-

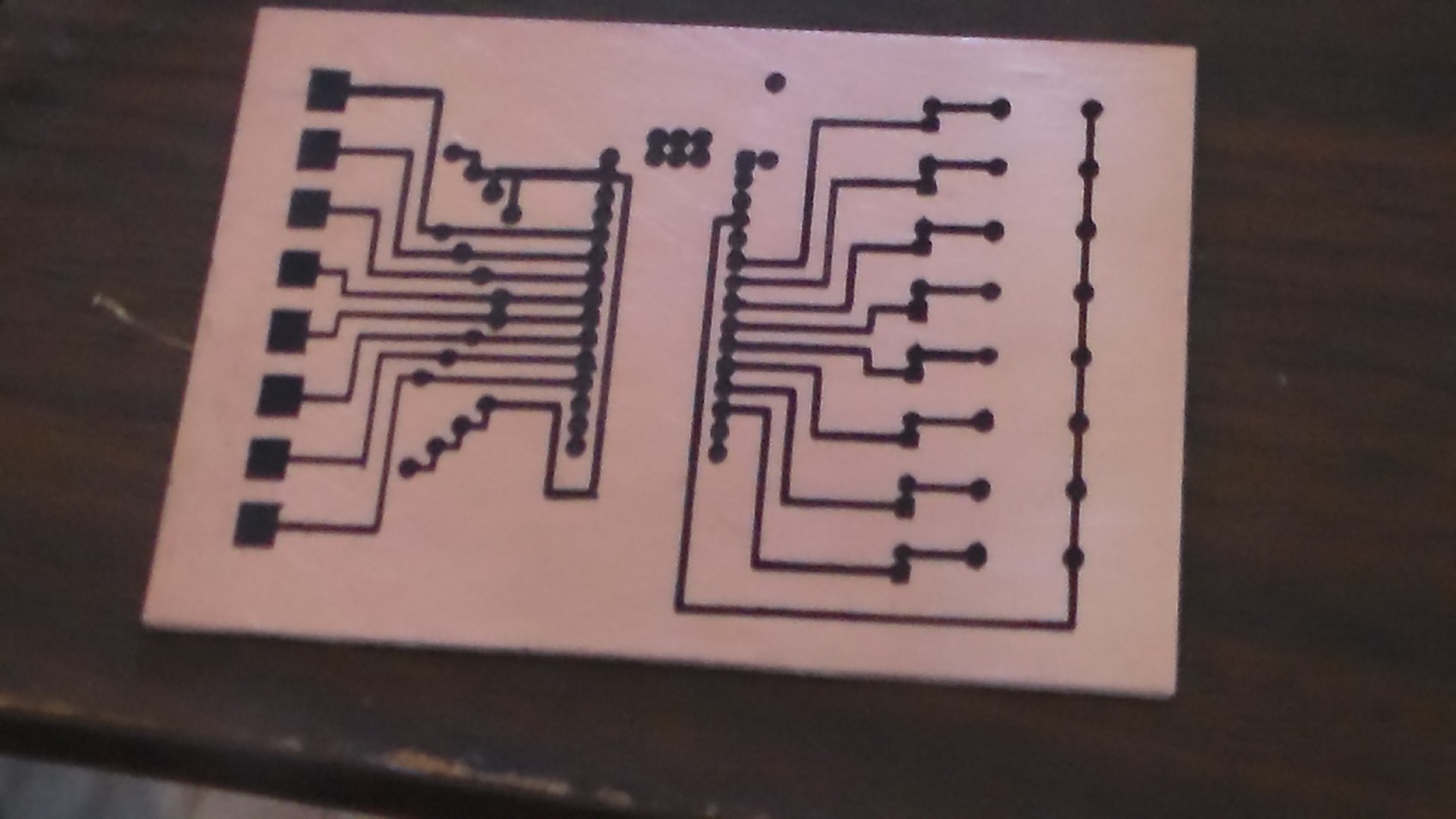

Trying a couple layers..

