Robot Tank /w Jetson Nano

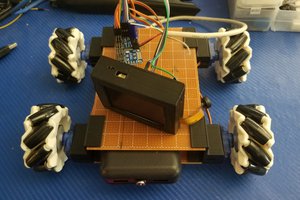

Starting work on a tank track robot. Purchased a Jetson Nano for the main controller brain. Arduino Mega + Ramps for motor control

Starting work on a tank track robot. Purchased a Jetson Nano for the main controller brain. Arduino Mega + Ramps for motor control

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

images.jpgInspiration for track shocksJPEG Image - 11.23 kB - 07/02/2019 at 00:50 |

|

|

20190630_193944.jpgMock up of track mounts. This went through 3 changes before i was happy. Now i cut my first aluminum pieces. Jigsaw and drill press. 1/4" aluminum sheet i had laying around. Should have enough to do other side and base plate of robot.JPEG Image - 3.67 MB - 07/02/2019 at 00:41 |

|

|

trackassemblytest_5pack.png5 pack of track pieces. for printing i combined 5 of them. I can print about 30 on my ender 3. But i typically print 20 at a time. In PLAPortable Network Graphics (PNG) - 96.22 kB - 06/25/2019 at 01:56 |

|

|

chassis_test2.pngtrack assembly test 2. Modified the brackets and moved the wheels around for better clearance. The blue squares are there so i can print to size A paper and align front and back pieces together. then i can glue to aluminum and cut out the shape with wheel alignment.Portable Network Graphics (PNG) - 338.99 kB - 06/25/2019 at 01:50 |

|

|

lowertrack_assembly.pngLower Track Assembly. Spring loaded wheels. Uses standard skateboard bearingsPortable Network Graphics (PNG) - 85.79 kB - 06/25/2019 at 01:47 |

|

|

Purchased 2 lipo batteries for this and printed a case to hold them under the main plate.

Also ordered 2 more aluminum sheets cut to size. With standoffs. That way i can put all electronics on the current base then another sheet above that to mount camera/sensors etc. Extra plate just in case i want 3 levels. Already super heav,y so not sure.

Cleaned out the garage and made storage shelfs. That is where the project is living right now. Life got busy last two years. and i've done almost nothing during pandemic :( Time to get back to this project.

See my other project, working on smaller robot. I wanted to build a large controller for this one. So my small robot gets a small controller to see how that goes first.

Then i can spend a lot for my tank controller. need a pi, big joysticks, touch screen. Going to have to cram into the largest box print size my printer can handle. 220x220mm ...going to be a tight fit. Maybe build 3 parts and glue together or snap fit together?

Oh yah i also printed a case for the motor controller. With 2 small fans for cooling. You can see in back left of image.

Need larger standoffs. motor controller case is a little bigger then 1" and wont fit under the plate. So i need 1.25" ones if i can find them.

Okay it's been awhile since I've put anything on here. 2020 has been a strange year.

Just wanted to add a quick update. I tried to design and print a 3D case for the jetson and it did not fit. instead of trial and error day after day i found a Jetson Nano 3D case with vesa mounts. This gives me what i need a case with mounts to screw into the tank case. See images.

Also i mounted both batters to the bottom of the chassis.

Added wifi/Bluetooth module to jetson nano

Plans to build two levels on top of the base of the chassis. so top down, PTZ camera plate, Sensor plate (ultrasonic, maybe lidar), power and control plate (the chassis plate)

I've seen other robots designed this way with levels for circuits and didn't want to follow it as it seems messy, but the more i think about it i guess it makes sense to do. So i need to cut out two more plates of metal so i can have room for everything.

Case found on thingiverse here https://www.thingiverse.com/thing:4082134 Thanks to whoever you are. They just fit together on my Ender 3 and at 0.3 print height it only took 4-5 hours

So i got my parts in a couple weeks back. assembled them and needed something to hold them together. So i put a plate together and mounted them up. So far so good. A couple holes were slightly off. ill just oversize the plate holes and it should be fine. but here it is assembled. Need to get the motor controller mounted somewhere and start playing with the drive system. Make sure nothing binds up and it can turn smoothly etc...

yay, so excited today!

Just recieved my tank track brackets from my friend. Had them laser cut. They came out so nice.

Cant wait to get home and assemble these with the tracks.

printed one half of the wheels brackets. Need to print the second set.

These parts are ambidextrous so I only have to print the same piece for both sides. For the wheel holders and the suspension bracket that holds them.

Then I press fit in all the bearings into the free wheels. Hammer bench vise and a perfect sized air line quick connect to hammer them in place. The air quick connect was perfect size for the outer part of the bearings. Wish I had a press.

Finished printing and assembling the second set of tracks. only had to print 60 because i had some left over when i printed 80 the first time. about 60-70 per side.

Because i undersized the holes i had to drill each side out and i tapped the inside holes to make it easier to screw in the machine screws. plastic self tapping may be easier? but i had 4x40 1" screws already to use.

Printing my wheels for the second track set. Another 5 hours in. Finally opened my second roll of PLA. About $20 in on printing this thing. Need to print the wheel brackets and the drive wheel needs a redesign for both tracks.

Okay back to printing.

Probably wont see anything else for awhile as i print out the second track. Going to take a couple days to get all this out.

Jetson Nano came in last night. Only had time to install the OS image on SD card and open the BOX. Looking into installing ROS on the nano now. Should be fun this weekend.

Create an account to leave a comment. Already have an account? Log In.

So far it is working good. I need to get stronger springs I think. once I get more weight on it I should know. My first thought was to use RC car shocks, but that increases cost and complexity a little. The springs snap into place. I have printed the parts with holes for the springs to recess into. Hard to assemble but it works.

What i need to do is lock the nuts in place better. They jiggle loose when the track is running. thinking nylon lock nuts would do better. Or loctite, but i want to remove if needed. I may try lock washers.

p.s. I started with 5/16-24 thread count but the local hardware store only has short bolts. So i had to switch to 5/16-18 coarse threads to get bolts in 3 inch lengths. The shock tracks are using the 5/16-24 but will replace all to have same 5/16-18 i think.

The track design is my interpretation of a real tank suspension i saw. Ill post an image of my inspiration

What screws are you using for track pins? I'm working on a similar project but I'm having trouble finding suitable fasteners at diameters less than 1/4". Especially ones that are mostly unthreaded.

Yes that was my thoughts too. I ended up using 4x40 1" threaded machine screws.

Another though i had was cotter pins with c clips. like you would see on RC car suspension. but they are expensive. about a $1 each. that adds up. with a 60-70 piece track.

Another guy i saw used small nails. that would press fit into the inside part of the track.

track pieces are about 2 1/2 inch wide. so i have 1/2 inch clearance between screws.

My tracks are similar to this design i saw on youtube https://www.youtube.com/watch?v=-z8VtRG6eug but i put the guides in the print and changed the pins to screws.

Become a member to follow this project and never miss any updates

Paul Crouch

Paul Crouch

E/S Pronk

E/S Pronk

pRoFiT

pRoFiT

Wow, is that suspension system for the treads your original design? Look like a good method to help keep the vibrations from shaking the body of the robot apart. Are you happy with the results so far?