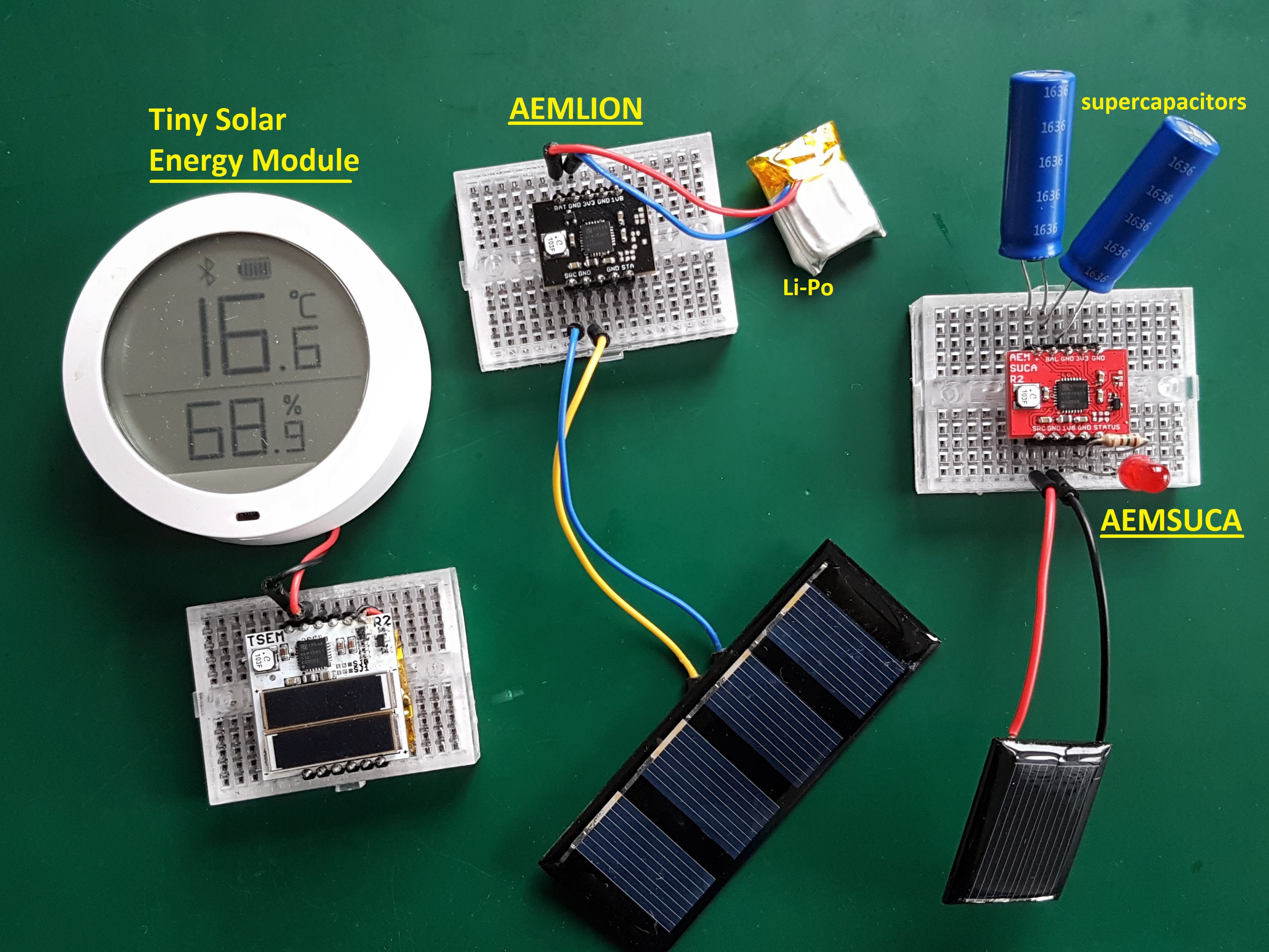

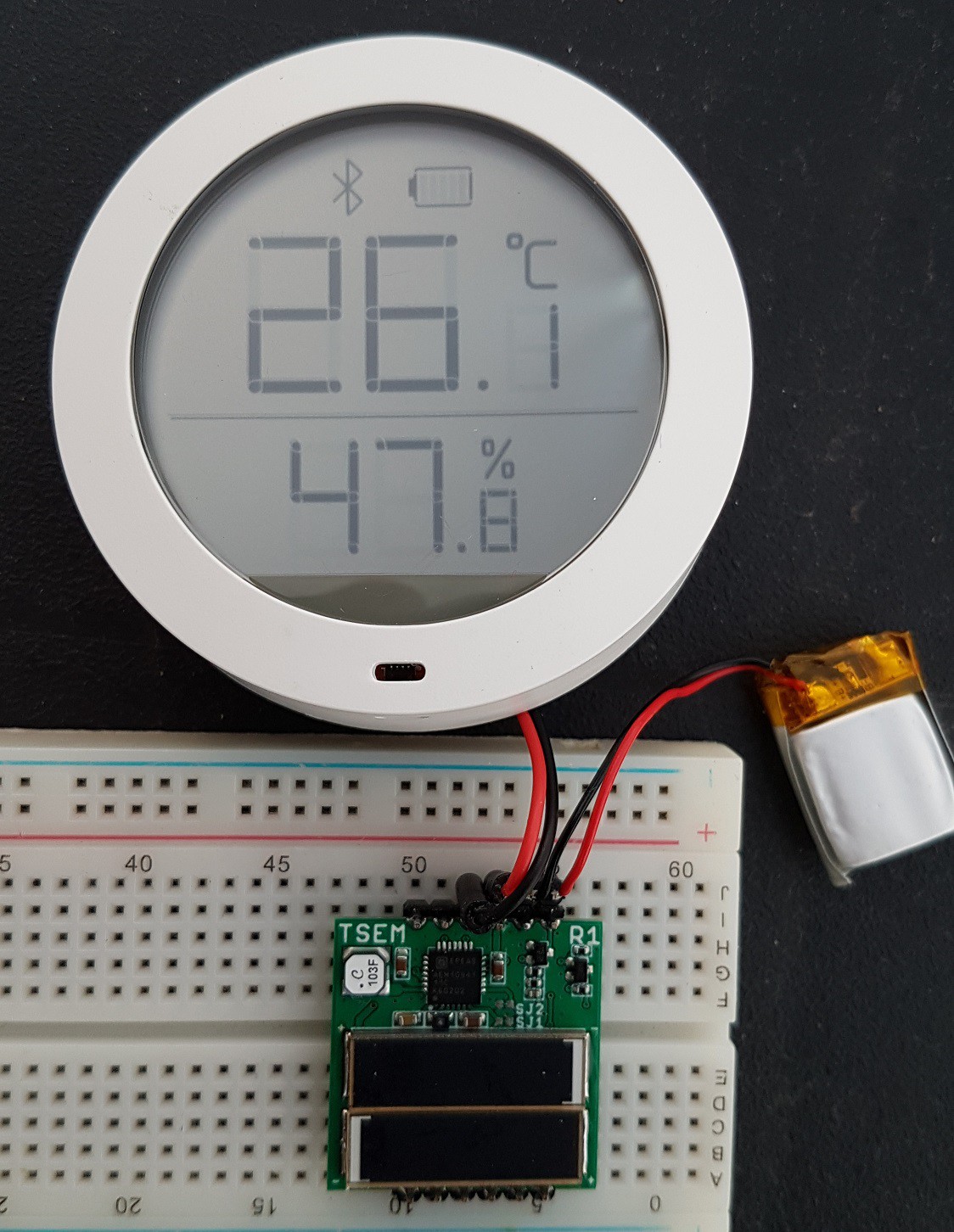

Ideal for indoor applications

The AEM10941 harvesting IC is very suitable for indoor applications because it has an ultra low power startup. The boost converter starts at a very low 380 mV input voltage and 3 uW input power. The IC gets most power out of the solar cells by doing MPPT maximum power point tracking every 5 seconds. In addition the mono crystaline solar cells have a very wide spectral range resulting in 22% efficiency. This makes TSEM very suitable for indoor applications.

How much energy does is harvest indoors?

