-

Bugs Bugs Bugs

06/13/2021 at 19:33 • 0 commentsThe problem with hardware is that bugs are much more of a pain in the arse. Unlike software you can't hide your hacks behind library boundaries

![]()

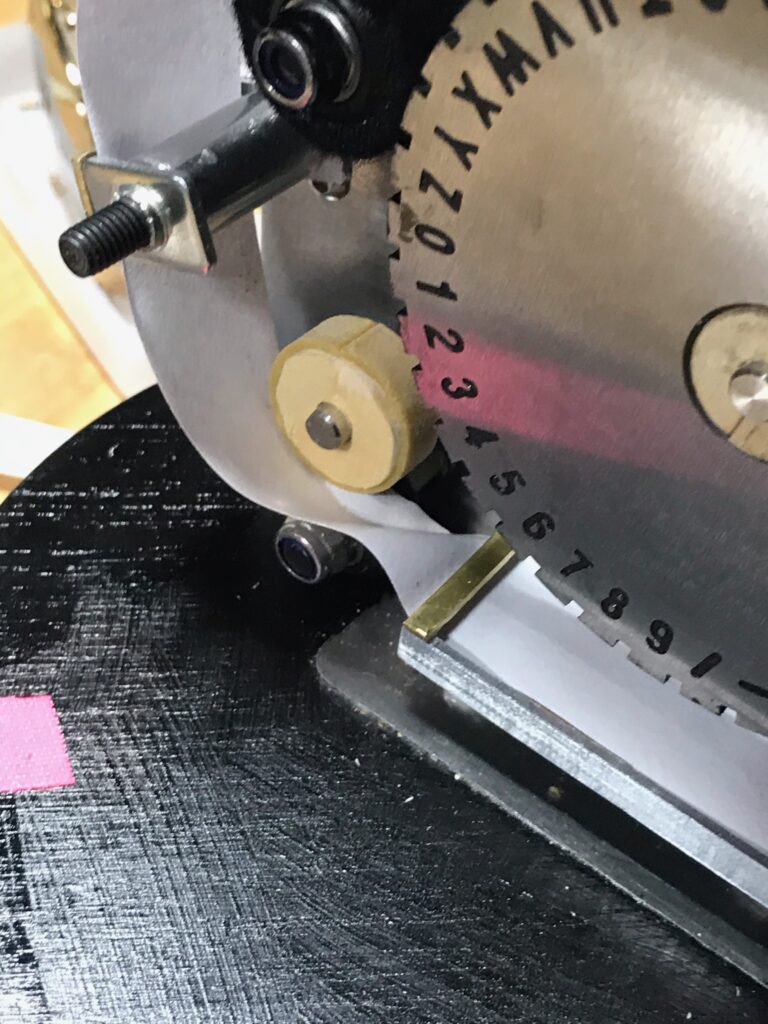

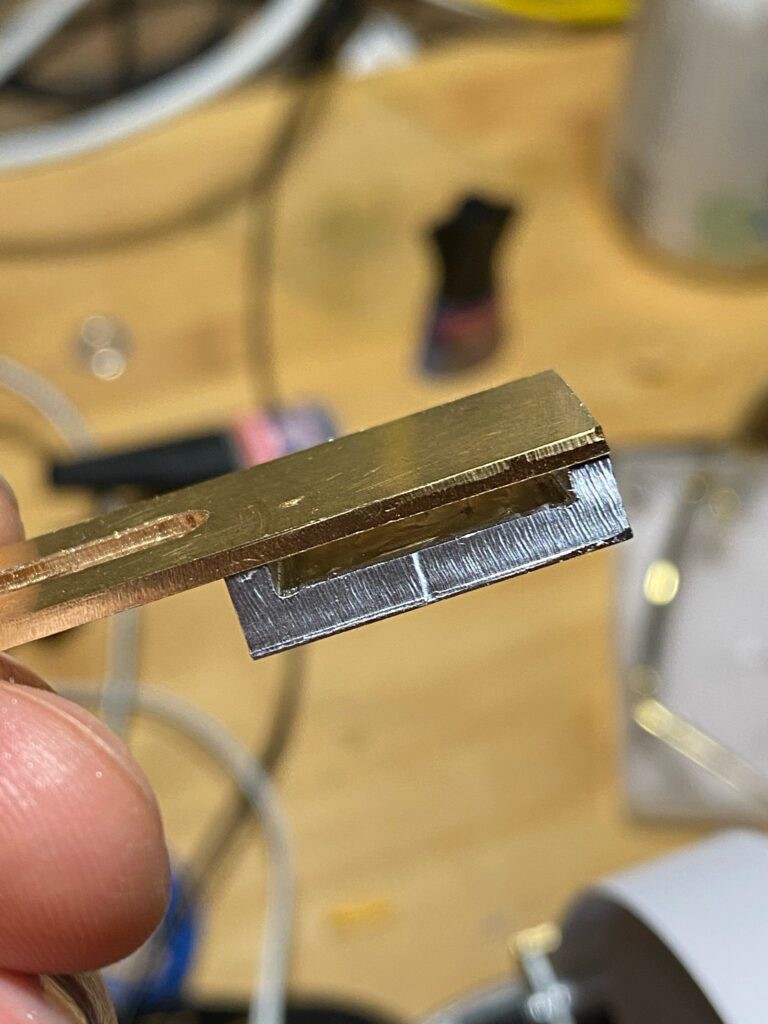

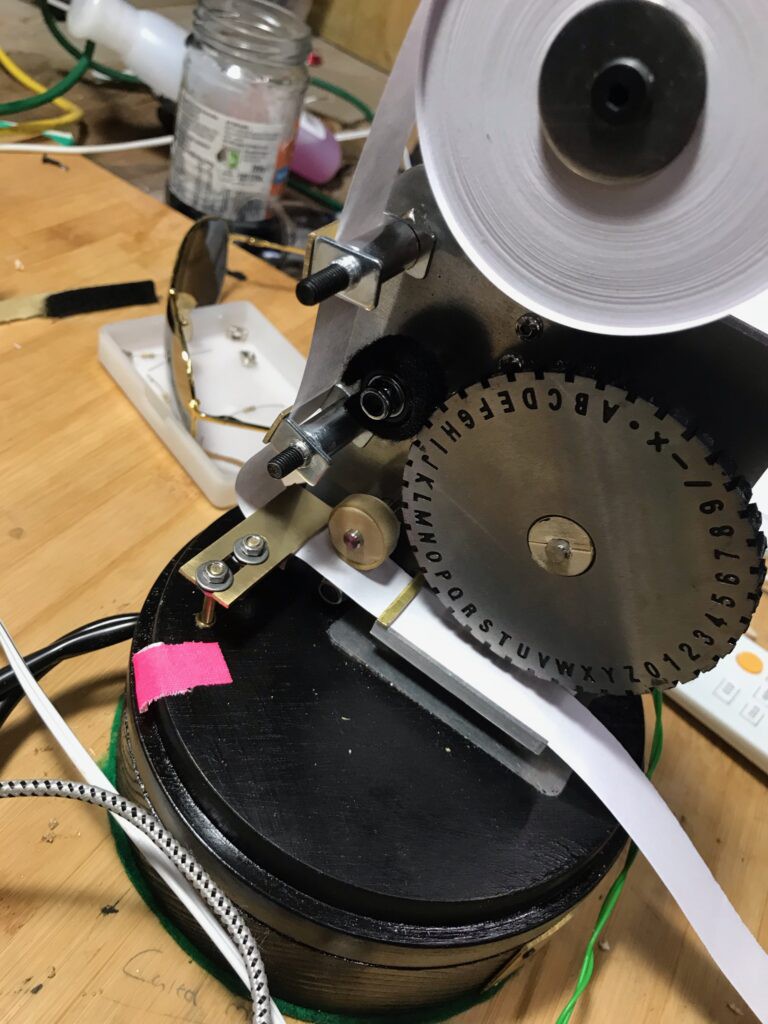

Because the paper can move left and right relative to the presser plate, it gets pinched. Which makes everything go wrong. This took a lot of fiddling to correct, but in the end the solution is quite simple:

![]()

![]()

The conformer makes sure that the paper can't move left or right, and surprisingly it works really well. It has lots of room for adjustment, which is a bit ugly, but means it actually works.

