Gosh it's 2021 already!

Details on a working prototype coming very soon... just need to put in one order on Tindie.com for that magic ingredient to polish things off.

Repurposing a low cost slow cooker to provide a simple (and maybe a more energy efficient) way to reflow PCB's

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Gosh it's 2021 already!

Details on a working prototype coming very soon... just need to put in one order on Tindie.com for that magic ingredient to polish things off.

We all know the drill, keep it simple stupid (kiss). So, when a project starts to get complicated STOP right there. This project log demonstrates this philosophy.

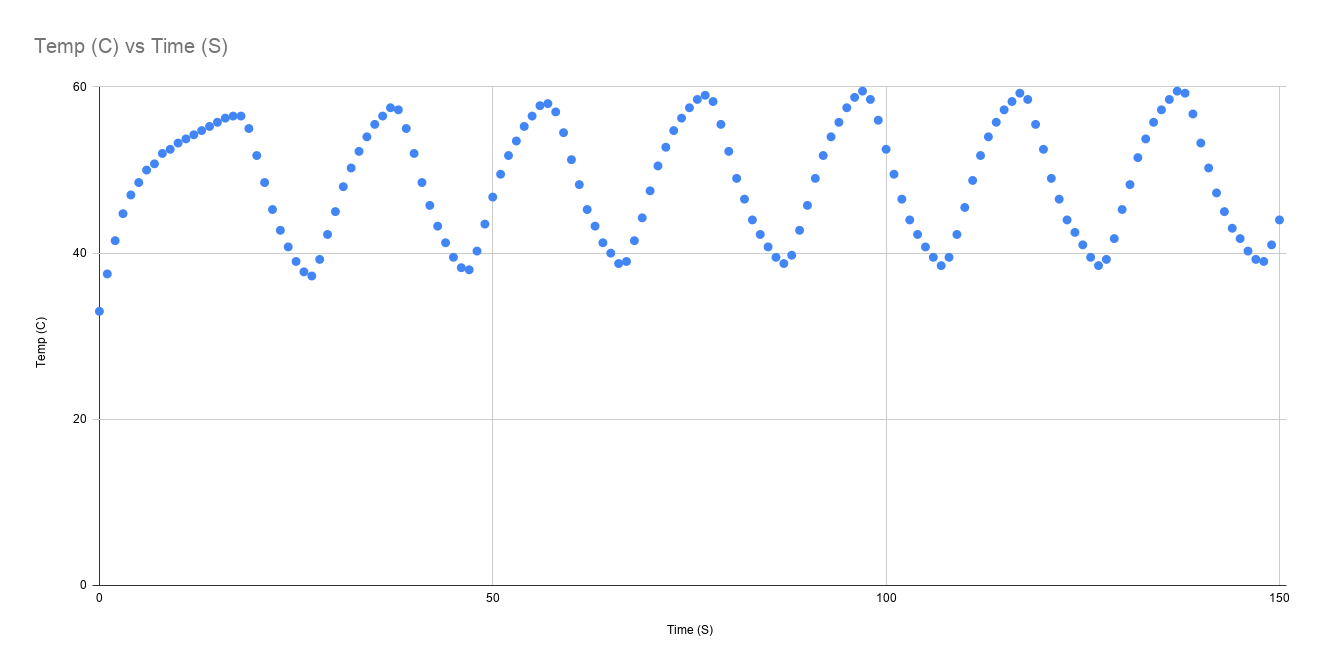

For the temperature measurement, I used an Arduino MKR1000 with a TFT screen and a MKR Therm shield. I added some bells and whistles to my firmware to tell me which reflow zone I was in and what my temperature gradient was looking like. For my testing phase I had a data stream going to the Serial Monitor at 1 second intervals, so I could then copy and paste this data into a spreadsheet for later analysis.

For my first temperature profile test, I wanted to see how fast the slow cooker could heat the PCB.

I used the high setting as this allows the temperature of the bowl to reach over 150 degrees C.

I placed the thermocouple onto an unpopulated or empty PCB and held it down with some wire making sure that the temperature probe was in the middle of the bai.

As can be seen by this chart, the heating profile achieved with the PCB inside the bowl was nice and linear but very slow.

