-

Files released for OpenTorque v2

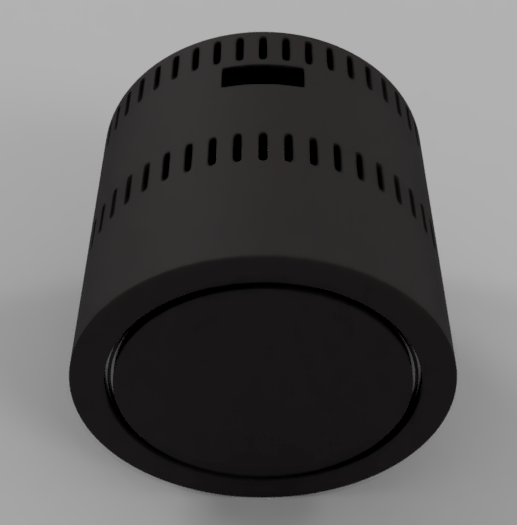

02/15/2019 at 23:17 • 1 commentV2 actuator on the right:

![]()

The first OpenTorque v2 unit is built and working successfully, so I'm releasing the design files. You can get them at https://github.com/G-Levine/OpenTorque-Actuator. They're licensed under Creative Commons BY-SA 4.0, so feel free to modify them and use them in your own projects.

I'm currently prioritizing passive cooling because my walking robot will have a low duty cycle on the motors. As a result, this version is releasing with passive cooling only. Active air-cooling will come in a future update. I'd recommend it if you plan on building a robot arm, as the duty cycle on an arm is near 100%.

Other future updates will include support for the single-axis ODrive board (once it's released). This will allow daisy-chained power and data connections between actuators, greatly simplifying the wiring.

-

OpenTorque v2

11/17/2018 at 00:36 • 2 comments![]()

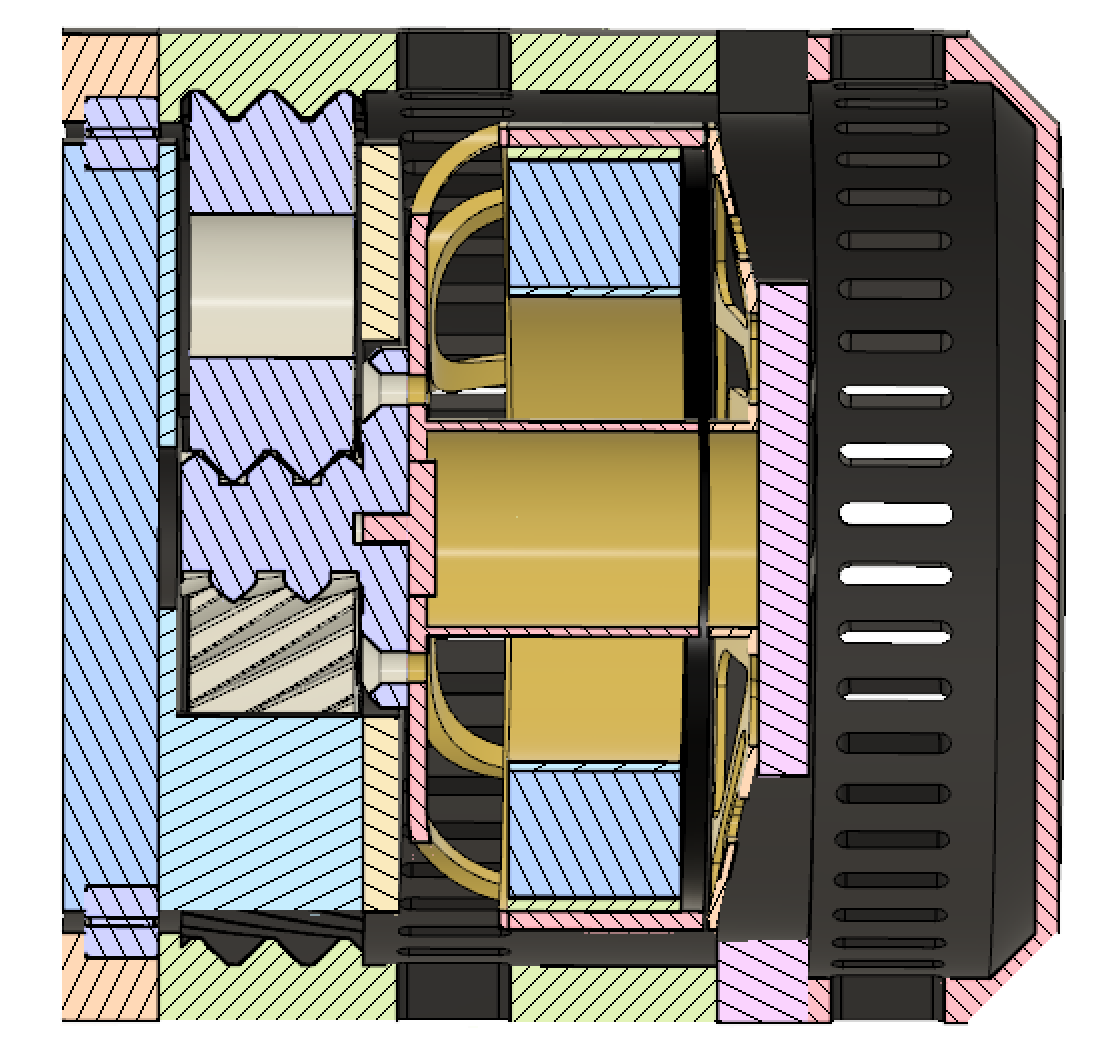

This is the new version of the OpenTorque actuator (still under development). I've made a number of design improvements:

- The two thin-section ball bearings are replaced by a single cross-roller bearing.

