 90 degree angle:

![]()

The length of the vinyl begins in the top "pinch" of the heart shape, runs along the whole diameter of the backpack and then terminates in the same location on the opposite side:

![]()

Similarly, there are a series of smaller holes along the frame that line up with the hole in the vinyl... and they want the same treatment:

![]()

It's much easier to get a soldering iron to the rivets if they are threaded from the inside of the heart and poking out as seen below:

![]()

Once all of those sharp spikes bits are capped off... I had to repeat the same song and dance with the top pieces. It's about as tricky to slot the upper lip of the vinyl into the channel of the frame, so I had to be patient!

![]()

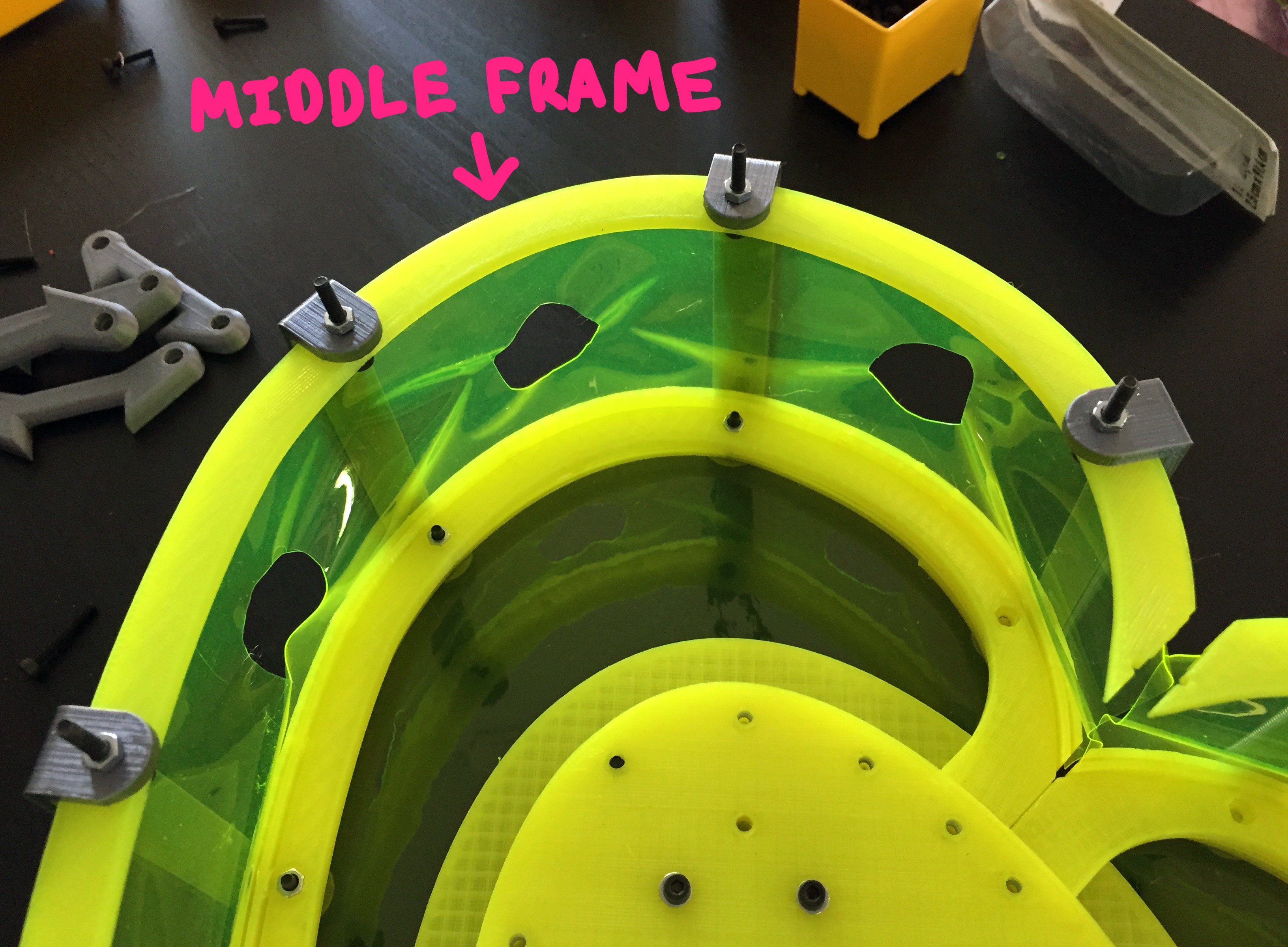

Once plastic welded together, the middle of my enclosure was complete (mostly). I now had two frames attached to the outer wall of the enclosure, like an accordion:

![]()

Once the plastic welding of the top heart,the bottom heart, and the bodyis complete; the next step is to combine the three fully assembled parts into one. I designed some clamp-like bracketsto do the job!

Before adding the structural brackets, I needed to insert the mounting plate! This is super important, as everything critical mounts to this one piece:

![]()

Once guided inside, the mounting plate screws into the bottom frame pieces from the back...

![]()

This is what the assembly looks like once the mounting plate is in its proper position:

![]()

The brackets hold the three pieces of the enclosure together like clamps; sandwiching the topand bottomframepieces to the middle frame piece. The 3mm hardware screws into captured nuts located in the middle frame pieces. In the image below, you can see the hardware going through the bracket, then the bottom framepiece, with a small bit of length left to screw into the middle framepiece of the enclosure:

![]()

the top portion of the middle framepiece attaches to the front half of the bracket:

![]()

...and the hardware also screws in from the back, so that the meat of the screw is sticking up. I capture the top half of the middle frame in place by adding a nut above the bracket:

![]()

The top frame piece drops onto the remaining thread of the hardware now poking up from the brackets! FIRST however, before I close this thing up, I want to install the portals along the wall of the enclosure!

![]()

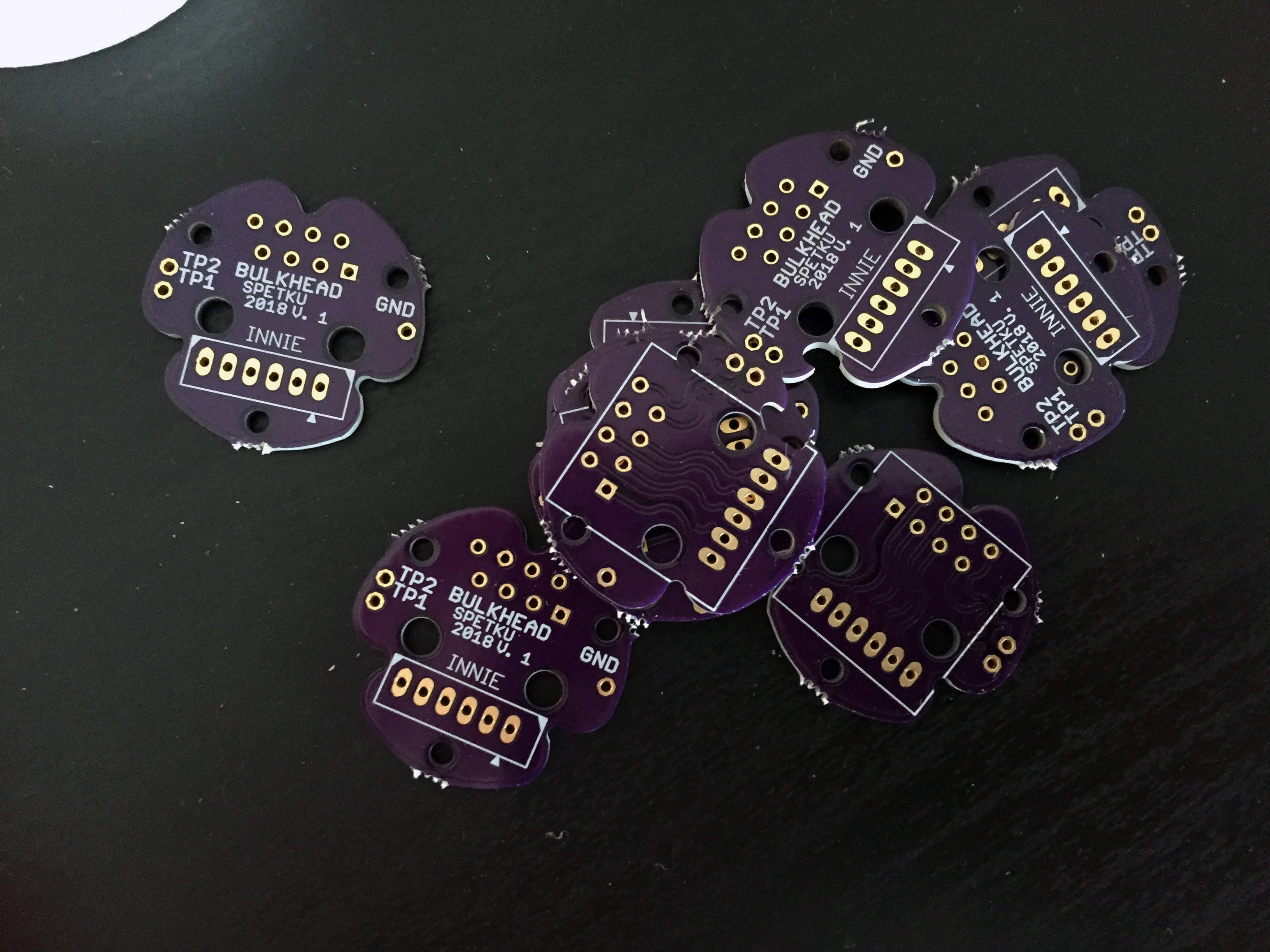

These sad empty holes need to be filled with something! A silver porthole adaptor threads through these gaps and houses a special PCB which converts wires for a molex connector into a cat 5 terminal.

![]()

So many holes:

![]()

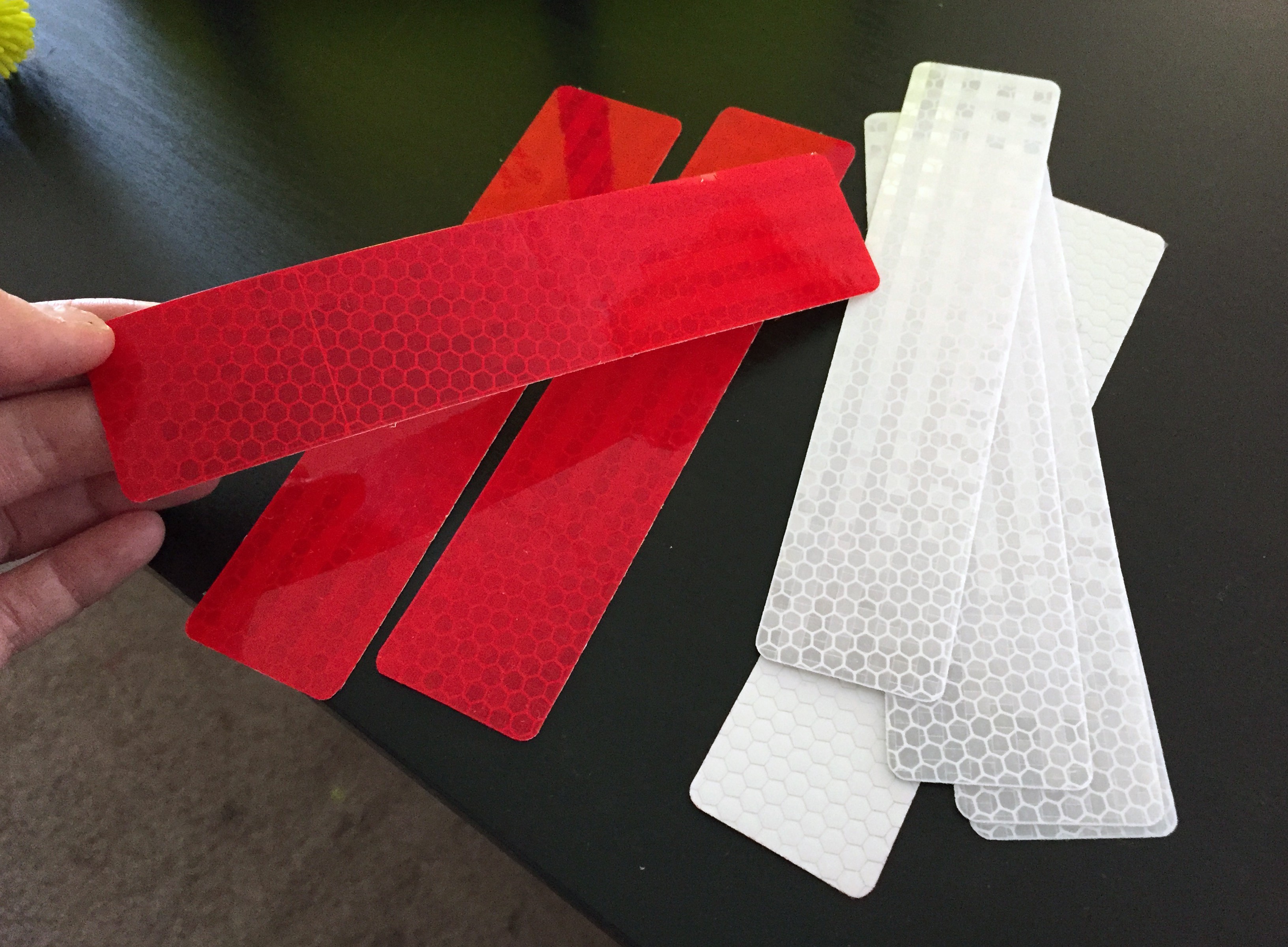

While I print (9) of these "bulkhead" adaptors, I'll dress up my brackets a little :P I picked up some adhesive reflectors from Home Depot!

![]()

I cut the red and white shinies into small strips to place on every-other bracket:

![]()

Around the time I was done with this task, the port-hole pieces and their corresponding nuts were finished printing and ready to go into the outer wall of the enclosure:

![]()

![]()

THE STRAPS

It was my goal that the straps of the backpack form to the contours of my shoulders. This wasn't hard to do, but I did need Mark's help placing short segments of masking tape directly on my skin to sculpt out the first rough pattern (in blue). The first two versions on the left were blind attempts where I just guessed at the curve needed to pull this off... and both were very much unsuccessful. The two on the right were the result of adhering tape directly to my body. You can see how off my first attempts were: =P

![]()

I chose to use an old roll of shelf liner material for my straps. This particular beige-colored fabric was slightly thick and had a spongy quality which I thought would be comfortable to wear. Most importantly, it doesn't deform when stretched or pulled, even with significant force:

![]()

I used my handy template to cut my straps in the beige material, as well as in vinyl. Since I wanted the vinyl to wrap around the edges of the shelf liner, I added a quarter inch margin past the template.

In order to fold the margin around the edge of the shelf liner, I had to cut out small wedges at the apex of each major curve (if you aren't sure where to cut them, just do so every inch or so on average!):

![]()

Next I folded the tabs down and taped them in place using some micro-pore paper tape. This shit is awesome because its incredibly thin, but sticks very well to pretty much everything! Since its soft, thin, and fabric-like, I am able to leave it permanently inside my straps instead of worrying about finding a way to remove it later:

![]()

To make the straps of the backpack a bit more comfortable to wear on my shoulders and chest (and to cover up this unsightly abomination of secret tape), I added neon yellow fleece to the back side:

![]()

I even got some matching neon yellow thread to stitch the seams together with:

![]()

A short loop of elastic at each end will allow the harness to give slightly while I'm trying to get the backpack on, and will also help me mount them to the adaptor plate seen below:

![]()

THE HARNESS ADAPTOR

Theharness adaptor screws directly onto the mounting plate within the main enclosure. It is also the thing that the harness attaches to directly:

![]()

I skinned the adaptor plate in the same fashion as the harness; with vinyl on the front, and fleece on the side which makes contact with my body:

![]()

fleece do:

![]()

Basically, the harness and the adaptor are their own separate assembly

![]()

COUPLING THE HARNESS TO THE ENCLOSURE

The harness adaptoris mounted to the back of the main enclosure, directly onto themounting plate:

![]()

The hardware used to make the connection screws into the nuts that are captured on the other side of these holes pictured below:

![]()

Once bolted down, this is what the back of the heart enclosure looks like:

![]()

Flip it around to view the whole assembly from the front, and you're now looking at this:

![]()

Here is the shiny new yellow next to the seasoned red backpack:

![]()

so pretty!