My first challenge was whether I could improve things just using the slow cooker. Then it dawned on me.

Who needs the bowl anyway as the heating comes through the aluminium shell. So, I removed the ceramic bowl and I placed the PCB inside the shell with the lid balanced on top (not quite a snug fit).

This provided a much much better temperature gradient. It took about 10 to 15 minutes to reach 150 degrees centigrade with the lid on.

This was an excellent start, in my opinion, as there is actually a science behind getting the whole PCB to reach the magic 150 degrees C in steady gradient for flux to do its thing and for "soaking" phase to kick in (I am using this PCB reflow reference as my guide).

Thus the slow but steady approach can be beneficial, if you are patient.

But I am not really the patient type so I immediately started looking at how this can be optimised through additional heating methods. This is where I thought the fan heater could be used with it's multiple heater settings.

Unfortunately, my temperature measurements using the fan heater did not go as well as I hoped for.

Using the first heat setting, with the fan heater over the bowl, the temperature profile was not great at all.

Then when using the maximum heat setting I had some improvement but this was not the profile I wanted at all. Clearly temperature control was kicking in.

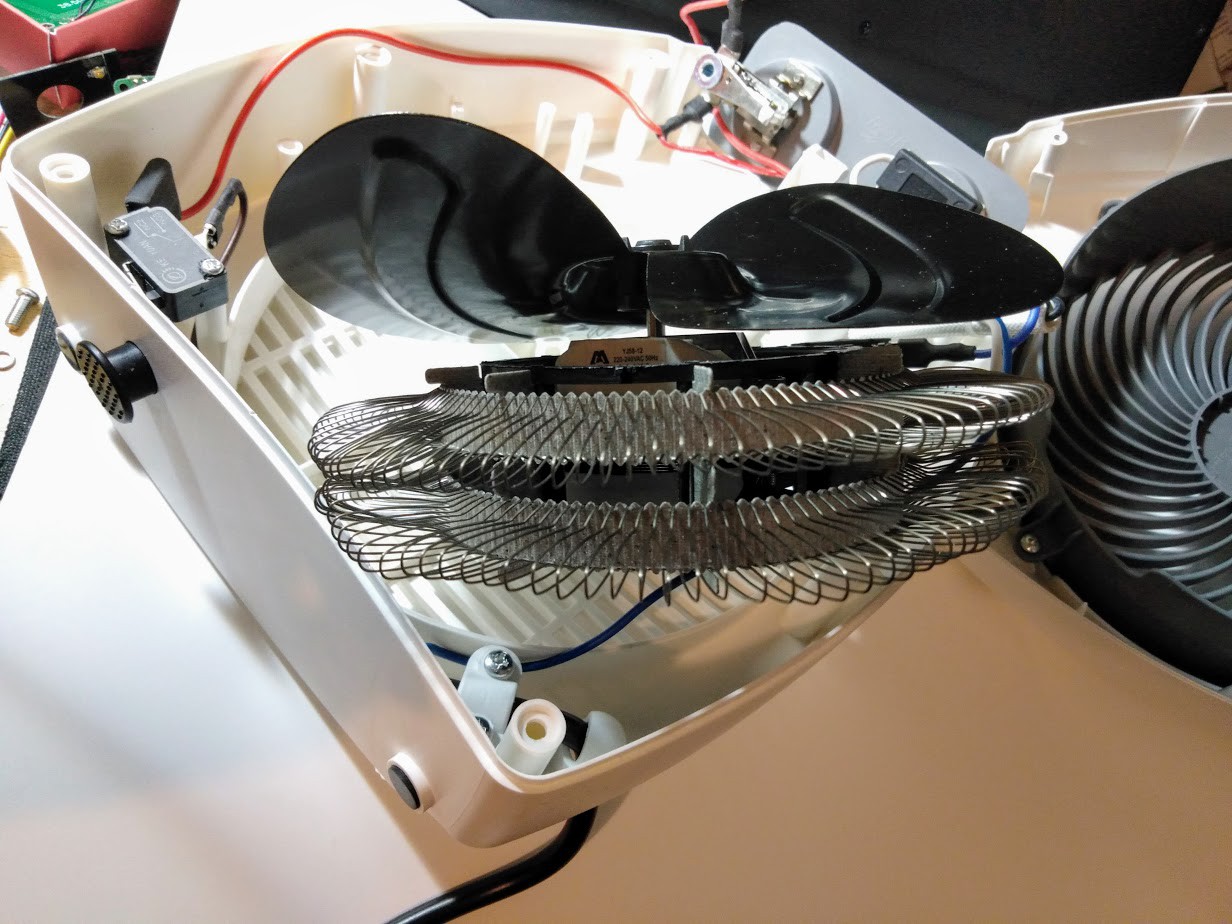

It was time to open up the fan heater and have a look inside.

