-

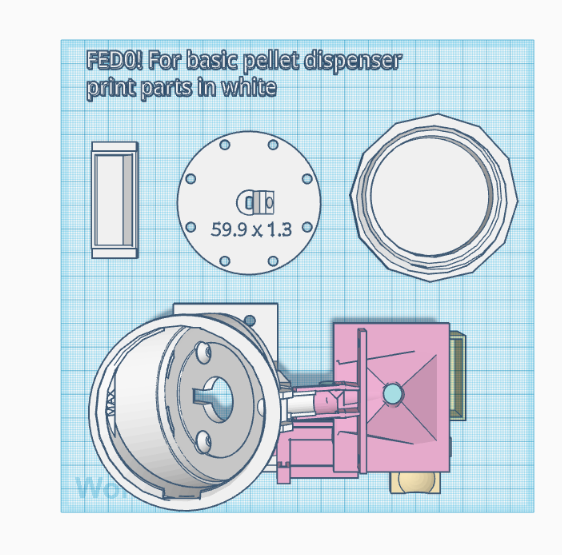

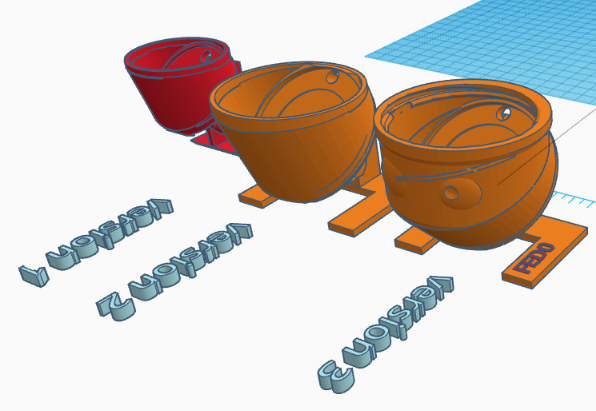

2022-04-02 updated 3D print files for feeders

04/02/2022 at 16:30 • 0 commentsAdded 5 new files:

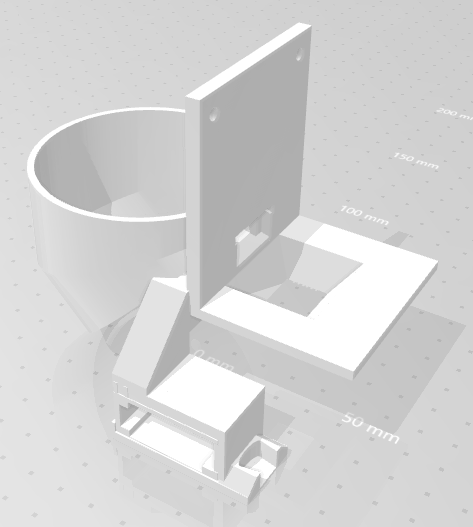

- new hopper body without a chute (to prevent jamming when sliding down to the receptacle), smoother surface for contact with the disk, wide mouth, larger debris vent. Note this version removed the photointerrupter slots, but this can be easily added back on in future designs if needed.