![]()

![]()

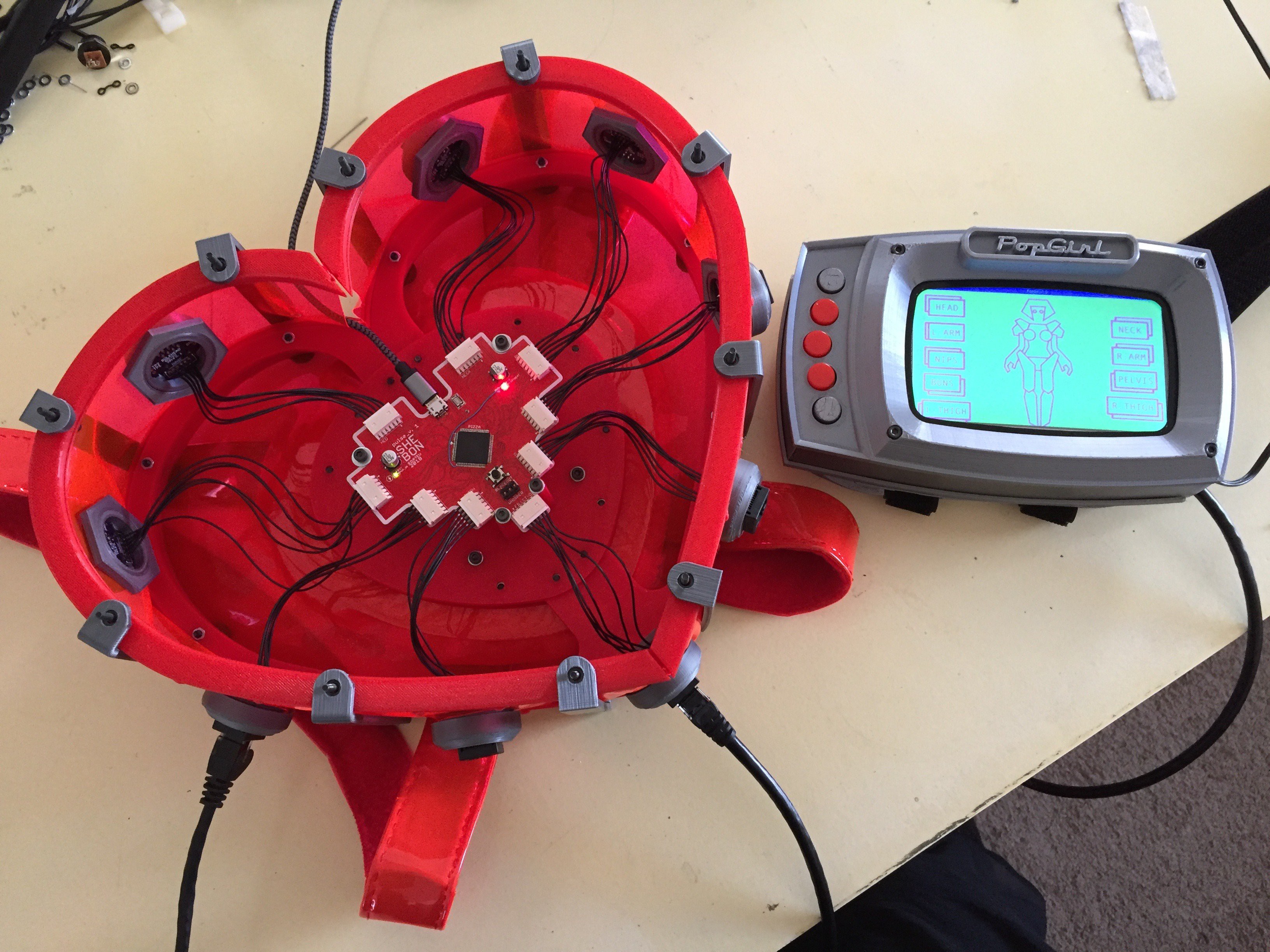

THE PULSE PCB

The circuitboard running the show is called the PULSE, and for the time being... it is more or less a repackaged Arduino MEGA. As mentioned, there will be (is) a separate post all about it. For this build, all you need to know is that this heart-shaped thing mounts in the center of the backpack on some standoffs =P

the red PCB looks pretty sharp mounted in the new yellow enclosure, me thinks:

![]()

MOLEX TO CAT 5

I think first and foremost, the concept evolved around the aesthetic of having large chunky cords stemming form a central location at the core of the body, and feeding out to other locations, like veins.

In some miscellaneous daydream of mine early this year, I imagined this being something transparent and heart-shaped. Once my mind saw it, that was what it had to be.

From the PCB mounted inside the enclosure, I saw many delicate wires terminating at the edge of the fabric, grouping together into bundles and then feeding out in all directions. I knew early on that I didn't want wires stretching all the way to parts of my body directly off the main board. That'd be silly, right?

The initial solution was to use a common connector, like molex, to come off the primary circuitboard. It would then terminate at the edge of the backpack and switch to something else at this junction. The "what" is still largely undecided, but for this first iteration of the backpack I went with CAT5. Its what I have an abundance of in the lab.

I designed a tiny little PCB that has the six wires from my molex connector going in one side, and a cat5 connector on the other side:

![]()

Once everything is soldered onto these little guys, they slide into those silver bulkhead adaptors like so:

![]()

Here is a closeup of the wires terminating into the BULKHEAD:

![]()

...and becoming a CAT5 socket on the other side of the outer wall of the backpack:

![]()

Once rigged up, the nervous system looks something like black spaghetti:

![]()

USB POWER

For now, v. 1 of the PULSE board receives its power from a rechargeable USB brick. There are (14) LEDs on the back side of the PULSE, so in the case that nothing is jacked into any of the sockets, it can at the very least pulse with colored light and look pretty:

![]()

NOW WHAT...

I now have two core systems: one in red and one in yellow! I can wear whichever hue suites my current mood. That's the beauty of it. <3

![]()

If any of this inspires you to develop your own platform; if not to sense arousal per-se, but maybe something else about your physical status that you'd like to communicate out in the wild- I hope you choose to create it!

In closing: the point of this whole project is to get people talking about how we can use the technology we create to communicate better with one another (through new forms of self expression). This project focuses on intimacy, but really... a dialogue about anything matters just the same to me. =)

Keep creating the things you wish to see exist, AND be the person who makes the experience of living more interesting for everyone. <3

-

2POPgirl Enclosure Build

I made a status indicator that notifies me of my body's relative state of arousal!

To help me visualize what's going on with the myriad of wearables I have set out to don at once, I've created an arm-mounted screen display that will tell me what I need to know at a glance.

The development of this little treat was of course a matter of hardware design and software development, so I'm breaking the build log into two parts. This first edition will cover the physical components, like the electronics, the enclosure for the electronics, and any other bells and whistles I needed to create to make it do.

BILL OF MATERIALS

Electronics stuff:

- 5" Raspberry Pi Compatable Touch Screen

- RaspberryPi Zero

- 5V, 5A Step-Down Voltage Regulator

- Logic Level Converter Bi-Directional Module 5V to 3.3V

- Round Push Buttons

- 1' HDMI cable

- Perf Board

- Stranded Wire

HARDWARE SIZES:

OTHER THINGS YOU'LL NEED:

- soldering iron

- access to a 3D printer

- filament in cool colors

- metric screw driver

- pliers

- sleet plastic (up to 1/16 inch thick)

- patience*

*I say you'll need patience, but really... you will need to perform some light modification of some cables in order to get them to fit within the profile of the enclosure. Specifically, you'll need to strip some of the casing from a USB mini cable, as well as strip the plug casing from an HDMI cable. =O

We'll talk more about that later.

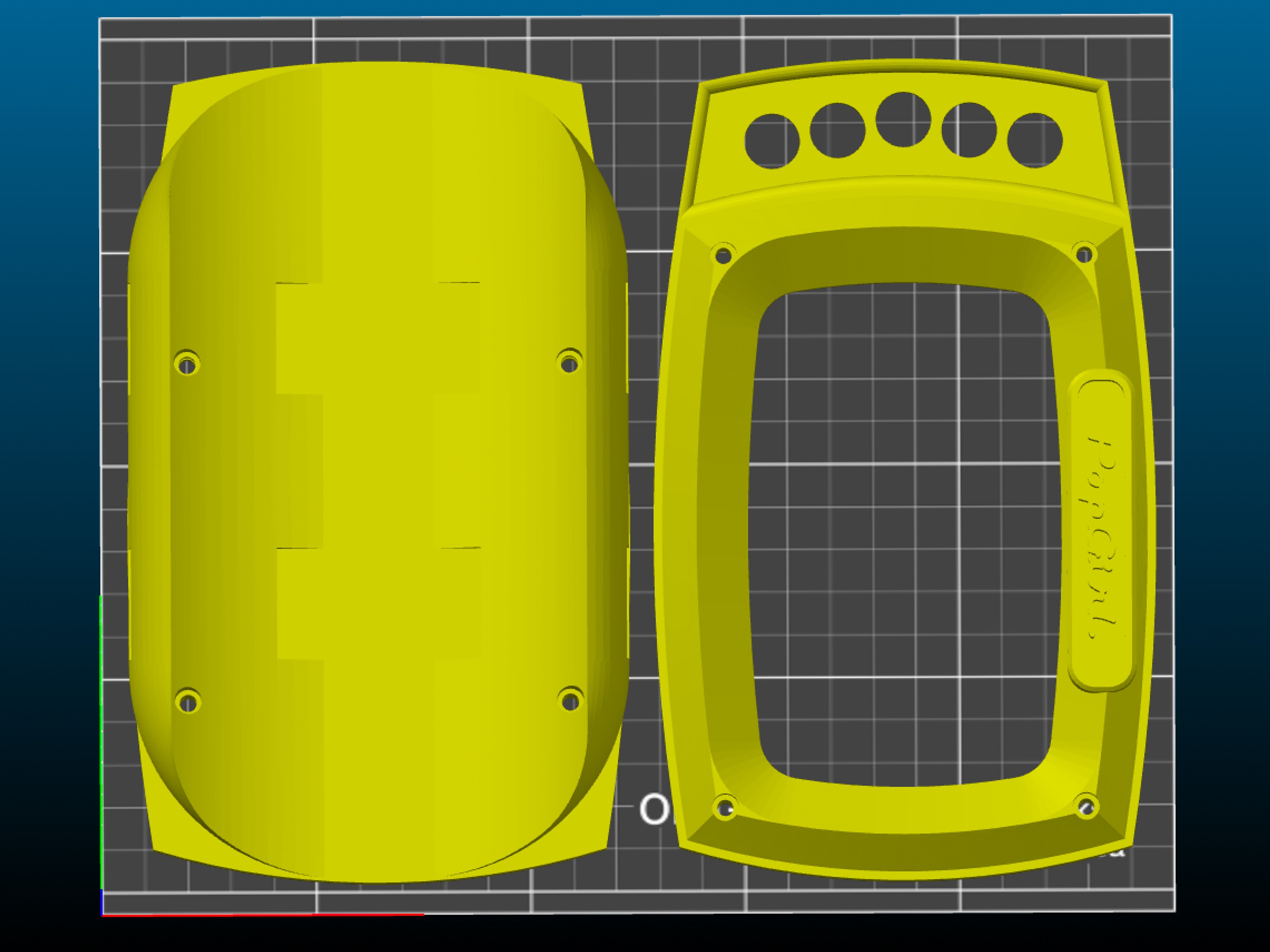

THE PRINTED STUFF

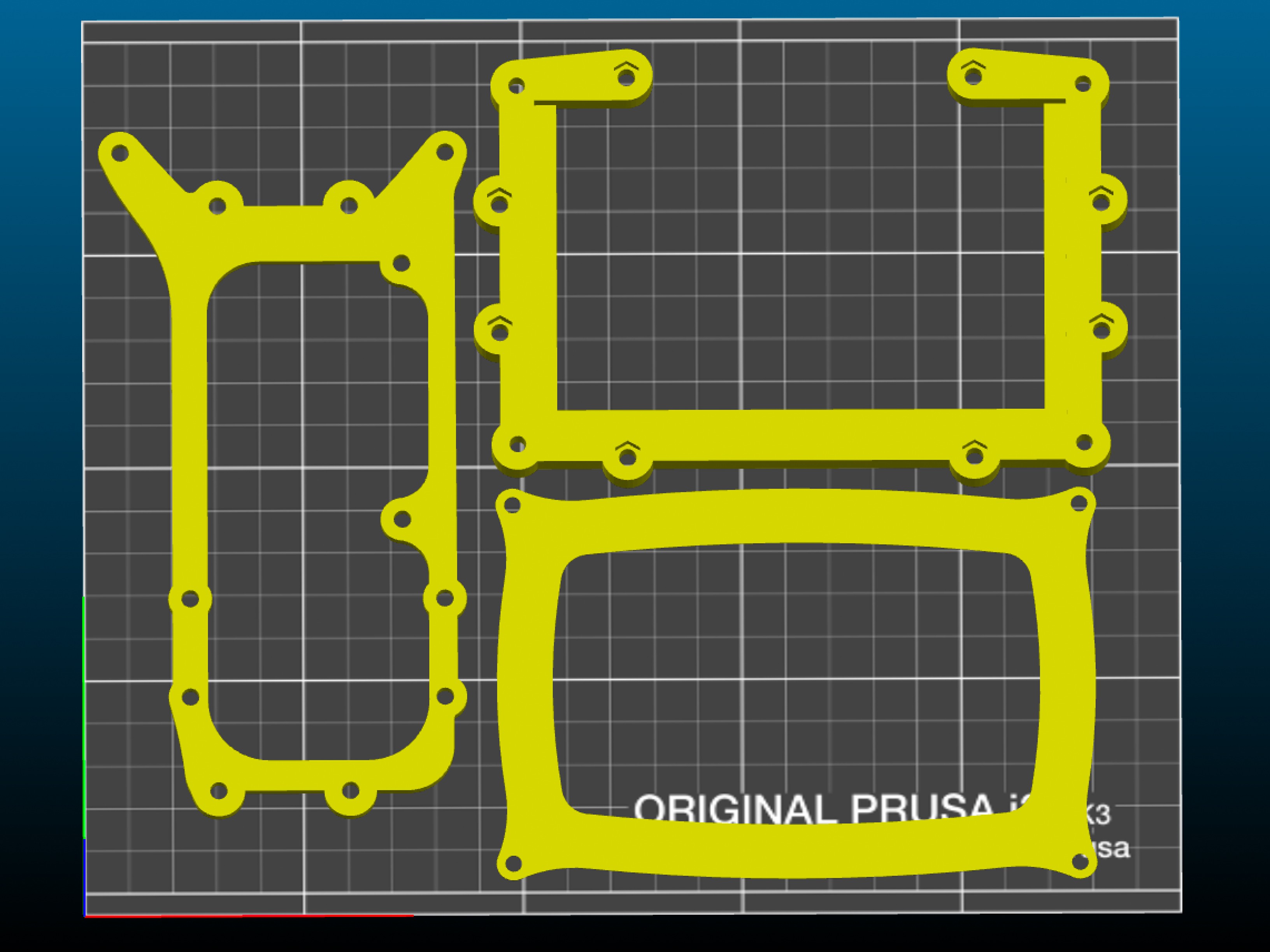

You'll be glad to know that there are only 5 core pieces you'll need to print in order to make your own POPgirl enclosure.

The .stl files can be found on my SHE BON gitHub repo!

The bad news is that a couple of them will take close to six hours to print a piece.

Stylistically, I chose to print the enclosure in silver and black... but you can use whatever colors of filament you'd like, of course. Here are the two trays of parts according to the color they'll be represented as in these build instructions:

SILVER PARTS:

![]()

- face_plate (~7 hours)

- arm_mount (~8 hours)

BLACK PARTS:

![]()

- PCB_mount (~1 hour)

- screen_frame (~2 hours)

- screen_gasket (5 minutes)

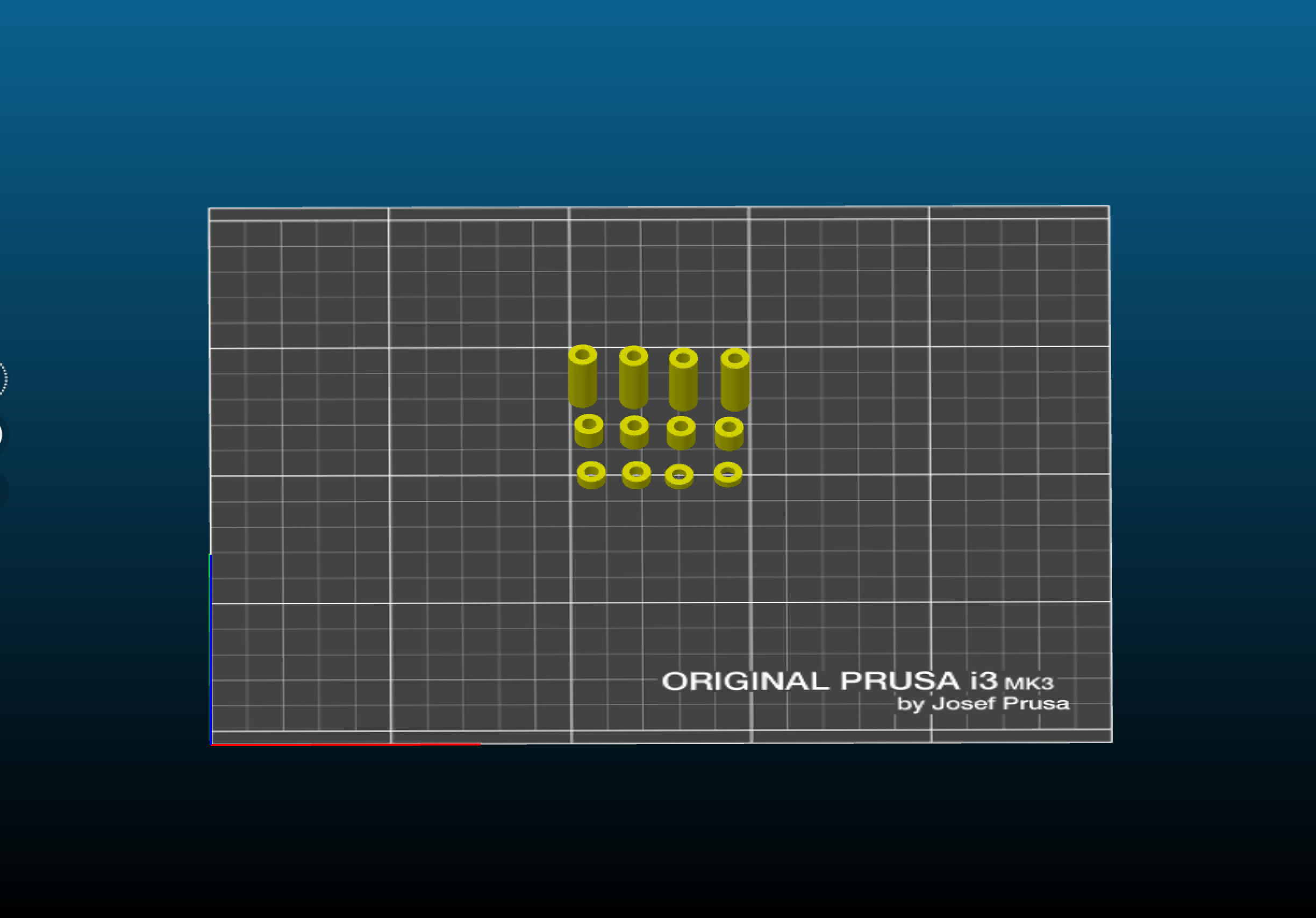

SPACERS:

![]()

In addition to the primary pieces, there are some super important spacers you'll need to print. I chose to print them in red, so they're easy to spot in case they roll off the table into the forever carpet.