- Better cooling. The GPU fan is replaced by a powerful 100mm centrifugal blower.

- Higher gear ratio of 8:1, for higher peak torque and reduced I2R losses under normal loads.

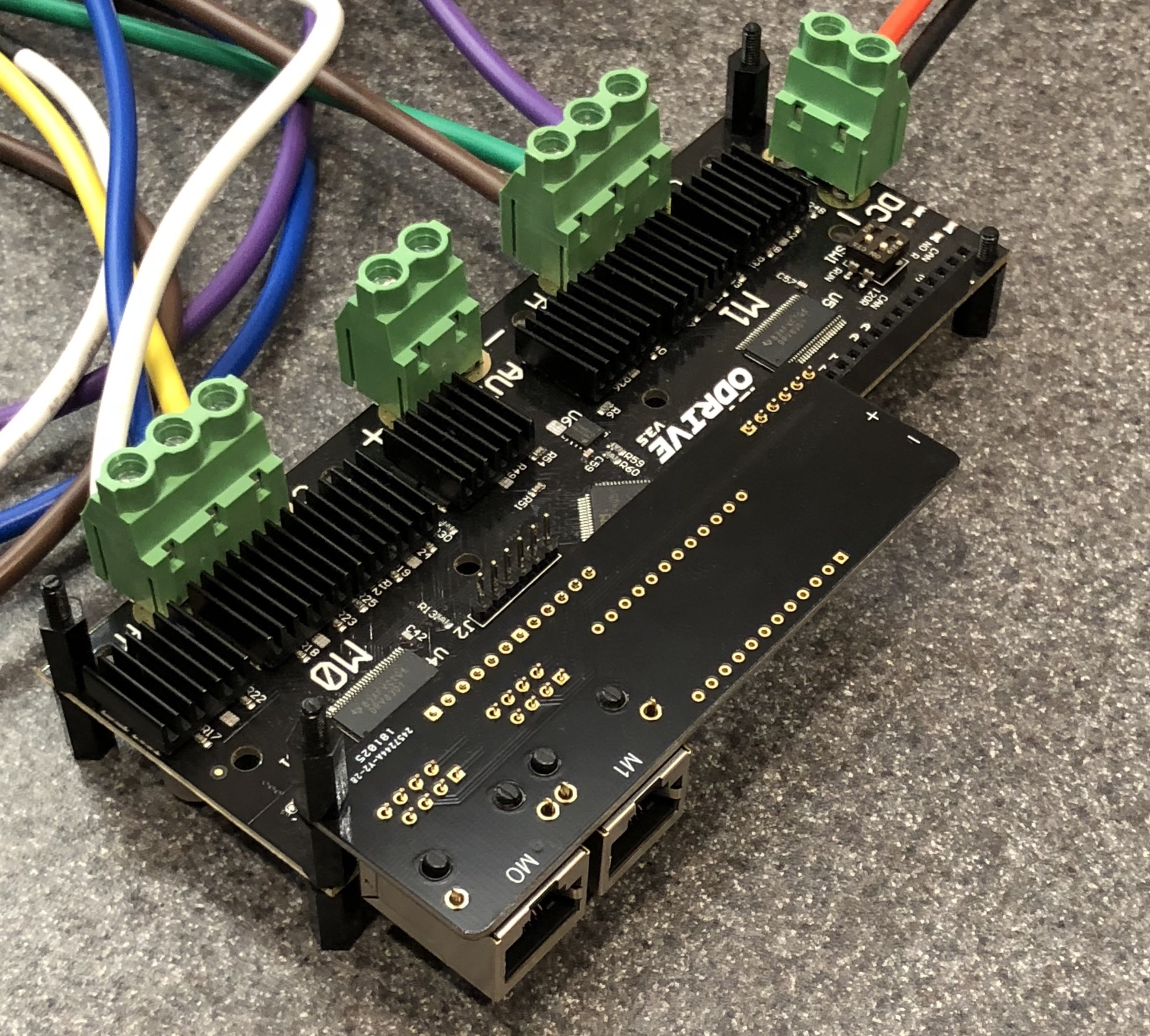

- Custom PCB that breaks out the encoder SPI lines along with thermistor output and fan power to an RJ45 connector. This connects via a CAT7 patch cable to a custom daughterboard on the ODrive, pictured below.

- Lighter and more compact than the V1 actuator, and a closed back (no more exposed fan).