Indoor light is about 1/100th of outdoor light or 10W/m2. At that power solar cell open voltage is 0.458V and I estimate Vmp at 0.36V per cell. Since we have two in series the booster will work at 0.72V input voltage. At that voltage boost efficiency is about 75% . LiPo charge efficiency is about 95%. Battery current is 5.72 times smaller than the solar current because the voltage increases from 0.72 V to 4.12 Volt. Finally I assume that indoor light is available for 10 hours a day. 44mA * 1/100th * 75% * 95% * 0.72V/4.12V * 10 hrs = 0.55 mAh is harvested every day. So an application must have an average current less than 0.55mAh/24h = 23uA, that's enough for a simple Bluetooth Low Energy beacon or a very simple LoRa application. However if the device is in full sun for only one hour a day it harvests ~10x more: 7 mAh.

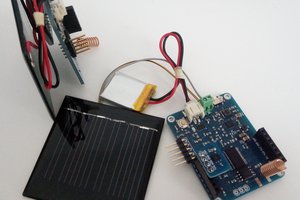

If you need to harvest more then you may connect an external solar panel to the castellated via's. Below is a comparison between the on-board solar cells and external solar cells with respect to cost, dimensions, and the energy harvested per day.

| Solar panel | Harvested energy per day, indoors (mAh) | Application average current (uA) |

|---|---|---|

| 2x $1.02 On-board 0.5V/44mA 22x7mm Ixys KXOB22-12X1L | 0.55 | 23 |

| 1x $1.06 External 1V/100mA 30x25mm | 1.1 | 45 |

| 1x $1.31 External 2V/100mA 79x28mm | 2.9 | 120 |

| 1x $1.18 External 4V/100mA 70x70mm | 6.7 | 279 |

The harvested energy can be stored in this 110mAh 3*20*25mm LiPo battery. This battery fits very nice below the module.

