-

Custom Lighting Module

05/04/2022 at 15:02 • 0 commentsOld Light

Previously, I had used a ring light bought off of Aliexpress. It worked well from a functional standpoint. However, there were some issues with it.

- Mounting it required a custom designed bracket

- It was wide enough to limit head travel distance.

- It has a power converter that was attached to the wires which was an awkward place.

![Old Ring Light Old Ring Light]()

The ring light used on the original design. Custom Light

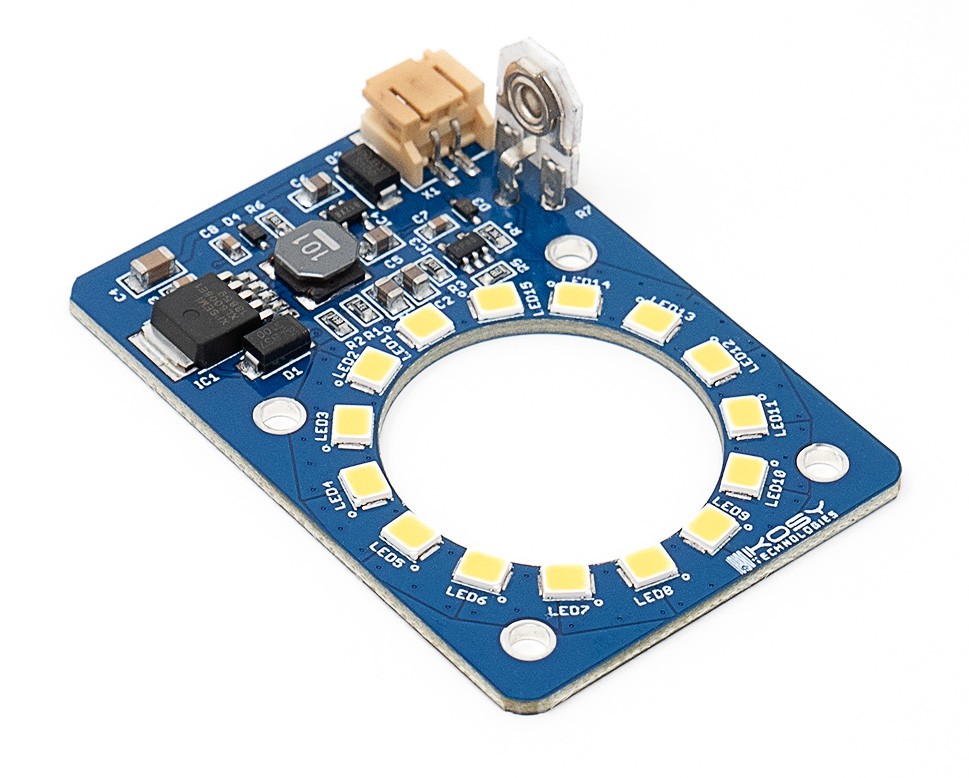

My friend designed a custom light to solve these issues and add functionality.

- Mounting compatible with ELP cameras.

- Same width as ELP cameras.

- Onboard power adaption.

- Adjustable light output (dimming).

![Ikosy Pick and Place Lighting Module Ikosy Pick and Place Lighting Module]()

Custom designed light for pick and place machines. -

Design Updates

03/22/2022 at 21:56 • 0 commentsIntroduction

After building and testing the machine, I started to notice some limitations, small design issues, and areas where improvements could be made. Several iterations later, I have an updated design that smooths out these rough edges.

Many of these are significant and will get their own log entries like a completely new head design, PCB holder, custom light, and nozzle tip holders. Stay tuned in for those.

Below are a few additional updates.