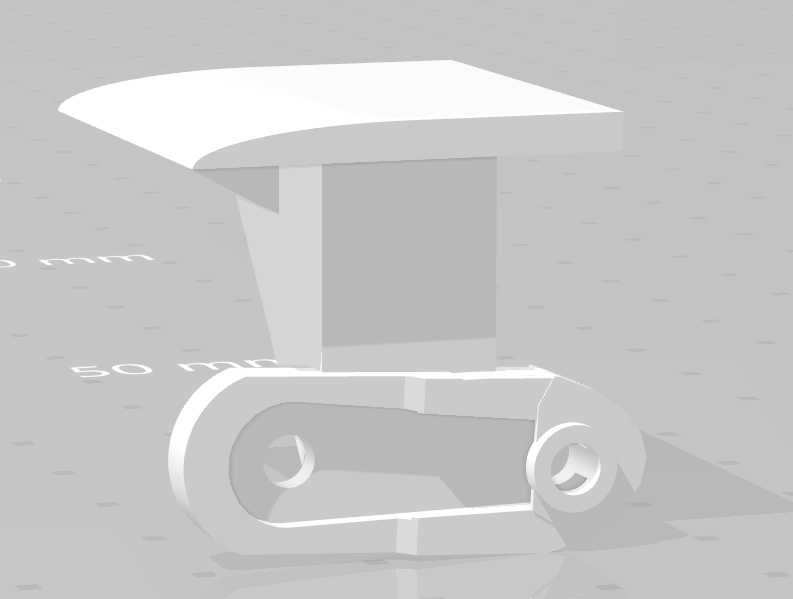

- new trap door that fits this body - it is anvil shaped / tapered in the front to prevent catching we sometimes experienced when the movement initiates or returns to rest. This works well but still needs to be optimized. Considering a horizontal orientation of the servo instead that spins a wedge trap door open vs closed instead of this vertical lever approach. Note from a bird's eye view, a goal to maintain is no "dark" spots emerging when the trap door is open that could throw off animal video tracking. Current design with vertical lever and a large enough trap door platform handles this well (i.e., the hole still appears white when trap door is open from a top down view).

- new catch basin that is sturdier and has a T connecter for more secure attachment

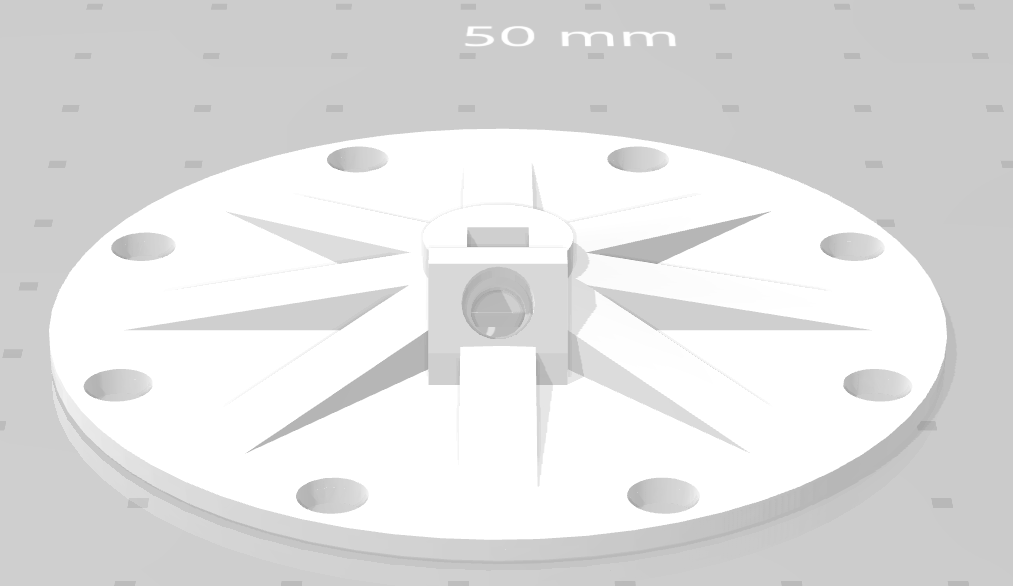

- disk with spokes developed by Lex

- a slightly modified thicker disk that may help prevent warping (noticing warping may be an issue with white resin but may not be an issue with clear resin - testing this again shortly).