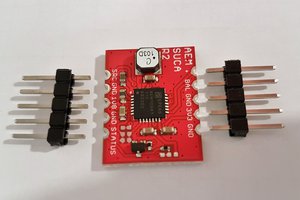

Specifications

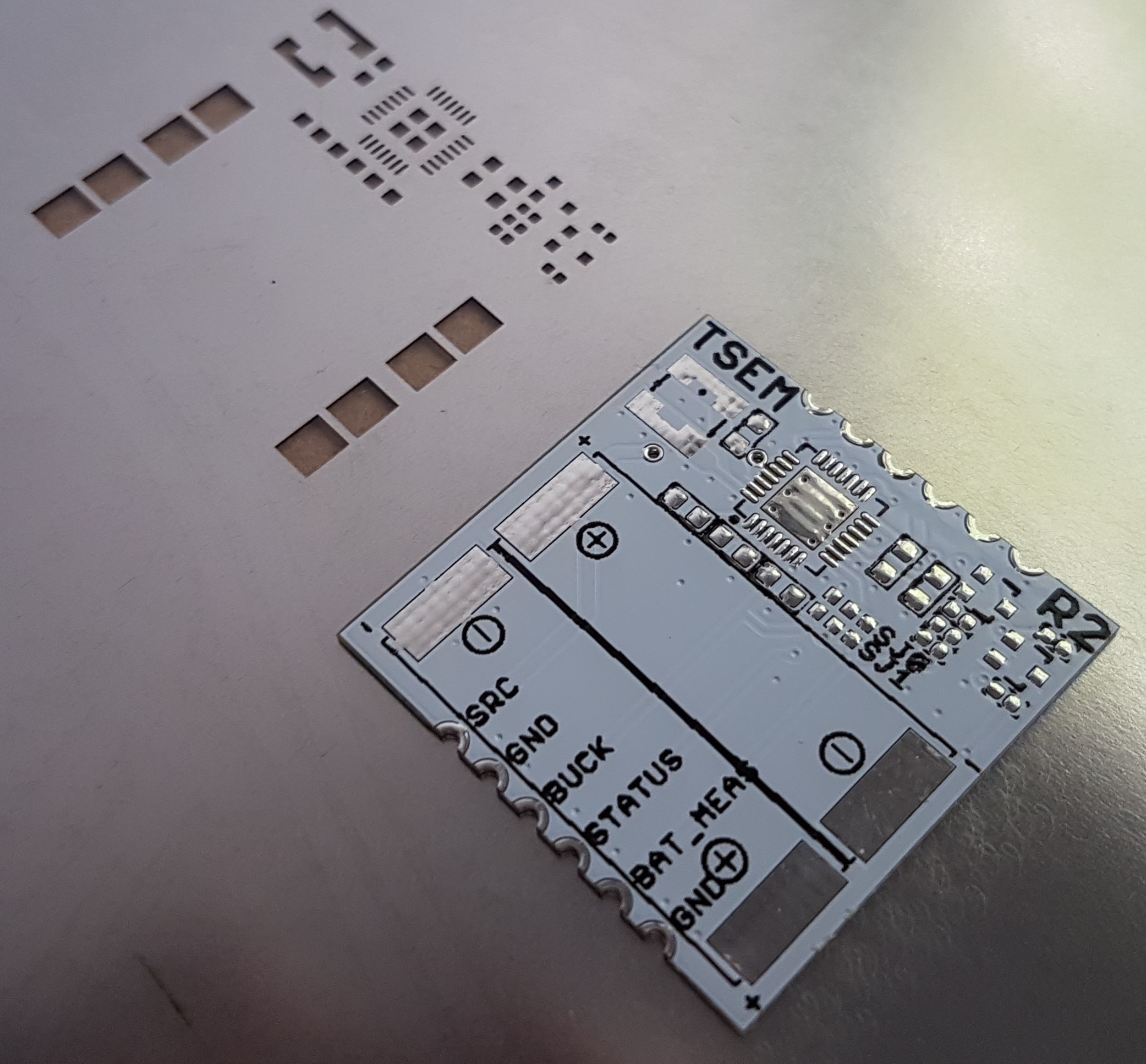

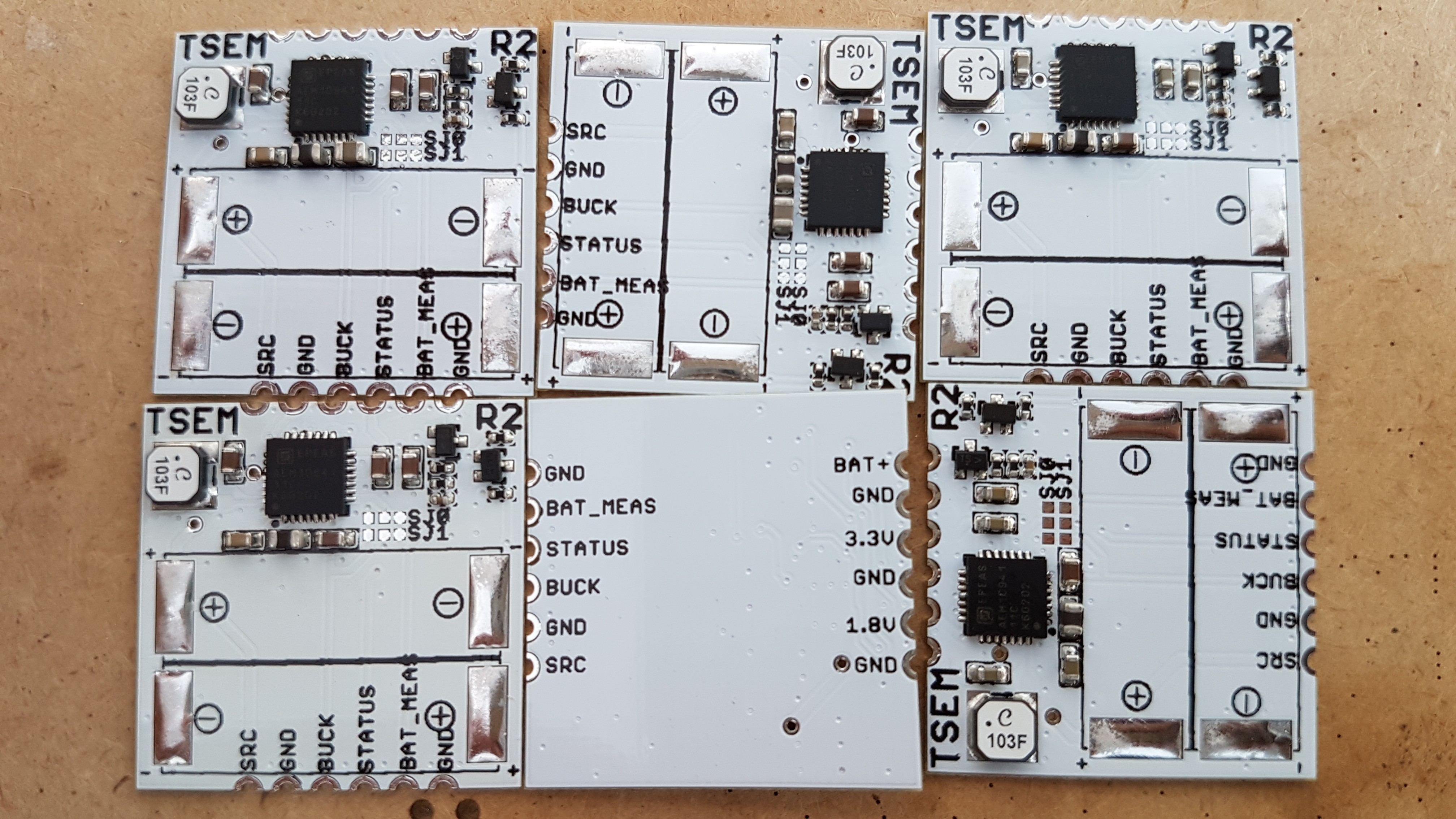

- PCB 2 layers 25.4 x 25.4 x 0.6 mm (1 x 1 inch)

- 2 onboard solar cells in series, 0.5V/44mA each, 22 x 7 x 1.8 mm each

- harvesting IC input voltage 50mV to 5V. Input current max 110mA. MPPT every 5 secs, MPPT set to 70% (adjustable).

