-

Update: January 2020

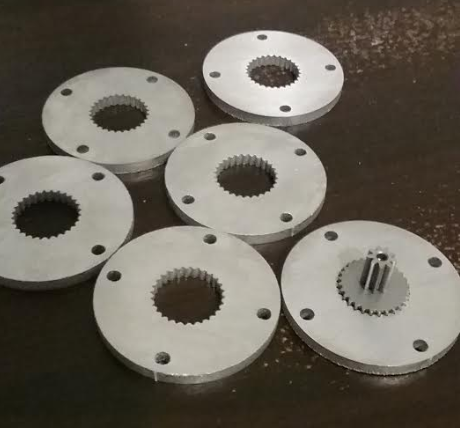

01/24/2020 at 03:55 • 0 commentsI'm now using aluminum adapters to transfer torque between the motor and sun gear as well as the carrier and output plate. This will allow the actuator to bear the stress of high-torque applications.

![]()

As far as custom metal parts go, these are dirt cheap. I purchased them from SendCutSend for a total of $29 with free shipping. I did have to tap the output plate adapters, though. Despite the low precision of laser cutting, concentricity tolerance isn't an issue as the sun gears are already mounted and centered on the 3 mm motor shaft tip. They also don't add backlash, as they're press fitted.

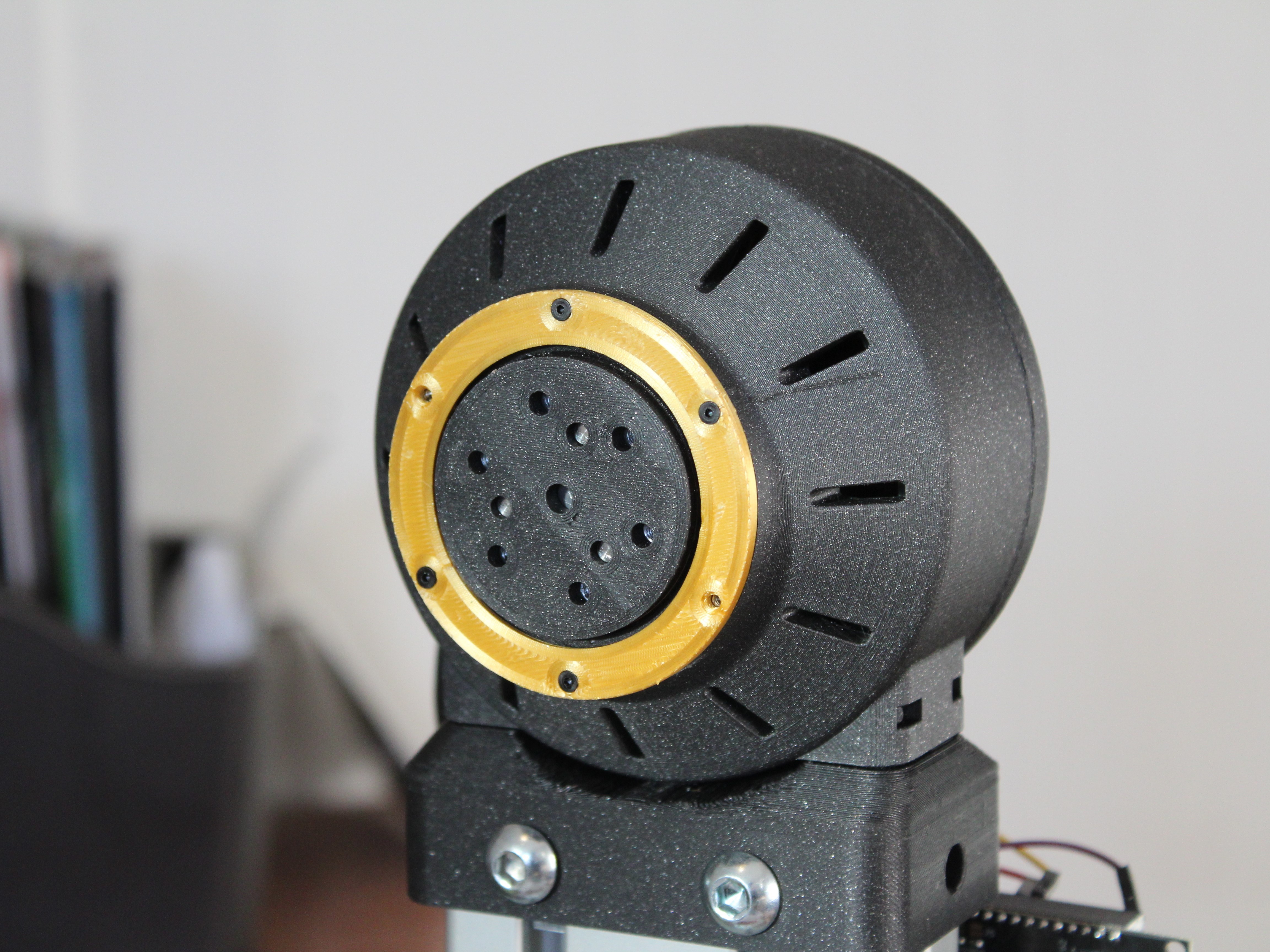

Also, vent holes for better cooling, especially if paired with a fan.

After finally getting around to running a few more tests (I've been busy with other life stuff), I'm now satisfied enough with the design to release it:

https://github.com/LocknutBushing/sprydrive

Instructions and BoM coming soon. Please critique!

In this video, I tested for 33 Nm, but theoretically the motor should be able to go much higher.

I also tested backlash. Should be roughly 0.13 degrees, or about 8 arcminutes.

-

Test #2

11/17/2019 at 22:35 • 1 commentNew and improved design. This iteration is 3 mm shorter than the previous.

I'm still getting some slight, unbalanced stiction when playing with the mechanism by hand, until it's connected to the motor. Once it's all fastened together the motion feels perfectly smooth, which is odd to me. My only guess is that the bearing support the motor provides to the sun gear is enough to fix whatever axial misalignment there is, so it's a non-issue...?

-

Test #1

11/17/2019 at 22:29 • 0 commentsFirst test of the actuator. It was a bit wobbly; I had to adjust some tolerances afterwards.

Ben Bokser

Ben Bokser