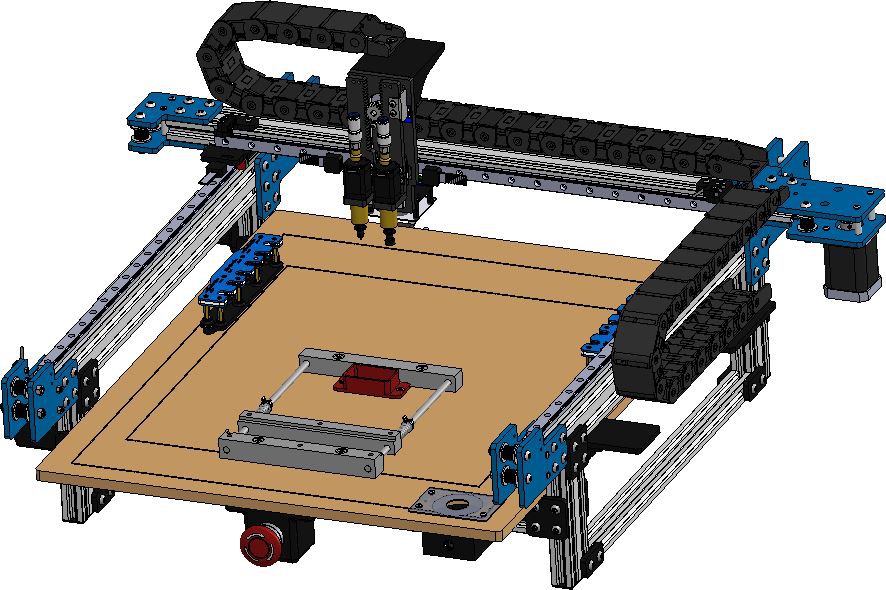

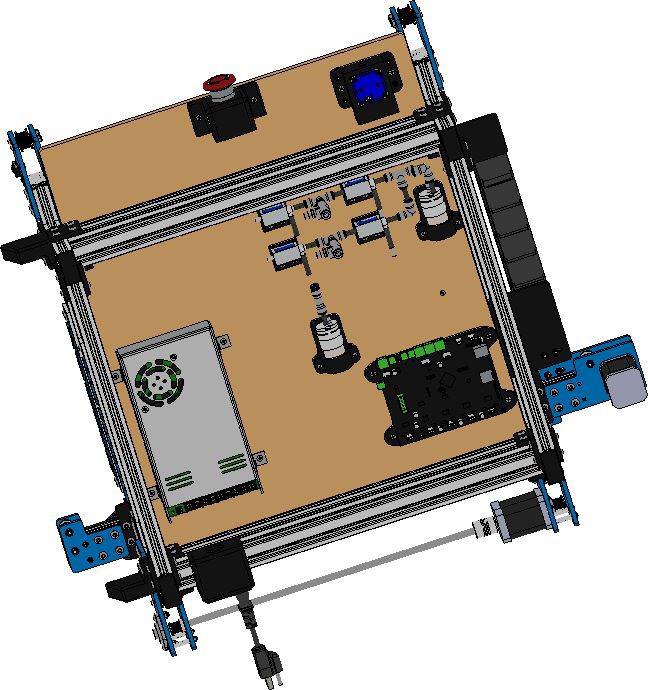

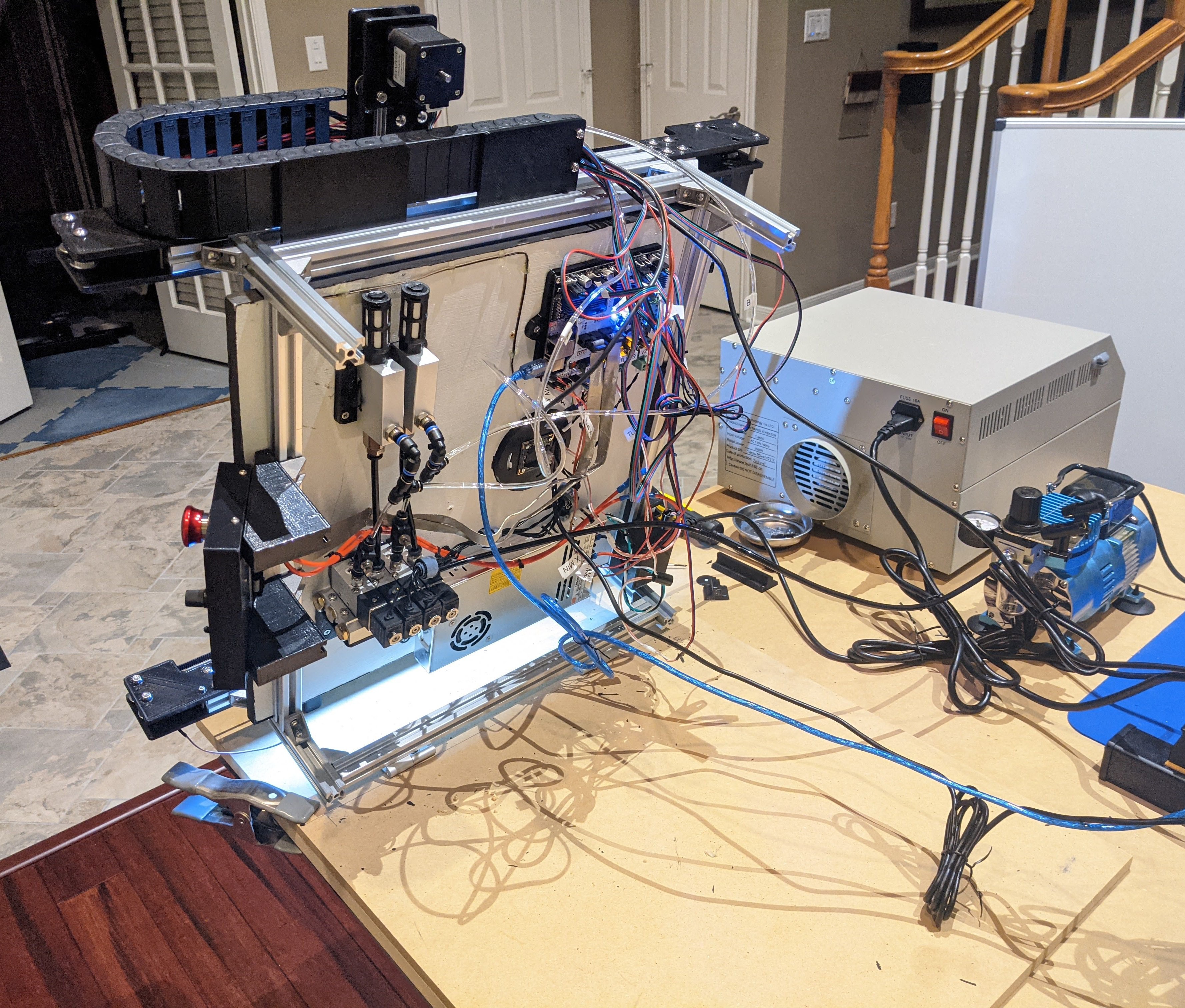

Here are some updated images of the machine.

![Machine Top Machine Top]()

The top of the machine. ![Machine Bottom Machine Bottom]()

The bottom of the machine. The electronics are mounted to the bottom of the build plate. Removed the LCD Screen

After testing with the LCD screen, it was determined it added little value to a pick-and-place machine. Unlike a 3D printer, a pick-and-place is always connected to a computer. All of the information that the LCD screen would be used for is available on the computer and easier to access. The emergency stop button was integrated into the original LCD screen mount, therefore, a new stop button holder was designed.

Camera Changes

The bottom camera was horribly mounted in the middle of nowhere. The consequences of this became apparent almost immediately. A shorter focal length was chosen to both allow the camera to be closer to the build table while maintaining the field of view, This also allowed the same cameras to be used for both the top and bottom.

-

Assembly Run

11/06/2021 at 15:17 • 0 commentsRunning a PCB on the Machine

After a lot of work, testing, debugging, and fixing, the machine is up and running and capable of assembling a PCB. There's still work to be done to make things easier to use. A new strip feeder design is likely. Rearranging the build table is coming in the near future. Overall, though, the machine works well and is really accurate.