The other important thing to note at this point of the build, is the length of hardware that goes with each space. This is key, because the screw length must be such that it is long enough to reach the countersunk nut it is being screwed into, but not too long otherwise it will bottom out (or poke a hole through the enclosure)

![]()

- (4) 5.5mm

- (4) 17mm

- (2) 2mm

- (2) 3mm

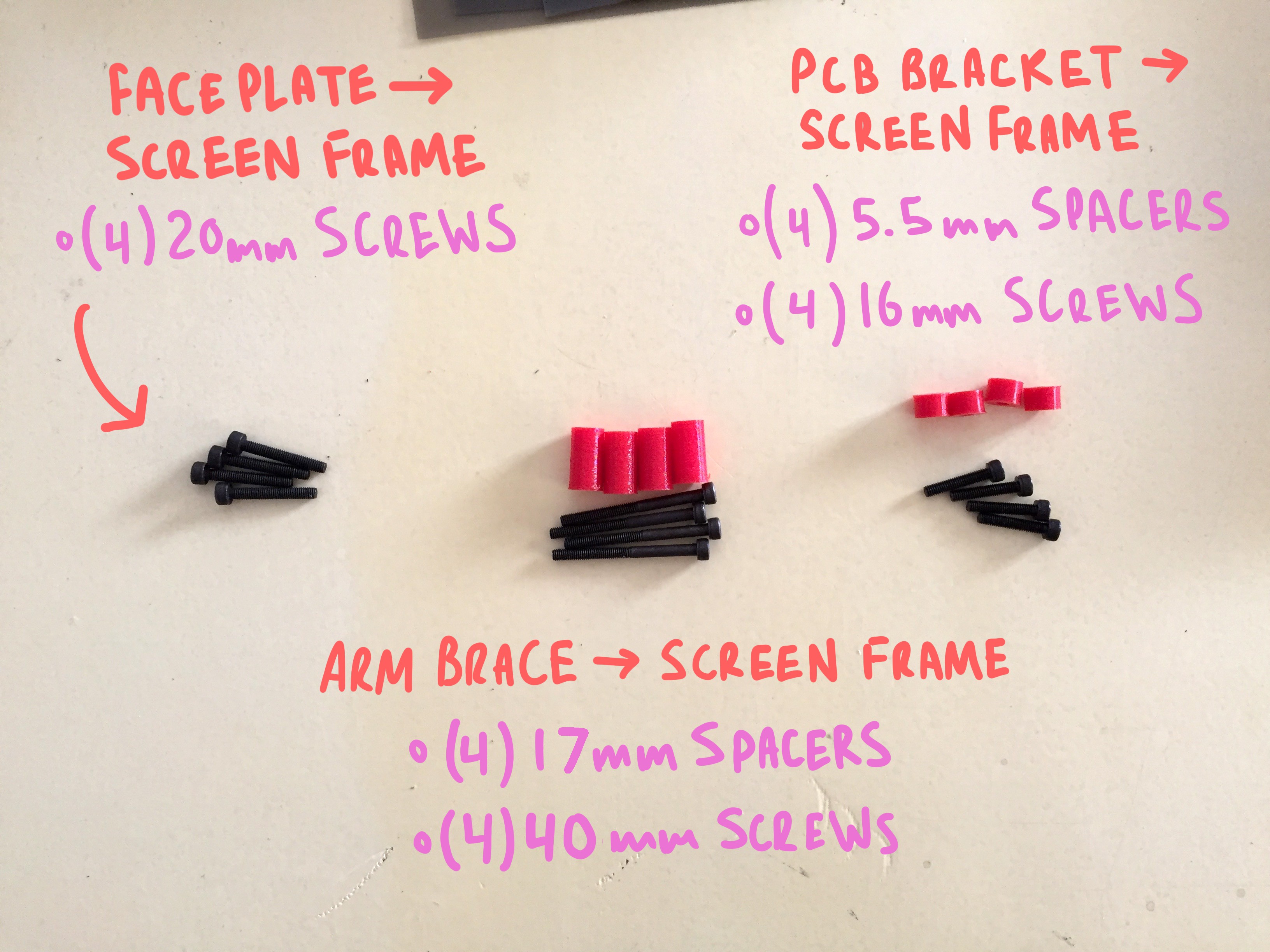

CAPTURING THE SCREEN

This entire build is constructed around a 5" touchscreen monitor which you can pick up from AdaFruit for ~$80. It's a little awkward to use, as it comes with three horrible PCB tumors hanging off from it at odd angles... but if you take care to secure them in place when you get it, they aren't the worst to work around.

Right away you can disconnect the ribbon between the screen itself and the main PCB, and also unplug the button board all together, as we won't be using it.

![]()

The other helpful thing to do as soon as you unpackaged your screen is to use some double sided silicone tape to adhere the thin and fragile touch-screen PCB directly to the back of the screen to keep it from flopping around all loose-like.

Just tack it down where it wants to lay naturally, and you should be good.

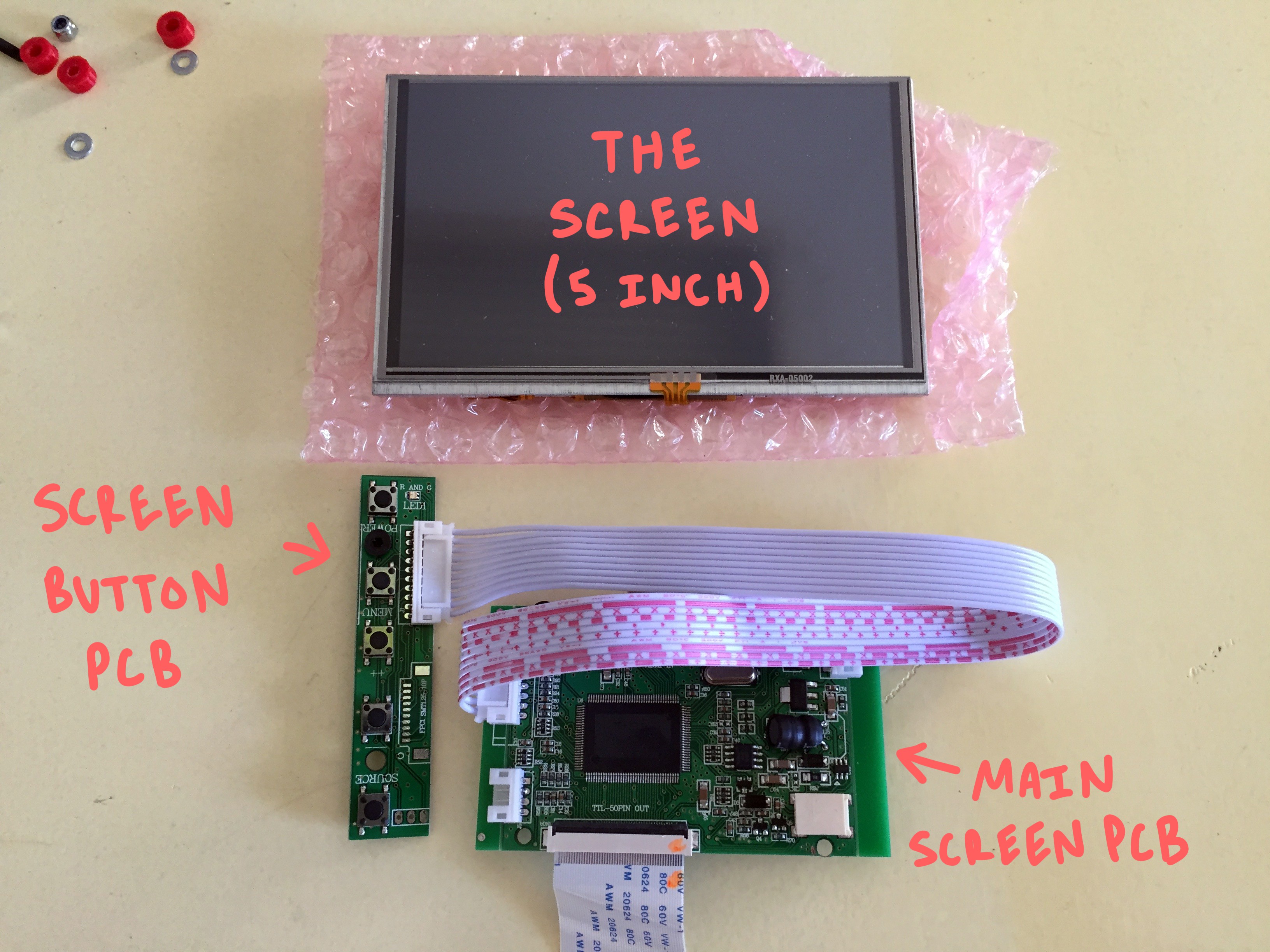

Take the "screen frame" and press-fit some nuts into all of the counter-sunk pockets. There should be (8) on the front, and (4) on the back.

Then lay the back on the screen into the frame so that its front is unobstructed and flush with the printed plastic:

![]()

next, place the thin gasket on top of the screen, lining up the four mounting holes at the corners. It should over-lap and frame the touch-area just slightly.

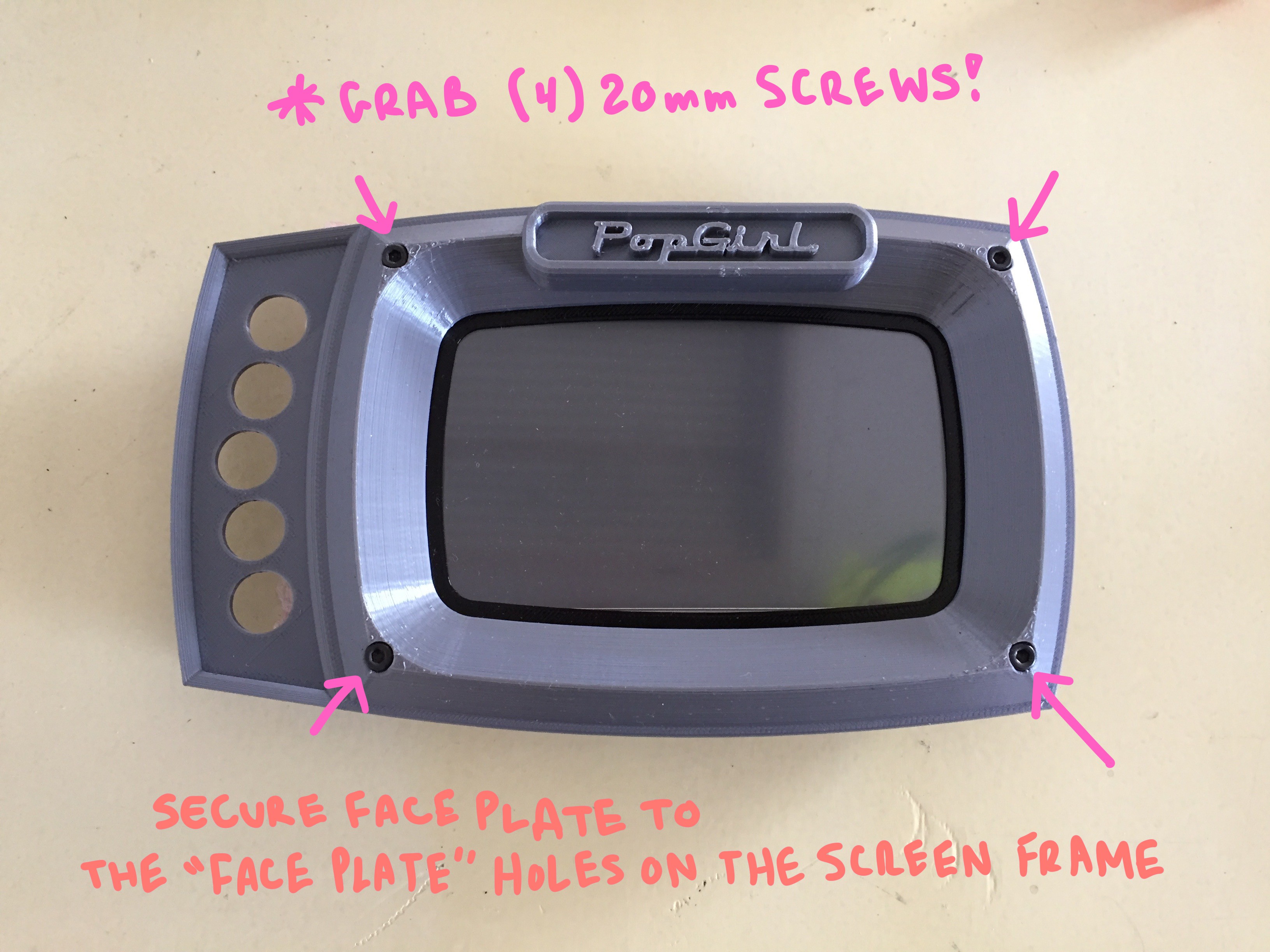

Lastly, the big dance "faceplate" piece should mount directly on top of the gasket. Like up the same hole along the four corners.

![]()

one these three pieces are sandwiched together, you can thread (4) 20mm screws through the from of the "Faceplate" into the corresponding counter-sunk nut holes in the "screen fame":

![]()

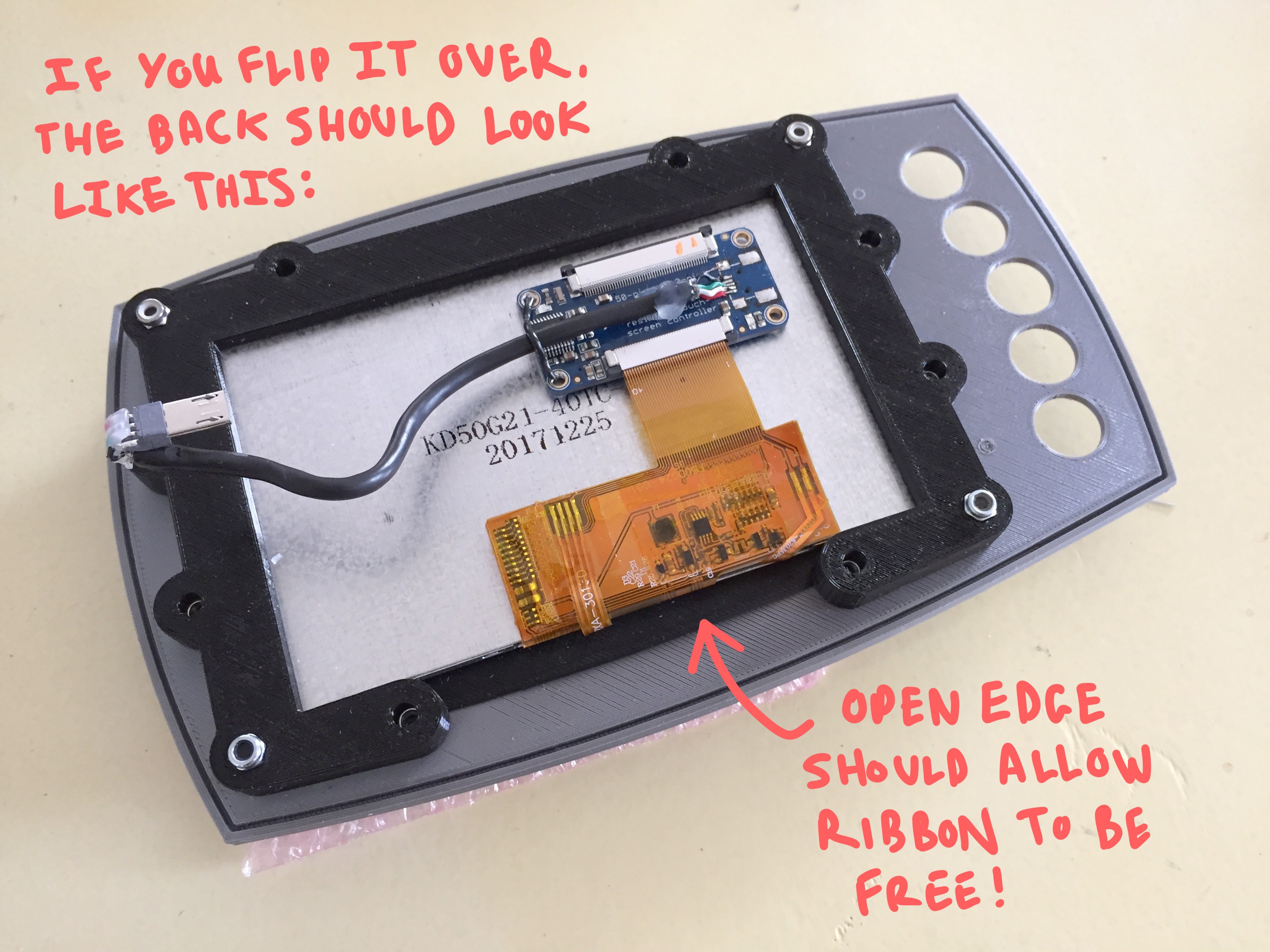

The back should now look like this, with both the ribbon cable and the open edge of the "Screen frame" facing the bottom edge of the assembly:

![]()

MOUNTING THE PCBS TO THE "PCB FRAME"