Inside the fan heater there was a mechanical type thermostat control mechanism. To solve my temperature fluctuation problem, I will have to remove this. For now, I am leaving this well alone.

So, it was back to the drawing board.

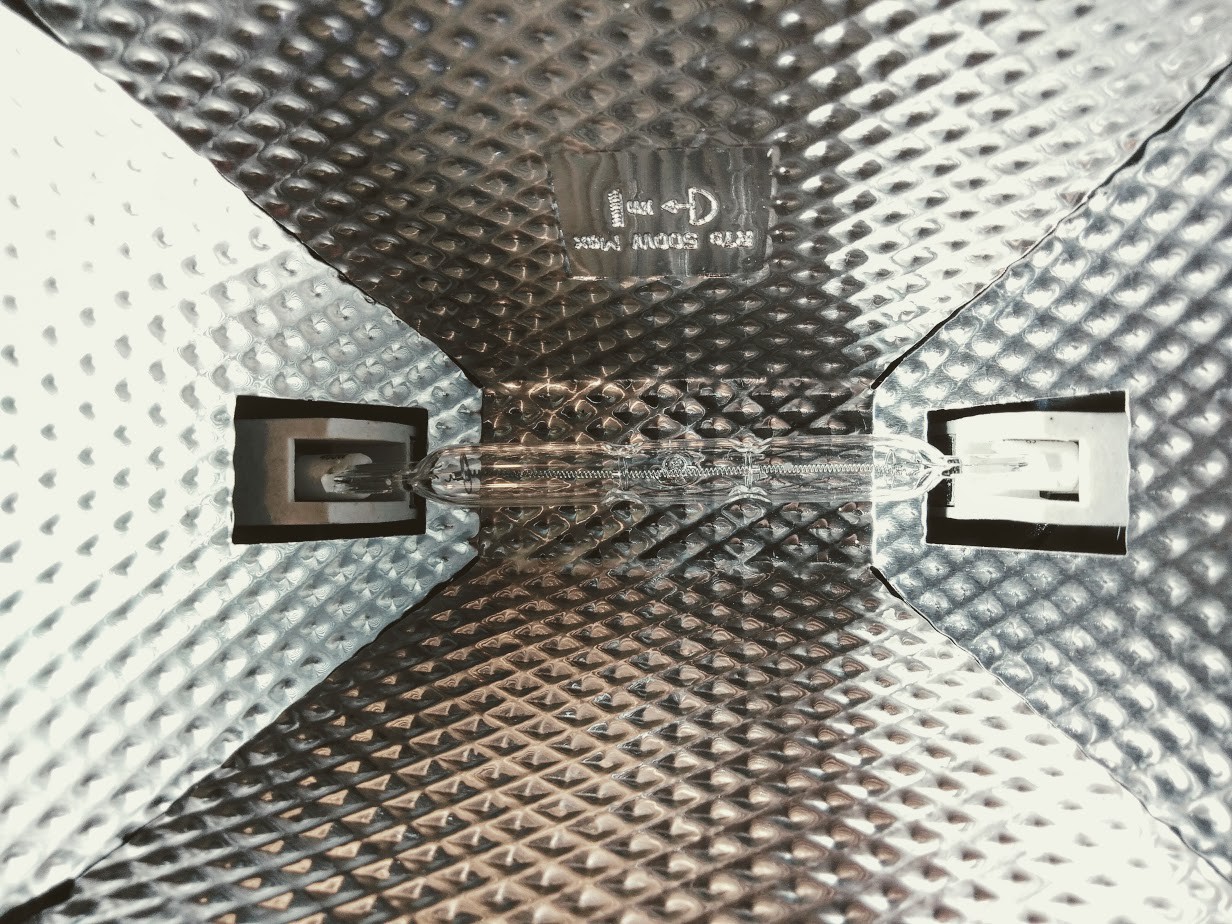

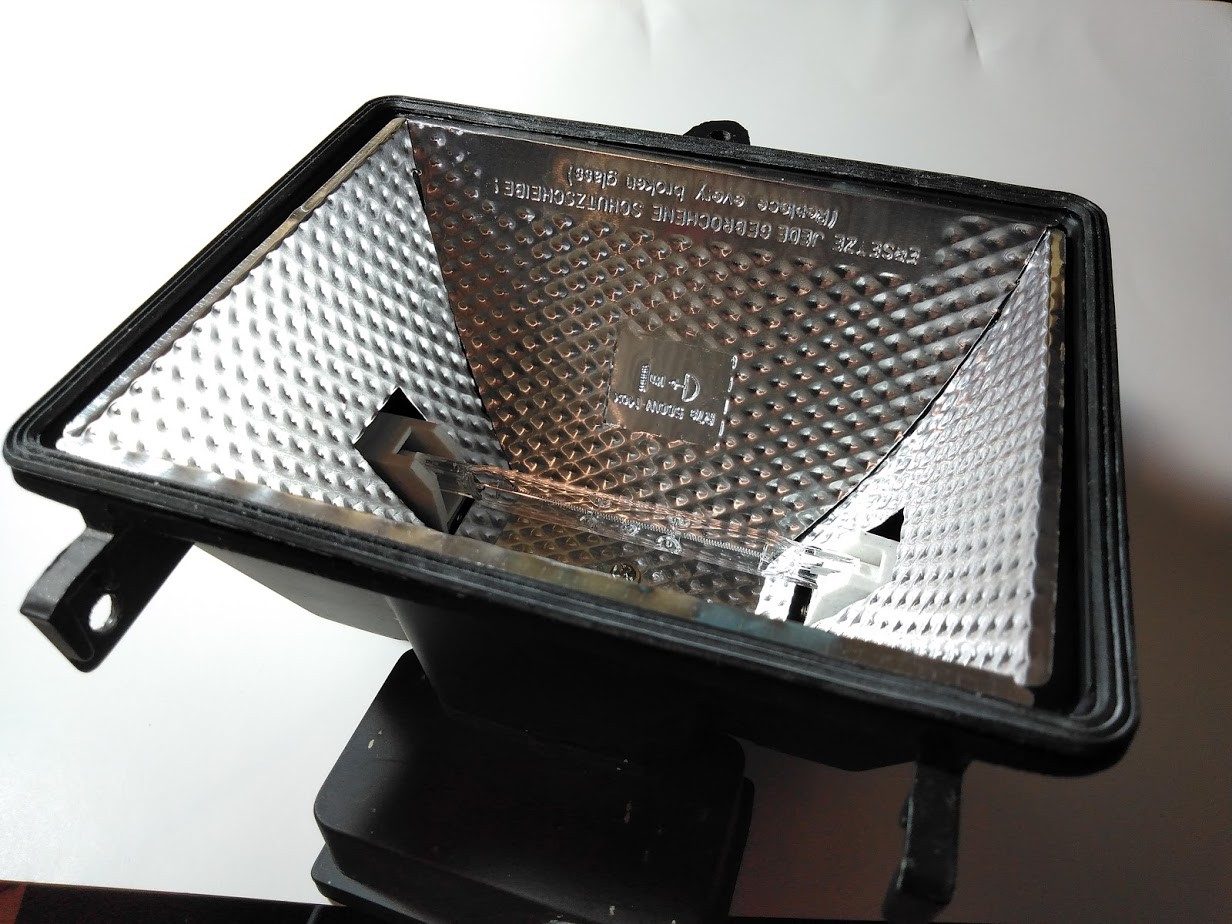

As I was rooting around looking for ideas, I spotted an old flood light I had in the shed. It was one of those that used a 400W halogen R7 type light bulb.

I recalled that these halogen light bulbs were really good a giving off loads of heat, as the exterior casing got very hot. Doing some prelim online research confirmed that these type of light bulbs reach some impressive high temperatures the higher the wattage.