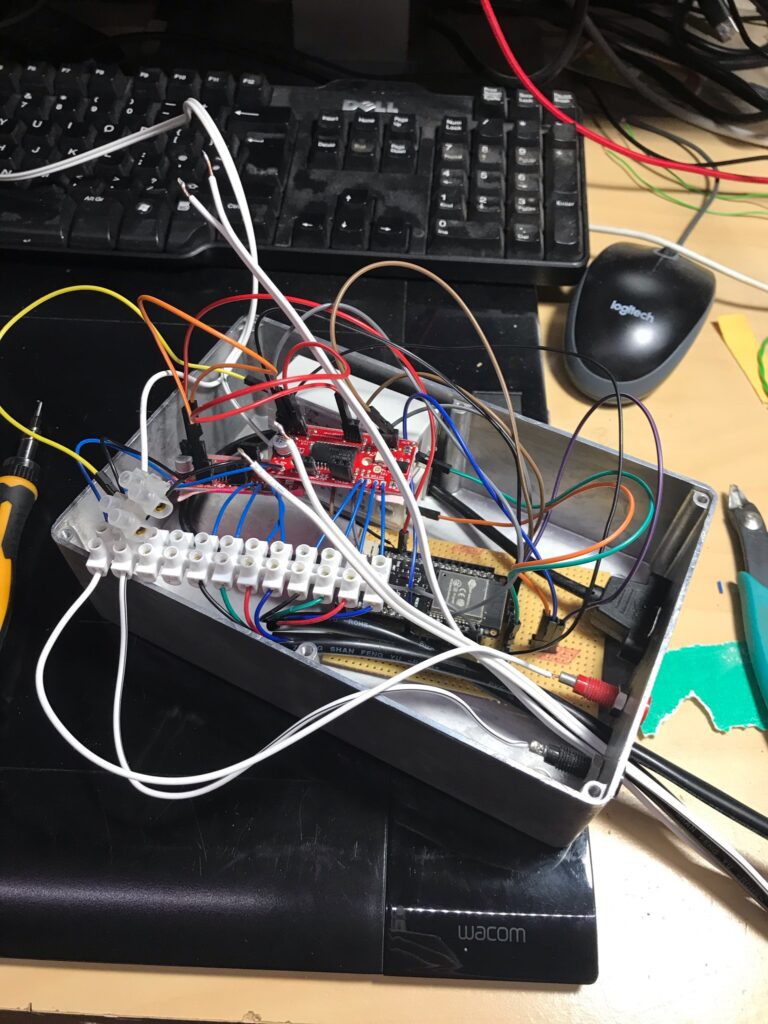

The other mess was the electronics. There is nothing ground breaking here, just two stepper controllers, a solid state relay and an ESP8266(wildly over powered). As we are dealing with 24v and lots of noise from the solenoids, I used a beefy SSR, so I didn't run the chance of accidentally shoving -32v through a USB line.

Its messy though![]()

but with a bit of wobbling, it was tamed. Plus with this lid on, you can see it. Perfect is the enemy of good and all that.

-

Main plate design

06/13/2021 at 17:31 • 0 commentsIts not overly obvious in the hand drawn design, but the main point of the main plate is as follows:

- Host a printing wheel that has the letters on it

- contain a paper feeding mechanism

- Be solid enough to cope with the hitting and pressing of the paper

Because aluminium is expensive, I started prototyping in plywood, to make sure my assumptions were correct, and that it all fitted inside the jar

![]()

Even though I had the mechanical drawings of the motors, I hadn't allowed enough space to fit all the paper handling bits in.

![]()

The other mistake I had made was not accounting for the width of the metal plate that holds the solenoids. Having learnt from my mistakes, and making some tweaks, I finally milled the aluminium plate

![]()

You can see some scratches in the black gloss, note to self, always finish your aluminium properly.

![]()