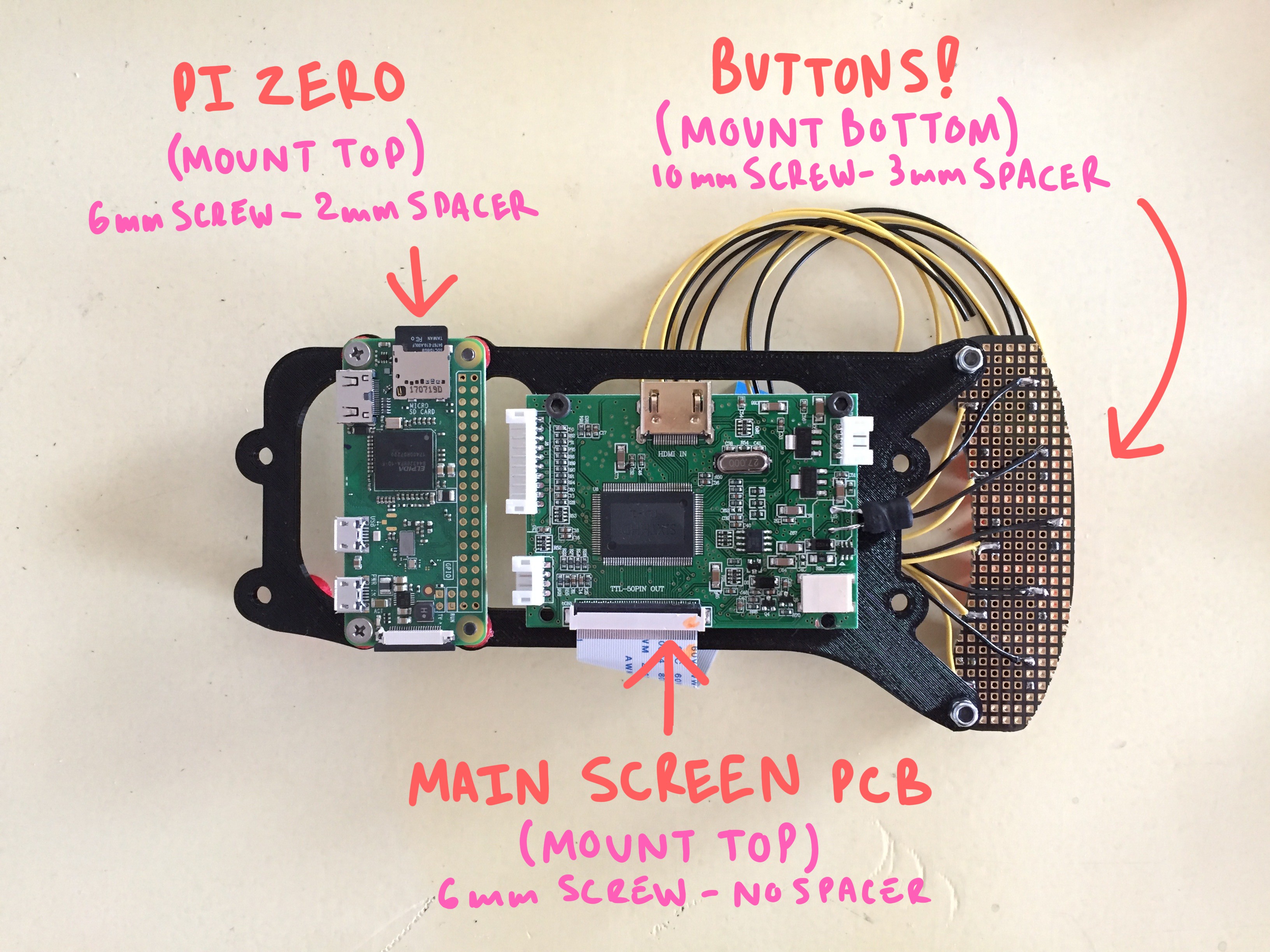

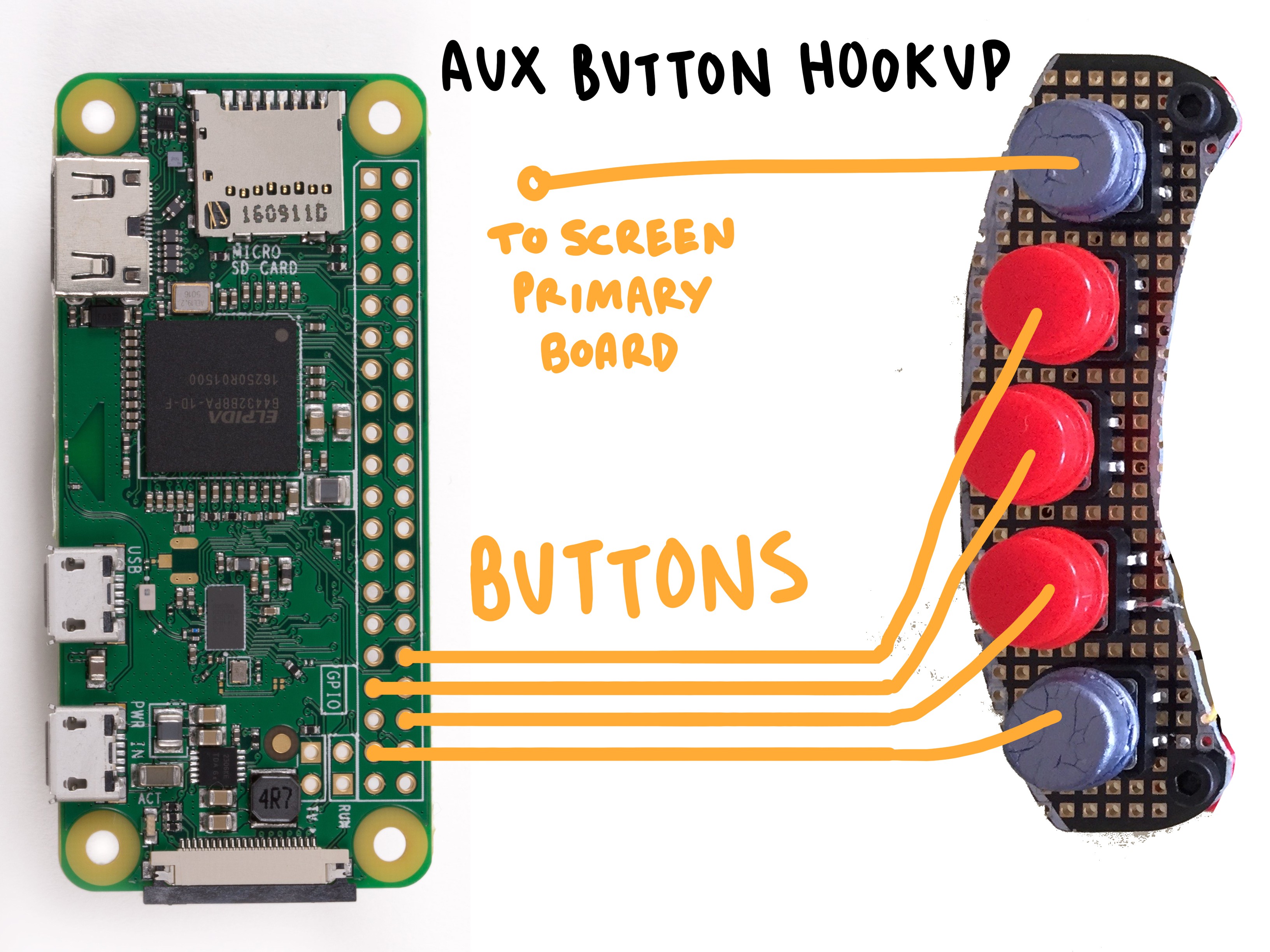

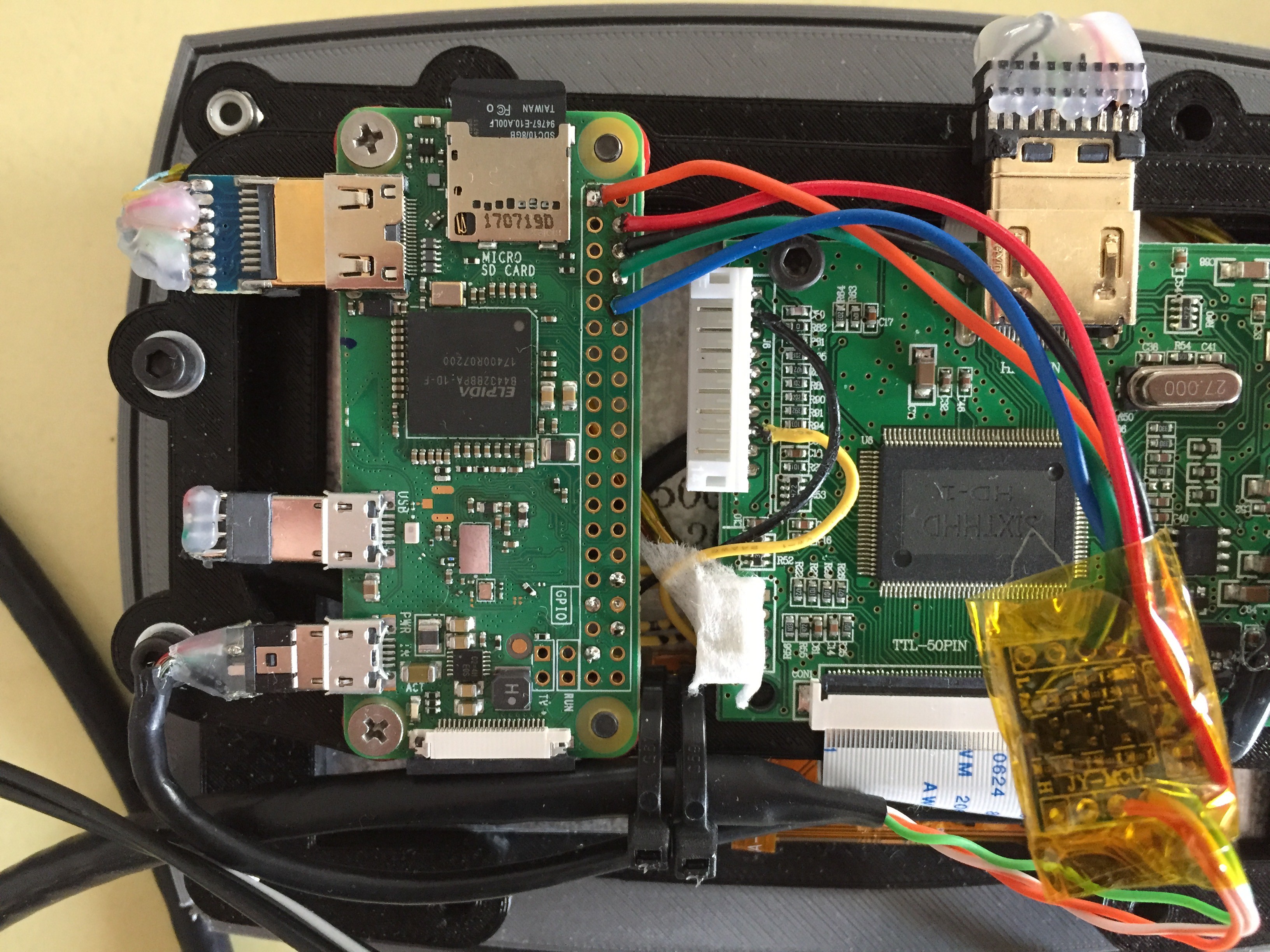

There are three circuit boards that will all share a single mounting frame. On the far left, there should be your "Raspberry Pi Zero", in the center will mount the screen's "primary board", and on the right will mount a "custom button board" that you'll need to put together with some perf-board and those tiny push buttons I listed on the bill of materials.

The completed board should look like this once completed:

![]()

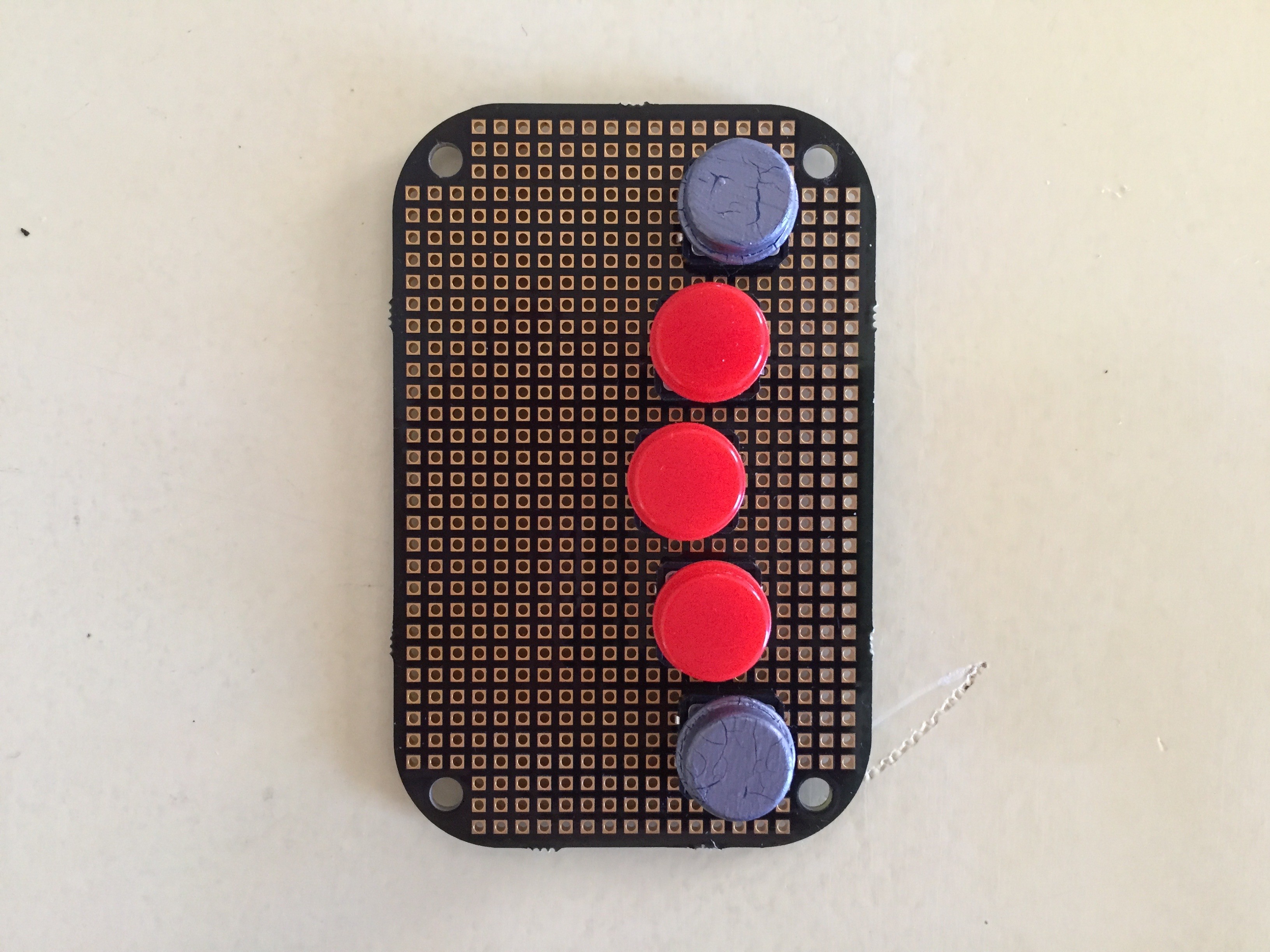

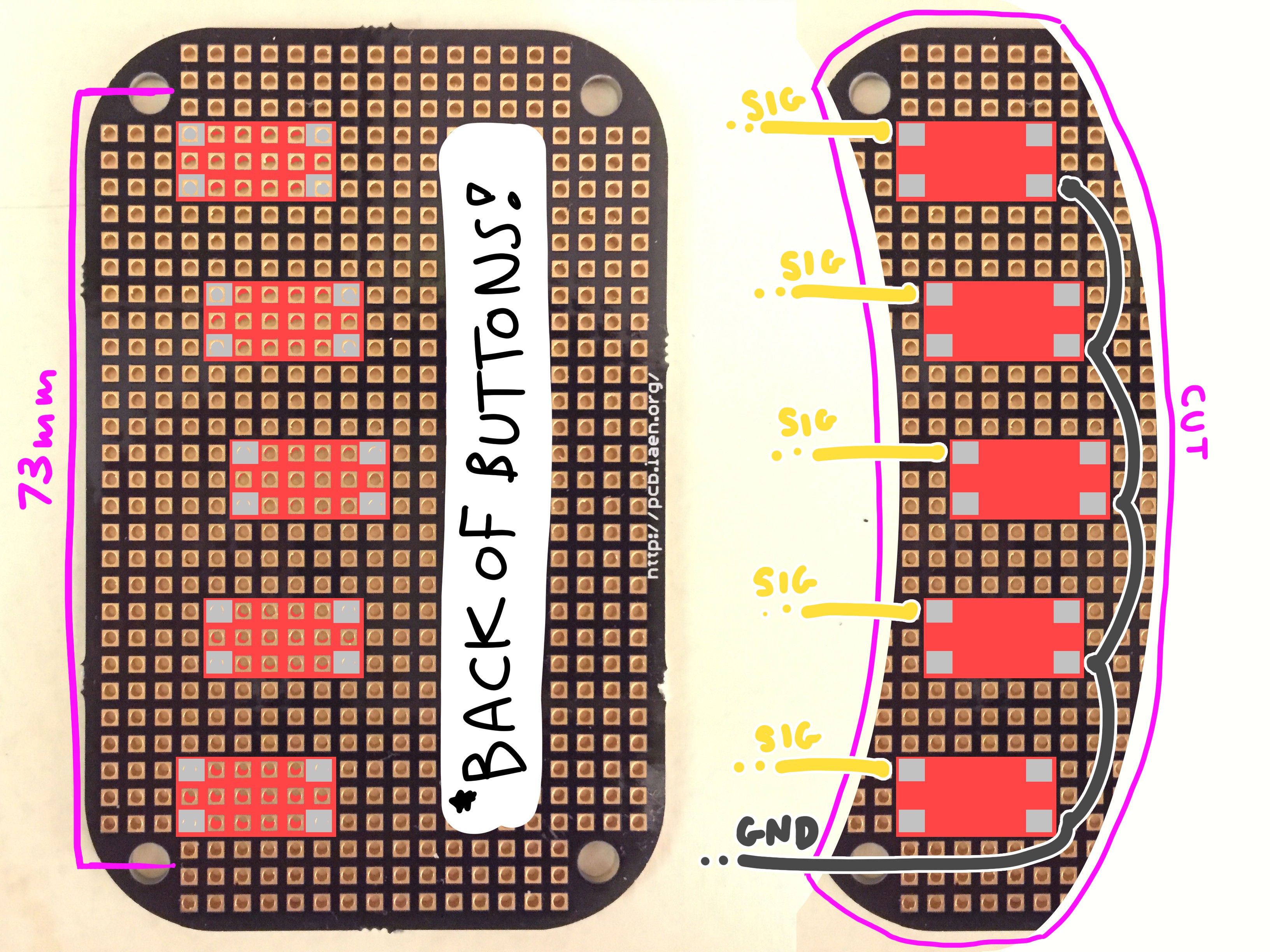

MAKING A CUSTOM BUTTON BOARD

You will need to solder up a quick button board module specifically fit to the clearance holes in the face plate!