-

Flip Your Lid

03/08/2021 at 17:06 • 0 commentsIntroduction

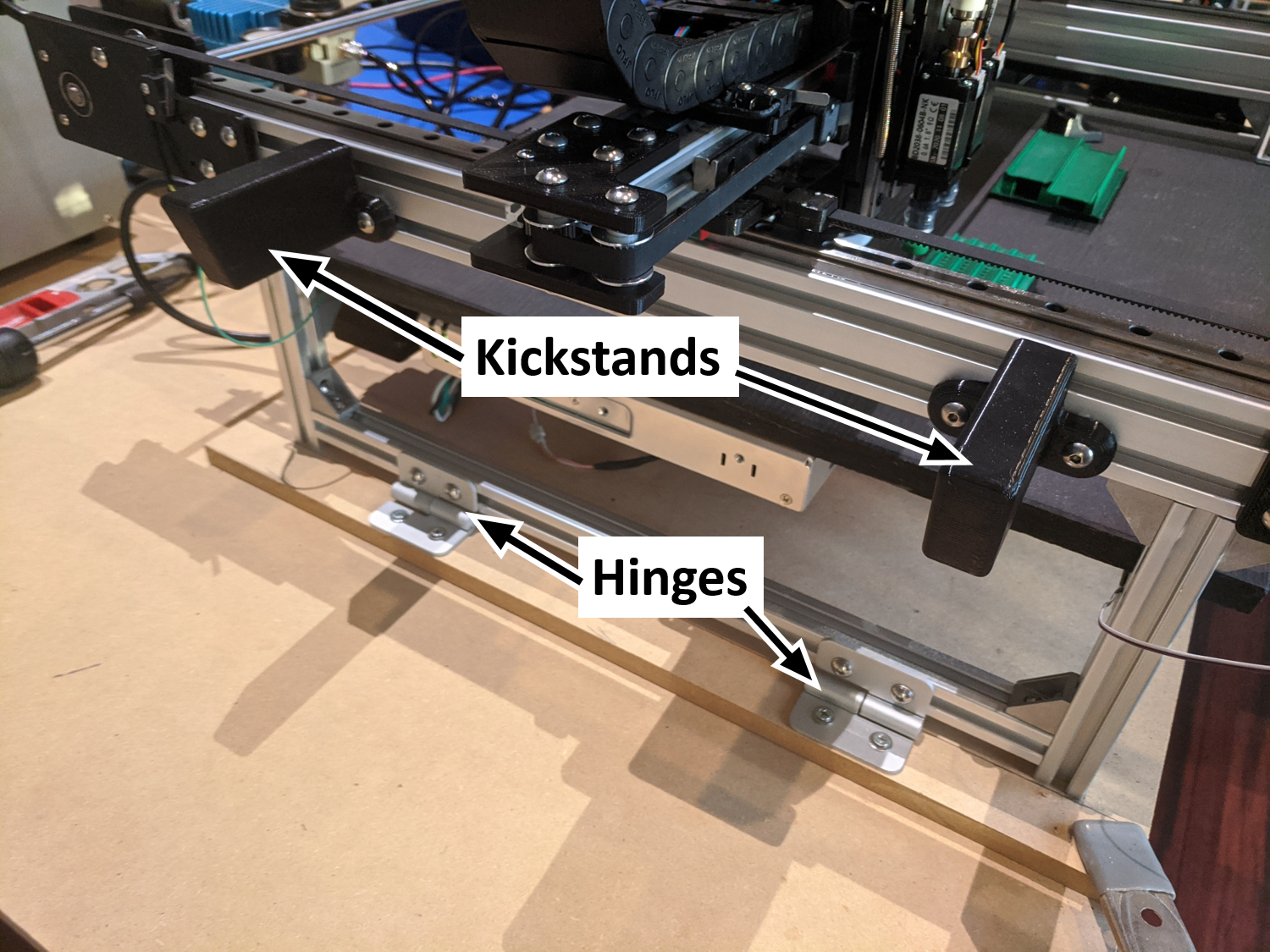

As with all first builds of a design, there was one thing that was certain: Changes were going to be required. And likely, they were going to be frequent. That's part of the process. Debugging and testing were going to create an even greater need to access the electronics and mechanics in the base of the machine. And that was going to be a problem. Unscrewing the build plate or disassembling part of the machine wasn't going to an option. This would require too much work and risk messing up machine alignment or setup. The solution was to put the machine on hinges so it could be flipped up.

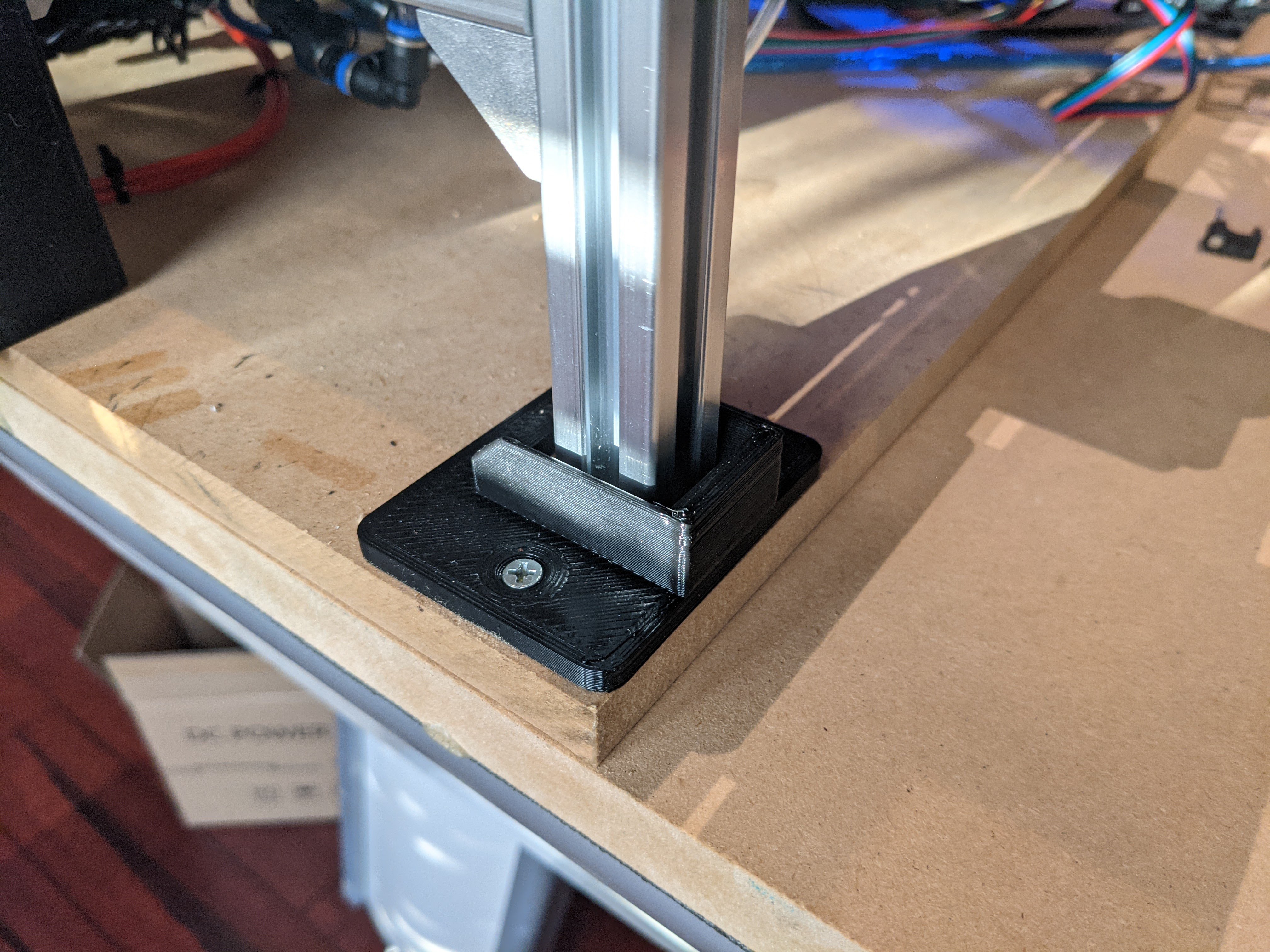

Setup

On one side of the machine, a set of hinges connects the machine to a base plate. A set of 3D printed kickstands attached to the side provide a place for the machine to rest on.

![Hinges and Kickstands Hinges and Kickstands]()

Hinges and kickstands are mounted to one side. On the opposite side, there are some 3D printed brackets screwed to the mounting plate. These are not attached to the machine. They act to ensure the machine is repositioned in the same place each time it is tipped up and set back down.