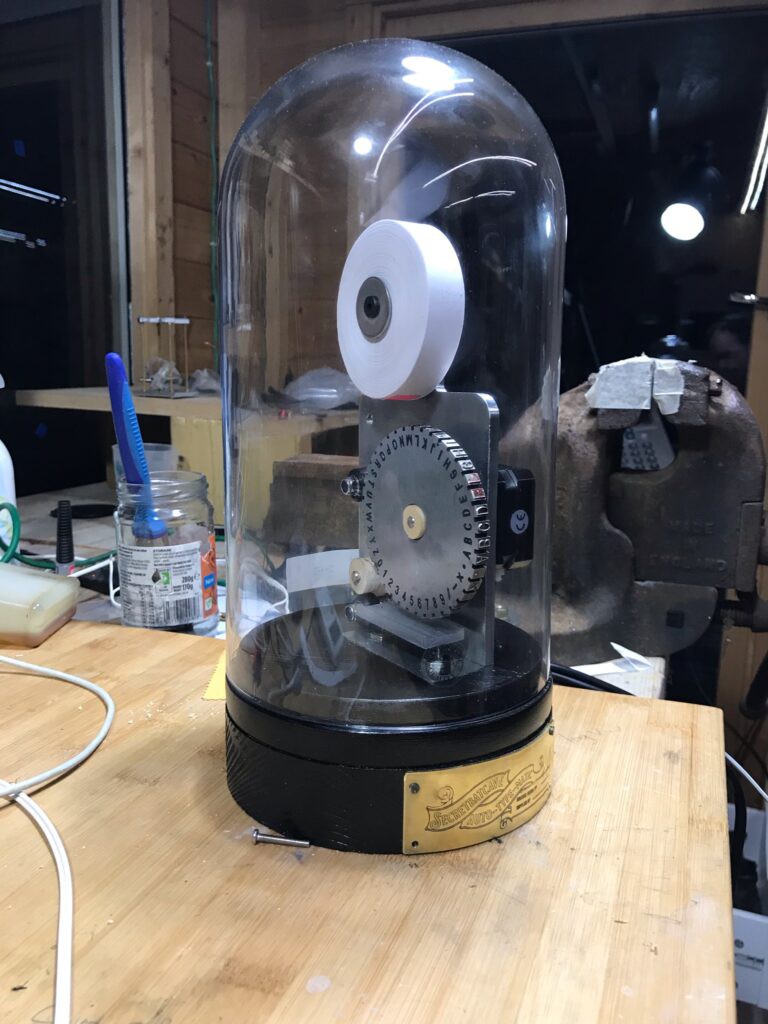

Its starting to look really nice now.

-

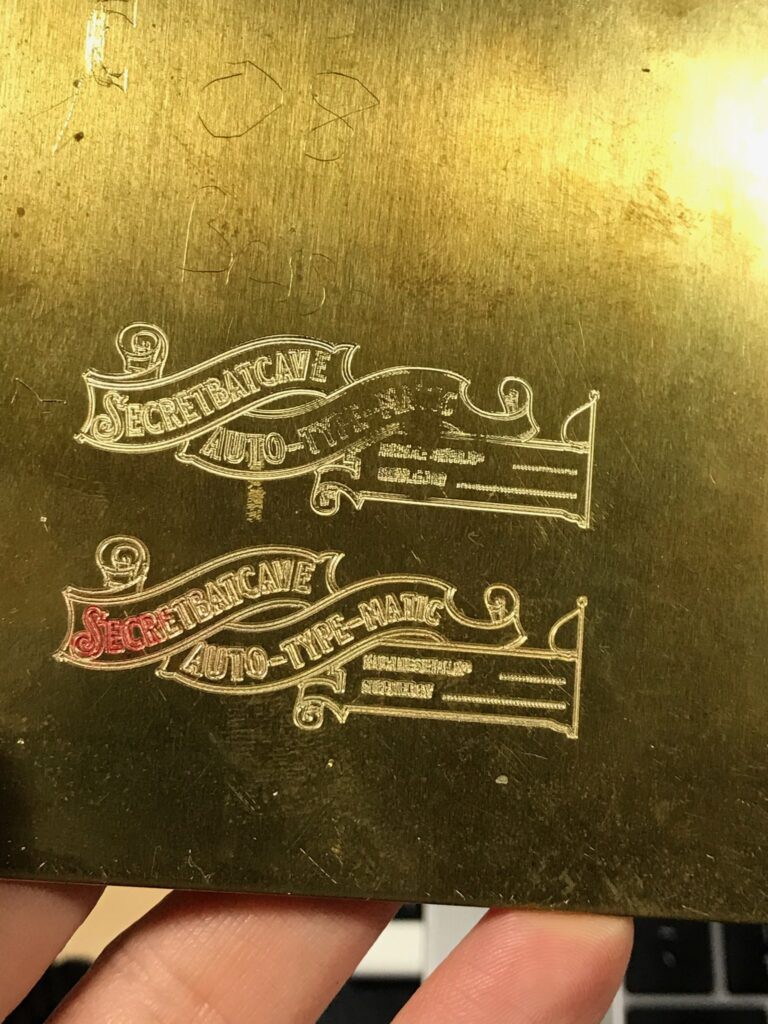

Logos are important

06/13/2021 at 17:16 • 0 commentsNormally I'd not bother with a logo, but as I've been given a Illustrator license through work, and the explosion in cheap heritage style clip art, means that its easier than ever for me to make a logo. Not only that, with the workbee its trivial to get that logo engraved in brass.

![]()

When engraving its really really important to make sure that your workbed is parallel to the spindle *and* that you've clamped your workpiece properly. As the depth of cut is <0.25mm it makes all the difference. TLDR: make sure you've surfaced your spoilerboard.

