What are the main challenges of this project?

- Delta robot kinematics

- Motion tracking of items on conveyor

- Vacuum gripping

The following video gives you an overview over these three aspects:

Motion tracking

The position of every item is captured by a laser light barrier. This lets the robot know when the item has passed a certain position on the conveyor. Furthermore, the conveyor speed is measured by reading a encoder signal. This lets the robot know how fast the item is moving. Given that imformation, the robot's movement can be calculated so that it picks the item at the right time.

Vacuum gripper

The items are manipulated by an vacuum gripper. Since I do not have a vacuum pump, I've looked for another solution to this task:

There are two pneumatic cylinders mounted next to each other. The first cylinder is connected to a valve the either lets pressure in or pressure out. The second cylinder is connected to a vacuum cup. When pressure is applied to the first cylinder it extends. As both pistons are mechanically connected to each other, the movement of the first cylinder also force the second cylinder to extend. However, this movement generates a vacuum inside the second cylinder. This vacuum is used for picking the items.

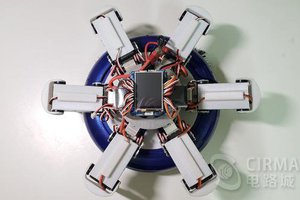

Delta Robot kinematics

Unlike simple kinematics such as linear kinematics that are often used in 3D printers

To control a delta robot with cartesian coordinates, so-called inverse kinematics is required. I've implemented inverse kinematics for delta robots according to a paper published by Robert L. Williams II: "The Delta Parallel Robot: Kinematics Solutions"

The following video gives you an intuition of what is possible with delta robots:

davidatfsg

davidatfsg

Cirmall

Cirmall

Malte Ahlers

Malte Ahlers

Victor Joo

Victor Joo

Really liked what you put together here. Quite inspirational. Hope to learn more about delta robots and inverse kinematics. Thanks!