![Centering Stand for Foot Centering Stand for Foot]()

A centering stand opposite the hinges ensures the machine returns to the same position after being tilted up and set down. ![Machine Flipped on the Side Machine Flipped on the Side]()

The machine can be flipped up to access the electronics and mechanics on the underside. -

Low Cost Rails

02/23/2021 at 01:59 • 0 commentsIntroduction

After extensive reading about low-cost rails, there seemed to be a mix of experiences. Some of them worked without issue, some had minor issues that they were able to resolve, and some had major issues with them that rendered them useless.

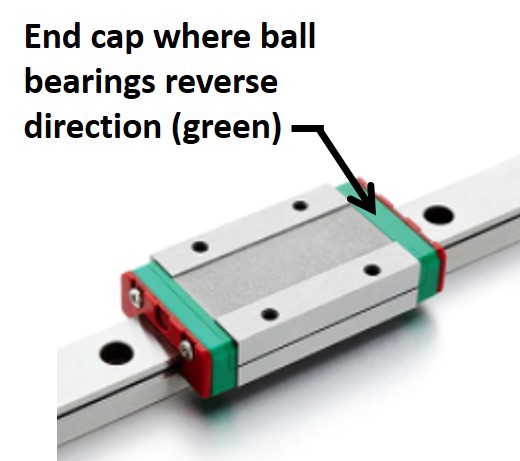

I purchased two sets of low-cost rails. For purposes of discussion, I will refer to them by the colors of their end caps (green and black).

Green Set

https://www.aliexpress.com/item/4000706013922.html?spm=a2g0s.9042311.0.0.27424c4dYpvk0n

![Green Rails Green Rails]()

The set of rails referred to as the "green rails." Black Set

https://www.aliexpress.com/item/32899285305.html?spm=a2g0s.9042311.0.0.27424c4dpy21Gc

![Black Rails Black Rails]()

The set of rails referred to as the "black rails." Discussion

An initial examination of both sets of rails left me to conclude they were pretty well made. Both sets of rails were well oiled. There were not any visible defects. There was a little bit of roughness around the counter-bore holes in the rails, but it was pretty minor and should not interfere with the operation since the carriage is not in direct contact with the top of the rail.

After working the rails for a while, both sets seem to exhibit intermittent sticking. It was repeatable but not completely consistent in location. I searched for the source for some time. Eventually, I concluded the issue was in the plastic end caps where the ball bearings did a 180-degree turn. It seems that because they are made of plastic, they have both a larger manufacturing tolerance and a higher coefficient of friction. One, or both, of these was causing occasion sticking.

![End Cap End Cap]()

The ball bearings reverse direction in the plastic end caps. ![Path of Ball Bearings Path of Ball Bearings]()

Approximate path (red loop) of the ball bearings in the carriage. Solution

I applied a generous amount of Unilube and worked it into the carriages. After lubrication and working the carriage back and forth, the sticking seemed to be largely resolved. I think these rails need a little "breaking in" and to be kept well lubricated.

-

Diodes for Stepper Motors

02/11/2021 at 17:15 • 1 commentIntroduction

To add protection against high voltage spikes damaging the stepper motor drivers, it is recommended to add diodes to the motor output. There is documentation on this at the Smoothieware site, however, I found there were some inconsistencies that led to some confusion.

The Documentation

You can find the information about adding diodes to the stepper motor drivers at the bottom of this page:

Smoothieware troubleshooting page

That page also links to a write up on the diode installation which I provide here for convenience:

The Confusion

Introduction

The documentation recommends using a TVS diode for protection. The first thing to note is that there are unidirectional and bidirectional TVS diodes.

First Point of Confusion

The documentation contains a link to the bidirectional diode. The pictures show a unidirectional diode (there is a cathode mark on one end).

Second Point of Confusion

The link in the documentation is for a diode on Digikey. The pictures on Digikey show a unidirectional diode on the pages for both the bidirectional and unidirectional diode. The products are correct, but the images are wrong for the bidirectional diode. To further complicate things, the description does not spell out which is the unidirectional diode and which is the bidirectional one. You have to read the datasheet and compare it to the part numbers.

Sorting it Out

After some research and testing, I concluded you need the bidirectional version. This is the version that has the "C" in the suffix. The links for Digikey and Mouser are provided below.

Digikey Original Diode

This is the link from the documentation.

Digikey Equivalent Replacement Diode

This has the same ratings as the diode in the documentation link. Its picture is correct so it is less confusing.

Mouser

-

Adding a LCD Screen

02/02/2021 at 04:10 • 0 commentsWarning

It appears that the connectors for the controllers are installed in different orientations depending on the manufacturer. Your adaptor board must match your controller (see Connectors below). It is HIGHLY recommended you either:

- Do extensive research ahead of time to ensure they are paired correctly.

- Get an adaptor board that is a kit and solder it together yourself so you can orientate the connectors according to your controller configuration.

Introduction

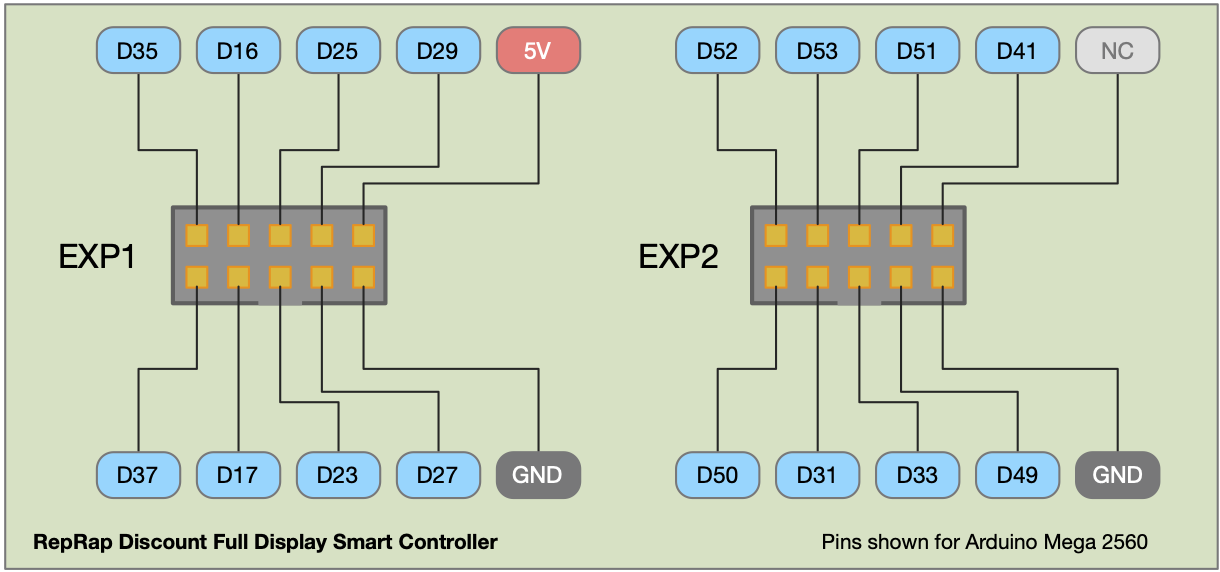

The Smoothieboard is capable of using a RepRapDiscount Full Graphic Smart Controller (https://reprap.org/wiki/RepRapDiscount_Full_Graphic_Smart_Controller). To connect a smart controller an adaptor card for the Smoothieboard is required (http://smoothieware.org/rrdglcdadapter).