- Battery: connect an external 3.7V Li-Po battery

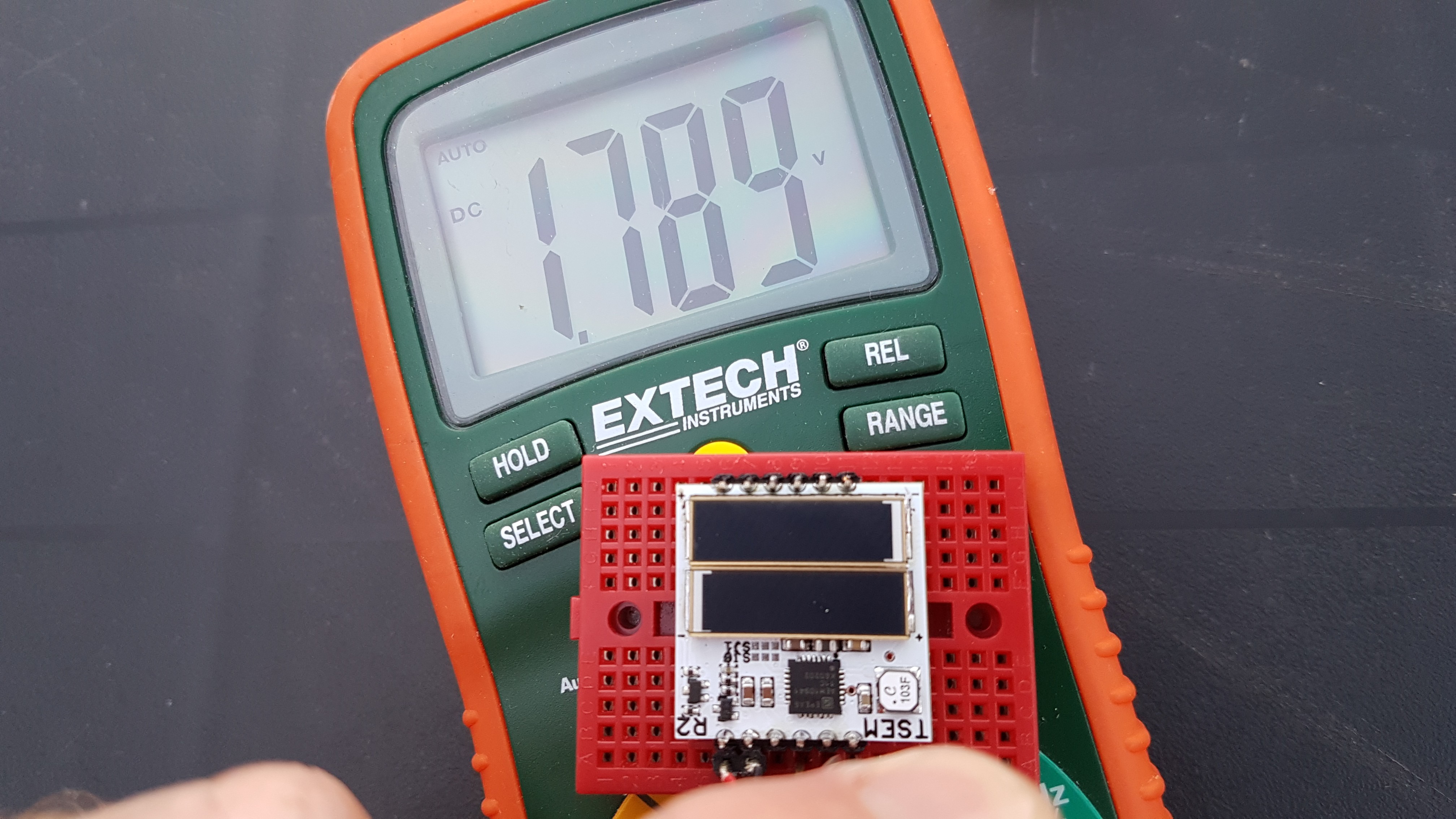

- 3.3V/80mA and 1.8V/20mA regulated outputs. These are enabled when battery voltage is between 3.60V and 4.12V (max charge voltage)

- voltage divider to monitor battery voltage using the host MCU

- 3.3V status output pin that warns the host MCU if battery voltage drops below 3.60V