Don't worry! If you have standardly spaced perf board, then you're all set. The front of the board should look like this. Five buttons, staggered by one row in a slight bow to the left:

![]()

Here is a diagram for the dimensions and space of the buttons as they should fit into the perf board:

![]()

There should be a wire coming off from each button that is ~7" long... and at least on ground wire!

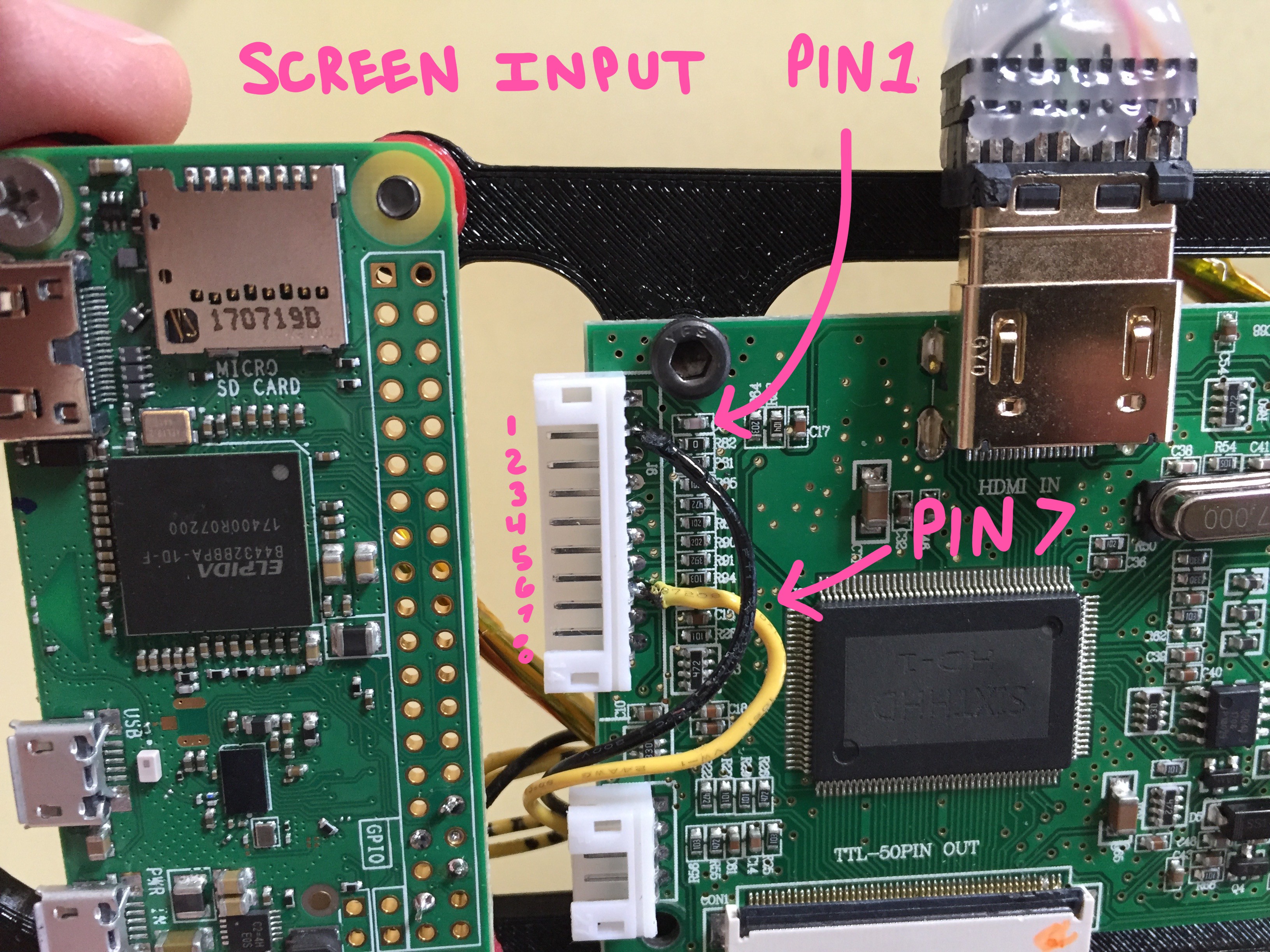

One of your buttons should connect to the "INPUT" of the screen, so that just incase the screen doesn't boot up in the correct mode, you'll be able to easily change it without needed to hook up the whole button bar tumor which came with the screen.

Pick a button, and wire to the pad leading into these two pins of the "button board" connector on the screen's "primary board":

![]()

The rest of the buttons on your "custom button board" can be wired into any input pin you'd like on the Raspberry Pi Zero. I personally chose these four pins on the pi:

![]()

CONNECTING THE PCBs TOGETHER

This part kinda sucks. :)

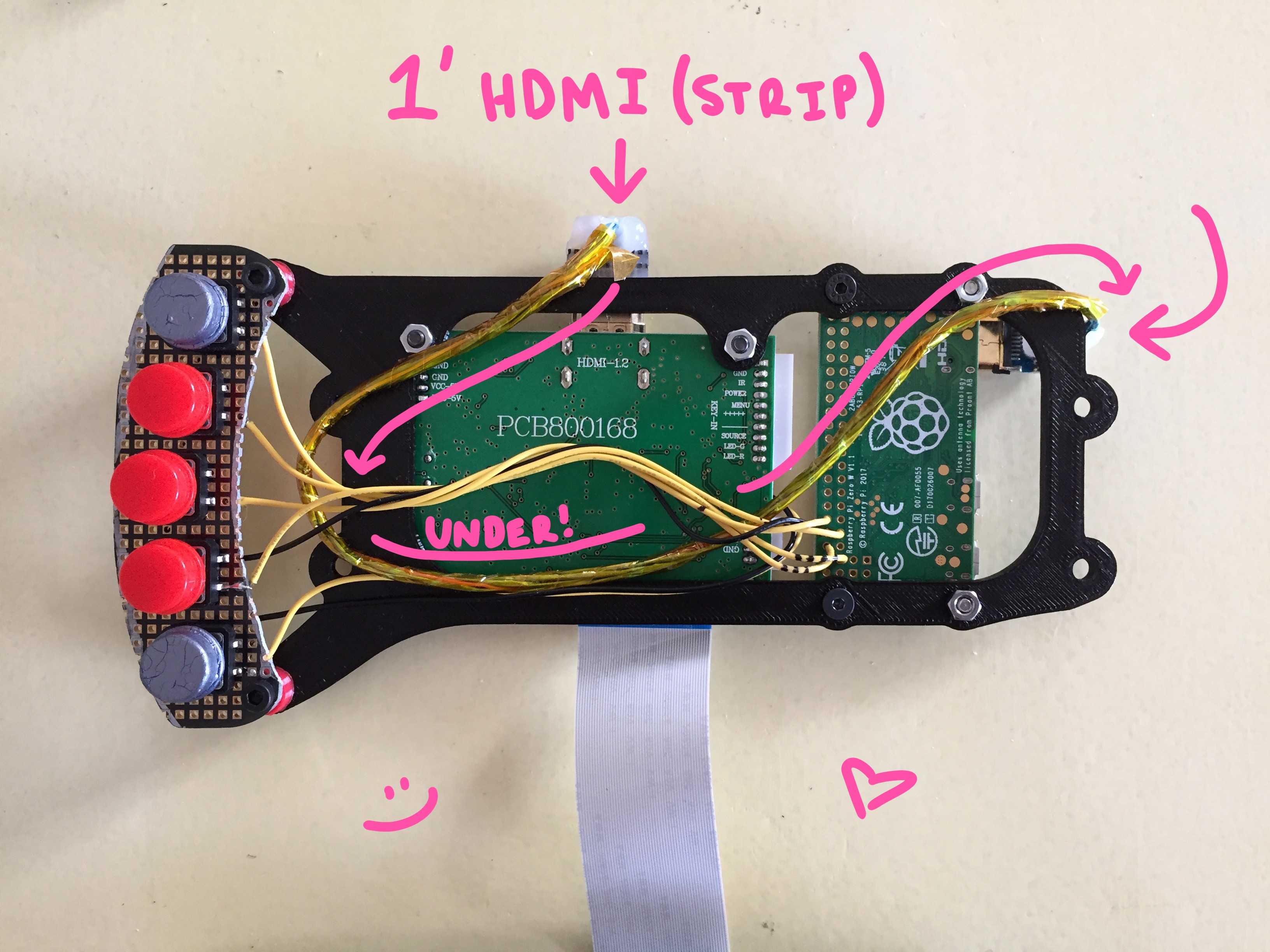

You will have to run *specifically* a 1' HDMI cable from the screen's "primary board" to the "Raspberry Pi" - but in order to get it to fit within the enclosure, you will have to skin it completely. (I will soon post a stream of Mark demonstrating how to do this)

The fully skinned HDMI cable should be routed as such:

![]()

There are eight remaining empty holes on the "screen frame" that will be used for attaching this PCB bracket, as well as for sealing up the enclosure.

ATTACHING THE LOGIC LEVEL CONVERTER

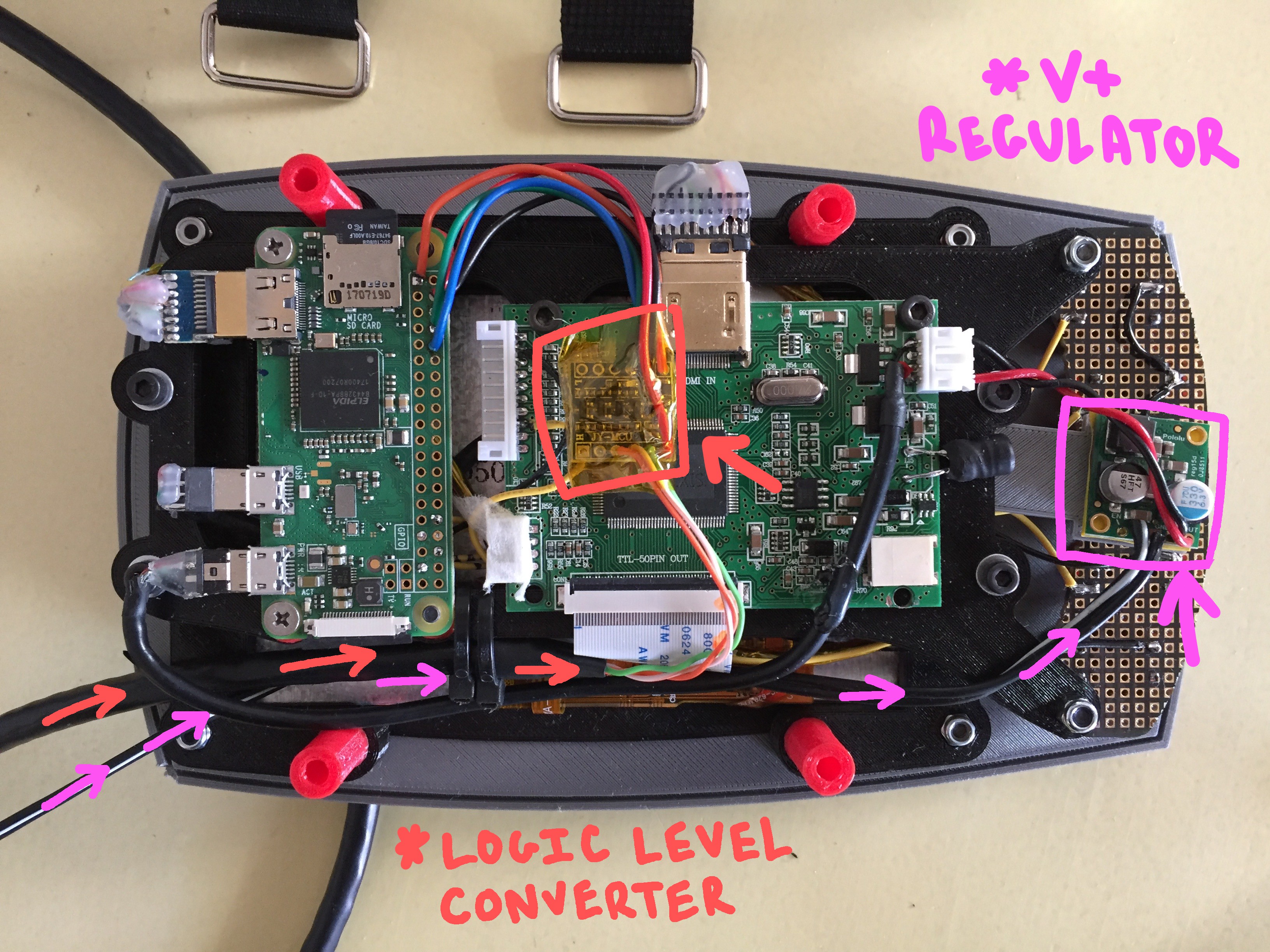

Floating inside of your enclosure, there will exist two voltage regulators. One is a logic converter which drops 5V to 3.3V, there other is for the system in general.

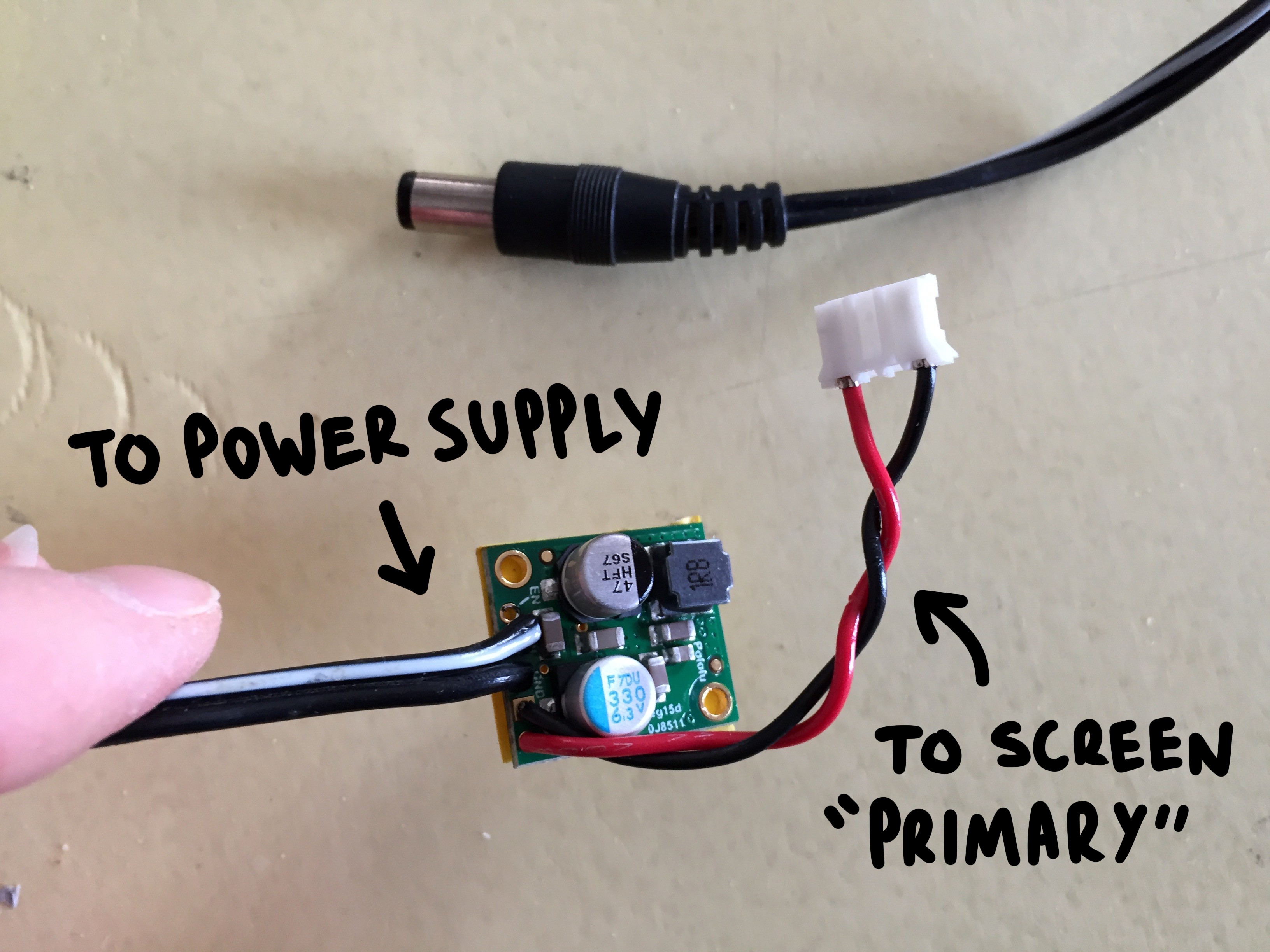

The main voltage converter is available from Pololu.com, and will go between your power supply and the system at large:

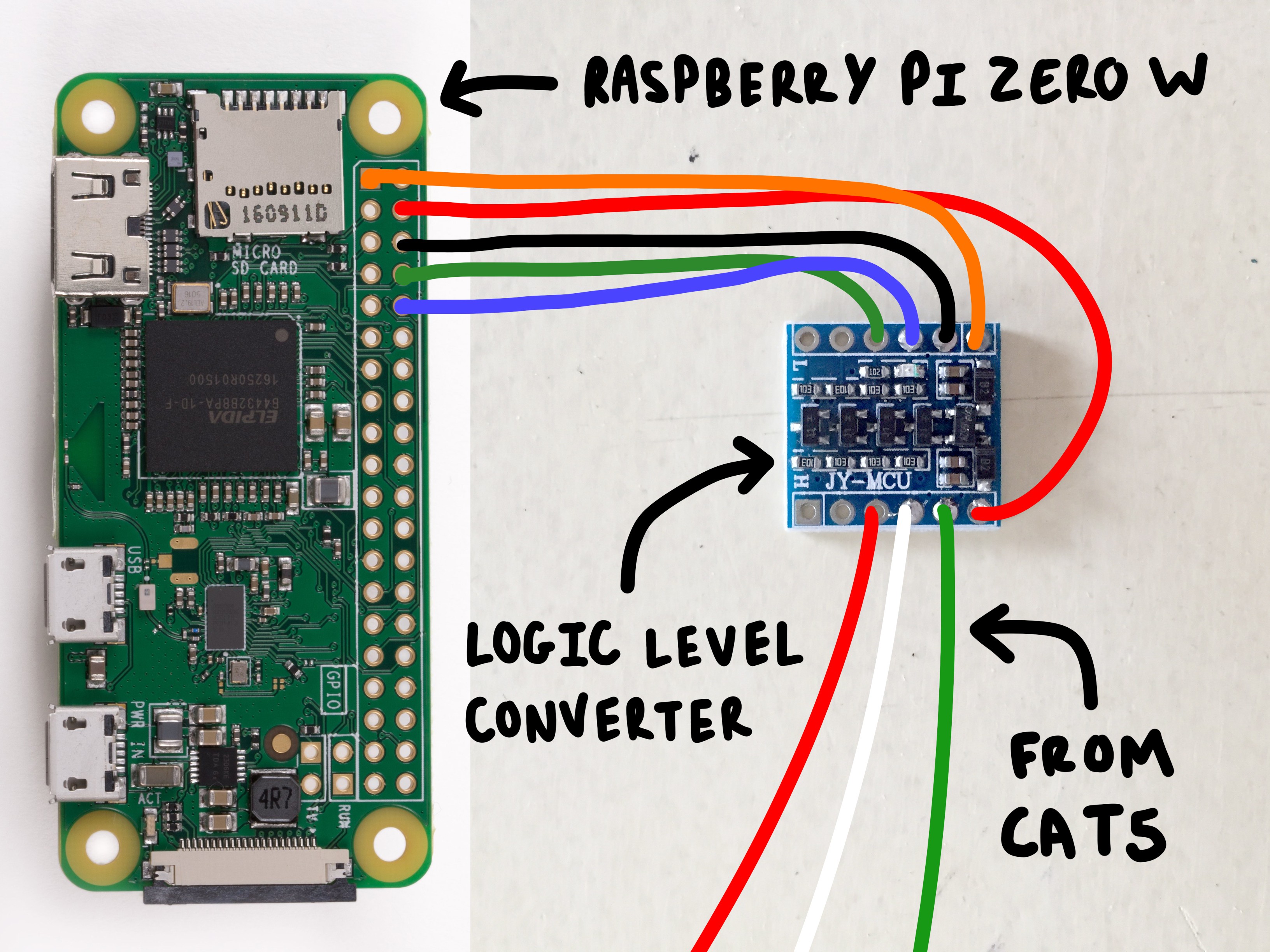

The logic converter is available on Amazon and will go between the Pulse board and the POPgirl's Raspberry Pi Zero board. The stripped end of your cat5 cable will attach to this board, as well as some wire going to your raspberry pi. The hookup will look like this:

![]()

Once its connected, wrap the module in some capton tape and let it rest over the middle the screen's "primary board" like a little floaty tumor:

![]()

ATTACHING THE VOLTAGE REGULATOR

The next tiny glad that you'll need to prepare is the "voltage regulator". You can read more about it on Pololu's specs page!

The cable from your chosen power supply should connect *in* to the board, and the male connector compatible with the screen's "primary pub" should be running *out* from the board:

![]()

Place some electrical tape along the back of the board and wrap it in capton tape to protect it, as this module will more or less "float" inside of the enclosure like a rogue organ:

![]()

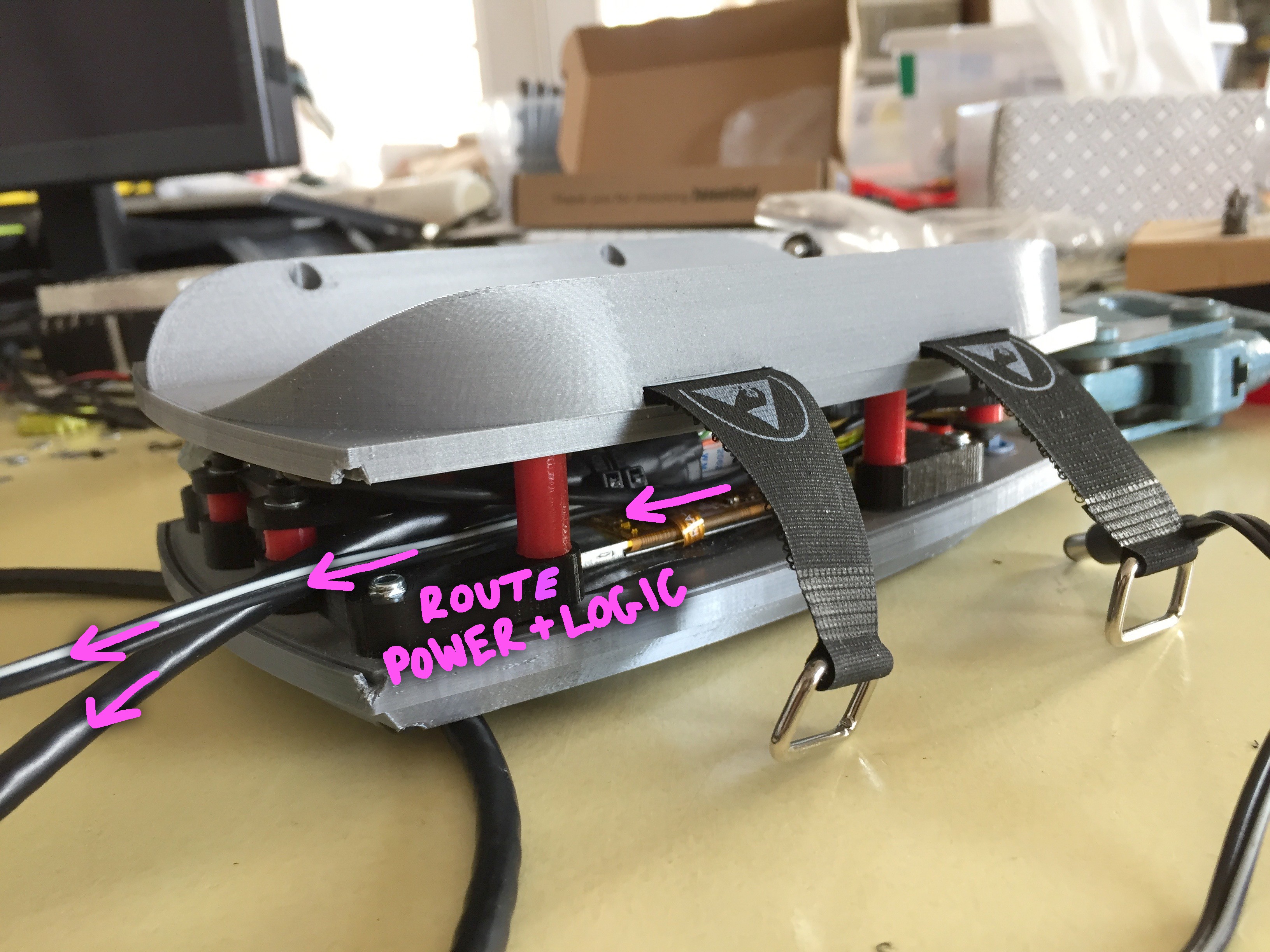

The cable running *in* from your power supply should rout along the bottom edge of the enclosure next to the CAT5 data line.

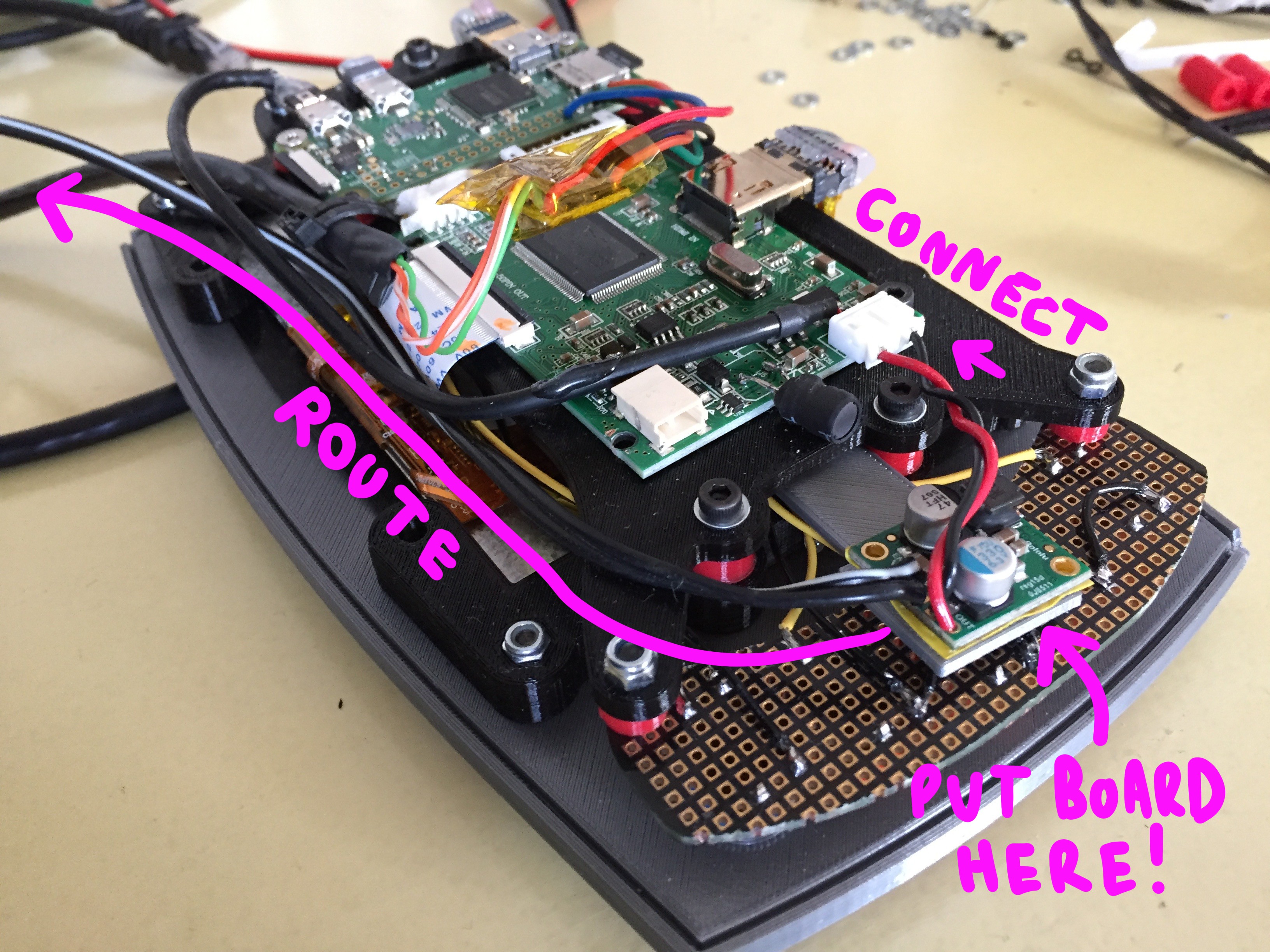

ATTACHING THE *FULLY LOADED* PCB MOUNT

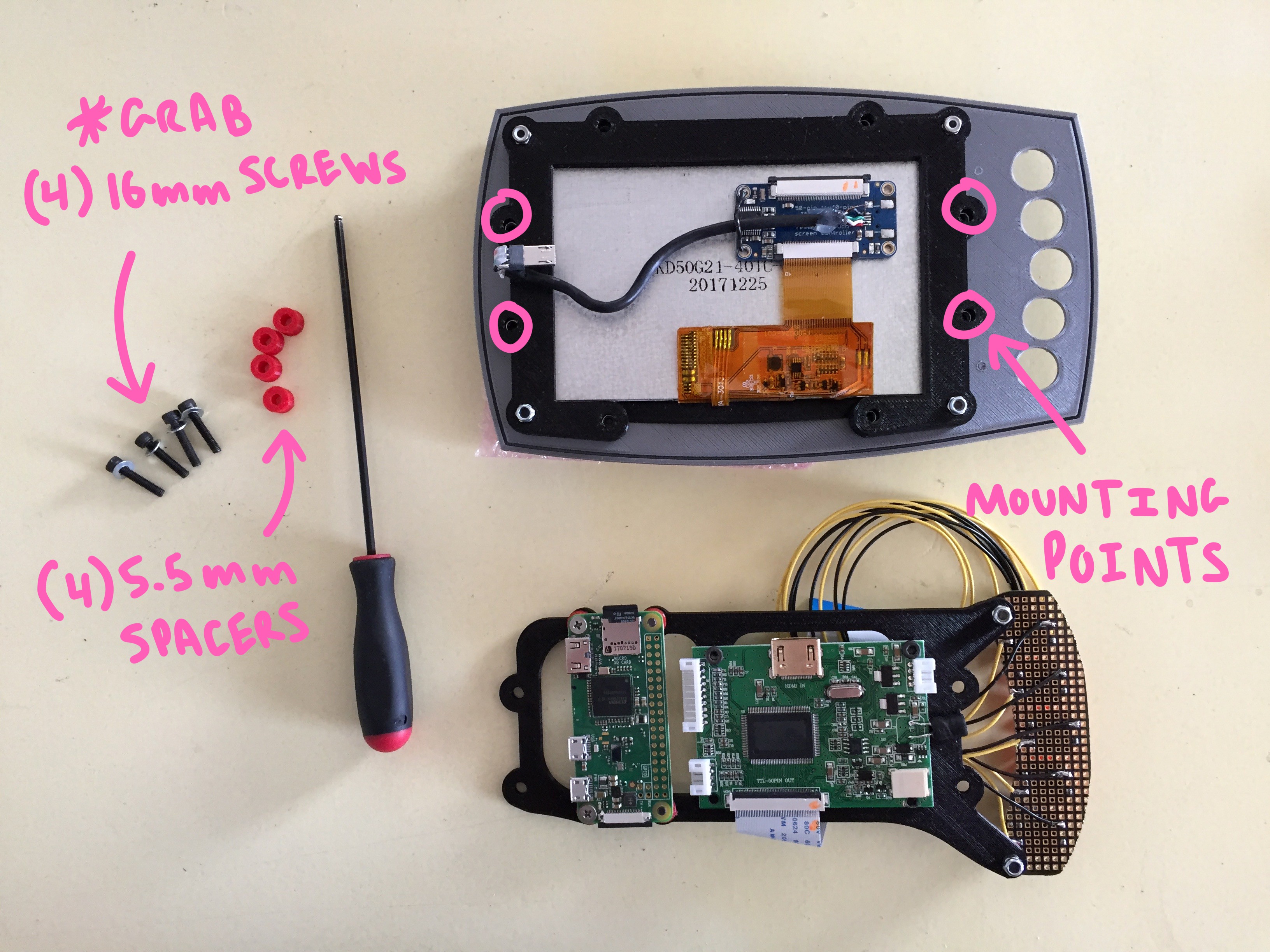

You'll be attaching your loaded PCB bracket to the four holes circled below:

![]()