The controller displays information and allows commands to be sent to the board. For a 3D printer or laser cutter, the smart controller also lets a job run without having a computer connected to the machine. A pick-and-place machine requires a connected computer to run, so there is less of a benefit.

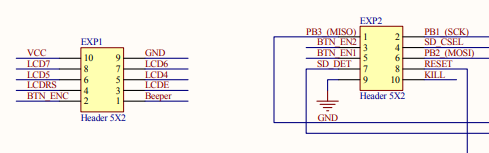

Connectors

Background

My controller did not match my adaptor card so when I plugged it in, nothing happened. Fortunately for me, the team at Fox.Build (https://hackaday.io/project/165743-foxbuild-pnp) had the same problem and noted the issue for them was reversed connectors. I had the potential cause a few minutes after the problem arose. However, their solution (and way of confirming the reversed connectors) was to force the connectors in backwards and see if it worked. I didn't care for this solution for a few reasons:

- My connectors were pretty stiff and I wasn't sure if I could force them in without breaking something.

- I wanted to be able to remove and reinsert the cables in the future. Repeating this brute force method magnified the opportunities for something to go wrong.

- I wanted to find a way for others to tell ahead of time that their controllers and adaptor cards match.

While there is a standard orientation of the connectors, it appears many manufacturers of both the Smart Controller and the adaptor card have ignored it. The page for the Smoothieboard adaptor makes note of this and states that you have to orientate your connectors according to how your controller is configured. They show pictures of connectors in both orientations but don't tell you how to determine which way to place your connectors. The RepRapDiscount Smart Controller page defines the pin out, but then shows a picture of the connectors on backwards. On the disorganization scale, I classify this as a C Level Cluster Bleep.

Determining the Orientation

On the wiki page for the Smart Controller, you can find both the schematics for the controller and a diagram of the connector pin out. Since these were from a reliable source and both agreed I declared this as the "correct" orientation. Rather, this is the intended orientation. Everything will work so long as the connectors are self-consistent between the adaptor card and the Smart Controller. In other words, correct is somewhat relative here. What's important is that things function correctly not that the connectors are in the designed orientation. Therefore, I will refer to the intended orientation as the standard orientation and the other as the reversed orientation.

![Connectors Schematic Connectors Schematic]()

The schematic for the connectors. This is taken from the Reprap Smart Controller wiki page. ![Smart Controller Connection Pin Out Smart Controller Connection Pin Out]()

The pin out for the Smart Controller connectors. This is taken from the Reprap Smart Controller page. We can now see that pin 1 is on the lower left when looking at the side of the connector with the orientation key. The key is just below the pins marked D23 and D33 in the above image.

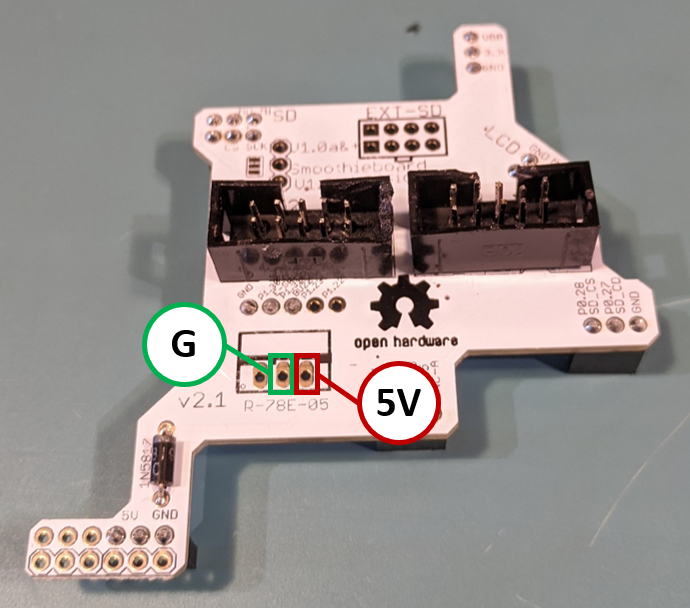

On the Smart Controller I had, I could just make out markings on the silk screen which seemed to locate the position of the orientation key. I dug into the source files from the Reprap site. The source files are in Altium, which I don't have access to. I opened the Gerber files and could determine the standard orientation. In the image below, note that you are viewing from the front so it looks reversed from what you would see looking at the back of a controller. You can make out where the two ground pins (pin 9) of EXP1 and EXP2 are connected. You can also see where 5V is connected to the Vin of U2 and this is enough to orientate the connectors. An easy way to remember is that PIN 1 of the connectors is AWAY from the SD card. Therefore, the orientation key should be down to be in the standard position. It is interesting to note that the picture of the controller card on the Reprap site has the connectors in the reversed orientation.

![Gerber files of Reprap Smart Controller Gerber files of Reprap Smart Controller]()

Gerber files of Reprap Smart Controller. You can make out where the two ground pins (pin 9) of EXP1 and EXP2 are connected. You can also see where 5V is connected to the Vin of U2 and this is enough to orientate the connectors. An easy way to remember is that PIN 1 of the connectors is AWAY from the SD card for the standard orientation. On the adaptor card, I came up with a simple check. By looking at the reference material for the card, you can note there is a location to add on an additional (optional) voltage regular. From the datasheet of the voltage regulator, you can locate the ground and 5v out pins. You can then use a multimeter on the continuity setting to see if the adaptor's connectors are orientated according to the standard above or if they are reversed.

![Smoothieboard Controller Adaptor Card Smoothieboard Controller Adaptor Card]()

Smoothieboard controller adaptor card with the ground and 5v pins indicated. Standard Orientation

![Standard Orientation of Connectors Standard Orientation of Connectors]()

For the standard orientation of the connectors, the controller and adaptors should have their connectors orientated in this configuration. Reversed Orientation

![Reversed Orientation of Connectors Reversed Orientation of Connectors]()

For the reversed orientation of the connectors, the controller and adaptors should have their connectors orientated in this configuration. Installation

