How To

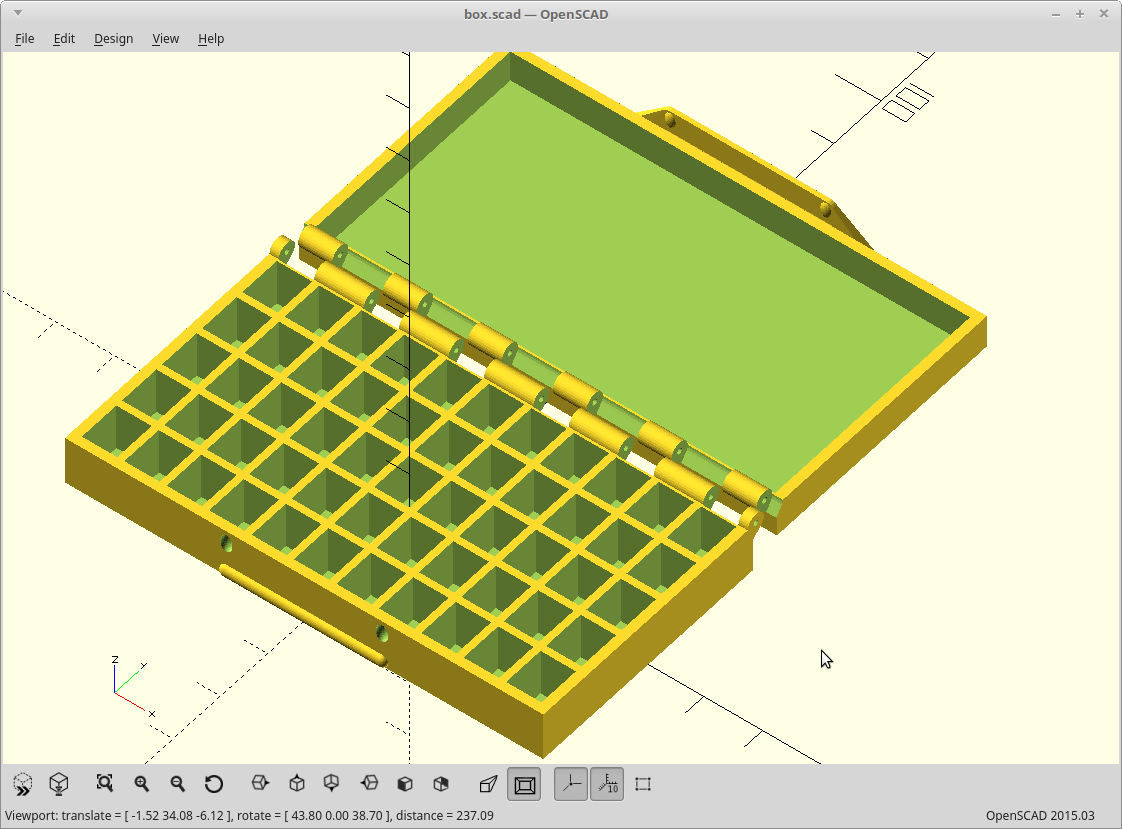

- Open up box.scad in your favorite text editor and OpenSCAD. Uncomment 'assembly();' and save to see what you are doing.

- Modify the arrays until you have the box you want.

- The rows array defines the number and size of each row. Similarly the cols array defines the number and size of columns.