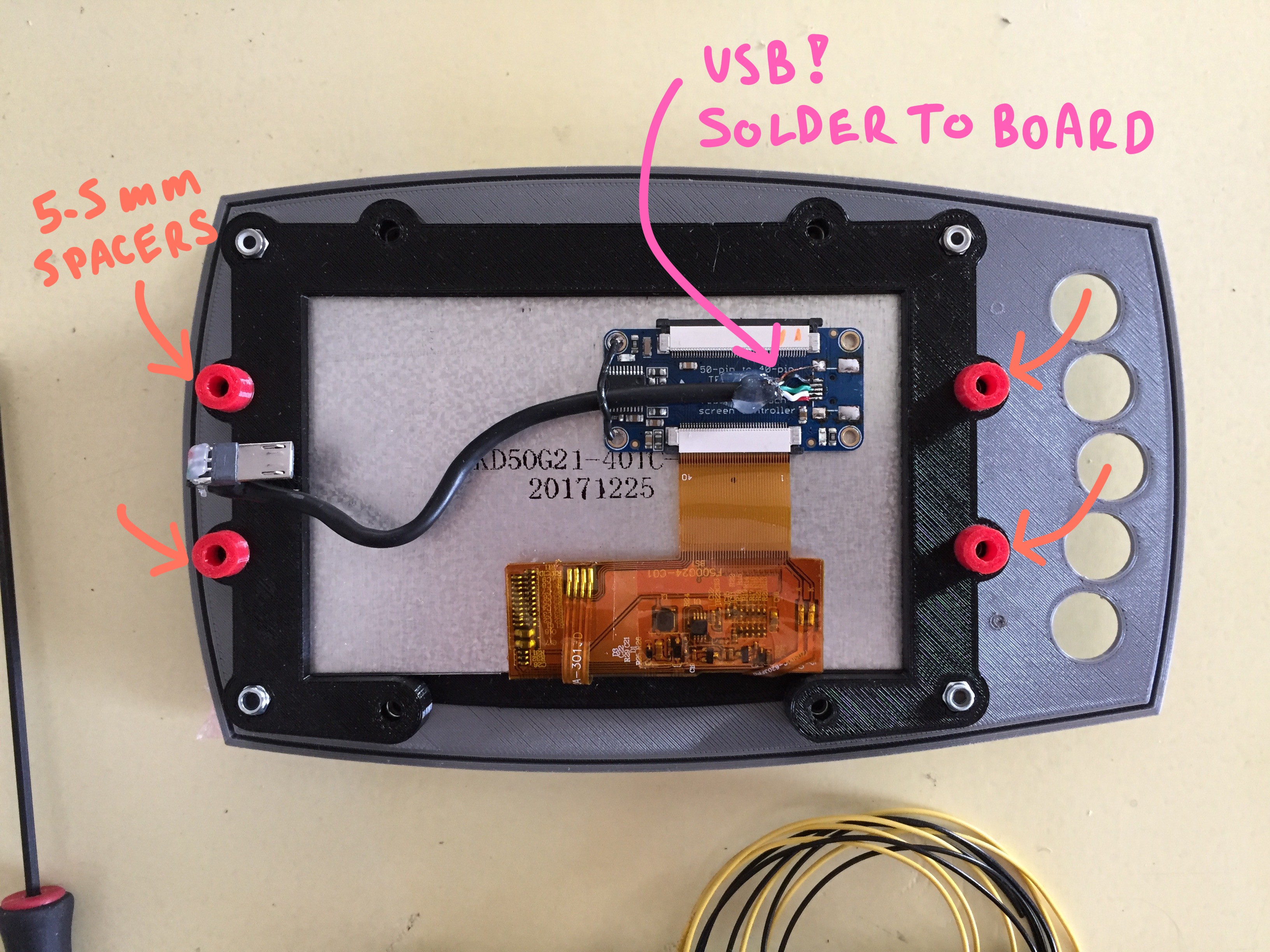

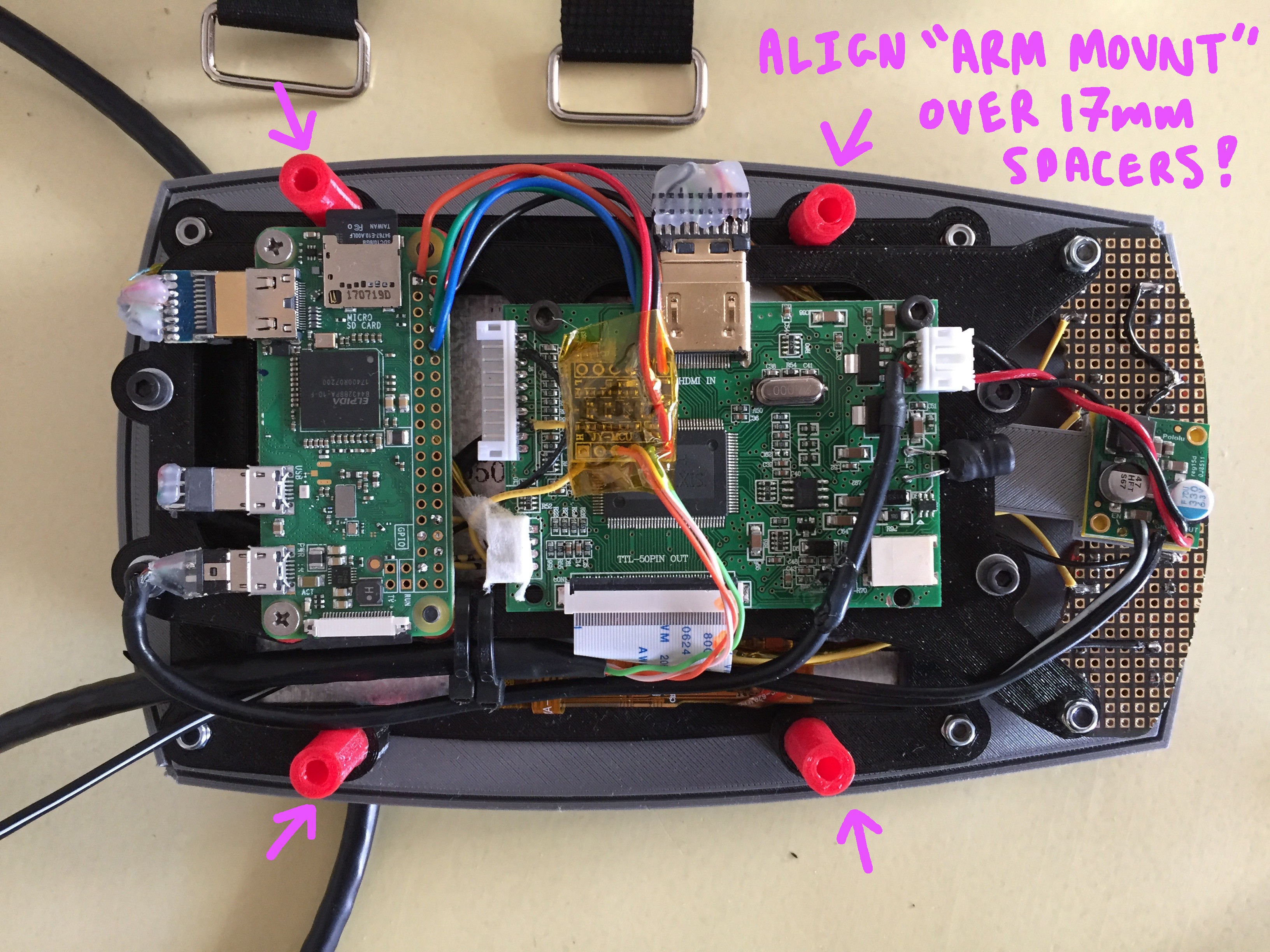

Grab your 5.5mm spacers and position them over these holes:

![]()

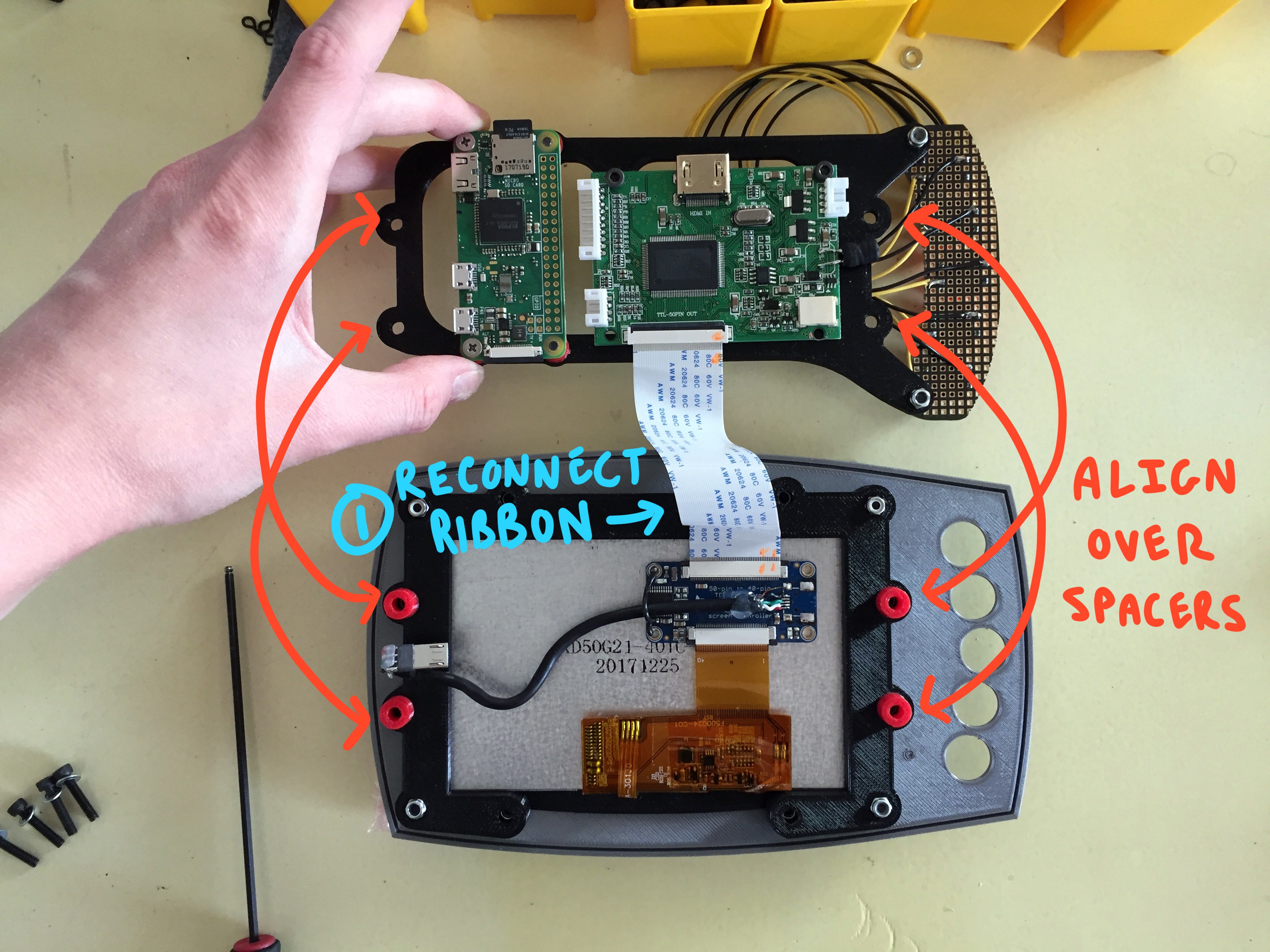

Be sure to reattach your ribbon cable from the touch screen PCB to the main screen board before you position the "PCB bracket" above the spacers:

![]()

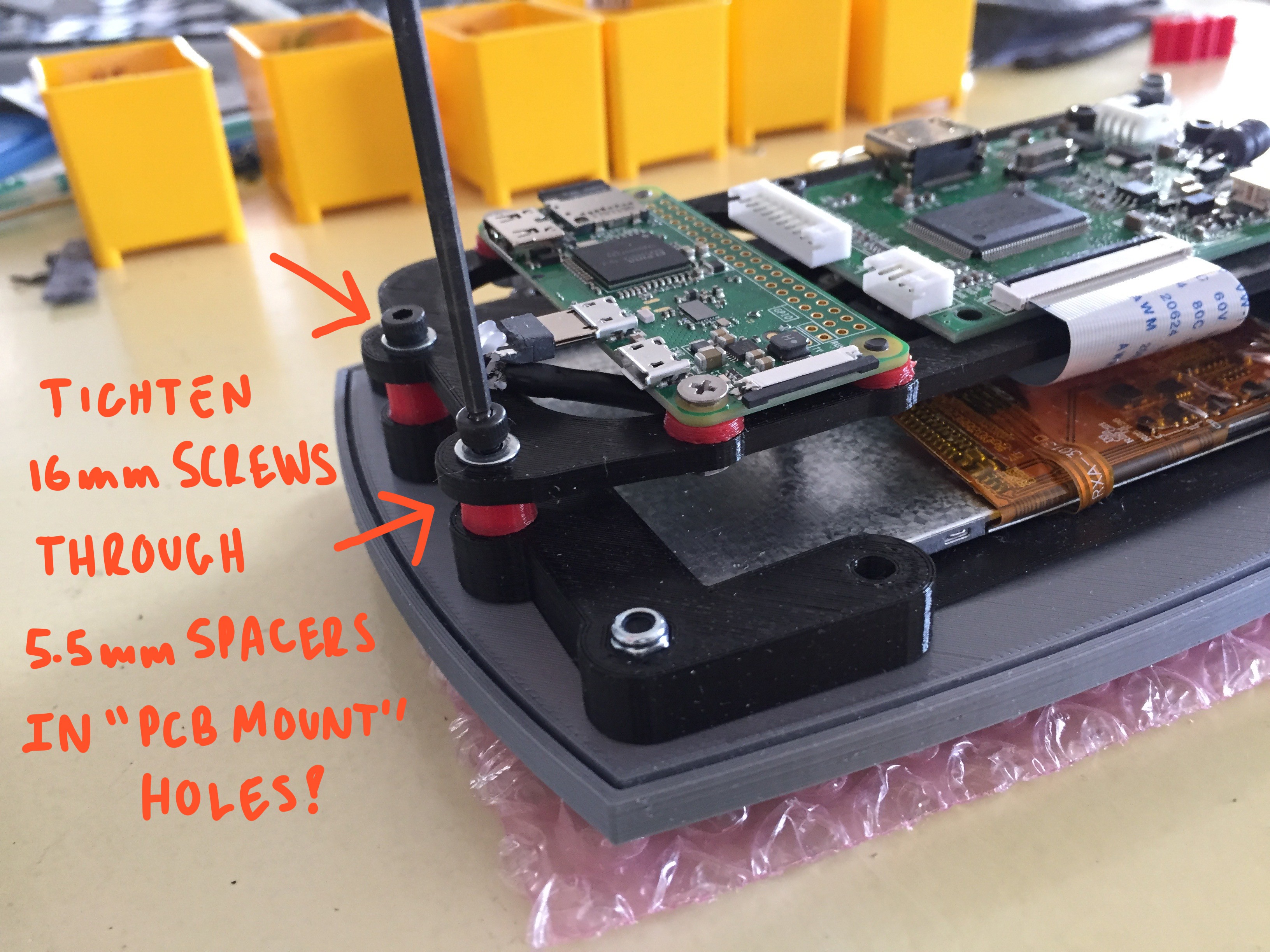

Line up the holes of the "PCB bracket" over the 5.5mm spacers and the receiving holes on the "screen frame", and thread in your 16mm hardware. It will be received by the countersunk nut inside the "screen frame":

![]()

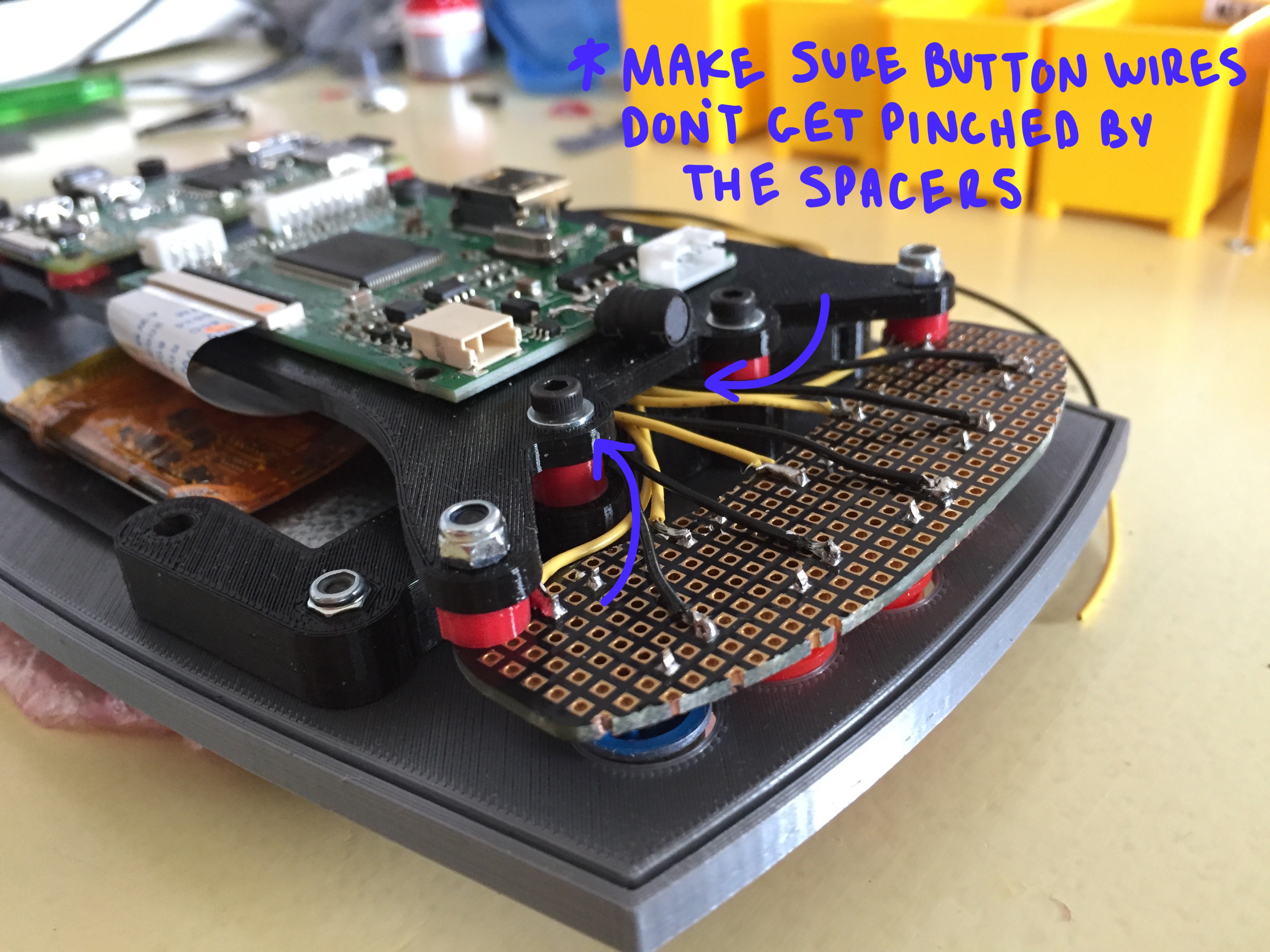

Maker sure that while you are doing this, none of the wires coming off your custom button board are being pinched or twisted strangely:

![]()

Make sure all of your cables are connected and that everything looks level and parallel. Then lay the assembly face down:

![]()

Your "logic level converter" and your "voltage regulator" should seat roughly in the areas shown above. Be sure to wrap them in protective capton tape so nothing shorts out!