-

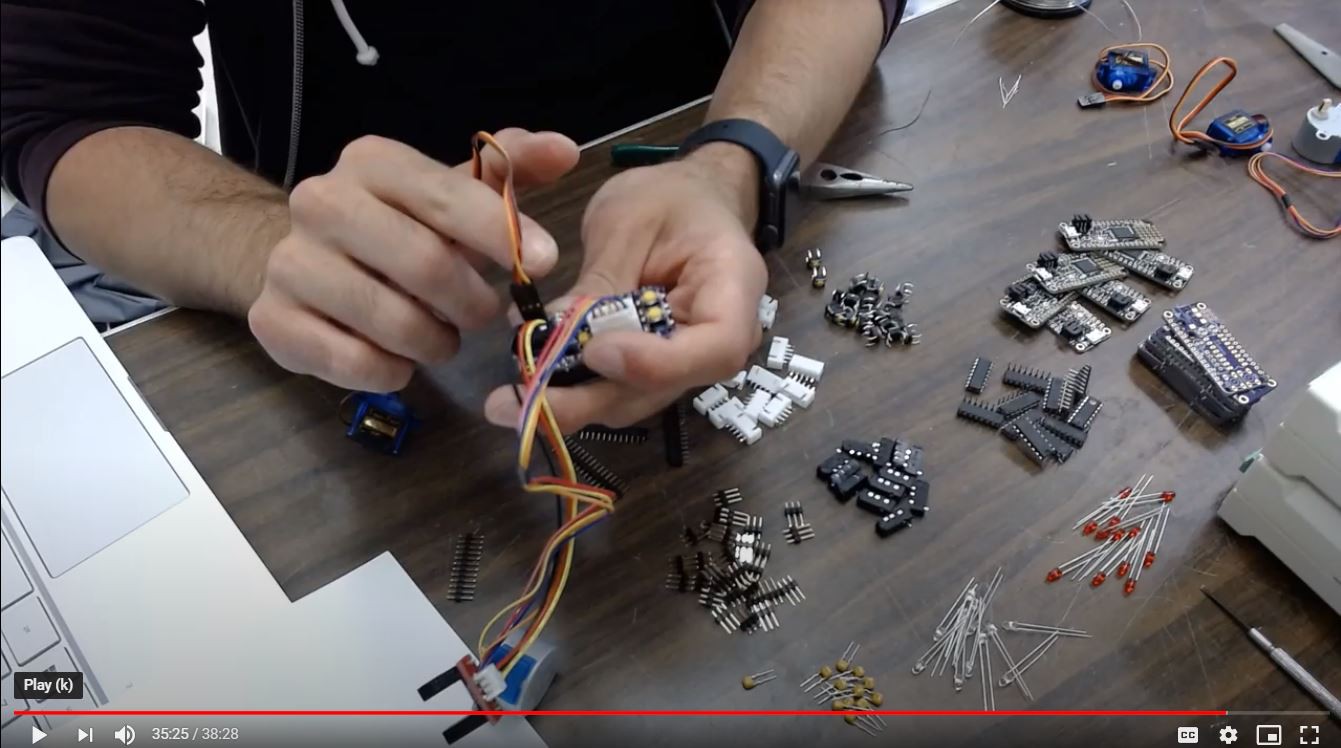

PCB Assembly Video

06/17/2020 at 15:54 • 0 commentsBelow is the link to a video of me soldering together all the component of the PCB board @Lex Kravitz designed!