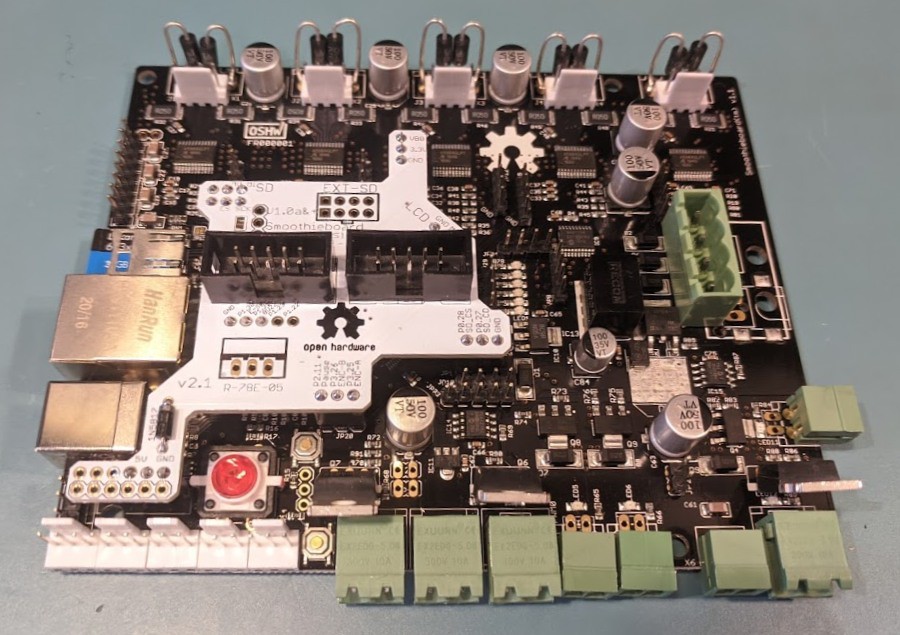

Below you can see how the graphics card (white) is orientated on the Smoothieboard (black). To say the least, it is a bit of an awkward fit with connector pins spread out across a large area of the Smoothieboard. Be careful to line up all the pins and then slowly press the card on. When pressing down on the pins, alternate between groups so the graphics card remains more or less parallel to the Smoothieboard. That way you do not bend pins as you press down.

![Smoothieboard with Controller Adaptor Card Installed Smoothieboard with Controller Adaptor Card Installed]()

The installation location of the adaptor card. -

End Caps and Belt Tensioning System

01/24/2021 at 17:34 • 0 commentsResearch

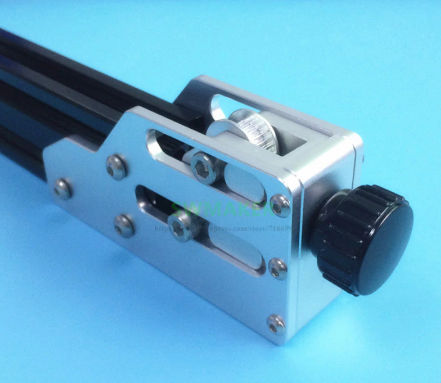

When it came to the end caps, the design is affected by a few criteria. They have to be able to accommodate your motor and pulley design. There also needs to be a belt-tightening system and this is typically either in the end caps or the carriage adaptor plates. I looked at commercial options and designs used by other makers/builders.

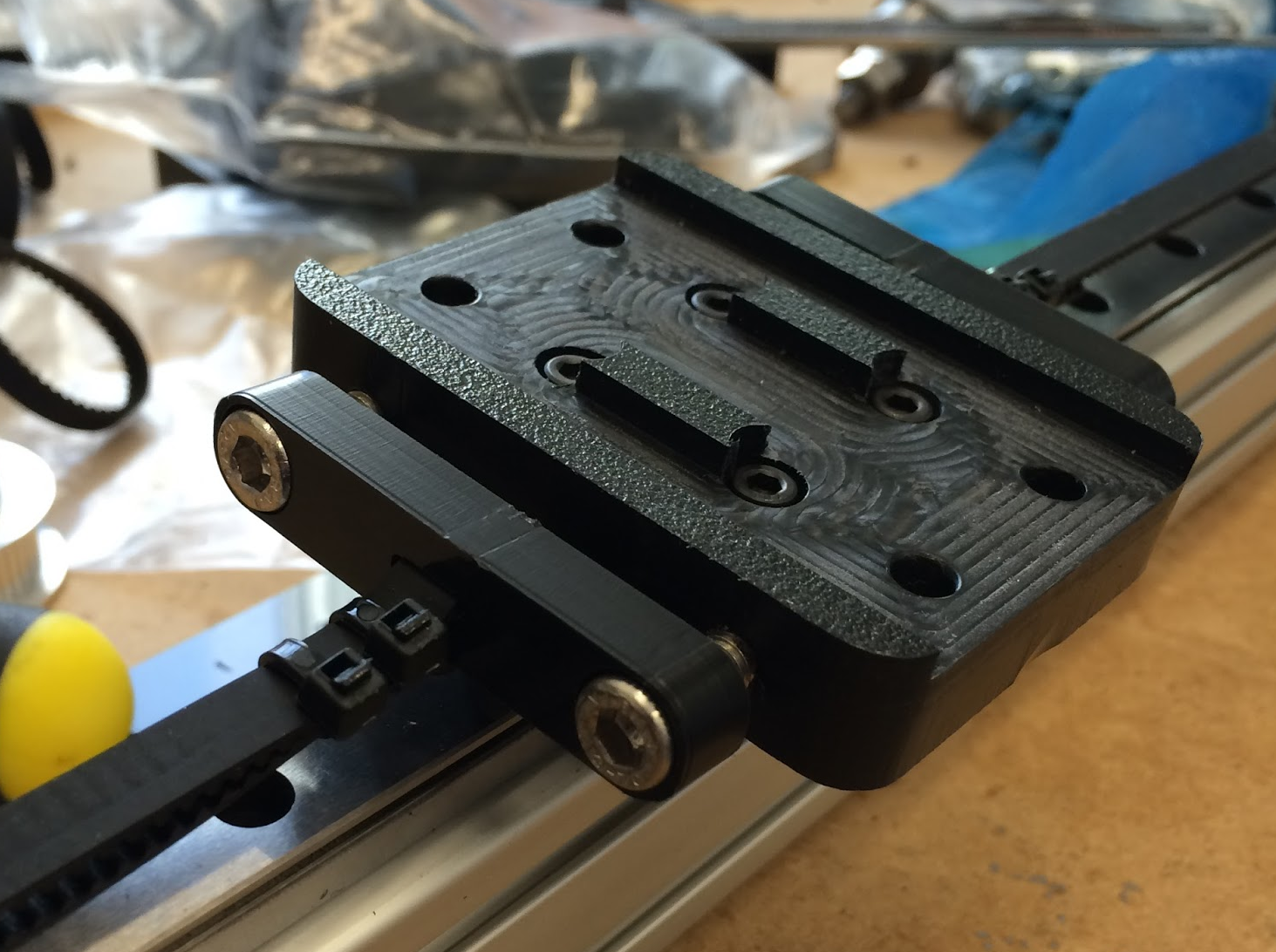

Belt Tensioning Integrated Into The Sled

Some have added tensioning systems into the carriage adaptor plates:

![]()

This removes the requirement for the end caps to have a tensioning system but requires a more complicated carriage adaptor.

Source: https://hackaday.io/project/9319-diy-pick-and-place

OpenBuilds End Caps

There are premade end caps that can be tensioned by pulling on them before tightening the screws. Below is an example from OpenBuilds:

![]()

3D Printer End Caps

There are some sophisticated end caps with built-in tensioners made for 3D printers:

![]()

Conclusions

All of these systems are viable options and I considered them at great lengths. In the end, I elected to design my own end caps and tension them by pulling them tight before tightening the screws (similar to how the OpenBuilds ones work).

