Abstract

We propose an automated guided vehicle (AGV)-based logistics transportation robot with a fork-type manipulator that are efficient in delivering various and small goods on the shelf. The proposed robot system can be divided into a main server part, a drive control part, and a fork lifter motion control part. The main server part includes the path and task planning algorithm, a communication system for exchanging information, and a database. The drive control part performs navigation control and position recognition through the camera. The fork lifter motion control part contains a control algorithm for transporting the product and basket on the shelf. To evaluate the performance of the proposed transportation robot system, the driving test was performed and a fork lifter working experiment was carried out. The experimental results show that the performance of the proposed robot system is satisfactory and can be applied to the transportation tasks in the distribution centers. Keywords: Logistics transportation robot, Fork-type manipulator, Fork lifter, Position recognition.

Introduction

As the proportion of logistics costs gradually increases, various logistics technologies are being developed to obtain price competitiveness of products through reduction of logistics costs. Especially, due to the successful commercialization of logistics transportation robots such as Amazon’s Kiva System, technology development of logistics robots has attracted great interest. Also, the element technology and robot system that can be applied to various logistics fields are being studied. Many companies are adopting various automation and information systems to increase profits and logistics efficiency.

2. Design of Transportation Robot System

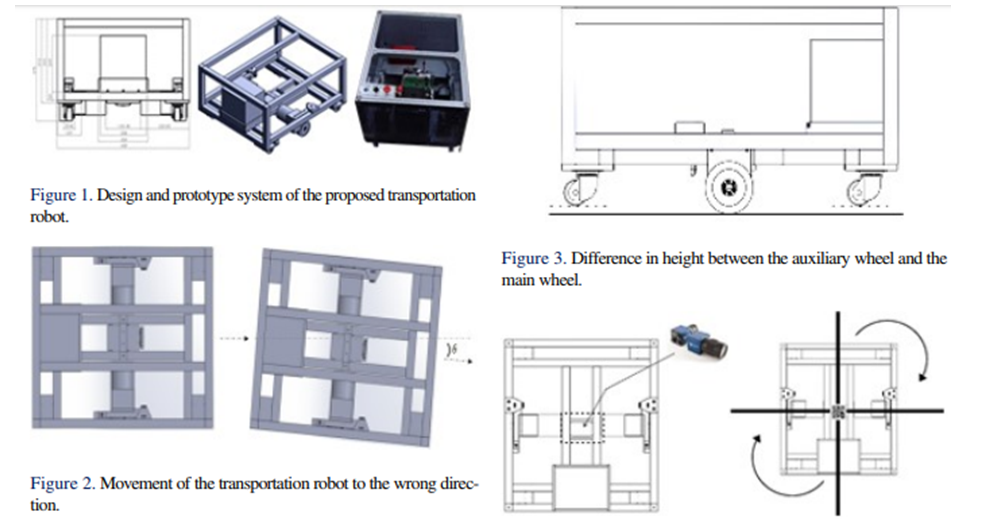

2.1 Design of Transportation Mobile Robot

The transportation robot applied to the logistics center needs driving technology, localization technology and task process technology. Driving technology is to safely transport the objects Table 1. Specification of the transportation robot Contents Values (mm) Width of robot’s frame (d) 600.0 Length of robot’s frame (L) 700.0 Radius of steerable wheel 24.4 Radius of active wheel (R) 50.0 Height of lifter’s frame 1596.0 Length of lifter’s frame 300.0 Width of fork-type element 196.0 Length of fork-type element 503.5 to a target location. The location recognition is required for driving and collision avoidance in the dynamic environment where several robots are operating. The task processing technique is to deliver products to an operator using a pallet, a shelf, or a rack, and the behavior of the robots varies depending on the tasks. The most important consideration in the design of these robots is the internal environment of the logistics center and the type of operation. Logistics transportation robots that perform diverse and precise tasks increase their development costs accordingly.

2.3 Design of the Embedded Control System

The control system of the proposed robot can be divided into a main server, a drive controller, and a forklift motion controller as shown in Figure 8. The main server plans the path of the individual transportation robots and the task schedule of the fork lifter. The information’s of paths and schedules are delivered to the robots via Wi-Fi communication. The information of completed tasks are received and stored in the server’s database. Based on the information of the stored database, it continuously calculates the path of the individual transportation robots, and transmits updated path and work plans to the logistics transportation robot in real time. The drive controller controls the drive motor to travel along the correct path to perform straight run and change of direction. The position information of the QR code is acquired through the camera at the robot. The current position is calculated through the image processing algorithm of Raspberry Pi-3 and the motor is controlled according to the path...

Read more » ensafatef

ensafatef