-

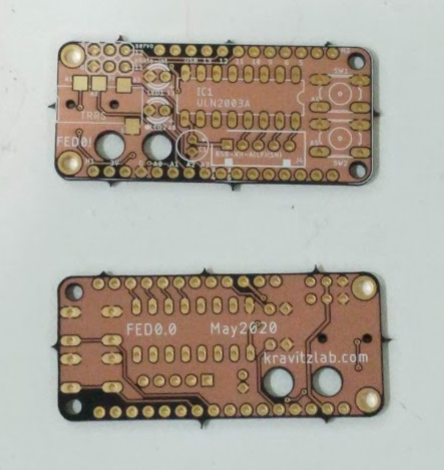

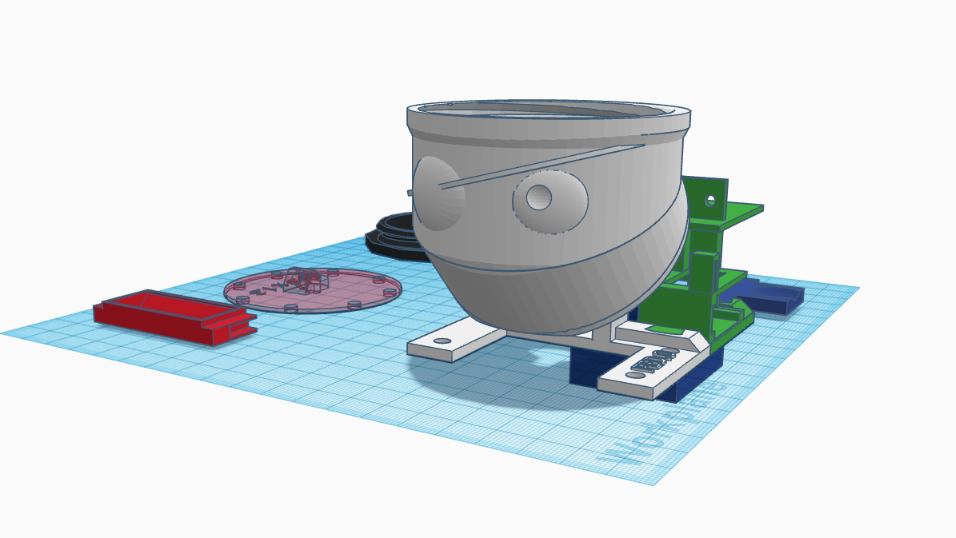

FED0 Printed Circuit Board!

05/27/2020 at 17:22 • 0 commentsI received the PCBs from Oshpark, in their beautiful After Dark color scheme!

Here it is populated with the ULN2003 motor driver, TRRS audio jack, motor header, servo header, photointerrupter header, and 2 buttons and LEDs for user input/feedback! All in a feather compatible board! I made this with through-hole components for everything as we don't anticipate making enough of these to get them professionally fabricated.Finally, here's a video of it in action:

PCB design files (Eagle) and BOM are in the Files area.