Integrated Into The Sled

The system with the tensioning system build into the sled is a slick design. However, it requires screws to be drilled and tapped into a solid piece of material. If you have this capability, then this is a great option. I wanted to design something that was accessible to more people and cheaper and easier to build.

OpenBuilds and 3D Printer End Caps

The OpenBuilds and 3D printer end caps are both an attractive option as they are a nice metal construction and they are commercially available.

The OpenBuilds, however, lock you into a very specific timing pulley size. The pulley is larger than I wanted. I wanted to design a machine that had as much positional accuracy as possible and that meant a smaller pulley.

Both of these end caps had a major issue, however. Neither of them allowed for mounting the bearing for the passive rail.

The 3D printer end caps are usually built for printers that have a single Y-axis, so no coupling is required.

The OpenBuilds hardware uses two Y-axis motors. There are reports that these are hard to keep synchronized. Obviously, it is possible to do since many machines use this design. But the added coordination effort and cost of another motor is not desirable. For a pick-and-place machine, this design is probably likely to fall out of favor for another reason. Already, hobbyists are building machines with 4 pickup heads. This requires a minimum of 6 stepper motor drivers so you cannot afford to have 2 Y-axis motors.

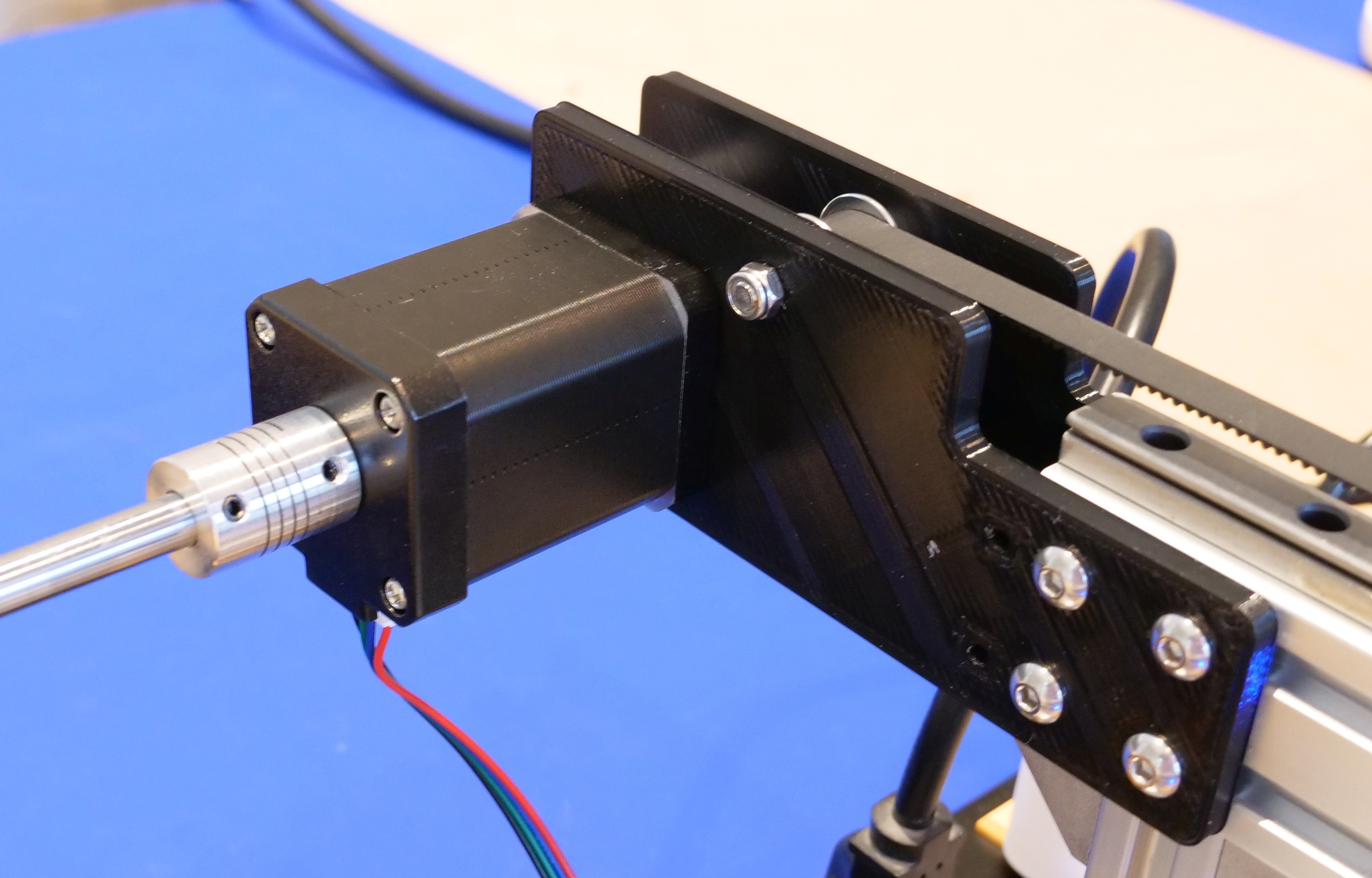

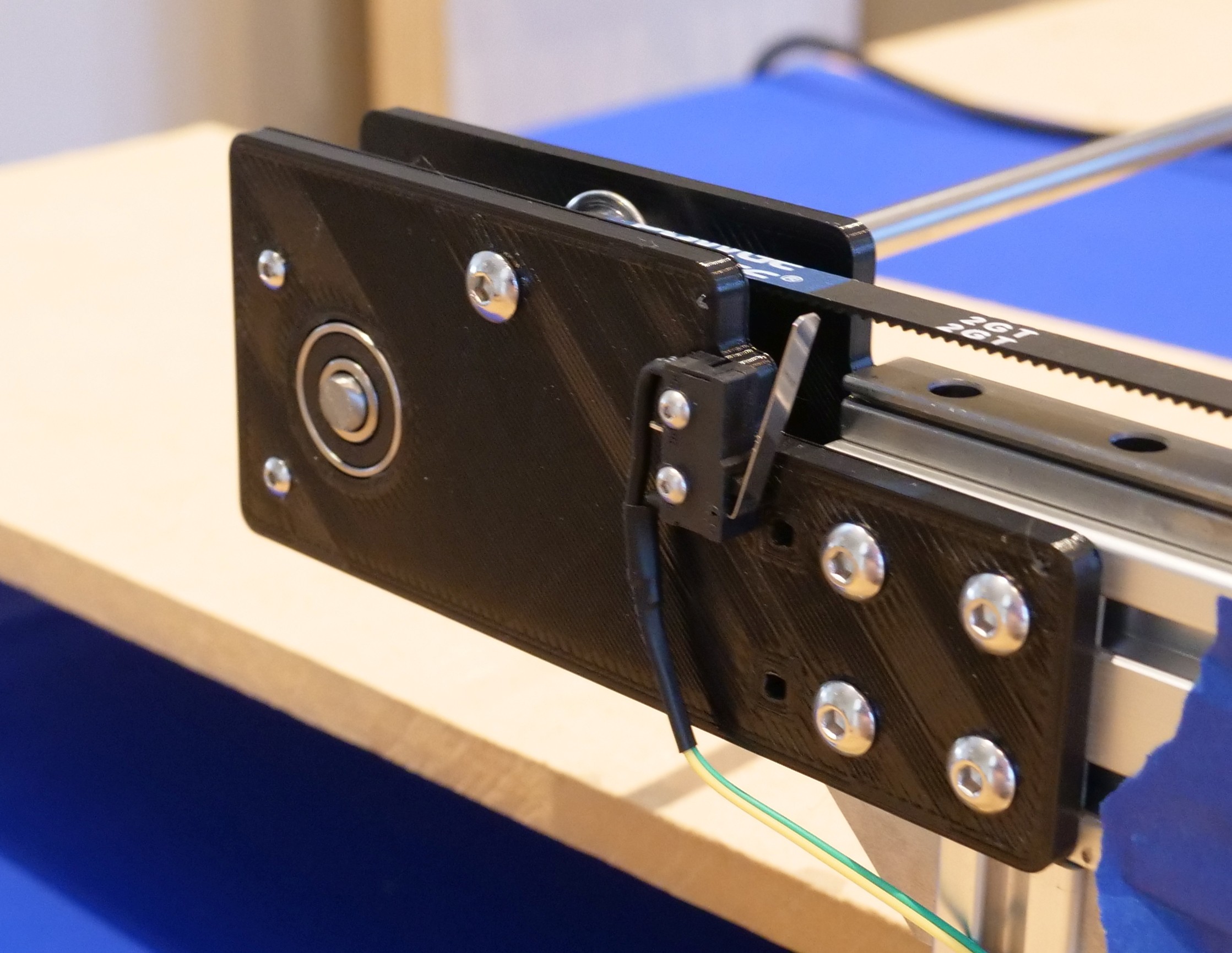

Design

I designed a series of plates that, when combined with the appropriate screws and spacers, create custom end caps that eliminate all the problems with the designs above.

![]()

![]()

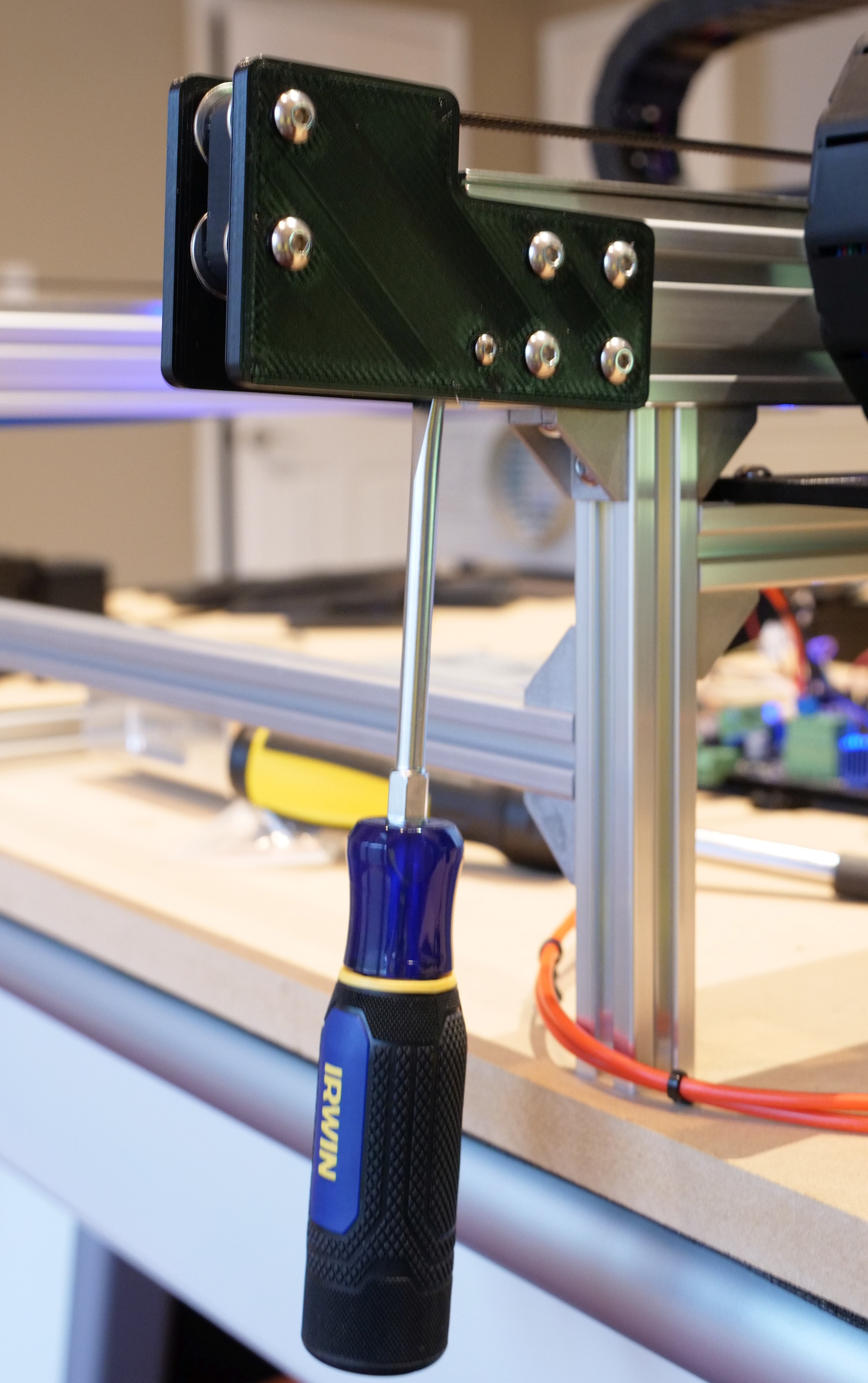

Similar to the OpenBuilds they are tensioned by sliding them out before tightening the screws. This is done on the idler pulley assemblies (front of the machine for the Y-axes and left side for the X-axis).

The belts need to be tight enough they don't slip and there isn't excessive slack in them. You don't want to over-tighten them or you could bend parts. Likely, you will be able to pull the belts tight enough with just your hands. If, however, you are not able to pull them tight by hand or if it is difficult to both hold the idler pulley assembly and tighten the screws, I have designed in a simple assistance device. There is an M3 screw that can be used for leverage. A flat head screwdriver works well to position and hold the assembly while the screws are tightened.

If you do need to use this technique, be careful not to over tighten the belts.

![]()

![]()

Lance

Lance