When I was designing the logo, I realised that the stock base that comes with the HÄRLIGA isn’t tall enough to house the solenoids. So I need to mill a base extension:![]()

This is useful because I now have a form to hammer the logo plate into.

![]()

Here is the finished logo in place.

Indian ink and acrylic gloss makes it much more believable:

![]()

-

Biscuit buttery base

06/13/2021 at 11:20 • 0 commentsIts time to cut the base. If you look at the hand drawn designs you can see that lots of attention is spent on making the base/stamping mechanism. I need to mill pockets to accept the solenoids and solenoid plate.

![]()

The great thing about having a workbee is that its trivial to cut wood with reasonable accuracy.

![]()

As good as the CNC machine is, it doesn't make up for user error, or my inability to measure.

![]()

The pressing foot is fitting really well

-

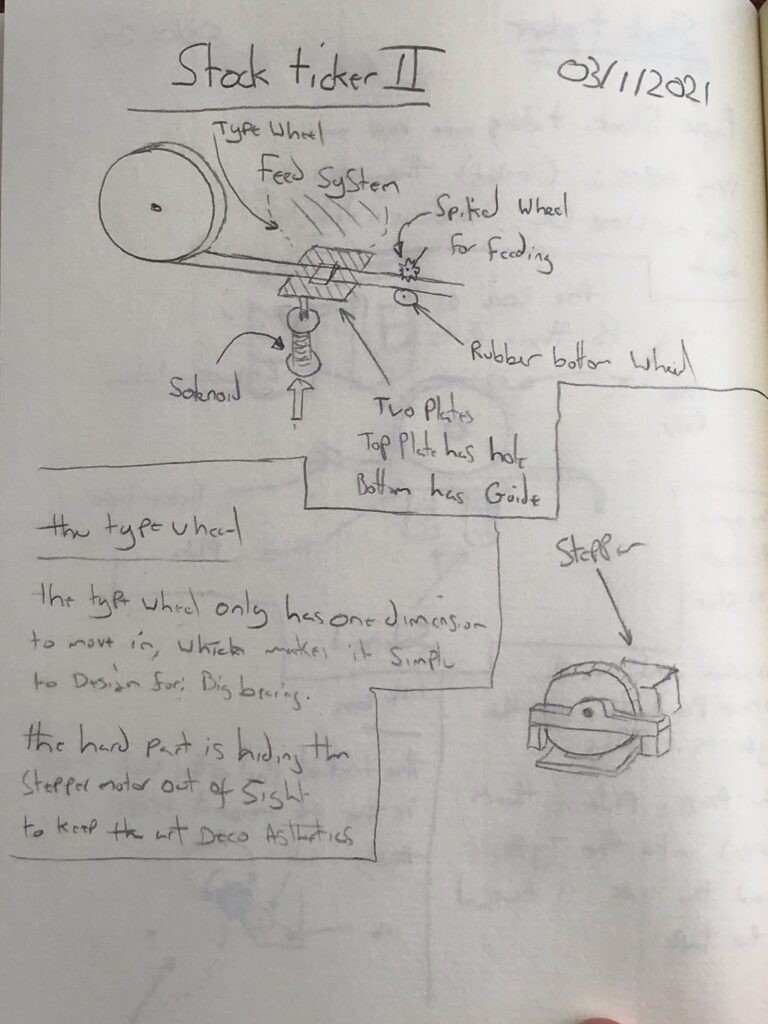

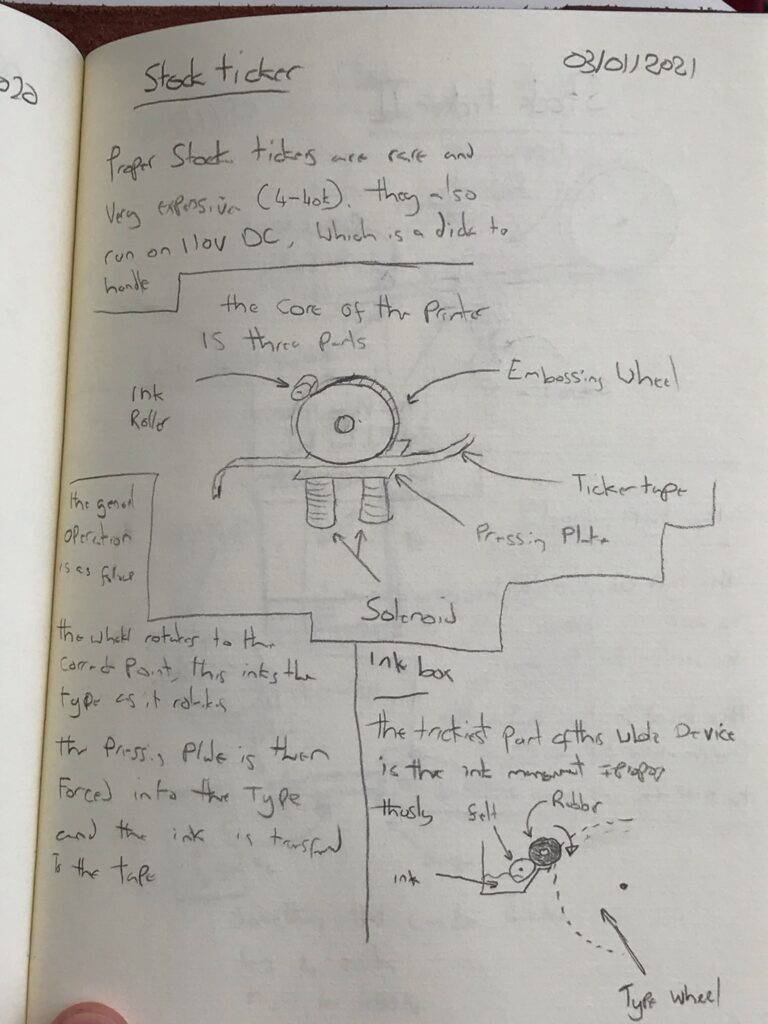

Initial Design

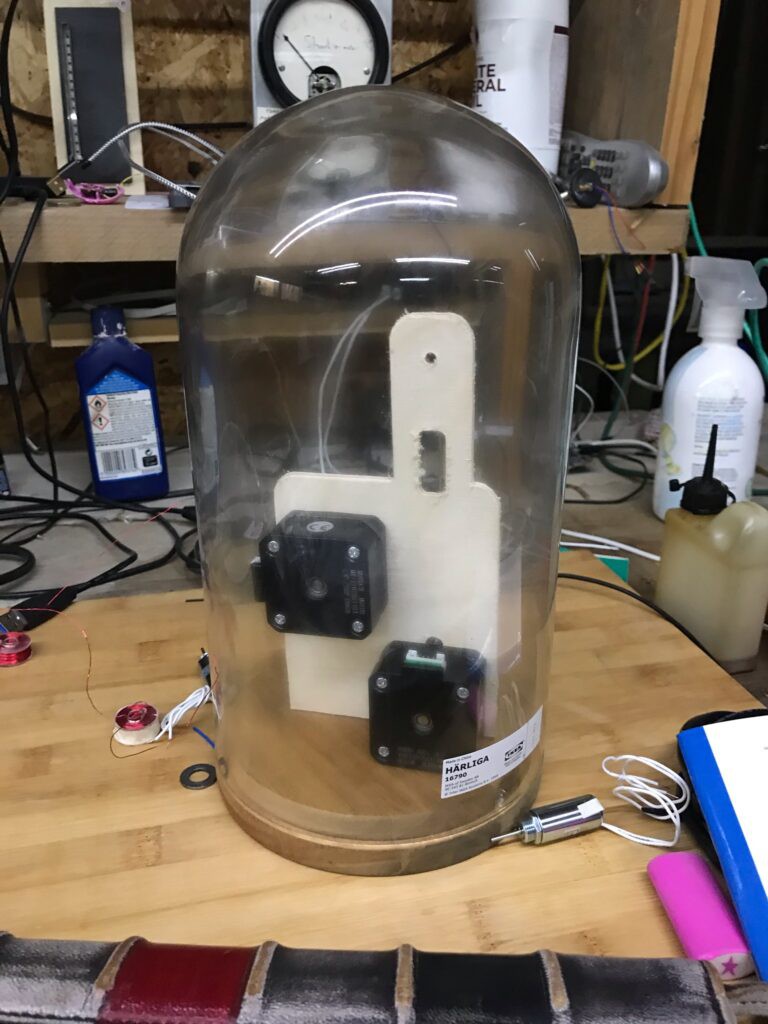

06/13/2021 at 11:09 • 0 commentsAs I can't buy a stock ticker, I need to make one. The first step of course is designing what I want it to look like. I bought a bell jar from ikea years ago, and this seems like the best thing to design around

![]()

Roughly working out how the print mechanism will work

![]()

A more reasoned design with ideas about ink holding

secretbatcave

secretbatcave