ADD STRAPS TO THE "ARM MOUNT"

Before you seal everything up, you'll need to do something a little screwy with your velcro straps (something I will likely fix in a later version of this build, but for now... we'll just do the weird work around)

![]()

Slide your velcro straps through the flat channels in the "arm capture" piece that you printed.

![]()

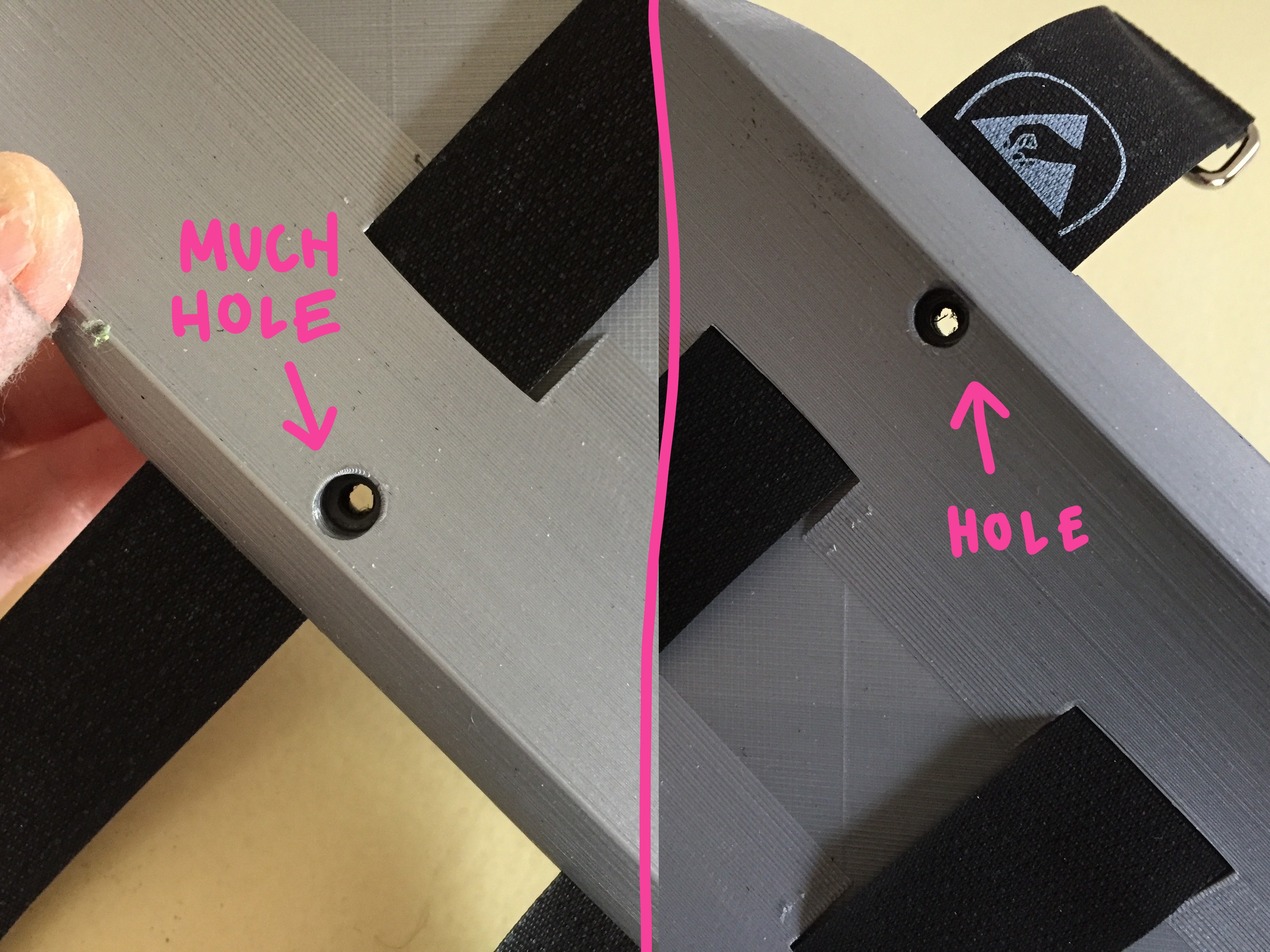

You'll notice one of them has a hole overlapping one of the channels... OOOPS. You will need to pass a piece of hardware through there to seal of the enclosure, so we're going to have to punch some holes in the strap.

Position the straps where they need to be fixed, relative to how they hit the girth of your arm, and then mark where the hole lands with silver sharpie:

![]()

Once marked clearly... use a 4mm punch to piece the velcro strap:

![]()

Yay! Now the hardware can pass through the strap when you're sealing up the enclosure!

There are four remaining holes at this point =O position the 15mm spacers over these holes and use your 35mm hardware to seal the enclosure, screwing from the "arm capture" plate through the spacers, and into the corresponding holes on the "screen frame" (there should be countersunk nylock nuts ready to receive them!).

CLOSE IT UP

Align the holes of the "arm mount" piece over the remaining 17mm spacers and the remaining holes on the "screen frame":

![]()

Make sure the cable from the power supply and the CAT5 data line are tucked along the inside of the spacers:

![]()

You will use your 40mm to seal the enclosure. Make sure the top assemble and the "arm mount" sandwich the 17mm spacers and that none of your chords or wires are being pinched as your tighten down the screws into the captured nuts in the "screen frame".

CREATE SOME EDGE

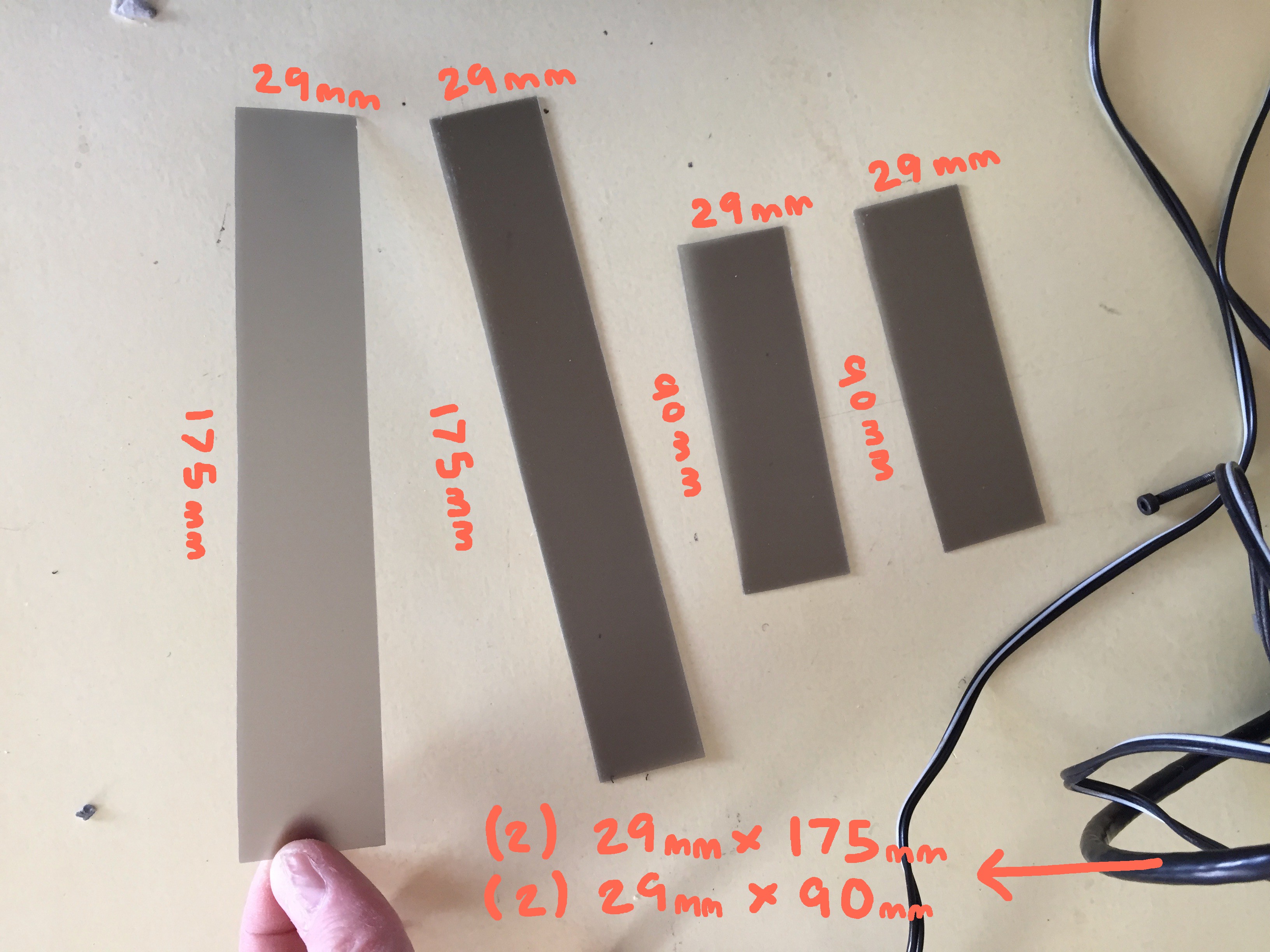

Using some sheet plastic, cut small rectangles in the following dimensions:

![]()

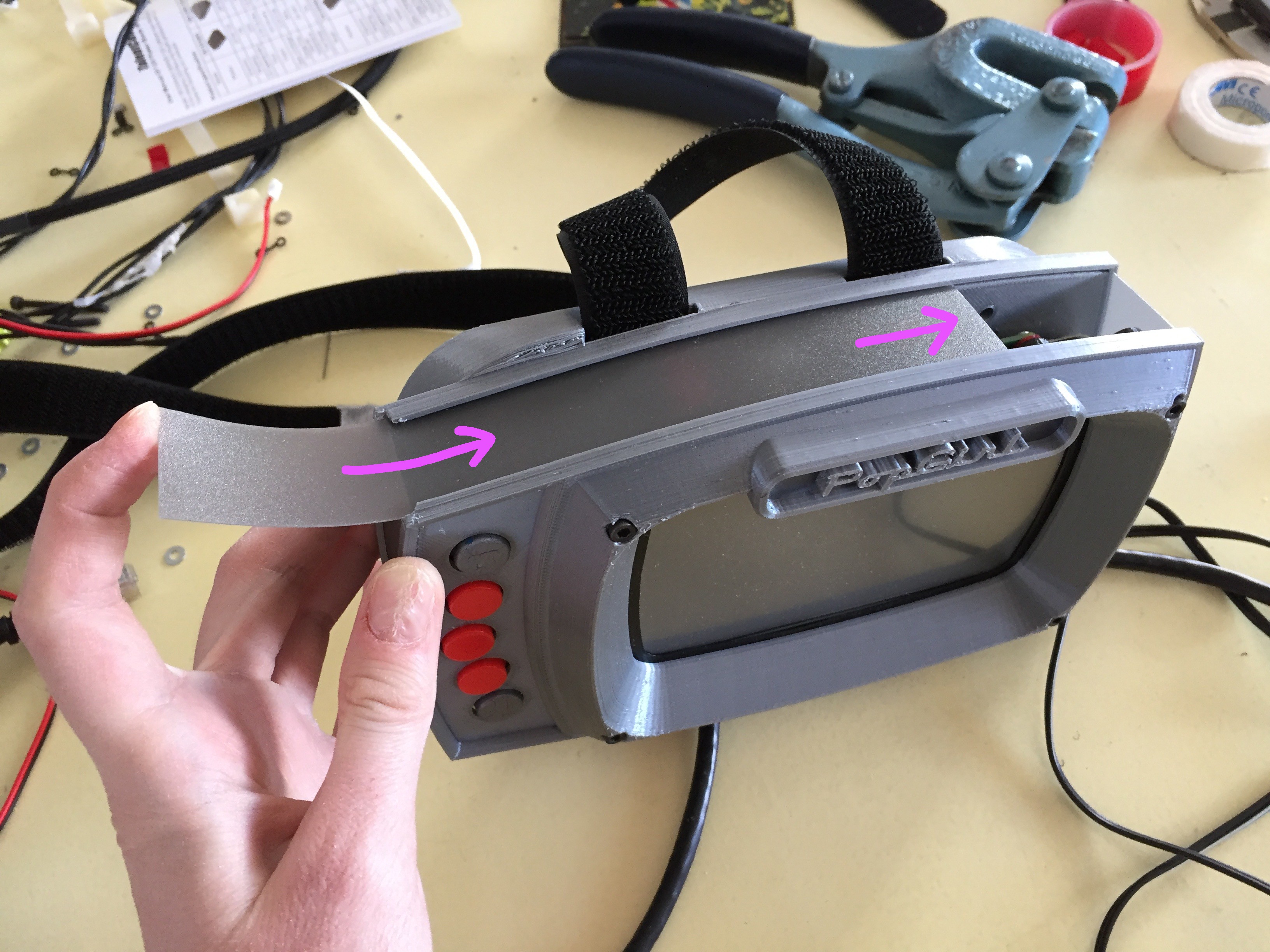

I found some semi-transparent grey sheet that defuses the inside slight from the indicator LEDs on the internal boards quite nicely. Once cut, slide them through the channels along the outside edge of the "face_plate" and the "arm_mount":

![]()

The right side of the enclosure wall should have a hole open for the CAT5 cable to pass through.

Once this finishing touch is added... you are ddddoooooonnnnneee.

![]()

The final step is to get the software running on the Pi. So, maybe don't close the thing up just yet. =P

![]()

is glorious!

![]()

The software instructions will come shortly! Until then- enjoy my wiggly concept sketch of the UI layout!

![]()

-

3POPgirl Software Setup

PopGirl Hardware and Software

Much of this is typed from memory and may be missing a step or some other detail here or there. Please feel free to share any corrections or contact us to help you get through a step that is failing.

In a nutshell:

- Set up a RaspberryPi Zero W with a fresh Raspian.

- Enable SSH and VNC.

- Disable the serial console.

- Increase the GPU RAM allocation to 128MB.

- Remove the Oracle Java and install OpenJava and OpenJavaFX.

- Install Pi4J

- Install WiringPi to version 1.2 or newer.

- Test our JavaFX based app.

- Automate the app startup at boot time.

HARDWARE

The PopGirl uses a Raspberry Pi Zero W to drive a AdaFruit 5" LCD with touch panel. The serial port pins (RX and TX) on the GPIO connector are level translated to 5V signal levels for communication with the heart shaped sensor processor board that is located in the heart-shaped backpack.

The sensor board collects and formats sensor data and then bursts them over the serial line once every half-second. The Raspberry Pi listens for this packet and decodes the values into their respective display values.

RASPBERRY PI ZERO

Configure a microSD card to run "Raspian with Desktop" from:

https://www.raspberrypi.org/downloads/raspbian/

If you are new to Raspberry Pi, there are a number of utilities to burn the Raspian image to the SD card. On our Mac, we used: Apple Pi Baker https://www.tweaking4all.com/?s=apple+pi

At first, you should hook your Raspberry Pi up to a regular monitor, keyboard and mouse. Boot the system up.

You will want to ultimately enable SSH and VNC so that you can administer and test the app from the comfort of your PC or Mac. Here is a link for how to enable SSH and VNC. Any other services should be left alone at this point as we don't use them.

https://www.raspberrypi.org/documentation/remote-access/

Disable Serial Console (because we need to use it for our hardware).

Read this to understand how to configure the serial: https://www.raspberrypi.org/documentation/configuration/uart.md

See the section called "Disabling Linux's use of console UART"

SOFTWARE

The PopGirl app is written in JavaFX using OpenJava8 but also leverages Pi4J and WiringPi to allow serial port communication as well as GPIO functions. There are a number of steps to get the stock Raspberry Pi ready for running the Java application.

The Oracle Java8 that is included with the Raspbian distribution will not work for JavaFX. Oracle has decided to decouple JavaFX from the core Java going forward. Future versions of Java will have a better mechanism for add JavaFX as an optional module, but for now we need to uninstall the Oracle Java and replace it with OpenJava. Then we can add the OpenJFX library.

Remove Oracle Java:

sudo apt-get remove --purge oracle-java8-jdk

Add Open Java:

sudo apt-get install openjava openjfx

WiringPi (to access the GPIO/Serial pins from Java)

The version of wiring-pi should be 1.2 or above. If it's 1.1 then you need to replace it:

curl -s get.pi4j.com | sudo bash

This Pi4J reference may also help: http://pi4j.com/install.html

GPU Memory Setting:

From the Desktop go to: [Menu] --> [Preferences] --> [Raspberry pi config..] --> [Performance]

Adjust the GPU memory to 128

APPLICATION

At this point, JavaFX applications should run OK.

Hiding the mouse cursor

Since we are using a touch screen, we want the mouse cursor to disappear. There's an app for that:

https://spellfoundry.com/2016/05/29/configuring-gpio-serial-port-raspbian-jessie-including-pi-3/

Let's assume that your Java app is called "PopGirl.jar" and you uploaded it into /home/pi/

Notice that we need to tell java to set the pi4j.linking=dynamic property so that it uses the newer version of WiringPi.

Running the app from the command line (you will need to set the X-display screen number):

export DISPLAY=:0

/usr/bin/java -Dpi4j.linking=dynamic -jar /home/pi/PopGirl.jar

If that's all working, then lets make the JAR start at boot.

Autostarting the app:

Edit: ~/.config/lxsession/LXDE-pi/autostart

Add this line to the end of the file (notice it starts with @ symbol):

@/usr/bin/java -Dpi4j.linking=dynamic -jar /home/pi/PopGirl.jar

The app should start up ten or so seconds after the desktop comes up.

If you need to debug why the app might not be coming up on it's own then look in this log file for clues:

cat /home/pi/.cache/lxsession/LXDE-pi/run.log

Sarah Petkus

Sarah Petkus

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.