04/07/2020 at 23:27 • 1 comment -

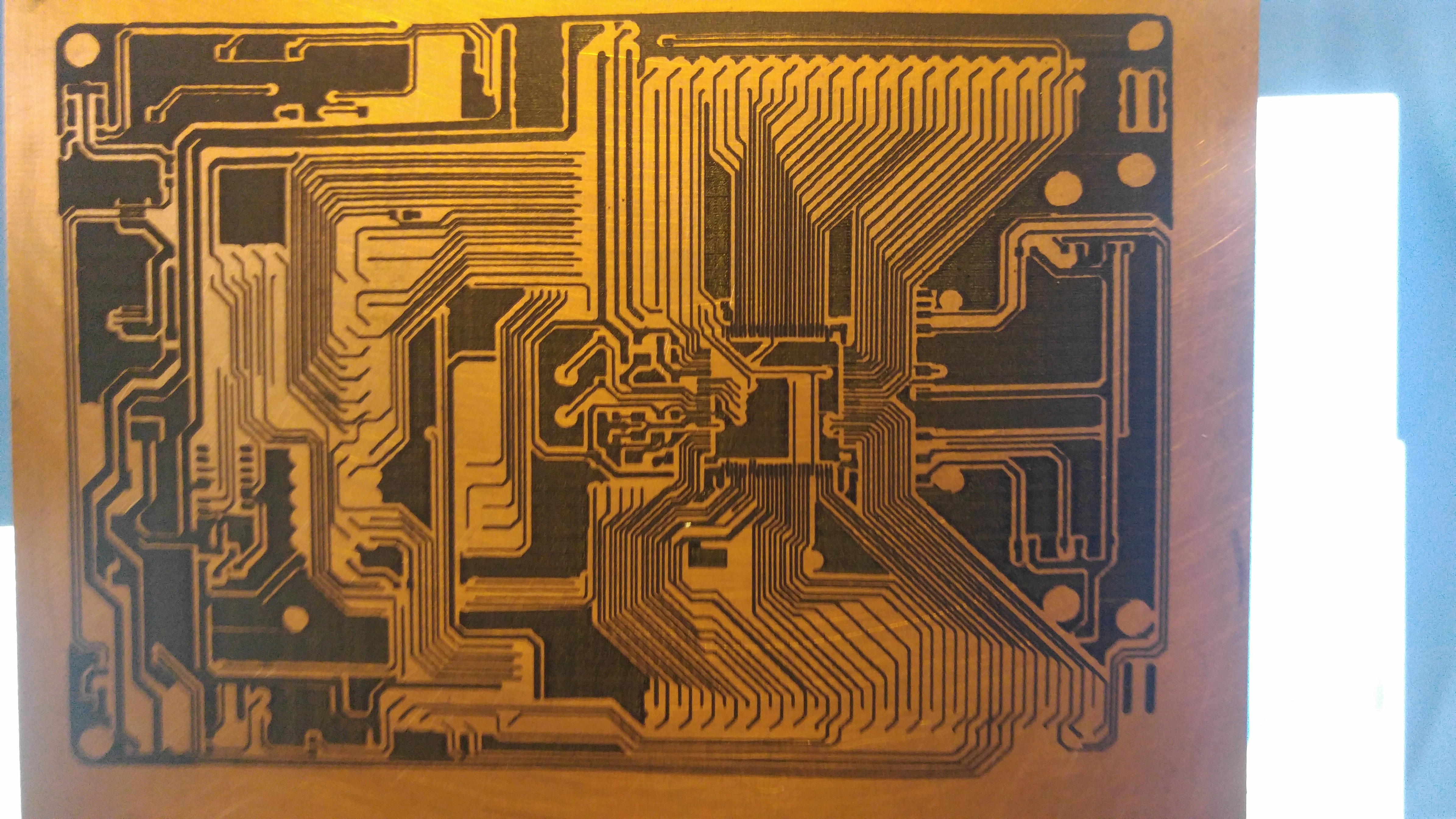

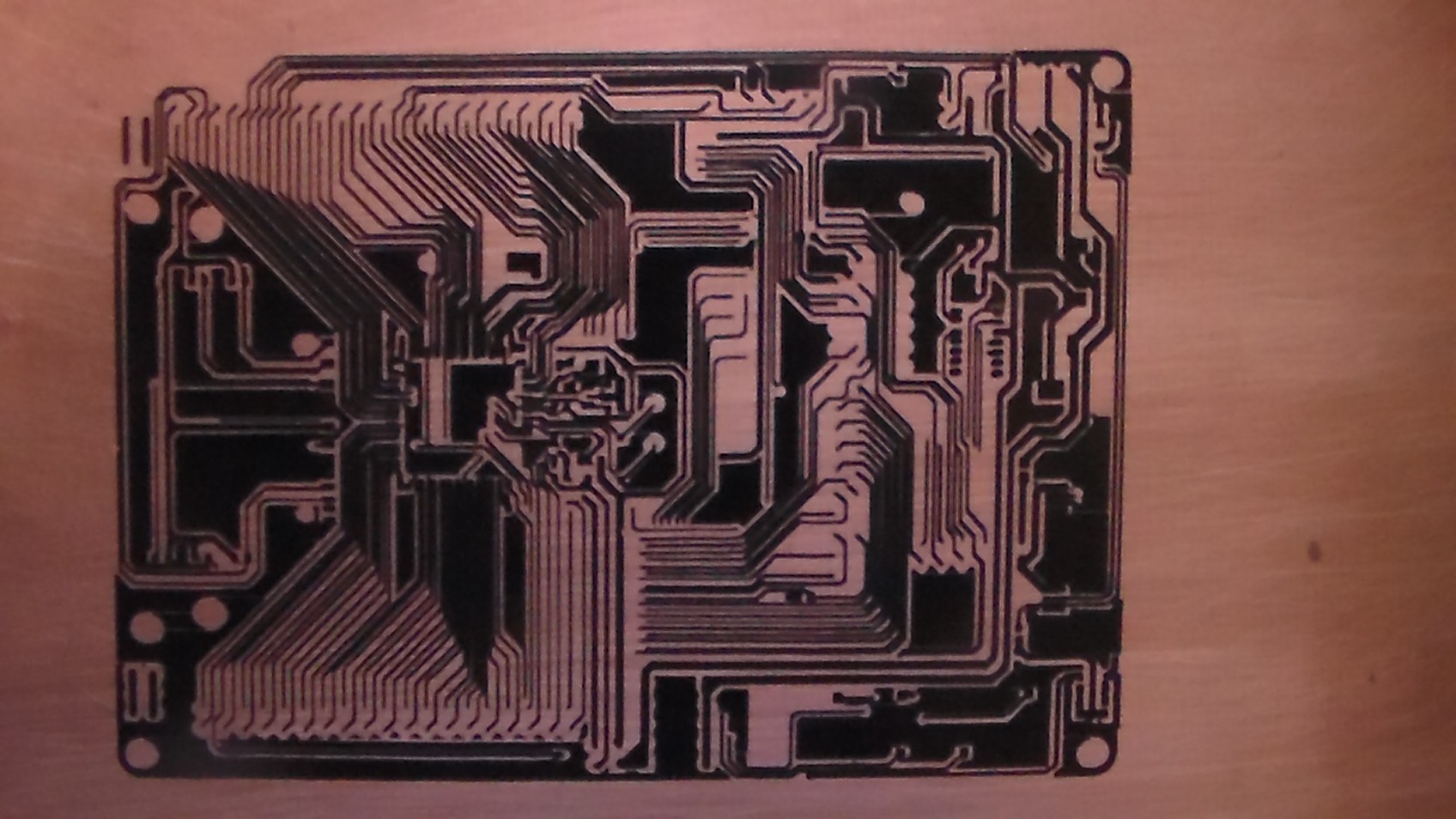

some shrinkage in large fields

04/05/2020 at 19:14 • 0 commentsI tried another board with large fields, I see shrinkage afterwards along the direction of laser travel. Might need to color these in with sharpie in certain cases, or do the borders & use paint/tape etc. I don't see this as a big problem, as long as I'm not fixing little stuff I'm happy.