To ensure I got max heat with my flood light, I removed the glass covering.

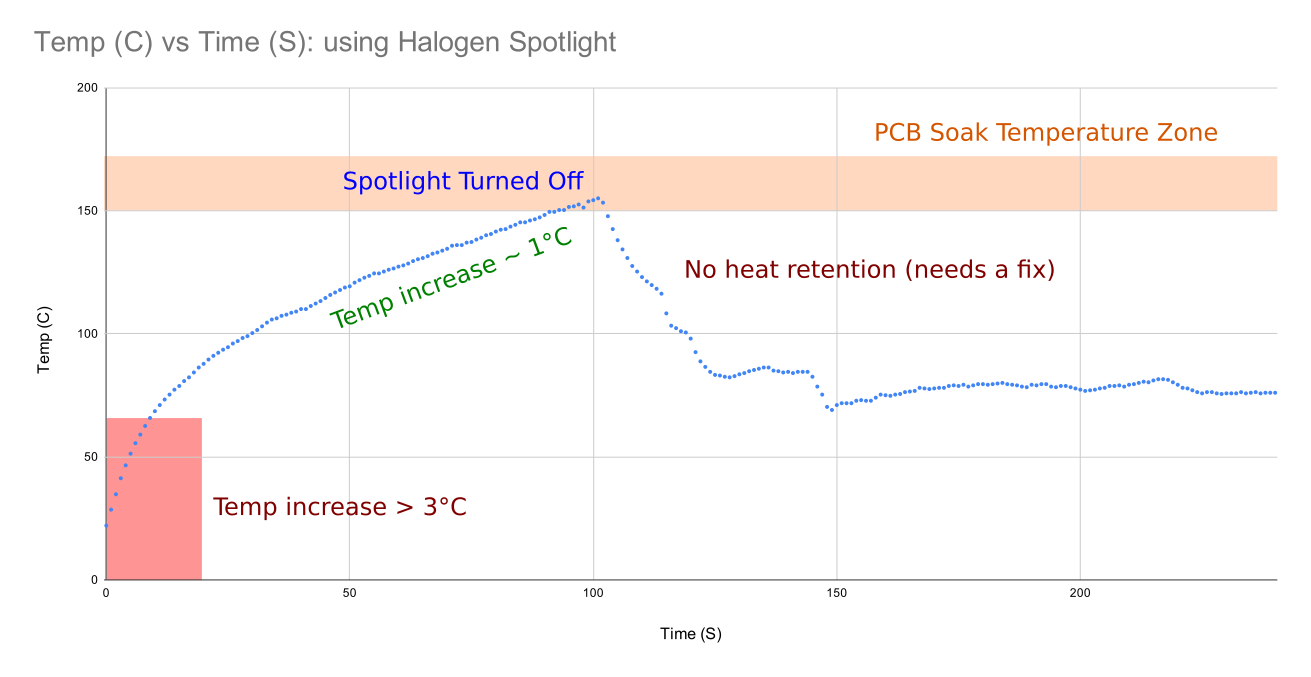

I then balanced it with some wood on top of the slow cooker and turned the light on (cooker remained switched off) and took some temperature measurements.

The results were really encouraging.

I am no PCB reflow expert so I am not sure what the implications are for the initial high temperature gradient (below 65 degree the temperature rise was about 5 degrees per second) but this eventually settled to a steady 1 degree per second rise all the way up to 150 degree, which is pretty darn good, in my opinion.

The problem...

Better to be cautious than having a cracked ceramic pot. Most of the online literature about slow cookers tell you not to put the ceramic pot in the oven etc.

As the duration of the reflow heating profile is quite short (about 5 minutes) my view is that it is better to treat the bowl like a glass bowl, which if subjected to a high temperature shock will crack.

To mitigate this cracking risk, I have been searching online for some thermal aids to place inside the bowl.

The first idea I thought of was fibreglass woven fabric, which can withstand high temperatures. You can readily find these sort of products on Amazon. Here is one such example:

https://www.amazon.com/Bondo-20128-Fiberglass-Cloth-sq/dp/B002JRGOT8

The next product I thought of, which could offer some thermal assistance was a silicon baking mat. These too can be readily purchased online or can be found at places like Ikea or any place specialising in baking products. I know Amazon stock some great ones which even include glass fibre.