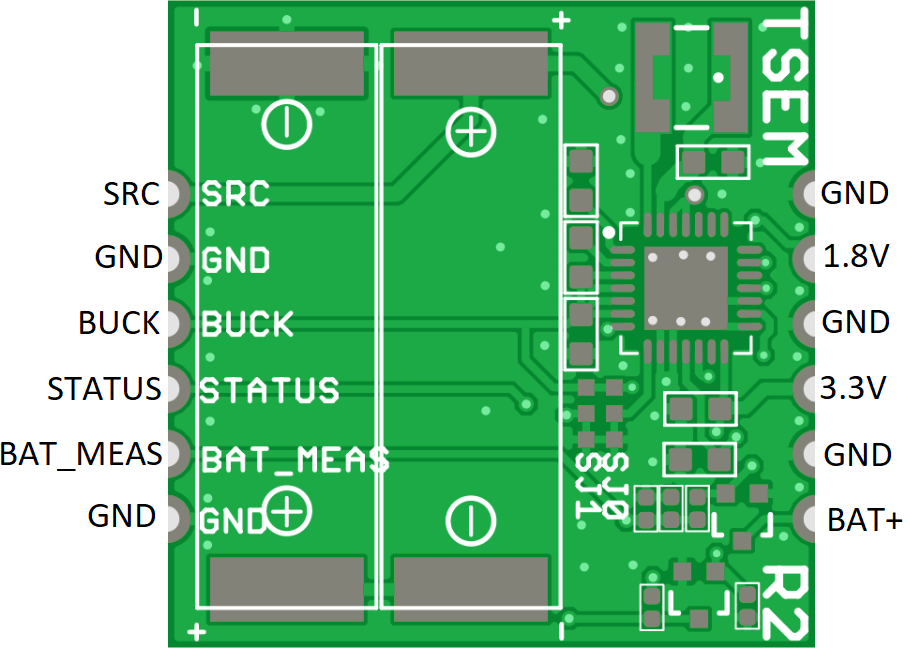

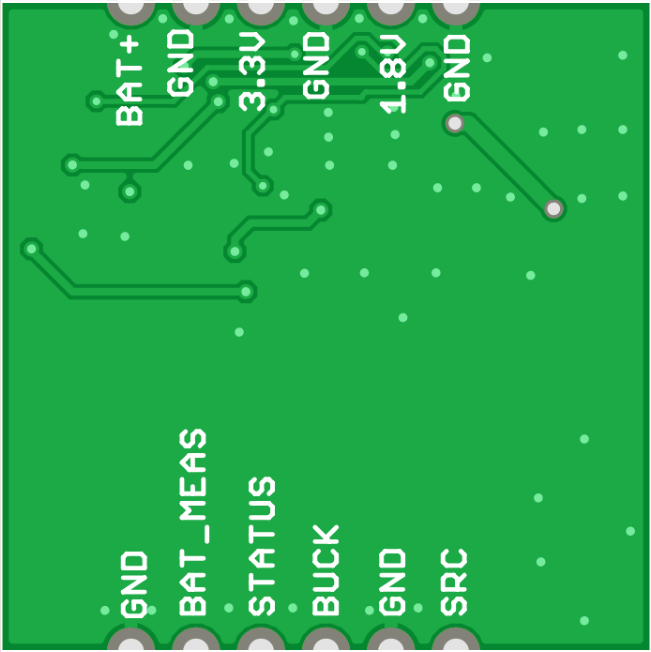

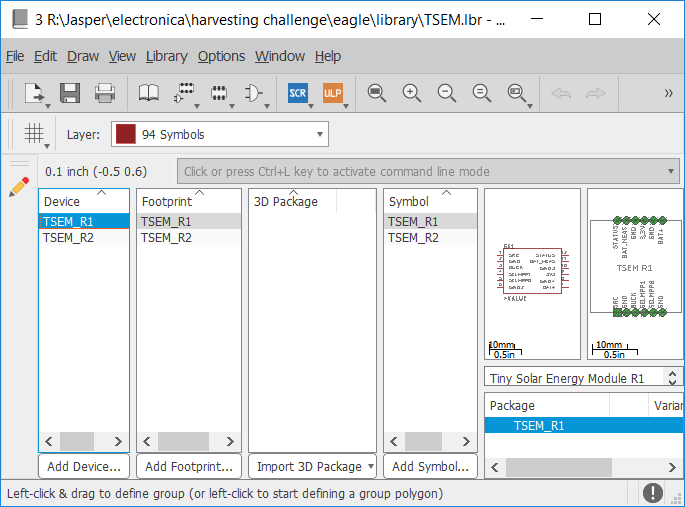

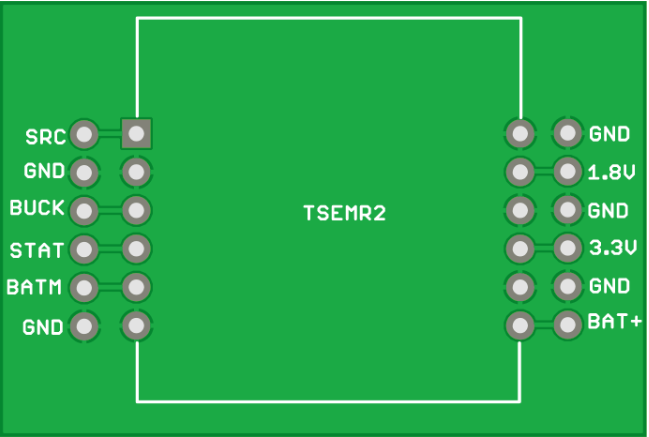

Pinout

SRC - solar panel positive terminal, input to the harvesting IC, connect only when you use external solar panel in stead of onboard solar cells

GND - solar panel negative terminal, connect only when you use external solar panel in stead of onboard solar cells

BUCK - can be used to pull SELMPP1 and SELMPP0 high, 2.2V

STATUS - open drain output with 1M pull up, when battery voltage falls below 3.6V it goes low 600ms before the 3.3V output is disabled. Can be used to warn the host MCU to gracefully terminate writing to eeprom/flash and prepare for power outage. Voltage level 0/3.3V.

BAT_MEAS - analog output, provides a divided battery voltage for the host MCU with ratio 10/(4.7+10) =0.68*Vbat

GND -

BAT+ - connects to Li-Po positive terminal

GND - connects to Li-Po negative terminal

3.3V - power supply output, provides 3.3V to your application circuit

GND - ground connection for the 3.3V output

1.8V - power supply output, provides 1.8V to your application circuit...

Read more » Jasper Sikken

Jasper Sikken

Tobias

Tobias

Do you have an approximate how much longer the battery can last when connected to the TSEM?