-

Trying Lightburn

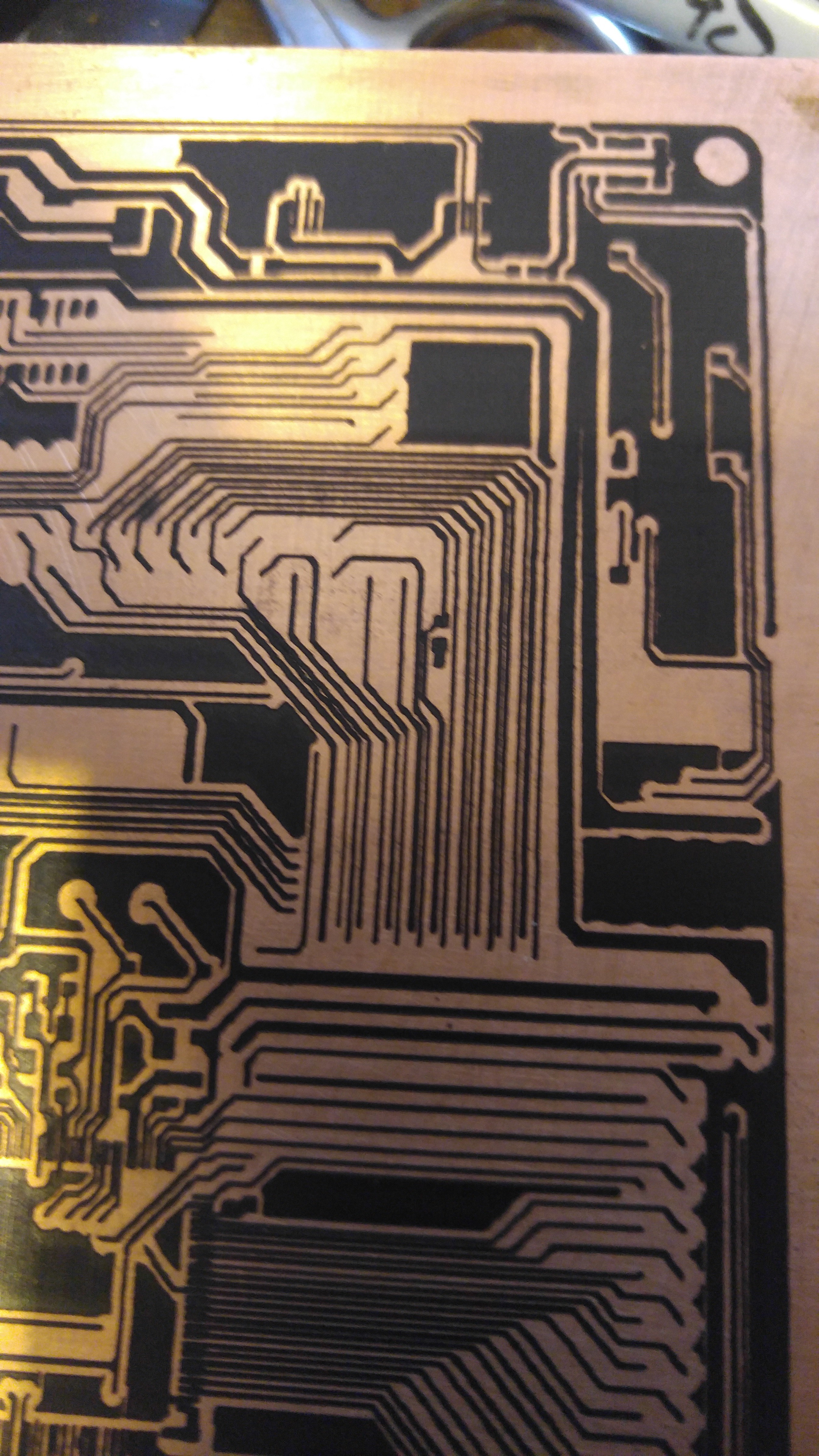

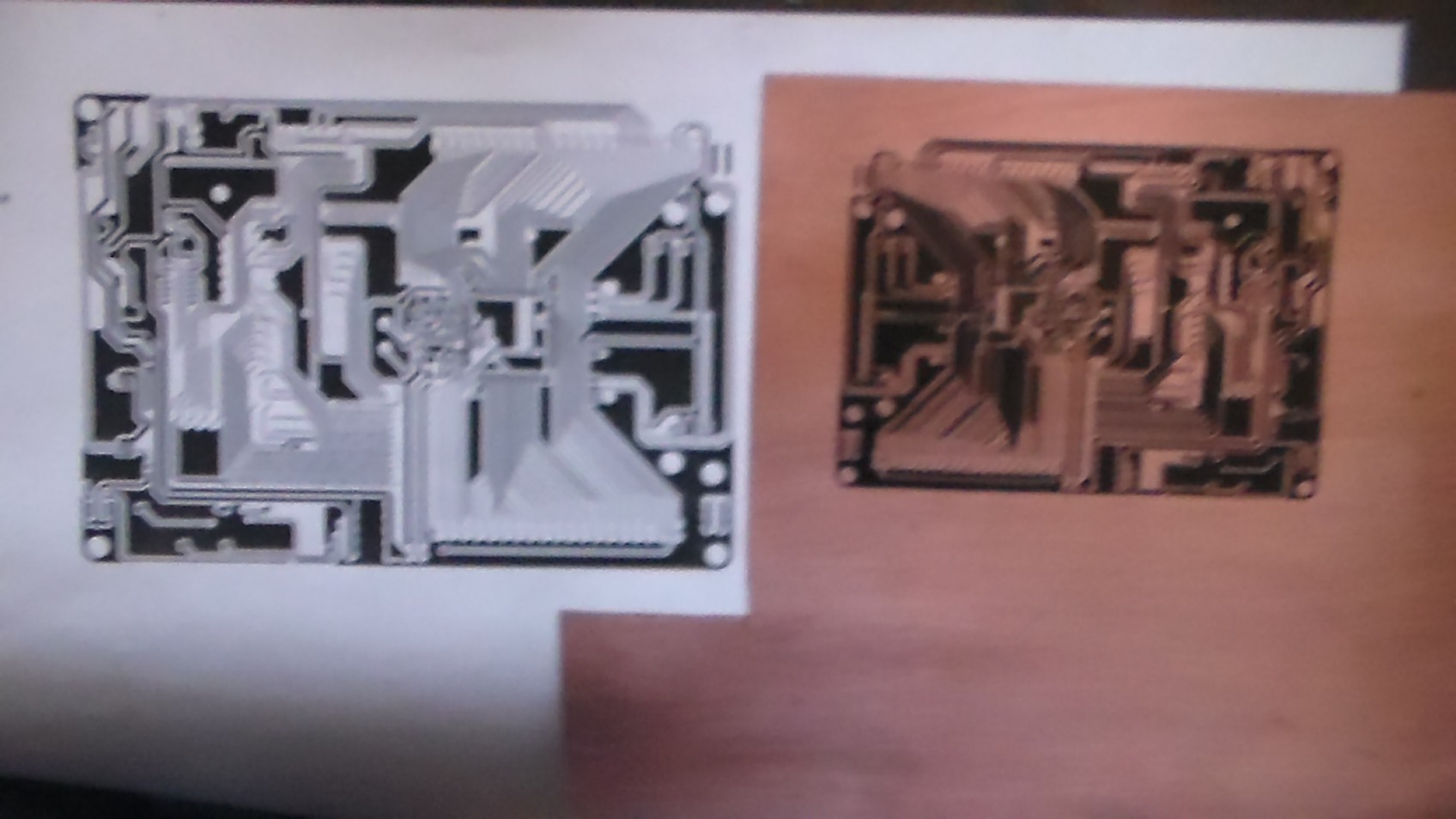

04/05/2020 at 19:06 • 0 commentsBurned one at 5% and 2200 mm/s and it's nearly perfect. But it's crooked & warped. Not going to bother wasting time on a pic. The software only accepts jpg, so I have to extract the image from the PDF. Then resize so it's right. The jpg is straight, but the print is way off.

So I'm trying Lightburn which imports PDFfiles, burning one now. The other possibility is the cable is getting hung up? We'll see. I can't get it to light the low power for testing size, but I used a big enough board to guess & it seems like it's going to work. I'd like to etch one of these eventually, since I have lots of acid just sitting here. FeCl