I found this silicon baking mat at a local store for less than $10.

Finally, another off the wall product I found online on Amazon where these silicon oven mitts or gloves. I thought these would provide even better thermal insulation if, in the unlikely event, it is needed.

My next step, is to now set up some temperature testing as my k-type thermocouple probes have arrived in the post as these fit my Arduino MKR Therm Shield, so I'm ready to go.

If the temperature of the ceramic bowl rises much above 180 degrees C, I may then add in further thermal insulation, such as foil under the silicon mat (the reason I did not simply use foil is that it creates too much heat reflection, which I do not want) or purchase those silicon oven mitts.

I've just purchased a new fan heater for $12. It may be overkill in terms of size or it may end up delivering a lukewarm result. Will wait and see. The nice thing is that it fits on top of the slow cooker (no wobbles so won't topple over).

Another benefit with this fan heater is that it potentially can be hacked without burning the house down. At the bottom of the heater there is a cut out switch which keeps power on if pressed in or switches power off if released. Just need to find the right relay to replace the tamper/kill switch.

Next part of research will be evaluating temperature profiles based on heat settings and fan speed.

Create an account to leave a comment. Already have an account? Log In.

Yes that is quite correct (I had eventually stumbled across that project). In fact that project had confirmed to me that halogen works. However, I discovered during testing that the slow cooker heating element adds in support for the soaking period (made it easier to maintain a temperature and allow for a slow increase). Also the size of slow cooker aluminium shell/pot allows for bigger boards or one or two more to be reflowed than what is possible when placing directly under a flood light (as demo'd in that link). I found that when placing a PCB directly or too close to a flood light you're at risk to thermal shock (although did not witness myself) due to rapid temperature increases (+10 degree C per sec). However, if using say a 200W halogen and for small boards that method is probably more efficient.

Another thing I hadn't considered initially, but still needs to be controlled is the cool down period post max temperature at reflow zone. The aluminium shell of the slow cooker reduces the rapid cooling down which can help at the higher temperatures.

Still waiting for my K-Type Thermocouple probes to start taking temperature readings. Expect delivery 1st week of July.

Now pontificating as to whether I add in a layer of insulation to prevent the slow cooker pot from cracking due to high heat... user manuals warn you not to put the ceramic bowl in the oven, for example. But maybe if I am only heating for about 5 minutes it should be OK. Temperature measurement will help.

For insulation, I've been looking at fibreglass woven fabric as this won't reflect heat back like foil insulation would. Also you can get a couple of feet of 2" or 5" fibreglass fabric tape for less than 10 dollars.

I wonder if you might have luck controlling the heating profile by moving the boards between different heat domains within the crock pot's volume. Like maybe moving it up off the floor to get cooler, and down closer to it to get hotter. That could turn the thermal momentum into an advantage rather than a deficiency.

When you see the size of the fan I just purchased, I don't think this will be much of an issue...

I wonder if the thermal momentum of that big, heavy crock pot will tend to distort the temperature curve of a proper SMT profile? Looking forward to your results - these things are stupid easy to find at thrift shops, or even new for a couple of bucks. I think we have a couple that were giveaways at the bank for opening an account.

Thanks for comment. Indeed so. I remember my grandmother often had one of these slow cookers on the go so there must be plenty lying around for a couple of bucks (I never looked around). Maybe if this works it provides an example for reuse of all the old ones. Regarding thermal momentum. Yes this is certainly something I plan to measure. My presumption is that if using a fan driven heater then the sluggish thermal characteristics of the crock pot would not have shifted that much within the 4 minutes it takes to reach the correct max temperature for pcb reflow (I was using this article for guidance on how long it takes: https://www.compuphase.com/electronics/reflowsolderprofiles.htm)

Become a member to follow this project and never miss any updates

Andrew Shevchuk

Andrew Shevchuk

RoGeorge

RoGeorge

Christoph

Christoph

SAYANTAN PAL

SAYANTAN PAL

Not sure if you have seen this: https://hackaday.com/2017/07/13/a-bright-idea-for-reflow-soldering/

Sounds like you already have the bits in place to skip the slow cooker entirely, and just go with the halogen light directly.