-

3D design complete

05/16/2020 at 15:33 • 0 comments -

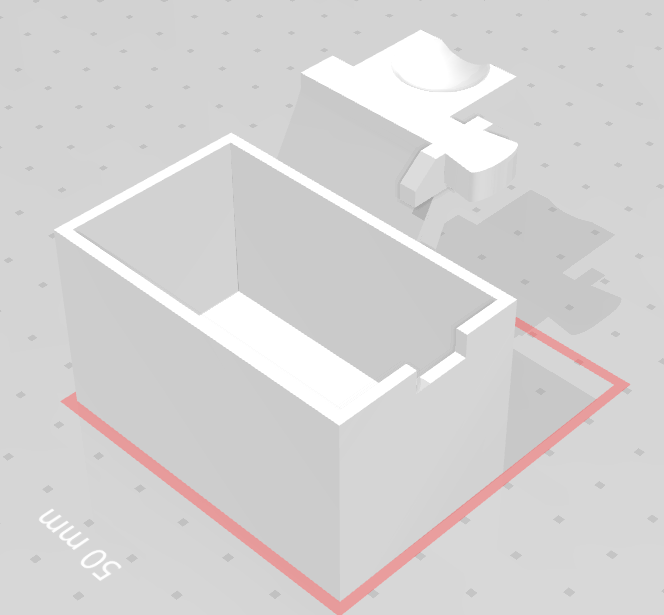

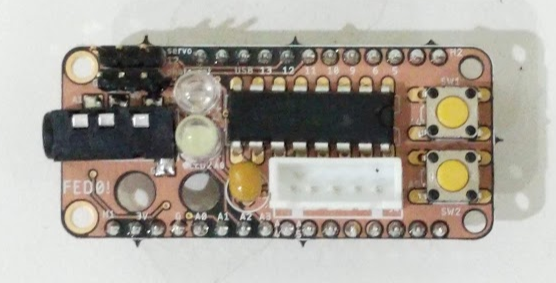

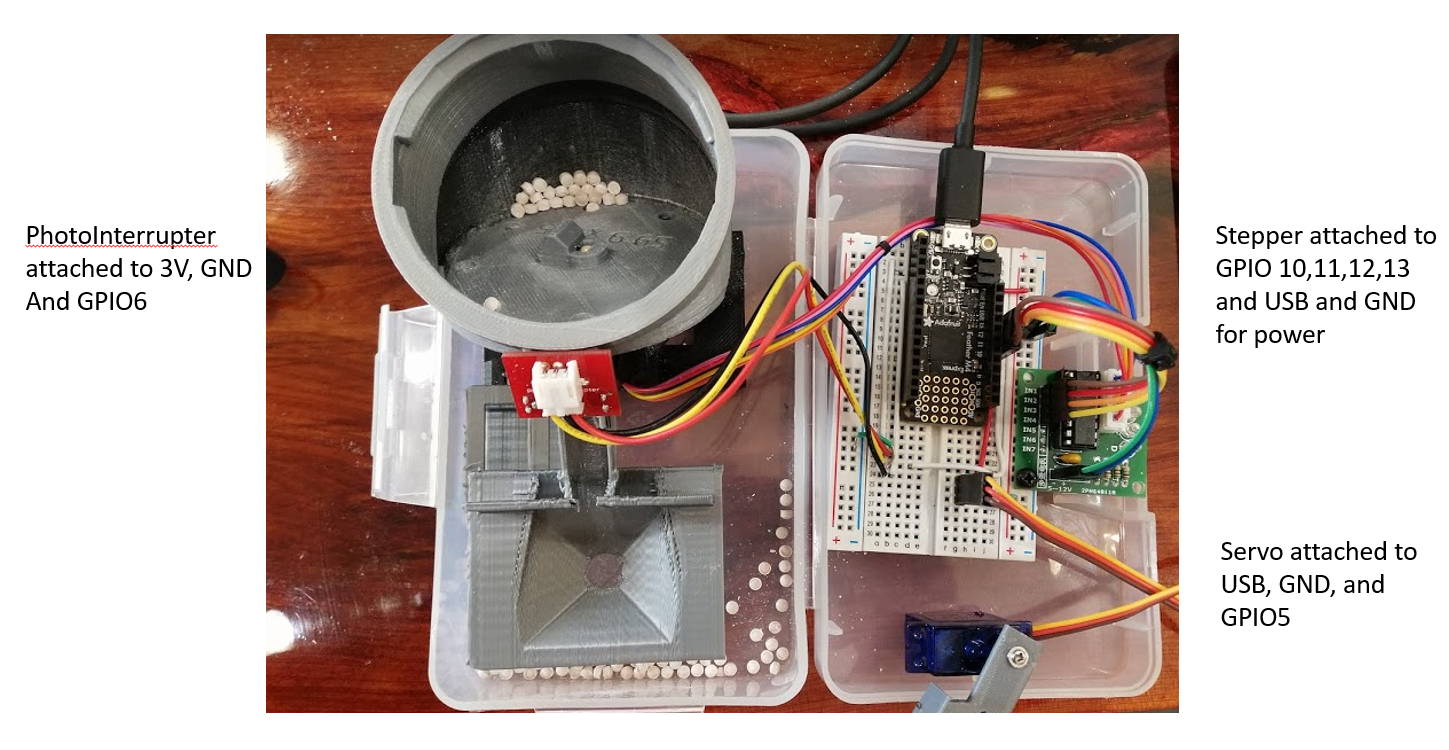

Final prototype with triggered inputs

05/16/2020 at 02:48 • 0 commentsI finished this prototype today and mounted everything on a permaboard. I updated the code to include two triggers, either triggered from the buttons on the board, or a TRRS input jack. Here is the final design working. The pellet dispenser has two inputs. When the first is triggered it attempts to dispense a pellet until it detects one with the photo-interrupter. When the second is triggered it moves a servo to open a trapdoor to remove the pellet.

The Neopixel on the Adafruit Feather M4 also displays some status information:

Green: All good, monitoring inputs

Red: Dispensing

Blue: Moving servo

Green with red flash - Pellet dispenser encountered a jam and needed to clear itself

The next step is a custom PCB! here's a sneak peak:

-

Servo mechanism to remove pellets

05/12/2020 at 20:38 • 0 commentsWe added a servo mechanism to remove the pellet from the dish if it is not taken. So far it's working well!

-

Update 5/11/20

05/11/2020 at 16:18 • 0 comments -

Dispensing and detecting pellets!