-

Test board #5

04/04/2020 at 22:04 • 0 comments -

Test board #4

04/03/2020 at 16:36 • 0 comments -

Test board 3

04/03/2020 at 05:12 • 0 comments -

Another test board & focus ramp

04/02/2020 at 20:36 • 0 comments

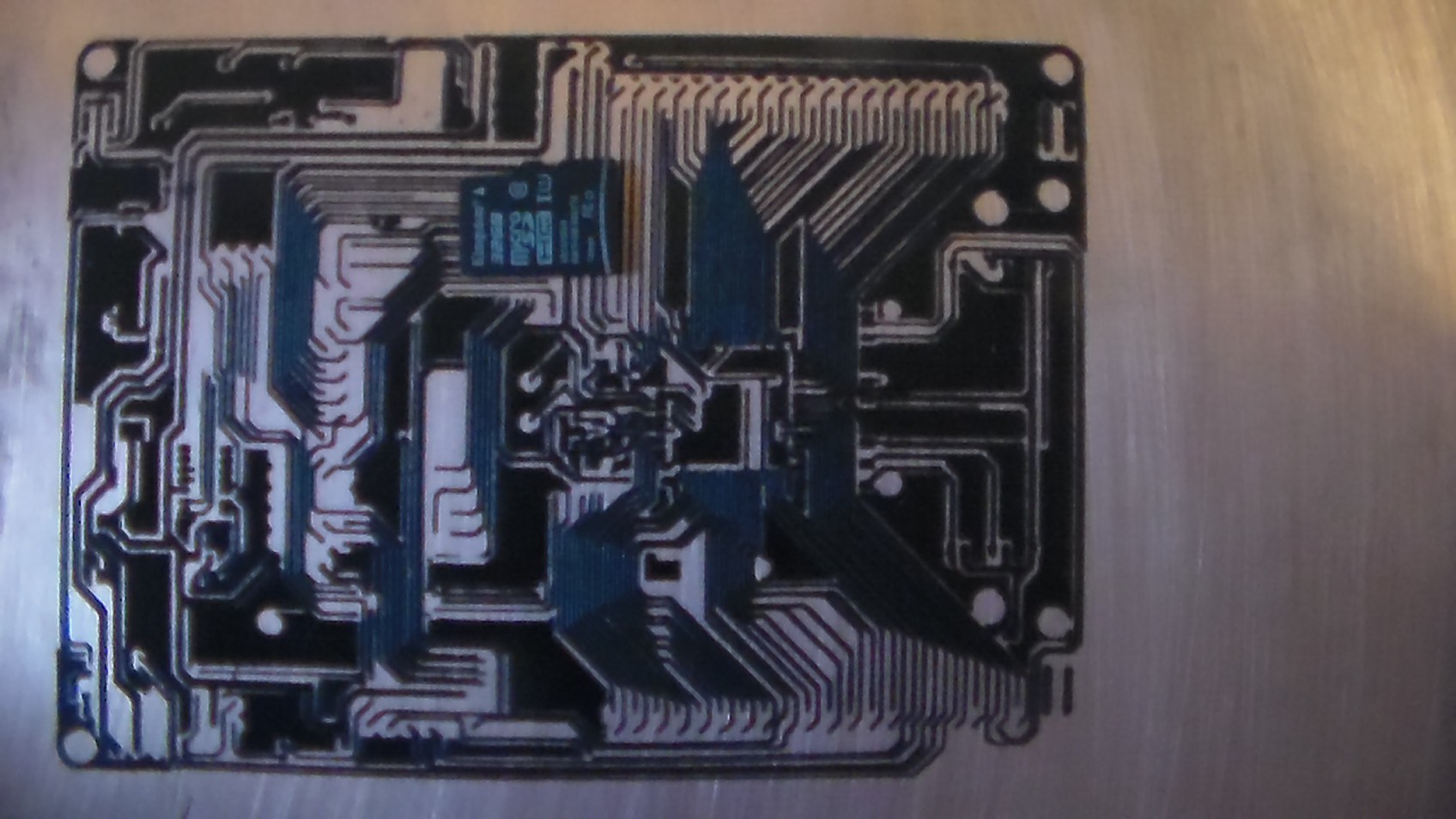

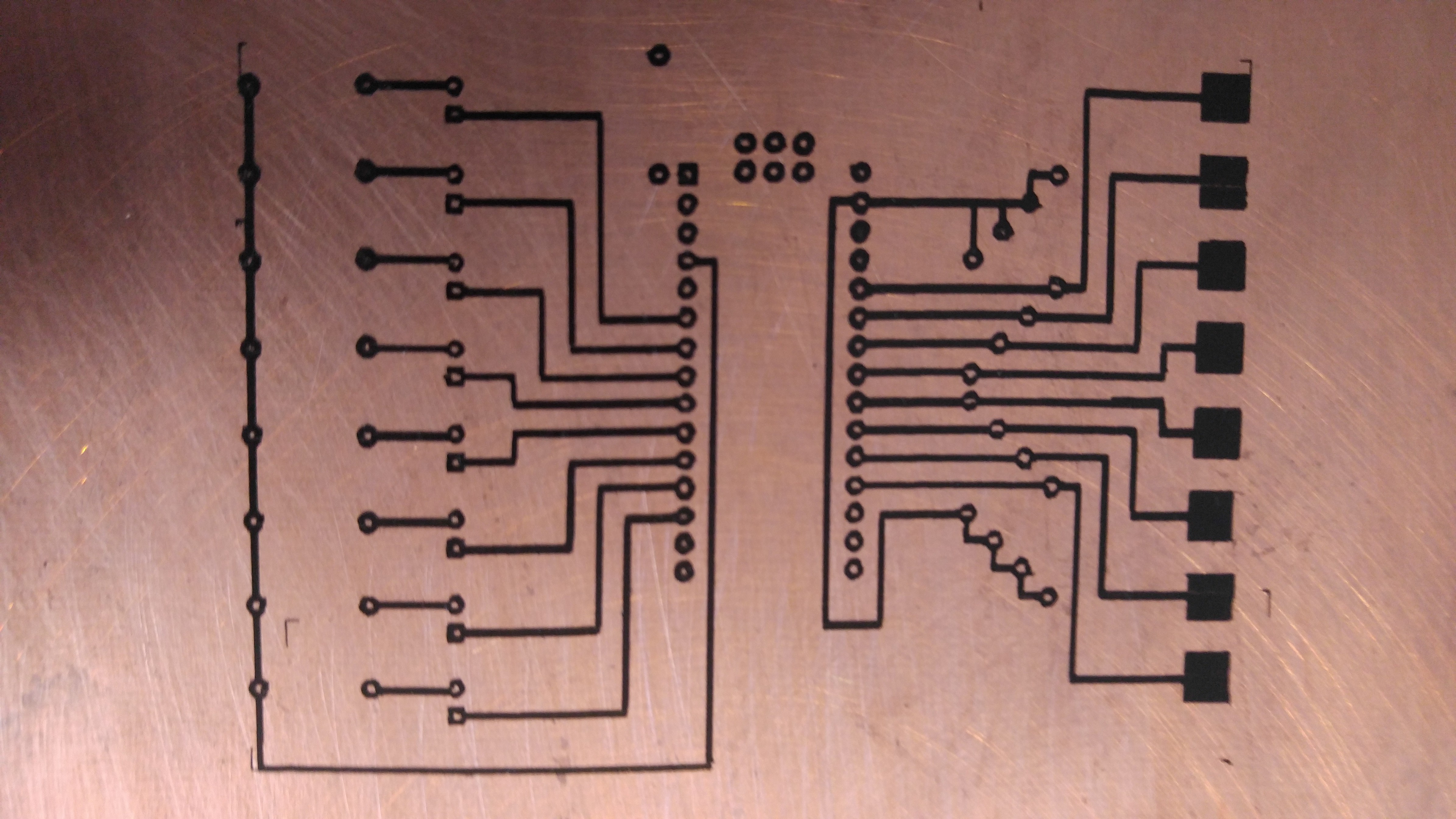

This is the ramp to check my focus, to the right is on the table, to the left is raised 3/4". Bottom line is 40% laser, 6th from the bottom is 15%. I still see smoke @ 15%, but I'm going to try it on the rest of the board.

So I shot this at table height @ 15% laser.

This is most certainly usable, I'd etch it but it's a mistake design I don't need. There's no voids or any of those missing spots you get with the paper peeling method. Just a nice layer everywhere it was intended to be. No guessing with the iron. Plus I'm washing my hands quite a bit with the leaky pickle jar powder gun. As soon as the real one gets here (movement now) this thing is going back to killing flies.

-

Test board 1

04/01/2020 at 19:47 • 1 comment -

Label created.....

04/01/2020 at 02:48 • 0 commentsThe guy STILL didn't ship the craftsman powder gun. Then I'm gonna have to leave it on the porch for 72 hrs.

Powder coat pcb with toner & laser sinter

So we powder coat a blank PCB with laser toner. Selectively melt with laser engraver and maybe get some good results.

eric

eric