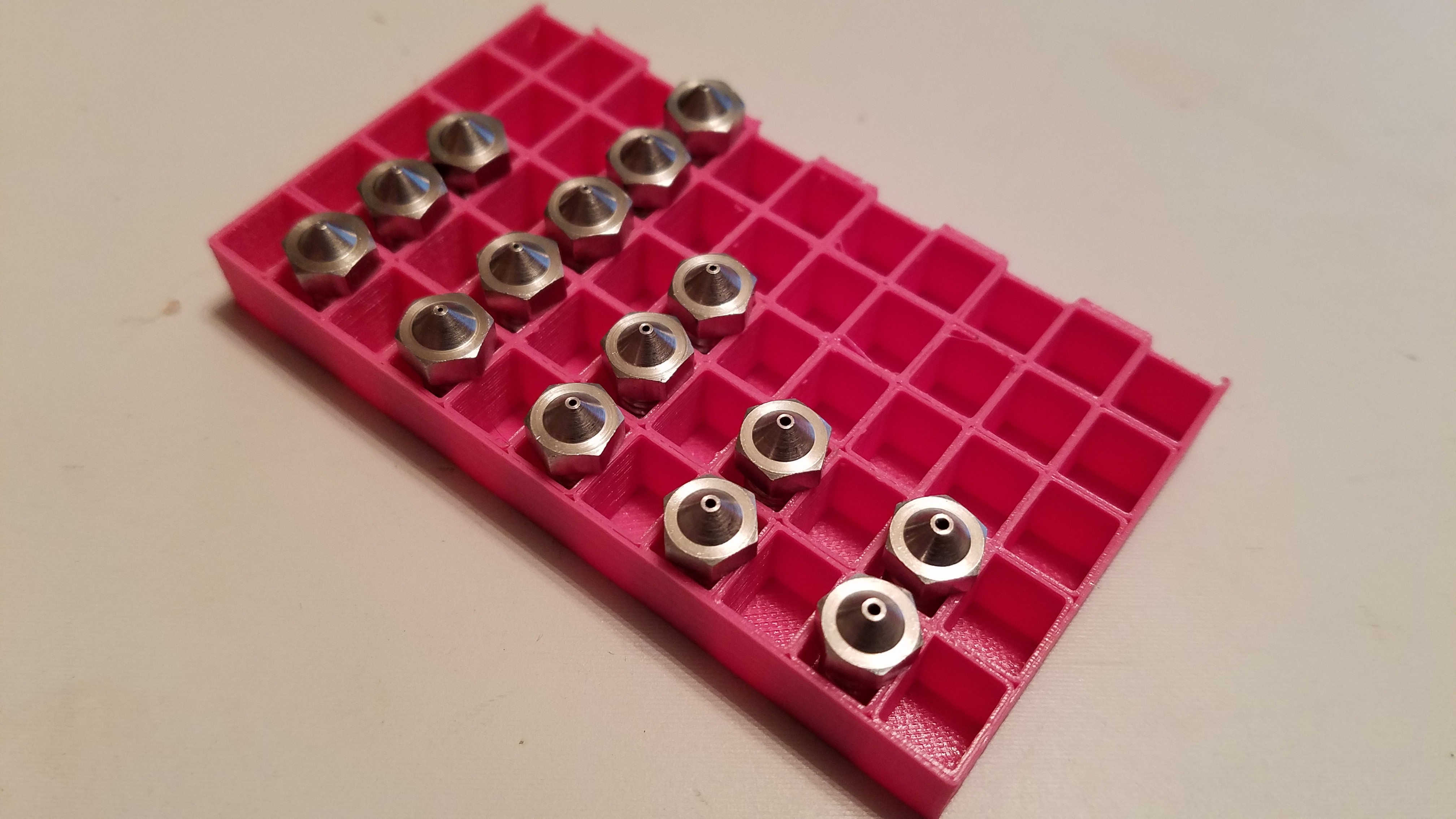

- Make the inner/outer wall thickness an even multiple of your nozzle size for best results.

- Wall thickness currently is subtracted from the cell size. For example, if you want a 7mm opening and are using 0.8mm walls, that array element would then need to be 7.8mm.

- Boxes with an odd number of columns generate better hinges. An even number will result in one end being un-terminated.

- Comment out 'assembly();', uncomment 'box();', save, render, export to stl.

- Comment out 'box();', uncomment 'lid();', save, render, export to stl.

- Slice. I would suggest enabling 'combing' and the hinge does better with a relatively low layer height (like 0.1mm for a 0.4mm nozzle).

- Print both parts, press in a bit of wire for a hinge pin, and enjoy your divided box.

MasterOfNull

MasterOfNull

Isaac S. Gentry

Isaac S. Gentry

Nice job. I'm going to have to start playing with Open SCAD - I could use a bigger version of such a box to organize RF adapters.