05/04/2020 at 16:49 • 0 commentsAfter a few rounds of tweaks, the pellet dispenser is operating pretty reliably! I also added the photointerrupter for detecting when a pellet is dispensed. Video below shows the current build. The code (running on an Adafruit Feather M4 express) will turn the stepper 1/8 rotation forward (this is the distance between holes on the pellet disk) and 1/32 rotation backwards, and repeat this movement until it detects a pellet through the pellet tube. When a pellet is detected the device will pause for 5 seconds. In the final build it will dispense under external TTL control.

Next up, going to add a servo to clear pellets out of the pellet dish if they're not taken within a period of time! -

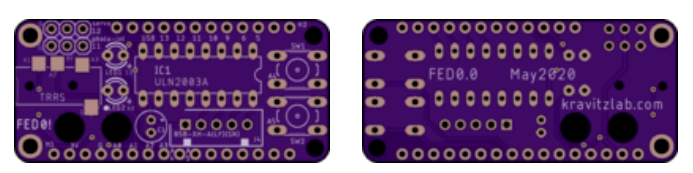

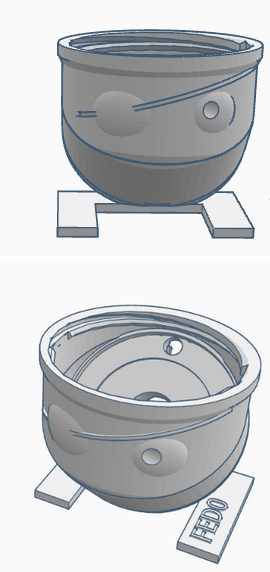

3D design update 050420

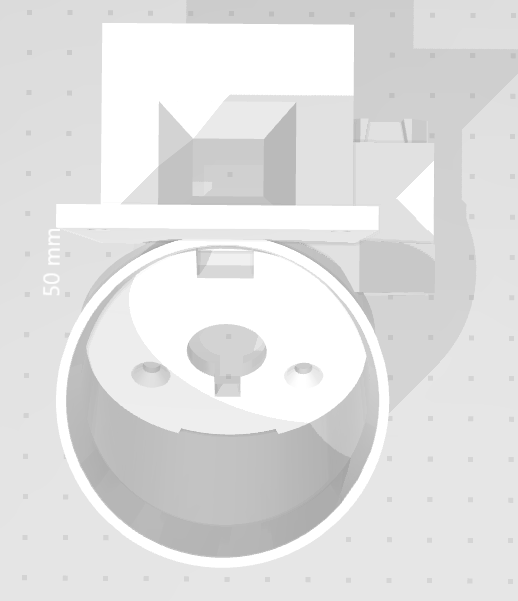

05/04/2020 at 16:29 • 0 commentsI've been tweaking the 3D designs to use an angled dispensing approach, rather than the horizontal approach used in FED3. The angled approach is interesting, in that it doesn't require a "foot" to prohibit multiple pellets from dispensing, which is a common solution for this problem used in most commercial pellet dispensers, as well as FED3. Notice the "foot" poking in on the top of pellet hopper of FED3:

While the foot method works, it can crush pellets and create dust, which leads to pellet jams. The angled approach uses gravity to keep multiple pellets from aligning over the dispensing tube, thereby obviating the need for the foot. It creates much less dust and seems to be more resistant to jamming.

I went through three major revisions of the design, with the first version containing a pellet disk and hopper the same size as FED3. While this worked, the angled disk is less space efficient as it can only be ~1/3 filled with pellets or it risks dispensing multiples. So this design only fit ~150 pellets. I made two adjustments to increase the overall size of the device (version 2), and make it bulge out a bit at the bottom (version 3). Version 3 can fit >500 pellets without dispensing multiples. These are printed in PLA on a Sindoh 3DWox1 printer.

Version 3 also seemed to be begging for some decoration so I also gave him an eyepatch :)

-

Spinning wheels

04/24/2020 at 03:30 • 0 commentsGot the stepper, servo, and Neopixel going, now just need to add TTL control to trigger each one, and the photo-interrupter pellet detection to terminate the stepper!

Brian M. Sweis

Brian M. Sweis