- Direct-drive version, in addition to the quasi-direct-drive version.

![]()

These improvements are aimed at making it easier to build systems with large numbers of OpenTorque actuators. I'm using the new actuator for my Blackbird Bipedal Robot but it's also well-suited for quadrupeds, robot arms, exoskeletons, and so forth.

-

Thermal Testing

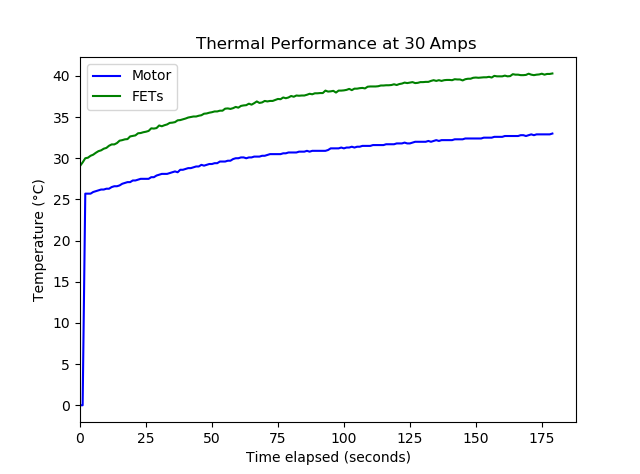

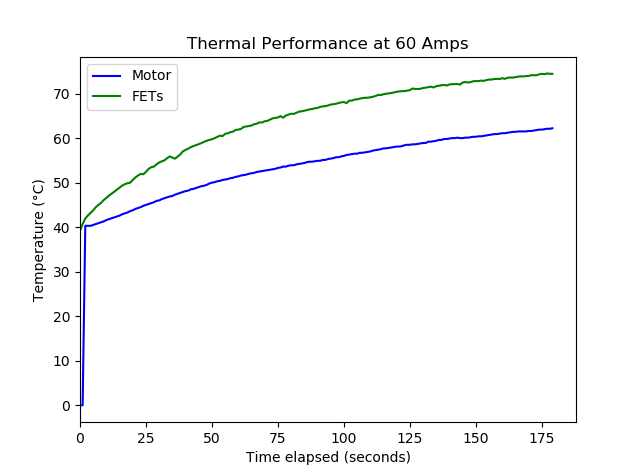

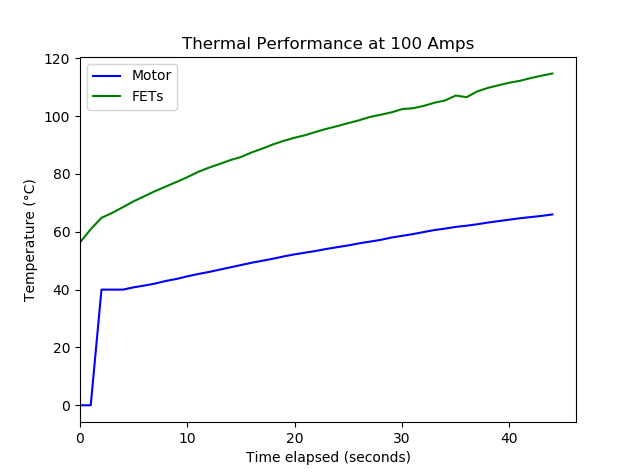

07/25/2018 at 07:54 • 1 commentI tested the thermal performance at 30A, 60A, and 100A. This was done by setting the calibration current to the desired level, then disconnecting the encoder and having the motor search for the index pulse. This results in the heat being evenly distributed among the 3 phases, as described here: https://discourse.odriverobotics.com/t/testing-forced-air-cooling-with-a-5060-motor/483. I collected data from a thermistor epoxied into the motor windings, and the built-in thermistor on the ODrive board.

Conclusions:

- The motor cooling works quite well. Three minutes of sustained 60A current caused a temperature rise of less than 20 degrees.

- The FETs on the ODrive board heat up quickly. Currently I'm just cooling the board with a desk fan, so I'll have to design a more sophisticated cooling solution.

![]()

![]()

![]()

-

Bipedal Robot Concept

07/04/2018 at 04:11 • 0 comments![]()

I'm building a bipedal robot inspired by Agility Robotics' Cassie. It uses 10 OpenTorque actuators.

These actuators are backdrivable and able to absorb kinetic energy during the walk cycle. As a result of this, there's no need for the complex series-elastic linkages present in Cassie. Instead, each leg consists of a simple parallelogram linkage with an extra joint at the ankle.

Carbon fiber tubes are used for the linkages in order to keep inertia as low as possible. The total weight is in the ballpark of 30 pounds -- substantially lower than the 60-70 pounds that Cassie weighs. This is helped by the use of 3d-printed plastic rather than CNC aluminum parts. (All the structural parts will be printed out of NylonX.)

To control this robot, I'm going to use reinforcement learning. I'll create an OpenAI training environment with a simulation of the robot, then let the controller learn a stable walking gait on its own. This is a lot easier than programming a walking gait by hand, and it's already been done successfully on the Minitaur robot.